Professional Documents

Culture Documents

Simple Ozonizer: Laboratory

Simple Ozonizer: Laboratory

Uploaded by

Anonymous FigYuONxuuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simple Ozonizer: Laboratory

Simple Ozonizer: Laboratory

Uploaded by

Anonymous FigYuONxuuCopyright:

Available Formats

8 INDUSTRIAL AND ENGINEERING CHEMISTRY VOL. 9, NO.

connections are tight and that the tubing contains no air bubbles, Materials, “1933 Book of Standards,” Part 11,p. 891; Federal

Place the condenser in position so that the lower end extends Specification VV-L-791a for “Lubricants and Liquid Fuels;

General Specifications (Methods for Sampling and Testing),”

directly into the upper end of the buret just above the water Method 300.13,p. 80.

level or connect to an adapter siphon, G, which discharges into (8) Hillebrand, W. F., U. S. Geol. Survey, Bull. 700, 102 (1919).

the buret. The cooling water ahould be 15.5’ C. or colder. (9) Ibid.. 700. 232 (1919).

I~ ~ I

Ice water may be desirable for low-boiling hydrocarbons. (10) Hoyt, L. ’F., and Pemberton, H. V., J. IND.ENG.CHEM., 14,

54, 340 (1922).

Weigh 100 grams ( *0.5 gram) of the soap (cut into cubes of (11) Munson, L. S., and Walker, P. H., J. Am. Chem. SOC.,28,663

about 1-om. edges) or 50 grams ( ~ 0 . 3gram) of boap powder (1906); Assoc. Official A m Chem.. Official and Tentative

and transfer to the evolution flask. Add about 10 grams of gum Methods of Analysis; U.S. Dept. Agr., Bur. Chem., Bull.

arabic (commercial) and 100 cc. of distilled water. Place the 107, 241 (1908).

(12) Poetschke, P., J. IND.ENQ.CHDM.,5, 645 (1913).

flask in position with 100 cc. of sulfuric acid (1t o 3) in a dropping (13) Procter & Gamble Co., Oil and Soup, 13, 6-10 (1936).

funnel, C, carried in the stopper. Connect with the steam line, (14) Soap Analysis Committee, Am. Oil Chemists’ SOC.,Ibid., 11,

wash the flasks and the condenser, making sure that the stoppers 90-5 (1934).

are tightly fitting and held in place by wiring. Rubber connec- (15) Ibid.. 12. 10 (1935).

tions in the lines between the evolution flask and condenser (16) Ibid., 12, 10Lll (1935); Wolff, H.,and Scholze, E., Chem.-

Ztg., 38,369,382,430 (1914).

should be avoided. (17) Trevithiok, H. P.,Soap, 7, No. 6, 29 (1931).

Add the acid t o the sample slowly to avoid excessive frothing.

While adding the acid, turn on the steam cautiously, so adjusting RECZIIVED

September 12, 1936. Presented a t the 92nd Meeting of the

American Chemical Sooiety, Pittsburgh, Pa., September 7 t o 11, 1936.

the pressure by a bleeder valve that just enough steam flows to Approved by the Supervisory Committee on Standard Methods of Analysis.

prevent any liquid from backing into the steam trap flask, and by the Council as official for the American Chemical Society,

When all the acid has been added, turn on enough steam to

cause brisk distillation, taking care that no liquid is carried over

from the evolution and wash flasks and that the condenser water

does not become warm.

Continue the distillation until there is no increase in the

A Simple Laboratory

volume of the upper layer for 45 minutes or no small droplets

can be noted in the condensate. Ozonizer

When distillation is completed, shut off and drain the condenser

water, and allow the steam to heat up the condenser to drive out W. SHEEHAN AND W. CARMODY

the last traces of volatile hydrocarbon. Shut off the steam as The Neville Company, Pittsburgh, Pa.

soon as vapor begins to issue from the lower end of the condenser.

I

Immediately open the stopcock of the dropping funnel t o prevent

caustic being drawn into the evolution flask.

Stopper the buret and allow its contents to come to room

B

c

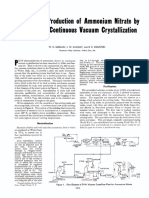

A QUICKLY assembled ozo-

nizer that can be operated

for relatively long periods to

temperature or bring them to a dehite temperature by immersing

give satisfactory yields is shown

the buret for 1 t o 2 hours in a water bath held at 25” C. in Figure 1, which is self-ex-

Read the volume of the upper layer t o the nearest 0.01 cc. The

planatory. It has been con-

volume multipled by the specific gravity equals the weight of 0

structed of a 600-mm. Pyrex

the volatile hydrocarbon. The specific gravity should be de-

condenser with extended side

termined at the temperature a t which the volume is read. A

arm, and from other materials

small Sprengel tube made of 3-mm. glass tubing is convenient E available in a laboratory. It

for this purpose. B is s i m p l e i n c o n s t r u c t i o n ,

Calcdation. quickly assembled, relatively in-

GO. of volatile hydrocarbon X specific gravity X 100 e x p e n s i v e , a n d can be dis-

weight of sample mantled into service as a stand-

per cent of volatile hydrocarbon

ard condenser.

For some samples the volatile hydrocarbon content may be The transformer u s e d was

so low that a larger sample than 50 or 100 grams is desirable. o b t a i n e d from a neon sign.

The size of the evolution flask may need t o be increased if larger Several were tried, r a n g i n g

samples are used. The amount of water in the evolution flask from 10,000 volts upwards; all

and acid used should also be correspondingly increased. Y

*- were satisfactory, and although

FIGURE 1. DIAQRAM OF

not a stockroom item with most

Literature Cited APPARATUS laboratories, they can be readily

Assoc. Official Agr. Chem., Official and Tentative Methods of A . Brass wire obtained from any neon sign

E N Rubber atop ers agency. Used transformers are

Analysis, p. 115 (1930); U. S. Dept. Agr., Bur. Chem., Bull. C.’ 6 per cent sulyuric acid

107, 169 (1908). D 15 000-volt transformer always avaiIable.

Assoc. Official Agr. Chem., Official and Tentative Methods of E: Alhninum foil The units are supported in

C. 600-mm. condenser

Analysis, p. 14 (1930). L. Ground

Ibid., p. 282; U. S. Dept. Agr., Bur. Chem., Bull. 107,53(1908). M. Oxygen

ordinary ring stands, insulation

Bennett, H.C., J. IND. ENQ.CHIM., 13, 813 (1921). T. 0501162 (oxygen) being provided by means of cork

Com. on Analysis of Commercial Fats and Oils, Ibid., 11, 1163 or rubber between the outer foil

(1919): Assoc. Official Agr. Chem., Official and Tentative and the support. Several can be used in series by making the

Methods of Analysis, p. 317 (1930).

Corn. on Methods of Analysis and Specifications of Commercial proper sealed connection.

Soaps and Soap Products, J. IND. ENQ.CHEM.,14, 1159-63

(1922). November 7,1936.

RECEIVED

Dean, E. W.,and Stark, D. D., Ibid., 12,486 (1920); Bidwell,

G.L., and Sterling, W. F., Ibid., 17, 147 (1925); Church, A.

K.,and Wilson, J. H., Soup, 7, No. 11, 35 (1931); Oil a n d

Soap, 9,253 (1932); “Standard Method of Test for Water

in Petroleum Products and Other Bituminous Materials,”

Serial Designation D-95-30,American Society for Testing

You might also like

- Sulfitos Monier-Williams AOAC 990-28Document2 pagesSulfitos Monier-Williams AOAC 990-28Paula Catalina Marín Uribe50% (2)

- Clinical 2Document2 pagesClinical 2Jonathan100% (1)

- Determination of Percent Water in A Compound and Empirical FormulaDocument4 pagesDetermination of Percent Water in A Compound and Empirical FormulaSugi MinNo ratings yet

- 1979 - Moult - Single Tray Rain Type PDFDocument5 pages1979 - Moult - Single Tray Rain Type PDFportolatinaNo ratings yet

- A Large Spinning-Band Fractionating ColumnDocument4 pagesA Large Spinning-Band Fractionating ColumnNestor Armando Marin SolanoNo ratings yet

- The Solubility of Carbon Dioxide in Calcium-Chloride-Water Solutions at 75, 100, 120 C and High PressureDocument5 pagesThe Solubility of Carbon Dioxide in Calcium-Chloride-Water Solutions at 75, 100, 120 C and High Pressuremoji20067147No ratings yet

- Research Paper On Purification by SublimationDocument6 pagesResearch Paper On Purification by SublimationGurdevNo ratings yet

- THE BY: D U L Y-Corrosion SteelDocument3 pagesTHE BY: D U L Y-Corrosion SteelSteve OoiNo ratings yet

- KDKDKDKDDocument4 pagesKDKDKDKDFauzi IhsanNo ratings yet

- AaaxxxxxxxxxxxxxxxxDocument7 pagesAaaxxxxxxxxxxxxxxxxcibin35477No ratings yet

- Reaction of PC With Carbon DioxideDocument6 pagesReaction of PC With Carbon DioxideNam HuynhNo ratings yet

- Theory, Production and Mechanism of Formation of Monodispersed HydrosolsDocument8 pagesTheory, Production and Mechanism of Formation of Monodispersed Hydrosolsivan celyNo ratings yet

- Roebuck 1942Document12 pagesRoebuck 1942Imam Saja DechNo ratings yet

- Separating Phenol From Phenol-Water SubazeotropeDocument4 pagesSeparating Phenol From Phenol-Water SubazeotropeHARSH DHOLAKIYANo ratings yet

- Biker Man 1952Document2 pagesBiker Man 1952Krupali Umeshkumar KapadiyaNo ratings yet

- Preparation of A Raney Nickel Catalyst 1946 - W-3Document1 pagePreparation of A Raney Nickel Catalyst 1946 - W-3masihNo ratings yet

- Asphaltene Deposition in Production Facilities: Ruksana Thawer, David C.A. Nicoli, Graeme DickDocument6 pagesAsphaltene Deposition in Production Facilities: Ruksana Thawer, David C.A. Nicoli, Graeme DickCarlos A MoyaNo ratings yet

- Brit. J. Anaesth. (1968), 40, 648: D. W. HillDocument12 pagesBrit. J. Anaesth. (1968), 40, 648: D. W. HillAteeq Ul rehmanNo ratings yet

- Kinetics The Catalyzed and Uncatalyzed Liquid-Phase Hydration of PropyleneDocument7 pagesKinetics The Catalyzed and Uncatalyzed Liquid-Phase Hydration of PropyleneAlejandro HernandezNo ratings yet

- Experiment 12Document6 pagesExperiment 12flakomusicNo ratings yet

- The Practical Aspects Handling High-Pressure Sour Gas: R. Mottley and C. PfisterDocument6 pagesThe Practical Aspects Handling High-Pressure Sour Gas: R. Mottley and C. PfisterAhmadFauziNo ratings yet

- Nitrógeno-Amonio-Proteína: Método Kjeldahl ModificadoDocument6 pagesNitrógeno-Amonio-Proteína: Método Kjeldahl ModificadoMirella MendozaNo ratings yet

- Iec 16 1125 1924Document1 pageIec 16 1125 1924Jeff ZabolotneyNo ratings yet

- Hydrogen Peroxide PropertiesDocument22 pagesHydrogen Peroxide PropertiesValentin HueNo ratings yet

- Pilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricDocument5 pagesPilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricIngrid ContrerasNo ratings yet

- Determination of Water in Gasoline As Received-Exposed To Atmosphere, To Humid Atmosphere, and Saturated With Water (15 March 1922)Document8 pagesDetermination of Water in Gasoline As Received-Exposed To Atmosphere, To Humid Atmosphere, and Saturated With Water (15 March 1922)raheyo6168No ratings yet

- Distillation FINALDocument9 pagesDistillation FINALvivianzhu120No ratings yet

- Adsorption 2Document76 pagesAdsorption 2Shangeetha Tangaraj0% (1)

- Oxygen Plant ExpbsionDocument2 pagesOxygen Plant Expbsionmuthu kujmarNo ratings yet

- PA-PAC Eutectic MixturesDocument4 pagesPA-PAC Eutectic MixturesRajeshNo ratings yet

- Films: The Effect of Monomolecular On The Rate G A S Absorption QuiescentDocument9 pagesFilms: The Effect of Monomolecular On The Rate G A S Absorption QuiescentGustavo Gabriel JimenezNo ratings yet

- CARBONDocument11 pagesCARBONnayanNo ratings yet

- DiEhtylEter RecipeDocument5 pagesDiEhtylEter RecipeVanilla47No ratings yet

- The Reversed-Phase Chromatography: Separation of The Fatty Acids by PartitionDocument7 pagesThe Reversed-Phase Chromatography: Separation of The Fatty Acids by PartitionIrna Puspita SariNo ratings yet

- Relative Humidity-Temperature Relationships of Some Saturated Salt Solutions in The Temperature Range 0 To 50 CDocument8 pagesRelative Humidity-Temperature Relationships of Some Saturated Salt Solutions in The Temperature Range 0 To 50 Chendry taputraNo ratings yet

- Experiment 2: Chemical Transformations and The Law of Conservation of MassDocument7 pagesExperiment 2: Chemical Transformations and The Law of Conservation of MassWill HallNo ratings yet

- The Poisoning of Nickel Hydrogenation Catalysts by Water Vapor' 'Document2 pagesThe Poisoning of Nickel Hydrogenation Catalysts by Water Vapor' 'victor japposanNo ratings yet

- Raney Ni PurificationDocument5 pagesRaney Ni Purificationanjireddy1612No ratings yet

- Strontium Sulfate Scale Control by Inhibitor Squeeze Treatment in The Fateh FieldDocument5 pagesStrontium Sulfate Scale Control by Inhibitor Squeeze Treatment in The Fateh FieldFarzad sadeghzadNo ratings yet

- RefluxDocument1 pageRefluxJakub LuczakNo ratings yet

- Analysis of Alum Alk (So) - 12H O Ap Chemistry Laboratory #12LDocument6 pagesAnalysis of Alum Alk (So) - 12H O Ap Chemistry Laboratory #12LJoshua A Gullace0% (1)

- Phthalic Acid SolubilityDocument3 pagesPhthalic Acid SolubilityRajeshNo ratings yet

- Solubility of Nitrobenzene in WaterDocument2 pagesSolubility of Nitrobenzene in WaterMuhammad Fiqih AlayubiNo ratings yet

- A Modification of The Demonstration of The Ostwald Process: Journal, 15 ItDocument1 pageA Modification of The Demonstration of The Ostwald Process: Journal, 15 ItSJ ChuaNo ratings yet

- Dehydration of An AlcoholDocument13 pagesDehydration of An AlcoholButterlesstoastNo ratings yet

- Low Temperature Stress Corrosion CrackinDocument8 pagesLow Temperature Stress Corrosion Crackinshanefulton2012No ratings yet

- United States Patent Office: Patented Feb. 6, 1951Document3 pagesUnited States Patent Office: Patented Feb. 6, 1951karmilaNo ratings yet

- IsoteniscopeDocument2 pagesIsoteniscopeRolando R. MartinezNo ratings yet

- On Acid (On: EffectDocument23 pagesOn Acid (On: Effectprakush01975225403No ratings yet

- FR Act DistillDocument13 pagesFR Act DistilljahmanNo ratings yet

- Oxygenplant Vaporizer ExplosionDocument4 pagesOxygenplant Vaporizer Explosionmuthu kujmarNo ratings yet

- SPE 56705 Chemical Defoamer Reduction With New Internals in The Mars TLP SeparatorsDocument5 pagesSPE 56705 Chemical Defoamer Reduction With New Internals in The Mars TLP SeparatorsRégis OngolloNo ratings yet

- Water Hammer in Condensate LinesDocument5 pagesWater Hammer in Condensate LinesAatish Chandrawar100% (1)

- Descaling Plate Heat ExchangersDocument2 pagesDescaling Plate Heat ExchangersrishimaranNo ratings yet

- Sulfonation With Sulfur TrioxideDocument4 pagesSulfonation With Sulfur TrioxideRashid SaleemNo ratings yet

- A. Gordon: S. Shankman atDocument4 pagesA. Gordon: S. Shankman atbuhalnitaNo ratings yet

- Net2f"25N: Accumulator With Diaphragm StabilizerDocument6 pagesNet2f"25N: Accumulator With Diaphragm StabilizerHassan KhattabNo ratings yet

- History of Vacuum UmpDocument7 pagesHistory of Vacuum UmploganatahnNo ratings yet

- Syn 98347Document2 pagesSyn 98347Ary RachmanNo ratings yet

- Decrease in Carbonyl Sulfide in The Feed To Claus Converters Shift CatalystsDocument3 pagesDecrease in Carbonyl Sulfide in The Feed To Claus Converters Shift CatalystsJoel OngNo ratings yet

- Al Stream Relationships - A Case Study in The Westend Basin of The Southern Pennines, England (Earth Surface Processes, Vol. 1, Issue 1) (1976)Document7 pagesAl Stream Relationships - A Case Study in The Westend Basin of The Southern Pennines, England (Earth Surface Processes, Vol. 1, Issue 1) (1976)Anonymous FigYuONxuuNo ratings yet

- Stability of Minels in Ring Reaneral Thchemical Approach (Earth Surface Processes, Vol. 1, Issue 1) (1976)Document8 pagesStability of Minels in Ring Reaneral Thchemical Approach (Earth Surface Processes, Vol. 1, Issue 1) (1976)Anonymous FigYuONxuuNo ratings yet

- Iterated Crossed Box Diagram in The Complex Angular Momentum Plane and Bethe-Salpeter EquationDocument15 pagesIterated Crossed Box Diagram in The Complex Angular Momentum Plane and Bethe-Salpeter EquationAnonymous FigYuONxuuNo ratings yet

- Inhomogeneous: SL (N, C)Document9 pagesInhomogeneous: SL (N, C)Anonymous FigYuONxuuNo ratings yet

- A Scree Slope Rockfa (Esses, Vol. 1, Issue 1) (1976)Document20 pagesA Scree Slope Rockfa (Esses, Vol. 1, Issue 1) (1976)Anonymous FigYuONxuuNo ratings yet

- The Erosion of Limestones Under Soil AND Vegetation Systems On LimestoneDocument11 pagesThe Erosion of Limestones Under Soil AND Vegetation Systems On LimestoneAnonymous FigYuONxuuNo ratings yet

- Hydrograph Peakedness and Basin Area (Es, Vol. 1, Issue 1) (1976)Document4 pagesHydrograph Peakedness and Basin Area (Es, Vol. 1, Issue 1) (1976)Anonymous FigYuONxuuNo ratings yet

- The Ground State Oi The Bose Gas By: AbstractDocument16 pagesThe Ground State Oi The Bose Gas By: AbstractAnonymous FigYuONxuuNo ratings yet

- Pedological Feeability of Hillydale, Yorire (, Vol. 1, Issue 1) (1976)Document14 pagesPedological Feeability of Hillydale, Yorire (, Vol. 1, Issue 1) (1976)Anonymous FigYuONxuuNo ratings yet

- Earth Surface Processes, Vol. 39, Issue 5Document1 pageEarth Surface Processes, Vol. 39, Issue 5Anonymous FigYuONxuuNo ratings yet

- Masthead (Earth Surface Processes, Vol. 1, Issue 1) (1976)Document1 pageMasthead (Earth Surface Processes, Vol. 1, Issue 1) (1976)Anonymous FigYuONxuuNo ratings yet

- On The Vacuum State in Quantum Field Theory. II: H. J. BorchersDocument23 pagesOn The Vacuum State in Quantum Field Theory. II: H. J. BorchersAnonymous FigYuONxuuNo ratings yet

- A Theorem Concerning The Positive Metric: Derek W. Robi NsonDocument6 pagesA Theorem Concerning The Positive Metric: Derek W. Robi NsonAnonymous FigYuONxuuNo ratings yet

- Upper Andlower Limitsforthe Number Ofbound States in A Given Central PotentialDocument9 pagesUpper Andlower Limitsforthe Number Ofbound States in A Given Central PotentialAnonymous FigYuONxuuNo ratings yet

- Divergence of Perturbation Theory For Bosons: ArthurDocument23 pagesDivergence of Perturbation Theory For Bosons: ArthurAnonymous FigYuONxuuNo ratings yet

- Evaluating Go Game Records For Prediction of Player AttributesDocument7 pagesEvaluating Go Game Records For Prediction of Player AttributesAnonymous FigYuONxuuNo ratings yet

- Measurement Distensibilitv Organic Finishes: NE Is A of A TDocument4 pagesMeasurement Distensibilitv Organic Finishes: NE Is A of A TAnonymous FigYuONxuuNo ratings yet

- Preparation of Vehicle Films Free of Supporting Foundation: Semi-MicromethodDocument1 pagePreparation of Vehicle Films Free of Supporting Foundation: Semi-MicromethodAnonymous FigYuONxuuNo ratings yet

- Microdetermination Zinc: Comparison Spectrographic and Chemical MethodsDocument3 pagesMicrodetermination Zinc: Comparison Spectrographic and Chemical MethodsAnonymous FigYuONxuuNo ratings yet

- A Photoelectric Method The Phosphorus': For DeterminationDocument3 pagesA Photoelectric Method The Phosphorus': For DeterminationAnonymous FigYuONxuuNo ratings yet

- An Improved Semi-Micro and Micro-Carius Determination: HE L. and of A and ToDocument2 pagesAn Improved Semi-Micro and Micro-Carius Determination: HE L. and of A and ToAnonymous FigYuONxuuNo ratings yet

- 44 GÇô45Document2 pages44 GÇô45Anonymous FigYuONxuuNo ratings yet

- Spectrographic Determination by The Method: Constant-PairDocument2 pagesSpectrographic Determination by The Method: Constant-PairAnonymous FigYuONxuuNo ratings yet

- Micromethod Analysis Adapted For Biological: StudiesDocument4 pagesMicromethod Analysis Adapted For Biological: StudiesAnonymous FigYuONxuuNo ratings yet

- Light Petroleum: AnalysisDocument5 pagesLight Petroleum: AnalysisAnonymous FigYuONxuuNo ratings yet

- Standard Quinhydrone Electrode: 5 VolsDocument2 pagesStandard Quinhydrone Electrode: 5 VolsAnonymous FigYuONxuuNo ratings yet

- 27 GÇô27Document1 page27 GÇô27Anonymous FigYuONxuuNo ratings yet

- Machine Rubber Testing: Impact ForDocument5 pagesMachine Rubber Testing: Impact ForAnonymous FigYuONxuuNo ratings yet

- Standard Methods The Sampling and Soam and Soap Products, RevisedDocument7 pagesStandard Methods The Sampling and Soam and Soap Products, RevisedAnonymous FigYuONxuuNo ratings yet

- JR 9430000050Document2 pagesJR 9430000050Anonymous FigYuONxuuNo ratings yet

- Oworin Meji Falokun Fatumbi Awo Ifa World PerspectiveDocument13 pagesOworin Meji Falokun Fatumbi Awo Ifa World PerspectiveLevy Braunstein100% (1)

- RM Group FormationDocument7 pagesRM Group FormationRaja. KumarNo ratings yet

- Elln Matrix: Valenzuela South District Ilang-Ilang St. Karuhatan, Valenzuela City Tel/fax No. 2944246Document1 pageElln Matrix: Valenzuela South District Ilang-Ilang St. Karuhatan, Valenzuela City Tel/fax No. 2944246rafaela villanuevaNo ratings yet

- Synopsis DhananjayDocument15 pagesSynopsis DhananjayDevendra DhruwNo ratings yet

- Patient Safety AjarDocument48 pagesPatient Safety AjarAngell YunitaNo ratings yet

- 3:3Document15 pages3:3Nicholas CemenenkoffNo ratings yet

- CV - Moges Alemu (Plant Manager)Document8 pagesCV - Moges Alemu (Plant Manager)MogesNo ratings yet

- XXXXXXX XXXXXXXXXXXXX XX Dsfasdfasdf Res: 00000000000Document3 pagesXXXXXXX XXXXXXXXXXXXX XX Dsfasdfasdf Res: 00000000000asksrsinfotechNo ratings yet

- 9701 Oct Nov 2011 All Mark SchemesDocument90 pages9701 Oct Nov 2011 All Mark SchemesRobert EdwardsNo ratings yet

- Computer POST and Beep CodesDocument8 pagesComputer POST and Beep CodesJDNo ratings yet

- Earth As A SphereDocument96 pagesEarth As A SphereMarlina MohamedNo ratings yet

- Offshore CNY Best Practice Guidelines For ConsultationDocument28 pagesOffshore CNY Best Practice Guidelines For Consultationargus-kerberNo ratings yet

- Lección 7 - Who - Why-Because (WH Questions)Document3 pagesLección 7 - Who - Why-Because (WH Questions)V QuintNo ratings yet

- Padlet Crib Sheet v0.2Document2 pagesPadlet Crib Sheet v0.2Abdou OsseniNo ratings yet

- List of DictionariesDocument38 pagesList of DictionariesSaraPhoenixNo ratings yet

- Effects of Online Distance Learning On The Performance of Kindergarten Learners in Selected Private Schools in Taytay, RizalDocument14 pagesEffects of Online Distance Learning On The Performance of Kindergarten Learners in Selected Private Schools in Taytay, RizalPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Data Protection Policy EnglishEWDocument8 pagesData Protection Policy EnglishEWAnkurNo ratings yet

- Ramadan The Collaborative CookbookDocument42 pagesRamadan The Collaborative CookbookIman SakandarNo ratings yet

- Datron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualDocument28 pagesDatron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualAlexander J RokowetzNo ratings yet

- Index SSPC: SpecificationsDocument1 pageIndex SSPC: SpecificationsjosNo ratings yet

- Notes Ed-124Document33 pagesNotes Ed-124Mary Cristine GaboteroNo ratings yet

- GBD26KS La26r71b GBD32KS La32r71b GBD40KS La40r71b GBD32KS La32r71wDocument177 pagesGBD26KS La26r71b GBD32KS La32r71b GBD40KS La40r71b GBD32KS La32r71wARTMehr Eng. GroupNo ratings yet

- Essay Topic - Distance LearningDocument3 pagesEssay Topic - Distance LearningFalling stonesNo ratings yet

- Our Lady of Guadalupe Minor Seminary Junior High School: Curriculum Map in Information and Communication TechnologyDocument7 pagesOur Lady of Guadalupe Minor Seminary Junior High School: Curriculum Map in Information and Communication Technologyreycelyn corsinoNo ratings yet

- Analysis and Design Methodology For An FRP Cable-Stayed Pedestrian BridgeDocument11 pagesAnalysis and Design Methodology For An FRP Cable-Stayed Pedestrian BridgeDavid IzquierdoNo ratings yet

- Bernard Stiegler - Nanomutations, Hypomnemata and GrammatisationiDocument12 pagesBernard Stiegler - Nanomutations, Hypomnemata and GrammatisationiIoana AlbertNo ratings yet

- Search Help Exit How ToDocument18 pagesSearch Help Exit How Tobra_mxoNo ratings yet

- Tugas B Ing FaldoDocument1 pageTugas B Ing FaldoFaldo AlfaizaNo ratings yet

- The Massive Korean Wave in Indonesia and Its Effects in The Term of CultureDocument6 pagesThe Massive Korean Wave in Indonesia and Its Effects in The Term of CultureRaven RhythmNo ratings yet