Professional Documents

Culture Documents

Last Edited MEI 2016 Module Page 1/11 Document Page 1

Last Edited MEI 2016 Module Page 1/11 Document Page 1

Uploaded by

janurtpatCopyright:

Available Formats

You might also like

- High Ambient Air Cooled Liquid ChillerDocument60 pagesHigh Ambient Air Cooled Liquid Chillerfmtechac75% (4)

- Top Drive WarriorDocument33 pagesTop Drive WarriorAlexander Bossio100% (2)

- (A. Basak) Analogue Electronic Circuits and SystemDocument376 pages(A. Basak) Analogue Electronic Circuits and SystemRusman Santai KaawuNo ratings yet

- Studi Kasus SCMDocument8 pagesStudi Kasus SCMMuflihul Khair0% (5)

- 70 Ebook Photography Download FreeDocument3 pages70 Ebook Photography Download Free-roger Ron Taylor-100% (3)

- Pasig RiverDocument34 pagesPasig RiverNhilo ReginoNo ratings yet

- Gma 5013Document10 pagesGma 5013janurtpatNo ratings yet

- Form 1.3 Identifying Training Gaps: Developed By: Revision #00Document2 pagesForm 1.3 Identifying Training Gaps: Developed By: Revision #00Jenny SamoranosNo ratings yet

- Process STD 1001 Rev0 Utilities - Boiler FeedwaterDocument105 pagesProcess STD 1001 Rev0 Utilities - Boiler FeedwaterSteve WanNo ratings yet

- Liebert Mini Mate2 1 1.5 Tons User Manual - 00 PDFDocument121 pagesLiebert Mini Mate2 1 1.5 Tons User Manual - 00 PDFjeisson alejandro franco torres100% (1)

- Form 1.4 Training Needs: Training Needs (Learning Outcomes) Module Title/Module of Instruction Core CompetenciesDocument1 pageForm 1.4 Training Needs: Training Needs (Learning Outcomes) Module Title/Module of Instruction Core CompetenciesJenny SamoranosNo ratings yet

- Process STD 1003 Rev0 Utilities - Steam SystemsDocument68 pagesProcess STD 1003 Rev0 Utilities - Steam SystemsSteve WanNo ratings yet

- Kolej Vokasional Batu Lanchang Rancangan Sesi Latihan (RSL)Document4 pagesKolej Vokasional Batu Lanchang Rancangan Sesi Latihan (RSL)farizanNo ratings yet

- Gma 6023 - Combine Harvester TroubleshootDocument12 pagesGma 6023 - Combine Harvester Troubleshootjanurtpat100% (1)

- Inspection ProcedureDocument13 pagesInspection ProcedureSantosh Kumar100% (1)

- Braun1988 PDFDocument434 pagesBraun1988 PDFDavid Pérez100% (1)

- MVAC Testing & Commissioning Procedure - 2007Document245 pagesMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- BS 7074-3 1989Document24 pagesBS 7074-3 1989geoff.ballNo ratings yet

- Danfoss Equil DOC137886464516Document84 pagesDanfoss Equil DOC137886464516JoseNo ratings yet

- EEMG Manual RevisedDocument277 pagesEEMG Manual RevisedsridharNo ratings yet

- Saep 142 PDFDocument17 pagesSaep 142 PDFRami Elloumi100% (1)

- Steam System DesignDocument74 pagesSteam System DesignIshan RanganathNo ratings yet

- Appendix D - Technical Specs & Equipment Selection Compliance Sheet V1.0Document5 pagesAppendix D - Technical Specs & Equipment Selection Compliance Sheet V1.0SAYED SAIFI AKHTARNo ratings yet

- Gma 501Document11 pagesGma 501Mohamad Nadzri YahayaNo ratings yet

- Quality Manual.4Document53 pagesQuality Manual.4dcol13100% (1)

- HVAC System Selection ReportDocument16 pagesHVAC System Selection ReportArman Ul Nasar100% (1)

- Liebert Mini Mate2 2 3 Tons User Manual - 00Document132 pagesLiebert Mini Mate2 2 3 Tons User Manual - 00Asad NizamNo ratings yet

- 2-Solar Water HeaterDocument124 pages2-Solar Water Heaterp4p7 projectsNo ratings yet

- N0470C ENG (1) - AqvalisDocument39 pagesN0470C ENG (1) - Aqvalisaleks canjugaNo ratings yet

- Chapter 5 - Rev ADocument30 pagesChapter 5 - Rev AAenur RofiiqNo ratings yet

- Variable Air Volume Units (VAV)Document22 pagesVariable Air Volume Units (VAV)rashid.khanNo ratings yet

- 3.3 SJ1085 RHD ZZ XX SP Z 0013 R1.0 Technical Specification For C04Document284 pages3.3 SJ1085 RHD ZZ XX SP Z 0013 R1.0 Technical Specification For C04Alif FirdausNo ratings yet

- 02810-Irrigation SystemDocument13 pages02810-Irrigation SystemAhmed HussienNo ratings yet

- Aspak: YCSE040-YCSE100 & YCRE040-YCRE100Document68 pagesAspak: YCSE040-YCSE100 & YCRE040-YCRE100ГОРОД КЛИМАТАNo ratings yet

- DNV Ru Ship Pt4ch5Document90 pagesDNV Ru Ship Pt4ch5Ken VikstromNo ratings yet

- IMCA-D-018 R2 SummaryDocument3 pagesIMCA-D-018 R2 SummaryMuaz Haziq MusaNo ratings yet

- Cover Sheet: - To Record Overall Project and Assessment DetailsDocument62 pagesCover Sheet: - To Record Overall Project and Assessment DetailsNabilBouabanaNo ratings yet

- Ceen622 - Control System 2Document14 pagesCeen622 - Control System 2Mija RashidNo ratings yet

- Jeo Uoc 10-Manage System Modification ActivitiesDocument41 pagesJeo Uoc 10-Manage System Modification ActivitiesTarmizi KembaliNo ratings yet

- GBH Enterprises, LTD.: GBHE-EDG-0501Document30 pagesGBH Enterprises, LTD.: GBHE-EDG-0501MosaddekNo ratings yet

- ICOM 035L02669-100 Rev1 (0905)Document52 pagesICOM 035L02669-100 Rev1 (0905)RANDOMNo ratings yet

- DNV Ru Ship Pt4ch3Document140 pagesDNV Ru Ship Pt4ch3Ken VikstromNo ratings yet

- Visionaire 2 3 Service Manual English PDFDocument47 pagesVisionaire 2 3 Service Manual English PDFQuarmina HesseNo ratings yet

- 2003 CPA Phys-Mech Manual Revised 10-13-03Document78 pages2003 CPA Phys-Mech Manual Revised 10-13-03Rubén Eduardo Galindo CarmonaNo ratings yet

- 0726 Precision Air Conditioning SystemDocument10 pages0726 Precision Air Conditioning SystemKeo SokhimNo ratings yet

- ME1925 Cooling Towers Part 1Document52 pagesME1925 Cooling Towers Part 12ravikanthNo ratings yet

- Maersk Laberinto HN4224 Machinery Operating Manual Issue 1 October 2012 PDFDocument411 pagesMaersk Laberinto HN4224 Machinery Operating Manual Issue 1 October 2012 PDFShikhar SwaroopNo ratings yet

- HVAC System Optimisation MethodologyDocument18 pagesHVAC System Optimisation Methodologythamer al-salekNo ratings yet

- Specification For Flue Gas Desulphurisation Plant by CEADocument448 pagesSpecification For Flue Gas Desulphurisation Plant by CEAproloy12No ratings yet

- Air Handling Units: Technical CatalogDocument72 pagesAir Handling Units: Technical Catalogarindam02041985No ratings yet

- ACMV TrainingDocument227 pagesACMV Traininghbitho75% (4)

- LNGC - Inigo Tapias - Machinery Systems Manual PDFDocument383 pagesLNGC - Inigo Tapias - Machinery Systems Manual PDFpNo ratings yet

- DNV Ru Ship Pt4ch10Document53 pagesDNV Ru Ship Pt4ch10Ken Vikstrom100% (1)

- Saes G 005Document56 pagesSaes G 005TrungNo ratings yet

- Competency-Based Learning Materials: Heating, Ventilating Air Conditioning and Refrigeration (Hvac/R)Document33 pagesCompetency-Based Learning Materials: Heating, Ventilating Air Conditioning and Refrigeration (Hvac/R)Jenny SamoranosNo ratings yet

- Guidelines For Fouling FactorsDocument8 pagesGuidelines For Fouling Factorsrajat vermaNo ratings yet

- Final ReportDocument94 pagesFinal ReportAJITH KUMAR100% (1)

- P260 MachineryA PDFDocument349 pagesP260 MachineryA PDFmariodalNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Stability and Control of Aircraft Systems: Introduction to Classical Feedback ControlFrom EverandStability and Control of Aircraft Systems: Introduction to Classical Feedback ControlNo ratings yet

- ANALISIS DATA Kualitatih KuantitatifDocument12 pagesANALISIS DATA Kualitatih KuantitatifjanurtpatNo ratings yet

- Land PreparationDocument3 pagesLand PreparationjanurtpatNo ratings yet

- SoftDocument8 pagesSoftjanurtpatNo ratings yet

- Land Preparation Machineries Used in AgricultureDocument47 pagesLand Preparation Machineries Used in Agriculturejanurtpat0% (1)

- Subunit Unit Mekanisasi AgroDocument5 pagesSubunit Unit Mekanisasi AgrojanurtpatNo ratings yet

- MPP 5013 Course Outline RDocument5 pagesMPP 5013 Course Outline RjanurtpatNo ratings yet

- Supervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdaraDocument5 pagesSupervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdarajanurtpatNo ratings yet

- Gma 5013Document10 pagesGma 5013janurtpatNo ratings yet

- Gma 6023 - Combine Harvester TroubleshootDocument12 pagesGma 6023 - Combine Harvester Troubleshootjanurtpat100% (1)

- Supervising Skills DevelopmentDocument5 pagesSupervising Skills DevelopmentjanurtpatNo ratings yet

- IEE Checklist InstructionsDocument20 pagesIEE Checklist InstructionsBalaji_Rajaman_2280No ratings yet

- Urinary SystemDocument9 pagesUrinary SystemMary Joyce RamosNo ratings yet

- UG RA 005 - Thermal Integrity and Resistivity TestingDocument6 pagesUG RA 005 - Thermal Integrity and Resistivity TestingshamshuddinNo ratings yet

- Raychem Molded PartsDocument28 pagesRaychem Molded PartsAMNo ratings yet

- (Chris A.M. Peters, Joseph H. M. Steenbrink) Mixed Hodge StructuresDocument467 pages(Chris A.M. Peters, Joseph H. M. Steenbrink) Mixed Hodge StructuresShaulB7100% (1)

- Campbeltown's Kilkerran Gun BatteryDocument2 pagesCampbeltown's Kilkerran Gun BatteryKintyre On RecordNo ratings yet

- Youjo Senki Side Story - A Borrowed Cat (v1.1)Document11 pagesYoujo Senki Side Story - A Borrowed Cat (v1.1)faiyaNo ratings yet

- Living in The I.T Era Module 2Document18 pagesLiving in The I.T Era Module 2Aivee GatzzNo ratings yet

- 320 Lecture 27Document8 pages320 Lecture 27Gathy BrayohNo ratings yet

- Methods?: Condoms Internal Condoms Sexually Transmissible Infections (Stis)Document25 pagesMethods?: Condoms Internal Condoms Sexually Transmissible Infections (Stis)Alecia R. CastilloNo ratings yet

- SOLOXLEXDocument4 pagesSOLOXLEXAlex KamaraNo ratings yet

- CCDS Parent Letter - Letter For Student-Contact To CaseDocument1 pageCCDS Parent Letter - Letter For Student-Contact To CaseActionNewsJaxNo ratings yet

- Valorisation of Spent Coffee Grounds Production of Biodiesel Via Enzimatic Catalisis With Ethanol and Co-SolventDocument14 pagesValorisation of Spent Coffee Grounds Production of Biodiesel Via Enzimatic Catalisis With Ethanol and Co-SolventAline GonçalvesNo ratings yet

- The Occidental Man in Search of Human ValuesDocument11 pagesThe Occidental Man in Search of Human ValuesBen Ritche LayosNo ratings yet

- KKSB1273 Teknologi Binaan Dan Bahan 01 1112 - 09 Konkrit Sebagai Bahan BinaanDocument56 pagesKKSB1273 Teknologi Binaan Dan Bahan 01 1112 - 09 Konkrit Sebagai Bahan BinaanFarhana NorzelanNo ratings yet

- Flushing StatementDocument4 pagesFlushing StatementMohd Salleh Zainal100% (1)

- The Talmud of Jerusalem - Schwab Moise 1839-1918 TRDocument201 pagesThe Talmud of Jerusalem - Schwab Moise 1839-1918 TRJanice O'BrianNo ratings yet

- Individual Development WorkoutDocument3 pagesIndividual Development WorkoutmichelleNo ratings yet

- Final Thesis of Tesfaye Asnake-Checked and CorrectedDocument93 pagesFinal Thesis of Tesfaye Asnake-Checked and CorrectedEsan DemissieNo ratings yet

- Open Web Floor Trusses - MiTek IncDocument7 pagesOpen Web Floor Trusses - MiTek IncinfoNo ratings yet

- QnA Intro To Gas Regulation in Indonesia (Ilham Maulana)Document15 pagesQnA Intro To Gas Regulation in Indonesia (Ilham Maulana)Ilham Maulana Ash Shiddieq100% (1)

- Basic Monte Carlo TechniquesDocument10 pagesBasic Monte Carlo TechniquesMobeen AhmadNo ratings yet

- Paper 2222Document16 pagesPaper 2222Abhijeet GholapNo ratings yet

- Parts Catalog ARDFDocument30 pagesParts Catalog ARDFUlmanu ValentinNo ratings yet

- CROSS REFERENCE DE VALVULAS SOLENOIDES - Danfoss - Alco - Sporlan-ParkerDocument4 pagesCROSS REFERENCE DE VALVULAS SOLENOIDES - Danfoss - Alco - Sporlan-ParkerJoss CastellNo ratings yet

- "Nausicaa" Compression SutureDocument14 pages"Nausicaa" Compression SutureAyu Dyah PrimaningrumNo ratings yet

Last Edited MEI 2016 Module Page 1/11 Document Page 1

Last Edited MEI 2016 Module Page 1/11 Document Page 1

Uploaded by

janurtpatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Last Edited MEI 2016 Module Page 1/11 Document Page 1

Last Edited MEI 2016 Module Page 1/11 Document Page 1

Uploaded by

janurtpatCopyright:

Available Formats

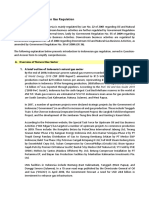

MINISTRY OF EDUCATION, MALAYSIA

VOCATIONAL COLLEGE STANDARD CURRICULLUM

COURSE INFORMATION

COURSE NAME : COOLING AND LUBRICATION SYSTEM

CODE NAME : GMA 5023

YEAR/SEMESTER : 1 SEMESTER 1

CREDIT UNIT : 3.0

CONTACT HOUR : FACE TO FACE : 4.0 HOURS/WEEK (2T+2P)

NON FACE TO FACE :

COURSE TYPE : VOCATIONAL

PRE-REQUISITE : -

CORE REQUISITE : -

Last Edited MEI 2016

Module Page 1/11 Document Page 1

COURSE OUTCOMES:

At the end of the course, the students should be able to:-

Perform the process of identifying cooling and lubrication system problems in agricultural machinery. (C3, PLO 3)

Practice the ability to repair the cooling and lubrication system according to service manual. (P3, PLO2)

Report in oral and written forms regarding the cooling and lubrication troubleshooting. (A2, PLO 4)

COURSE DESCRIPTION

This course is designed to expose students to the cooling and lubrication systems as well as their importance in agricultural vehicles. In

this course, the students are required to identify and solve the problem and enable students to solve problems related to the cooling and

lubrication systems in agricultural machinery. The students need to generate reports related to the troubleshooting in cooling and

lubrication system of agricultural machinery.

Last Edited MEI 2016

Module Page 2/11 Document Page 2

CONTENT AND LEARNING STANDARD

PROGRAM : DIPLOMA TEKNOLOGI MEKANISASI AGRO

COURSE NAME : COOLING AND LUBRICATION SYSTEM

CODE NAME : GMA 5023

COMPETENCY : 1

CONTACT CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

HOURS performance performance , condition performance,condition, standard

32 HOURS 1. Verify cooling system 1.1 Obtain verification 1.1.1 Identify source of cooling system verification

(8 WEEKS) maintenance works checklist checklist according to manufacture

1.1.2 Describe procedures of acquiring cooling system

verification checklist according to manufacture

1.1.3 List cooling system verification checklist according

to manufacture

1.1.4 Determine source of cooling system verification

checklist according to manufacture

1.1.5 Acquire cooling system verification checklist

according to manufacture

1.1.6 Interpret cooling system verification checklist

according to manufacture

Last Edited MEI 2016

Module Page 3/11 Document Page 3

1.2 Execute verification 1.2.1 Describe thermostat unit replacement work based

cooling system on standard form requirement

maintenance works

1.2.2 Explain water pump replacement work based on

standard form requirement

1.2.3 Explain radiator assembly servicing works based

on standard form requirement

1.2.4 Describe cooling system flushing works based on

standard form requirement

1.2.5 Explain oil cooler unit servicing works based on

standard form requirement

1.2.6 Justifying maintenance works based on standard

form requirement

1.2.7 Determine thermostat unit replacement work

based on standard form requirement

1.2.8 Determine water pump replacement work based

on standard form requirement

1.2.9 Determine radiator assembly servicing works

based on standard form requirement

1.2.10 Determine cooling system flushing works based on

standard form requirement

Last Edited MEI 2016

Module Page 4/11 Document Page 4

1.2.11 Determine oil cooler unit servicing works based on

standard form requirement

1.2.12 Justify maintenance works based on standard

form requirement

Last Edited MEI 2016

Module Page 5/11 Document Page 5

1.3 Compile verification report 1.3.1 Explain types of verification report checklist

according to standard form

1.3.2 State technique of fill in verification report checklist

according to standard form

1.3.3 Describe methods of fill in verification report

checklist according to standard form

1.3.4 Describe recording of verification report checklist

according to manufacture

1.3.5 State of verification report checklist according to

standard form

1.3.6 State techniques of recording verification report

works according to standard form

1.3.7 Describe methods of drafting up verification report

content according to standard form

1.3.8 Determine types of verification report according to

standard form

1.3.9 Fill in verification report according to standard form

1.3.10 Apply technique of filling in verification report

checklist according to standard form

1.3.11 Record verification report checklist according to

standard form

Last Edited MEI 2016

Module Page 6/11 Document Page 6

1.3.12 File verification report checklist according to

standard form

1.3.13 Apply techniques of recording verification report

works according to standard form

1.3.14 Draft verification report content according to

standard form

1.3.15 Perform meticulous in filling service checklist form

according to standard form

1.3.16 Perform meticulous in filing information according

to standard form

1.3.17 Perform meticulous when recording scheduled

maintenance book according to standard form

CONTENT AND LEARNING STANDARD

Last Edited MEI 2016

Module Page 7/11 Document Page 7

PROGRAM : DIPLOMA TEKNOLOGI MEKANISASI AGRO

COURSE NAME : COOLING AND LUBRICATION SYSTEM

CODE NAME : GMA 5023

COMPETENCY : 2

CONTENT

CONTACT LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD

HOURS performance , condition performance,condition, standard

performance

24 HOURS 2 Verify lubrication 2.1 Obtain verification checklist 2.1.1 List sources of lubrication system verification

(6 WEEKS) system checklist according to manufacture

maintenance works

2.1.2 Describe procedures of acquiring lubrication

system verification checklist according to

manufacture

2.1.3 Explain lubrication system verification checklist

based on standard form requirement

2.1.4 Determine source of cooling system verification

checklist based on standard form requirement

2.1.5 Acquire cooling system verification checklist

based on standard form requirement

2.1.6 Interpret cooling system verification checklist

based on standard form requirement

Last Edited MEI 2016

Module Page 8/11 Document Page 8

2.2 Execute verification 2.2.1 Describe pressure unit replacement work

lubrication system according to manufacture

maintenance works

2.2.2 Explain greasing work according to manufacture

2.2.3 Explain oil pump servicing works according to

manufacture

2.2.4 Justifying maintenance works according to

manufacture

2.2.5 Determine pressure unit replacement work based

on verification checklist

2.2.6 Determine greasing work based on verification

checklist

2.2.7 Determine oil pump servicing works based on

verification checklist

2.2.8 Justify maintenance works based on verification

checklist

Last Edited MEI 2016

Module Page 9/11 Document Page 9

2.3 Compile verification report 2.3.1 Identify types of verification report checklist

according to standard form

2.3.2 Explain technique of fill in verification report

checklist according to standard form

2.3.3 Describe methods of fill in verification report

checklist according to standard form

2.3.4 Specify recording of verification report checklist

according to standard filing system

2.3.5 Specify filing of verification report checklist

according to standard filing system

2.3.6 Determine machine verification report recording

format based on standard form

2.3.7 Describe methods of compiling verification report

based on standard form

2.3.8 Determine types of verification report based on

standard form

2.3.9 Fill in verification report according to standard

form

2.3.10 Apply technique of filling in verification report

checklist according to standard form

2.3.11 Record verification report checklist according to

standard filing system

Last Edited MEI 2016

Module Page 10/11 Document Page 10

2.3.12 File verification report checklist according to

standard filing system

2.3.13 Apply techniques of recording verification report

works according to standard filing system

2.3.14 Apply methods of compiling verification report

according to standard filing system

2.3.15 Perform meticulous in filling service checklist form

according to standard filing system

2.3.16 Perform meticulous in filing information according

to standard filing system

2.3.17 Perform meticulous when recording scheduled

maintenance book in accordance with

manufacturer’s maintenance book

Last Edited MEI 2016

Module Page 11/11 Document Page 11

You might also like

- High Ambient Air Cooled Liquid ChillerDocument60 pagesHigh Ambient Air Cooled Liquid Chillerfmtechac75% (4)

- Top Drive WarriorDocument33 pagesTop Drive WarriorAlexander Bossio100% (2)

- (A. Basak) Analogue Electronic Circuits and SystemDocument376 pages(A. Basak) Analogue Electronic Circuits and SystemRusman Santai KaawuNo ratings yet

- Studi Kasus SCMDocument8 pagesStudi Kasus SCMMuflihul Khair0% (5)

- 70 Ebook Photography Download FreeDocument3 pages70 Ebook Photography Download Free-roger Ron Taylor-100% (3)

- Pasig RiverDocument34 pagesPasig RiverNhilo ReginoNo ratings yet

- Gma 5013Document10 pagesGma 5013janurtpatNo ratings yet

- Form 1.3 Identifying Training Gaps: Developed By: Revision #00Document2 pagesForm 1.3 Identifying Training Gaps: Developed By: Revision #00Jenny SamoranosNo ratings yet

- Process STD 1001 Rev0 Utilities - Boiler FeedwaterDocument105 pagesProcess STD 1001 Rev0 Utilities - Boiler FeedwaterSteve WanNo ratings yet

- Liebert Mini Mate2 1 1.5 Tons User Manual - 00 PDFDocument121 pagesLiebert Mini Mate2 1 1.5 Tons User Manual - 00 PDFjeisson alejandro franco torres100% (1)

- Form 1.4 Training Needs: Training Needs (Learning Outcomes) Module Title/Module of Instruction Core CompetenciesDocument1 pageForm 1.4 Training Needs: Training Needs (Learning Outcomes) Module Title/Module of Instruction Core CompetenciesJenny SamoranosNo ratings yet

- Process STD 1003 Rev0 Utilities - Steam SystemsDocument68 pagesProcess STD 1003 Rev0 Utilities - Steam SystemsSteve WanNo ratings yet

- Kolej Vokasional Batu Lanchang Rancangan Sesi Latihan (RSL)Document4 pagesKolej Vokasional Batu Lanchang Rancangan Sesi Latihan (RSL)farizanNo ratings yet

- Gma 6023 - Combine Harvester TroubleshootDocument12 pagesGma 6023 - Combine Harvester Troubleshootjanurtpat100% (1)

- Inspection ProcedureDocument13 pagesInspection ProcedureSantosh Kumar100% (1)

- Braun1988 PDFDocument434 pagesBraun1988 PDFDavid Pérez100% (1)

- MVAC Testing & Commissioning Procedure - 2007Document245 pagesMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- BS 7074-3 1989Document24 pagesBS 7074-3 1989geoff.ballNo ratings yet

- Danfoss Equil DOC137886464516Document84 pagesDanfoss Equil DOC137886464516JoseNo ratings yet

- EEMG Manual RevisedDocument277 pagesEEMG Manual RevisedsridharNo ratings yet

- Saep 142 PDFDocument17 pagesSaep 142 PDFRami Elloumi100% (1)

- Steam System DesignDocument74 pagesSteam System DesignIshan RanganathNo ratings yet

- Appendix D - Technical Specs & Equipment Selection Compliance Sheet V1.0Document5 pagesAppendix D - Technical Specs & Equipment Selection Compliance Sheet V1.0SAYED SAIFI AKHTARNo ratings yet

- Gma 501Document11 pagesGma 501Mohamad Nadzri YahayaNo ratings yet

- Quality Manual.4Document53 pagesQuality Manual.4dcol13100% (1)

- HVAC System Selection ReportDocument16 pagesHVAC System Selection ReportArman Ul Nasar100% (1)

- Liebert Mini Mate2 2 3 Tons User Manual - 00Document132 pagesLiebert Mini Mate2 2 3 Tons User Manual - 00Asad NizamNo ratings yet

- 2-Solar Water HeaterDocument124 pages2-Solar Water Heaterp4p7 projectsNo ratings yet

- N0470C ENG (1) - AqvalisDocument39 pagesN0470C ENG (1) - Aqvalisaleks canjugaNo ratings yet

- Chapter 5 - Rev ADocument30 pagesChapter 5 - Rev AAenur RofiiqNo ratings yet

- Variable Air Volume Units (VAV)Document22 pagesVariable Air Volume Units (VAV)rashid.khanNo ratings yet

- 3.3 SJ1085 RHD ZZ XX SP Z 0013 R1.0 Technical Specification For C04Document284 pages3.3 SJ1085 RHD ZZ XX SP Z 0013 R1.0 Technical Specification For C04Alif FirdausNo ratings yet

- 02810-Irrigation SystemDocument13 pages02810-Irrigation SystemAhmed HussienNo ratings yet

- Aspak: YCSE040-YCSE100 & YCRE040-YCRE100Document68 pagesAspak: YCSE040-YCSE100 & YCRE040-YCRE100ГОРОД КЛИМАТАNo ratings yet

- DNV Ru Ship Pt4ch5Document90 pagesDNV Ru Ship Pt4ch5Ken VikstromNo ratings yet

- IMCA-D-018 R2 SummaryDocument3 pagesIMCA-D-018 R2 SummaryMuaz Haziq MusaNo ratings yet

- Cover Sheet: - To Record Overall Project and Assessment DetailsDocument62 pagesCover Sheet: - To Record Overall Project and Assessment DetailsNabilBouabanaNo ratings yet

- Ceen622 - Control System 2Document14 pagesCeen622 - Control System 2Mija RashidNo ratings yet

- Jeo Uoc 10-Manage System Modification ActivitiesDocument41 pagesJeo Uoc 10-Manage System Modification ActivitiesTarmizi KembaliNo ratings yet

- GBH Enterprises, LTD.: GBHE-EDG-0501Document30 pagesGBH Enterprises, LTD.: GBHE-EDG-0501MosaddekNo ratings yet

- ICOM 035L02669-100 Rev1 (0905)Document52 pagesICOM 035L02669-100 Rev1 (0905)RANDOMNo ratings yet

- DNV Ru Ship Pt4ch3Document140 pagesDNV Ru Ship Pt4ch3Ken VikstromNo ratings yet

- Visionaire 2 3 Service Manual English PDFDocument47 pagesVisionaire 2 3 Service Manual English PDFQuarmina HesseNo ratings yet

- 2003 CPA Phys-Mech Manual Revised 10-13-03Document78 pages2003 CPA Phys-Mech Manual Revised 10-13-03Rubén Eduardo Galindo CarmonaNo ratings yet

- 0726 Precision Air Conditioning SystemDocument10 pages0726 Precision Air Conditioning SystemKeo SokhimNo ratings yet

- ME1925 Cooling Towers Part 1Document52 pagesME1925 Cooling Towers Part 12ravikanthNo ratings yet

- Maersk Laberinto HN4224 Machinery Operating Manual Issue 1 October 2012 PDFDocument411 pagesMaersk Laberinto HN4224 Machinery Operating Manual Issue 1 October 2012 PDFShikhar SwaroopNo ratings yet

- HVAC System Optimisation MethodologyDocument18 pagesHVAC System Optimisation Methodologythamer al-salekNo ratings yet

- Specification For Flue Gas Desulphurisation Plant by CEADocument448 pagesSpecification For Flue Gas Desulphurisation Plant by CEAproloy12No ratings yet

- Air Handling Units: Technical CatalogDocument72 pagesAir Handling Units: Technical Catalogarindam02041985No ratings yet

- ACMV TrainingDocument227 pagesACMV Traininghbitho75% (4)

- LNGC - Inigo Tapias - Machinery Systems Manual PDFDocument383 pagesLNGC - Inigo Tapias - Machinery Systems Manual PDFpNo ratings yet

- DNV Ru Ship Pt4ch10Document53 pagesDNV Ru Ship Pt4ch10Ken Vikstrom100% (1)

- Saes G 005Document56 pagesSaes G 005TrungNo ratings yet

- Competency-Based Learning Materials: Heating, Ventilating Air Conditioning and Refrigeration (Hvac/R)Document33 pagesCompetency-Based Learning Materials: Heating, Ventilating Air Conditioning and Refrigeration (Hvac/R)Jenny SamoranosNo ratings yet

- Guidelines For Fouling FactorsDocument8 pagesGuidelines For Fouling Factorsrajat vermaNo ratings yet

- Final ReportDocument94 pagesFinal ReportAJITH KUMAR100% (1)

- P260 MachineryA PDFDocument349 pagesP260 MachineryA PDFmariodalNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Stability and Control of Aircraft Systems: Introduction to Classical Feedback ControlFrom EverandStability and Control of Aircraft Systems: Introduction to Classical Feedback ControlNo ratings yet

- ANALISIS DATA Kualitatih KuantitatifDocument12 pagesANALISIS DATA Kualitatih KuantitatifjanurtpatNo ratings yet

- Land PreparationDocument3 pagesLand PreparationjanurtpatNo ratings yet

- SoftDocument8 pagesSoftjanurtpatNo ratings yet

- Land Preparation Machineries Used in AgricultureDocument47 pagesLand Preparation Machineries Used in Agriculturejanurtpat0% (1)

- Subunit Unit Mekanisasi AgroDocument5 pagesSubunit Unit Mekanisasi AgrojanurtpatNo ratings yet

- MPP 5013 Course Outline RDocument5 pagesMPP 5013 Course Outline RjanurtpatNo ratings yet

- Supervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdaraDocument5 pagesSupervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdarajanurtpatNo ratings yet

- Gma 5013Document10 pagesGma 5013janurtpatNo ratings yet

- Gma 6023 - Combine Harvester TroubleshootDocument12 pagesGma 6023 - Combine Harvester Troubleshootjanurtpat100% (1)

- Supervising Skills DevelopmentDocument5 pagesSupervising Skills DevelopmentjanurtpatNo ratings yet

- IEE Checklist InstructionsDocument20 pagesIEE Checklist InstructionsBalaji_Rajaman_2280No ratings yet

- Urinary SystemDocument9 pagesUrinary SystemMary Joyce RamosNo ratings yet

- UG RA 005 - Thermal Integrity and Resistivity TestingDocument6 pagesUG RA 005 - Thermal Integrity and Resistivity TestingshamshuddinNo ratings yet

- Raychem Molded PartsDocument28 pagesRaychem Molded PartsAMNo ratings yet

- (Chris A.M. Peters, Joseph H. M. Steenbrink) Mixed Hodge StructuresDocument467 pages(Chris A.M. Peters, Joseph H. M. Steenbrink) Mixed Hodge StructuresShaulB7100% (1)

- Campbeltown's Kilkerran Gun BatteryDocument2 pagesCampbeltown's Kilkerran Gun BatteryKintyre On RecordNo ratings yet

- Youjo Senki Side Story - A Borrowed Cat (v1.1)Document11 pagesYoujo Senki Side Story - A Borrowed Cat (v1.1)faiyaNo ratings yet

- Living in The I.T Era Module 2Document18 pagesLiving in The I.T Era Module 2Aivee GatzzNo ratings yet

- 320 Lecture 27Document8 pages320 Lecture 27Gathy BrayohNo ratings yet

- Methods?: Condoms Internal Condoms Sexually Transmissible Infections (Stis)Document25 pagesMethods?: Condoms Internal Condoms Sexually Transmissible Infections (Stis)Alecia R. CastilloNo ratings yet

- SOLOXLEXDocument4 pagesSOLOXLEXAlex KamaraNo ratings yet

- CCDS Parent Letter - Letter For Student-Contact To CaseDocument1 pageCCDS Parent Letter - Letter For Student-Contact To CaseActionNewsJaxNo ratings yet

- Valorisation of Spent Coffee Grounds Production of Biodiesel Via Enzimatic Catalisis With Ethanol and Co-SolventDocument14 pagesValorisation of Spent Coffee Grounds Production of Biodiesel Via Enzimatic Catalisis With Ethanol and Co-SolventAline GonçalvesNo ratings yet

- The Occidental Man in Search of Human ValuesDocument11 pagesThe Occidental Man in Search of Human ValuesBen Ritche LayosNo ratings yet

- KKSB1273 Teknologi Binaan Dan Bahan 01 1112 - 09 Konkrit Sebagai Bahan BinaanDocument56 pagesKKSB1273 Teknologi Binaan Dan Bahan 01 1112 - 09 Konkrit Sebagai Bahan BinaanFarhana NorzelanNo ratings yet

- Flushing StatementDocument4 pagesFlushing StatementMohd Salleh Zainal100% (1)

- The Talmud of Jerusalem - Schwab Moise 1839-1918 TRDocument201 pagesThe Talmud of Jerusalem - Schwab Moise 1839-1918 TRJanice O'BrianNo ratings yet

- Individual Development WorkoutDocument3 pagesIndividual Development WorkoutmichelleNo ratings yet

- Final Thesis of Tesfaye Asnake-Checked and CorrectedDocument93 pagesFinal Thesis of Tesfaye Asnake-Checked and CorrectedEsan DemissieNo ratings yet

- Open Web Floor Trusses - MiTek IncDocument7 pagesOpen Web Floor Trusses - MiTek IncinfoNo ratings yet

- QnA Intro To Gas Regulation in Indonesia (Ilham Maulana)Document15 pagesQnA Intro To Gas Regulation in Indonesia (Ilham Maulana)Ilham Maulana Ash Shiddieq100% (1)

- Basic Monte Carlo TechniquesDocument10 pagesBasic Monte Carlo TechniquesMobeen AhmadNo ratings yet

- Paper 2222Document16 pagesPaper 2222Abhijeet GholapNo ratings yet

- Parts Catalog ARDFDocument30 pagesParts Catalog ARDFUlmanu ValentinNo ratings yet

- CROSS REFERENCE DE VALVULAS SOLENOIDES - Danfoss - Alco - Sporlan-ParkerDocument4 pagesCROSS REFERENCE DE VALVULAS SOLENOIDES - Danfoss - Alco - Sporlan-ParkerJoss CastellNo ratings yet

- "Nausicaa" Compression SutureDocument14 pages"Nausicaa" Compression SutureAyu Dyah PrimaningrumNo ratings yet