Professional Documents

Culture Documents

Pumps Sizing Calculations 1 PDF

Pumps Sizing Calculations 1 PDF

Uploaded by

ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pumps Sizing Calculations 1 PDF

Pumps Sizing Calculations 1 PDF

Uploaded by

ahmedCopyright:

Available Formats

ATTACHMENT 7.

1

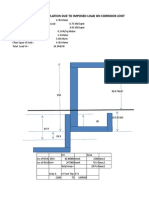

Pipe Sizing Calculations

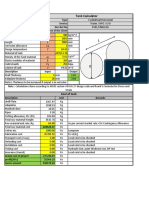

# DESCRIPTION FORMULA UNITS SUCTION SIDE DISCHARGE SIDE

1 Pipe Material - - Carbon Steel Carbon Steel

2 Material Specification & Grade - - ASTM A106 Gr. B ASTM A106 Gr. B

3 Design Flow Rate QInput m3/h 15.60 12.00

0

4 Minimum Design Temperature Tdesign , Min C 5 5

0

5 Maximum Design Temperature Tdesign , Max C 55 55

7 Maximum Design Velocity V Design m/s 1.00 2.50

Density ρ

8

@ Minimum Design Temperature

kg/m3 1000

Viscosity ν

9 cSt 1.52

@ Minimum Design Temperature

Vapor Pressure Pvapor

10 Pa 15761

@ Maximum Design Temperature

11 Maximum Design Head Loss Hloss m/100m 2.50 7.50

2

12 Flow Minimum Area AMinimum =QInput / Vdesign mm 4333.33 1333.33

Minimum Pipe Diameter

13 mm 74.28 41.20

(Based on Velocity Criteria)

Minimum Pipe Diameter

14 mm 85.81 62.04

(Based on Head Loss Criteria)

15 Required Minimum Pipe I.D Di (Minimum) mm 85.81 62.04

16 Selected Pipe D.N. DNB mm 100.00 65.00

17 Pipe O.D. DO mm 114.30 73.03

Velocity

18 V Nominal m/s 0.55 1.00

(Based on nominal diameter)

Reynolds Number

19 Re - 36298 42957

(Based on Nominal Diameter)

20 Type of Flow - - Turbulent Turbulent

21 Pipe Roughness ε - 0.0460 0.0460

22 Moody Friction Factor f - 0.0238 0.0239

23 Design Pressure PDESIGN barg 2.0000 17.000

0

24 Design Temperature TDESIGN C 60.000 60.000

Allowable Stress

25 SEKSI KSI 17.1 17.1

(As per ASME B31.1 Table A-2)

26 Allowable Stress SKGCM=(SKSI x1000) / 14.2233 MPa 117.90 117.90

Weld Joint Efficiency

27 EWELD - 1.000 1.000

(As per ASME B31.1)

Corrosion/Erosion/Threading

28 ALCorrosion mm 3.0000 3.0000

Allowance

Y-Coefficient

29 YCOF - 0.400 0.400

(As per ASME B31.1 Table104.1.2(A))

TMIN=(((PDESIGN x DO x 0.1) /( 2 x

Minimum Calculated Pipe

30 (YCOF x PDESIGN + SKGCM x mm 3.0963 3.4978

Thickness

EWELD))+(ALCORRO)/10) x 10

31 Mill Negative Tolerance TOLMILL % 12.5 12.5

Minimum Required Wall

32 TM-REQ=(TMIN / (1-(TOLMILL/100)) mm 3.54 4.00

Thickness for The Pipe

33 Selected Thickness of Pipe TSELECT mm 6.02 5.16

34 Pipe I.D DID=(DO - ( 2 x TSELECT )) / 1000 mm 102.26 62.71

35 Flow Area AFLOW = ( 3.14 x DID x DID / 4 ) mm2 82.09 30.87

36 Calculated Velocity VCAL = QV_PERLEAD / AFLOW m/s 0.53 1.08

37 Pipe Schedule - SCH Sch 40 Sch 40

38 Selected S&L Pipe PDT - - S&L 0659 S&L 0659

You might also like

- Base Ring (Welded) - Vertical Vessel REV.1Document3 pagesBase Ring (Welded) - Vertical Vessel REV.1dskr fkshNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Cylcone Type Selection RouteDocument75 pagesCylcone Type Selection RouteAnonymous pVoSWn8yh0No ratings yet

- Cyclone Design Tool - 1Document3 pagesCyclone Design Tool - 1mshah222No ratings yet

- CentrifugalCompressorPower SI UnitsDocument4 pagesCentrifugalCompressorPower SI UnitsReza GhanavatiNo ratings yet

- Book 1Document1 pageBook 1Manju NaikNo ratings yet

- Weld Neck Flange DesignDocument2 pagesWeld Neck Flange DesignKashif KaziNo ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On Cladrsubramani100% (1)

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Document3 pagesFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnNo ratings yet

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- SMHB SDN BHD: Jurutera PerundingDocument5 pagesSMHB SDN BHD: Jurutera PerundingAnonymous D8aZCZ98No ratings yet

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIDocument5 pagesReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiNo ratings yet

- CO2 LoadingDocument12 pagesCO2 LoadingMuhammad Sheraz GorayaNo ratings yet

- Data Sheet For T-8101.RevCDocument5 pagesData Sheet For T-8101.RevCSuresh SjNo ratings yet

- Boil Up RateDocument1 pageBoil Up RateNitin KurupNo ratings yet

- PEC EN STN C 13619 17 Mar 2014Document169 pagesPEC EN STN C 13619 17 Mar 2014Raja RamNo ratings yet

- Corsair CalcDocument126 pagesCorsair CalcCouderoyBrown100% (1)

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- 16 - Blending and AgitationDocument27 pages16 - Blending and AgitationSimon Tin Hann PyngNo ratings yet

- Gear Pump Design SheetDocument3 pagesGear Pump Design SheetJagankumarNo ratings yet

- Pump CurveDocument3 pagesPump CurveLINIEL DE JESUSNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- SP by CantileverDocument18 pagesSP by CantileverPaldexNo ratings yet

- Pipes. Flow Rate and Pressure Loss EquationsDocument62 pagesPipes. Flow Rate and Pressure Loss EquationsFrancisco AlvarezNo ratings yet

- Weight Calculation For VesselDocument6 pagesWeight Calculation For VesselDesign SadhanaNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelineschrisevabNo ratings yet

- Engineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsDocument1 pageEngineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsAnonymous EarAM2100% (1)

- API 650 Tank Nozzle Load Allowable For Tank DiaDocument1 pageAPI 650 Tank Nozzle Load Allowable For Tank Diasemin prsesNo ratings yet

- 50KL Tank - API CalcDocument1 page50KL Tank - API CalcRathika100% (1)

- Annexure-2 Tailing Lug DesignDocument2 pagesAnnexure-2 Tailing Lug DesignRajeshNo ratings yet

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitNo ratings yet

- API650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146Document11 pagesAPI650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146nassmechNo ratings yet

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RDocument3 pagesSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinNo ratings yet

- Ellipsoidal Flange To Circular ConverterDocument3 pagesEllipsoidal Flange To Circular Converternaveenkumar_madasett100% (1)

- Cone Area Inside Shell Area Bottom Area Railing Area Inside: Input: Input: InputDocument3 pagesCone Area Inside Shell Area Bottom Area Railing Area Inside: Input: Input: Inputpurav_patel20079232No ratings yet

- Astm D3294 PtefDocument6 pagesAstm D3294 PtefIsabella RomeroNo ratings yet

- XCELDocument2 pagesXCELridanormaNo ratings yet

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- Pump Branch DesignDocument7 pagesPump Branch DesignMarcelo PerettiNo ratings yet

- CS SS - Pipe Weight CalculationDocument1 pageCS SS - Pipe Weight CalculationTashrif Yusuf0% (1)

- Dynamic Analysis of Slug by Advance Input MethodDocument53 pagesDynamic Analysis of Slug by Advance Input MethodYogesh Pangare100% (1)

- Find Eq - Length (M) :: Manual Pressure Drop CalculationDocument7 pagesFind Eq - Length (M) :: Manual Pressure Drop Calculationcryptic postNo ratings yet

- Calculation BS 31.3Document1 pageCalculation BS 31.3prabhjot123No ratings yet

- ANZ-DS-E-5016 HV Surge DiverterDocument17 pagesANZ-DS-E-5016 HV Surge Divertermika cabelloNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- Qest Ok: System Pump CharacteristicsDocument6 pagesQest Ok: System Pump CharacteristicsGJ CCNo ratings yet

- Ball Mill DesignDocument3 pagesBall Mill DesignDoaa BadarnehNo ratings yet

- BoilerDocument29 pagesBoilerhonchoabhiNo ratings yet

- Standard Specification For Hot Insulation Piping EquipmentDocument62 pagesStandard Specification For Hot Insulation Piping EquipmentAri SupramonoNo ratings yet

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 pagesValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNo ratings yet

- Tightening Torque Calculation For Screw V0001Document4 pagesTightening Torque Calculation For Screw V0001vijay10484No ratings yet

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelNo ratings yet

- Design Calculations Sheet - 12.75": SL .No. Symbol Value UnitDocument6 pagesDesign Calculations Sheet - 12.75": SL .No. Symbol Value UnitASHOK SWAMINo ratings yet

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- ASME B31.4-Wall Thickness Calc For 6 InchDocument2 pagesASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Iocl Drawing Rev-00Document6 pagesIocl Drawing Rev-00dejiinfrastructuresNo ratings yet

- Expansion Vessels enDocument32 pagesExpansion Vessels enahmed100% (1)

- Equipment Owner Preliminary Process 1st Issue MEP 2nd Issue DCS 3rd Issue Instrument Electrical SiemensDocument3 pagesEquipment Owner Preliminary Process 1st Issue MEP 2nd Issue DCS 3rd Issue Instrument Electrical SiemensahmedNo ratings yet

- Pressure Drop in Piping Total DP VG 46 34.7 L/S 5.5 4 Bar 0.15 1.5 BarDocument1 pagePressure Drop in Piping Total DP VG 46 34.7 L/S 5.5 4 Bar 0.15 1.5 BarahmedNo ratings yet

- Hydraulic Retention TimesDocument1 pageHydraulic Retention TimesahmedNo ratings yet

- Steam Out Nozzle (Inches)Document1 pageSteam Out Nozzle (Inches)ahmedNo ratings yet

- Column and Vessel NozzleDocument1 pageColumn and Vessel NozzleahmedNo ratings yet

- API 610 Major Changes From 5th Through 10th Editions 4Document1 pageAPI 610 Major Changes From 5th Through 10th Editions 4ahmedNo ratings yet

- Annex 8Document1 pageAnnex 8ahmedNo ratings yet

- Product Proposed CapacityDocument1 pageProduct Proposed CapacityahmedNo ratings yet

- EQUIPMENT On The Discharge of A PumpDocument1 pageEQUIPMENT On The Discharge of A PumpahmedNo ratings yet

- API 610 Major Changes From 5th Through 10th Editions 1Document1 pageAPI 610 Major Changes From 5th Through 10th Editions 1ahmedNo ratings yet

- Operating Conditions: Required Driver Power at BL KWDocument2 pagesOperating Conditions: Required Driver Power at BL KWahmedNo ratings yet

- Pump Rules of Thumb 4Document1 pagePump Rules of Thumb 4ahmedNo ratings yet

- API 610 Major Changes From 5th Through 10th Editions 2Document1 pageAPI 610 Major Changes From 5th Through 10th Editions 2ahmedNo ratings yet

- API 610 Major Changes From 5th Through 10th Editions 3Document1 pageAPI 610 Major Changes From 5th Through 10th Editions 3ahmedNo ratings yet

- API 610 Major Changes From 5th Through 10th Editions 5Document1 pageAPI 610 Major Changes From 5th Through 10th Editions 5ahmedNo ratings yet

- Pumps Sizing Calculations 2Document1 pagePumps Sizing Calculations 2ahmedNo ratings yet

- Pumps Types SelectionDocument2 pagesPumps Types SelectionahmedNo ratings yet