Professional Documents

Culture Documents

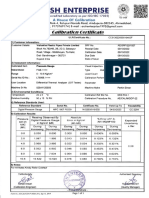

Pressure Gauge Calibration

Pressure Gauge Calibration

Uploaded by

Kram Alim VillonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Gauge Calibration

Pressure Gauge Calibration

Uploaded by

Kram Alim VillonCopyright:

Available Formats

Purpose Calibration Procedure for Pressure Gauge

Safety and Standard PPE is required that includes protection against H2S Gas.

Environmental

Requirements

References ILD, P&ID, Operation/maintenance manual, and instrument datasheet.

Job Prerequisites 1. Obtain work permits

2. Ensure that work permit / JSA is read and understood in toolbox talk with all involved personal

3. Ensure all PPE requirements are met as listed in work permit / JSA before conducting the work.

4. Ensure the online equipments/instruments are isolated / removed from the system, as per P&ID

given by operations and as per C&E Matrices.

Tools and Equipment 1. Pressure Calibrator/Multifunction Calibrator (with Hand pump and accessories).

2. Needle Remover

3. Adjustable Wrench and set of spanners

4. Rags and cleaning agent (if applicable)

5. Teflon tape or liquid sealant

6. 2 2-Way Radios (1 for CCR Operator and 1 for Field Technicians)

Persons Required 1. Senior Instrument Technician

2. Instrument Technician

Job Procedure 1. Isolate the gauge to be serviced, observe for any defects, readability, and movement.

2. If the unit is to be brought to the workshop, you can use Dead Weight tester, if not, a standard

pressure reference and a set of pump would do the work. In this case, a field calibration for gauge.

3. Hook up the calibration equipment and the gauge to be calibrated as shown below:

4. Before applying any pressure to the gauge, set the pointer to read zero on the scale.

5. Apply the full range pressure to the gauge. Adjust the linkage so that the pointer is at the maximum

reading on the scale, (full scale deflection).

6. Reduce the pressure to zero and check that the pointer reads zero on the scale. Adjust the pointer

if necessary.

7. Repeat steps (2) and (3) until both readings are correct.

8. If the Pressure gauge has a linearizing adjustment, set the applied pressure to 50% of the

maximum scale reading. Adjust the linearizing adjustment so that the pointer reads at 50% of the

maximum scale reading.

9. Check the Pressure gauge reads correctly at 0, 50% and maximum scale reading. You may need to

adjust the gauge many times before the gauge is correct. You must be patient and careful.

10. When step (6) is completed, write down the reading on the gauge for the applied pressure

readings on a calibration sheet.

11. Record the obtained readings of the gauge and the applied pressures (increasing and decreasing)

as AS FOUND data, and if adjustments were done, also write down the AS LEFT values.

You might also like

- Worry Domains QuestionnaireDocument2 pagesWorry Domains QuestionnaireGemmaNo ratings yet

- 500 104 MTESTQuattroCalibration Rev2Document5 pages500 104 MTESTQuattroCalibration Rev2Javier RochaNo ratings yet

- U 929 RPM MeterDocument7 pagesU 929 RPM MeterAmit KumarNo ratings yet

- EAP Grammar in Context: Reading & WritingDocument27 pagesEAP Grammar in Context: Reading & WritingMónica Coirolo50% (2)

- Calibration Procedure - Pressure Test Gauges For API Specification 6A ApplicationsDocument6 pagesCalibration Procedure - Pressure Test Gauges For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- 01 Pressure Gauge CalibrationDocument3 pages01 Pressure Gauge CalibrationSantosh Odiyar0% (1)

- Calibration of ThermocoupleDocument4 pagesCalibration of ThermocoupleAmar Singh100% (1)

- Length Calibration For Pin Gauge and Feeler Gauge. - SarmientoDocument38 pagesLength Calibration For Pin Gauge and Feeler Gauge. - SarmientoEricson Ramos100% (1)

- Sample Calibration CertificateDocument2 pagesSample Calibration CertificateRaunakNo ratings yet

- Insulation Tester 1 CI 02 I2Document13 pagesInsulation Tester 1 CI 02 I2ebbasinghNo ratings yet

- Control Valve Calibration FFDocument3 pagesControl Valve Calibration FFKram Alim VillonNo ratings yet

- Docshare - Tips Hairdressing CBLMDocument205 pagesDocshare - Tips Hairdressing CBLMmarvin tubat100% (1)

- Pre Employment Medical Form PDFDocument1 pagePre Employment Medical Form PDFKristina Miller100% (1)

- Cutting HandlingDocument25 pagesCutting HandlingWalid AmdouniNo ratings yet

- Calibration of Pressure GaugeDocument16 pagesCalibration of Pressure GaugeRITIKA SHUKLANo ratings yet

- PC-EI-MS-05 Instrument Calibration PDFDocument11 pagesPC-EI-MS-05 Instrument Calibration PDFahmed011No ratings yet

- Safety Understand The Requirement Calibration Documentation Calibration Procedure For Various InstrumentDocument6 pagesSafety Understand The Requirement Calibration Documentation Calibration Procedure For Various Instrumentkrishna kumarNo ratings yet

- SIP-SOP03-R0-2017 SOP Temperature Transmitter CalibrationDocument2 pagesSIP-SOP03-R0-2017 SOP Temperature Transmitter CalibrationDwi Mulyanti DwimulyantishopNo ratings yet

- DPT Calibration FFDocument4 pagesDPT Calibration FFKram Alim VillonNo ratings yet

- Procedure For Calibration and Installation of InstrumentsDocument62 pagesProcedure For Calibration and Installation of InstrumentsAbdul SammadNo ratings yet

- METHOD STATEMENT PRESSURE SWITCH UAE Univ.Document2 pagesMETHOD STATEMENT PRESSURE SWITCH UAE Univ.Muhamed RasheedNo ratings yet

- Standard Check List: Pressure TransmiterDocument3 pagesStandard Check List: Pressure TransmiterROUNAK MANDALNo ratings yet

- Mitutoyo Bore Gauge PDFDocument12 pagesMitutoyo Bore Gauge PDFJageNo ratings yet

- Calibration of AnemometerDocument4 pagesCalibration of AnemometerAhmet ŞenNo ratings yet

- Standard Calibration Procedure Densitometer Doc. No. Call/SCP/032 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Densitometer Doc. No. Call/SCP/032 Rev. 00 May 01, 2015Ajlan Khan100% (2)

- Method Statement For PH MeterDocument2 pagesMethod Statement For PH MeterMuhamed RasheedNo ratings yet

- DKD R 6 2 t5 e PDFDocument9 pagesDKD R 6 2 t5 e PDFDragan Ilic100% (1)

- SOP-Procedure Calibration of Metal TapesDocument12 pagesSOP-Procedure Calibration of Metal Tapeshaharamesh100% (1)

- U 5753 Centrifuge 17300Document1 pageU 5753 Centrifuge 17300NENO BHUBANESWAR100% (1)

- Analytical Balance SOPDocument2 pagesAnalytical Balance SOPdivine productionNo ratings yet

- Temperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Document40 pagesTemperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Tin ThanNo ratings yet

- Method Statement For Instrument Calibration PDFDocument14 pagesMethod Statement For Instrument Calibration PDFMohamed Adel100% (1)

- Calibration Certificate - Gas Coriolis - Unit#1Document2 pagesCalibration Certificate - Gas Coriolis - Unit#1Said100% (1)

- EURAMET-cg-08 V 2.1 ChangesDocument18 pagesEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoNo ratings yet

- Certificate of Calibration: HTLS/DPG/04Document2 pagesCertificate of Calibration: HTLS/DPG/04Umang SOdhiNo ratings yet

- Bmts-Cp-003a CBR Mould BsDocument2 pagesBmts-Cp-003a CBR Mould BsvirajNo ratings yet

- Height Gauge Calibration Procedure: 1.0 Standards and EquipmentDocument2 pagesHeight Gauge Calibration Procedure: 1.0 Standards and EquipmentKiranNo ratings yet

- Standard Procedure For Calibration of GaugesDocument12 pagesStandard Procedure For Calibration of Gaugessharif sayyid al mahdalyNo ratings yet

- Calibration Procedure For Calibration of External MicrometerDocument11 pagesCalibration Procedure For Calibration of External MicrometerDiganta Hatibaruah100% (1)

- Procedure - Testing and Calibration For Process InstrumentDocument10 pagesProcedure - Testing and Calibration For Process Instrumentjabpun0% (1)

- Pneumatic ComparatorDocument2 pagesPneumatic Comparatornveman100% (2)

- PH Electrodes 2724 To 2726 From GF SignetDocument6 pagesPH Electrodes 2724 To 2726 From GF Signetguita riefNo ratings yet

- 1218 Instrument Testing & Calibration Procedure NTGFDPDocument50 pages1218 Instrument Testing & Calibration Procedure NTGFDPTaha Hasan100% (1)

- Terms of Calibration Service (Rev. 7, May 2014)Document1 pageTerms of Calibration Service (Rev. 7, May 2014)John Paul RosNo ratings yet

- DP Transmitter CalibrationDocument2 pagesDP Transmitter Calibrationsupercontroller100% (1)

- Method Statement Pressure RecorderDocument2 pagesMethod Statement Pressure RecorderMuhamed RasheedNo ratings yet

- Fluk Ammeter CalibrationDocument250 pagesFluk Ammeter CalibrationASHUTOSH BHATTNo ratings yet

- SOP For Calibration of Conductivity TDS MeterDocument6 pagesSOP For Calibration of Conductivity TDS MeterSolomon Gamanuel100% (1)

- Calibration TablesDocument32 pagesCalibration TablesJoao SilvaNo ratings yet

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- 65-Muffle Furnace Calibration CartificateDocument1 page65-Muffle Furnace Calibration CartificateCustomer SupportNo ratings yet

- Standard Calibration Procedure Pressure Switch Doc. No. Call/SCP/015 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Pressure Switch Doc. No. Call/SCP/015 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- Calibration Procedure - Pressure TransmitterDocument1 pageCalibration Procedure - Pressure TransmittersathyanduraisamyNo ratings yet

- Flowmeter Calibration ProcedureDocument8 pagesFlowmeter Calibration ProcedureShesadri ChakrabartyNo ratings yet

- Thermocouple Calibration FurnaceDocument4 pagesThermocouple Calibration FurnaceAHMAD YAGHINo ratings yet

- 1.SOP For Calibratioon of Pressure GaugesDocument3 pages1.SOP For Calibratioon of Pressure Gaugesget_engineer05100% (1)

- Calibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Document4 pagesCalibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Sherwin John Navarro100% (1)

- Calibration of ChronometersDocument13 pagesCalibration of ChronometersGustavo SánchezNo ratings yet

- Digital Multimeter CalibrationDocument11 pagesDigital Multimeter CalibrationprettywomenNo ratings yet

- Calibration, American Laboratory: FlijkeDocument3 pagesCalibration, American Laboratory: FlijkeAMINE MEDDAHINo ratings yet

- NIST Stopwatch & Timer Calibrations 2009Document82 pagesNIST Stopwatch & Timer Calibrations 2009ririmonir100% (1)

- Calibration of Pressure GaugeDocument2 pagesCalibration of Pressure GaugeLugabalugaNo ratings yet

- Calibration of InstrumentsDocument3 pagesCalibration of InstrumentsCristan DomingoNo ratings yet

- PH Calibration 5Document10 pagesPH Calibration 5BAN ZANGHANANo ratings yet

- Rosemount Pressure Calibration ProcedureDocument6 pagesRosemount Pressure Calibration ProcedureLorenzoNo ratings yet

- DP CalibrationDocument12 pagesDP CalibrationGeorge AsuncionNo ratings yet

- Bently Nevada Vibration Bypass Procedure (PE3) - 2Document8 pagesBently Nevada Vibration Bypass Procedure (PE3) - 2Kram Alim Villon100% (1)

- DPT Calibration FFDocument4 pagesDPT Calibration FFKram Alim VillonNo ratings yet

- LT Radar-GWR Calibration FFDocument2 pagesLT Radar-GWR Calibration FFKram Alim VillonNo ratings yet

- 122644Document352 pages122644Kram Alim VillonNo ratings yet

- Fisher Fieldvue Dvc6200F Digital Valve Controller PST Calibration and Testing Using Valvelink SoftwareDocument24 pagesFisher Fieldvue Dvc6200F Digital Valve Controller PST Calibration and Testing Using Valvelink SoftwareKram Alim VillonNo ratings yet

- E+H Levelflex (Ao) Error Removal Yta110/320Document2 pagesE+H Levelflex (Ao) Error Removal Yta110/320Kram Alim VillonNo ratings yet

- BEAMEX MC2-MF vs. MC4Document23 pagesBEAMEX MC2-MF vs. MC4Kram Alim Villon100% (1)

- Sensors Installed Across The Conveyor Emitting Diffused Beams Causing Detection in All Four (4) Sensors Installed in The Tray Pusher SectionDocument15 pagesSensors Installed Across The Conveyor Emitting Diffused Beams Causing Detection in All Four (4) Sensors Installed in The Tray Pusher SectionKram Alim VillonNo ratings yet

- KIS MYP Summative Assessment - Grade 7 C ADocument4 pagesKIS MYP Summative Assessment - Grade 7 C AAahan ShahNo ratings yet

- Roche Et Al. 2017 Faltering GrowthDocument6 pagesRoche Et Al. 2017 Faltering GrowthSatesh BalachantharNo ratings yet

- Porter MXR and MXR 1 Flowmeter Users Manual FM 286Document19 pagesPorter MXR and MXR 1 Flowmeter Users Manual FM 286Μαριτίνα ΑλεξίουNo ratings yet

- Policy School November GuideDocument7 pagesPolicy School November GuideGuido FawkesNo ratings yet

- SPM English Yellow ModuleDocument200 pagesSPM English Yellow ModuleAKMAL KAMALNo ratings yet

- Get Used To Jumbled WordsDocument3 pagesGet Used To Jumbled WordsThantzinNo ratings yet

- World Food Problems and Their Possible SolutionDocument9 pagesWorld Food Problems and Their Possible SolutionAjiteshNo ratings yet

- ResumescDocument2 pagesResumescapi-662191303No ratings yet

- Gregorio, Forgive Us All: Community Health Nursing 1 Activity #1Document2 pagesGregorio, Forgive Us All: Community Health Nursing 1 Activity #1Cacamo Rexell-anNo ratings yet

- Turquoise Heart Vector Medical Brochure PDFDocument2 pagesTurquoise Heart Vector Medical Brochure PDFHERNEY LEANDRO PEREZ CADENANo ratings yet

- Suraj LRP PDFDocument40 pagesSuraj LRP PDFsuraj tripathiNo ratings yet

- 1 DHI and Weight Loss, 2020Document11 pages1 DHI and Weight Loss, 2020diyansetyajiNo ratings yet

- Genu ValgumDocument5 pagesGenu Valgumtjr845sjvbNo ratings yet

- No.16, MARCH BNCDocument2 pagesNo.16, MARCH BNCBlgu LucogNo ratings yet

- General and Specific Purposes of ResearchDocument2 pagesGeneral and Specific Purposes of ResearchDnnlyn CstllNo ratings yet

- COVID-19 Response Toolkit For New Mexico's Public SchoolsDocument29 pagesCOVID-19 Response Toolkit For New Mexico's Public SchoolsErika EsquivelNo ratings yet

- Approaches To The Study of Hypnotic Dreams: Charles T. TartDocument1 pageApproaches To The Study of Hypnotic Dreams: Charles T. TartIno MoxoNo ratings yet

- Economic Issues - CABUDSANDocument3 pagesEconomic Issues - CABUDSANSolah CabudsanNo ratings yet

- dm2019-0365 Interim Guidelines On LNS SQDocument8 pagesdm2019-0365 Interim Guidelines On LNS SQMary Joy GaloloNo ratings yet

- Assignment 2 RecruitmentDocument6 pagesAssignment 2 RecruitmentOmar Martinez PNo ratings yet

- Good' Food Islamic Food Ethics Beyond Religious Dietary LawsDocument16 pagesGood' Food Islamic Food Ethics Beyond Religious Dietary Lawsnovi diyantoNo ratings yet

- Key Components of Literature ReviewDocument8 pagesKey Components of Literature Reviewhinlcxtkg100% (1)

- Final Exam Schedule-StudentsDocument2 pagesFinal Exam Schedule-StudentsBLESSEDNo ratings yet

- Royal Alexandra Hospital For Children: Policy & Procedures ManualDocument73 pagesRoyal Alexandra Hospital For Children: Policy & Procedures ManualDivya NarayanNo ratings yet

- What Is A Competent TeacherDocument2 pagesWhat Is A Competent TeacherJoy Dacuan100% (2)