Professional Documents

Culture Documents

BV 120130813

BV 120130813

Uploaded by

Clinton ThomsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BV 120130813

BV 120130813

Uploaded by

Clinton ThomsonCopyright:

Available Formats

American Journal of Engineering Research (AJER) 2013

American Journal of Engineering Research (AJER)

e-ISSN : 2320-0847 p-ISSN : 2320-0936

Volume-3 pp-08-13

www.ajer.org

Research Paper Open Access

Safe Vulcanisation System for Heat Resistant Natural Rubber

Products for Engineering Applications

Abhitha K., Thomas Kurian

Department of Polymer Science and Rubber Technology, Cochin University of Science and

Technology, Kochi – 682022, India

Abstract: - Natural rubber is a very versatile material that has been successfully used in engineering

applications for over a century. The rubber articles that are vulcanised using conventional accelerators such as

tetra methyl thiuram disulphide (TMTD) are carcinogenic because of the production of nitrosamines (NA)

during heating for the vulcanisation reaction. The nitrosamine producing TMTD has to be replaced with a safe

accelerator. Tetrabenzyl thiuramdisulphide (TBzTD) is reported to be a safe (non-carcinogenic) accelerator. An

efficient vulcanization system has been selected to get heat and reversion resistance to the natural rubber

vulcanisates during the long service life in engineering applications. Safe natural rubber vulcanisates have been

prepared using TBzTD in an efficient vulcanisation system. The vulcanisates prepared using the

safe vulcanisation system shows properties comparable to the vulcanisate prepared using TMTD. The

compound containing TBzTD shows better scorch safety. The novel safe vulcanisate shows comparable

crosslink density and improved aging resistance. The test results indicate that the TBzTD can be used as a safe

accelarator for the manufacture of rubber products for general engineering functions such as shock, noise and

vibration control.

Keywords: - binary accelerator, cross linking, mechanical properties, natural rubber, nitrosamine.

I. INTRODUCTION

Vulcanisation or curing is the insertion of a relatively small number of chemical cross links, by the

addition of vulcanizing agents along the polymer chains to enable the strength and elastic properties inherent in

raw rubber to be fully realized [1]. This is achieved when the compounded rubber is heated to an appropriate

temperature. The first commercial method of cross linking has been attributed to Charles Goodyear in 1839 [2]

who could improve the mechanical properties of natural rubber by heating after mixing with sulphur. Over the

year’s three special types of sulphur vulcanisation systems such as efficient vulcanisation (EV) systems, semi

efficient vulcanisation (SEV) systems, and conventional vulcanisation (CV) systems have been developed.

EV systems are those where a low level of sulphur (0.3 – 0.8 phr) and a correspondingly high level of

accelerator (6.0 – 2.0 phr) are used for achieving an extremely high heat and reversion resistance in the rubber

vulcanisates [1, 2, 3]. In the CV systems, the sulphur dosage is high (2 – 3.5 phr) and correspondingly the

accelerator level is low (1.0 - 0.4 phr). The CV systems provide better flex and dynamic properties but thermal

and reversion resistance are poor. For optimum levels of mechanical and dynamic properties of vulcanisates

with intermediate heat and reversion resistance SEV systems with an intermediate level of accelerator (2.5 – 1.0

phr) and sulphur (1.0 – 1.8 phr) are employed [1, 2]. In the vulcanisation reaction of elastomers, accelerators

perform the important function of bringing down the time needed for vulcanisation.

Over the last century or so, a large number of basic and specialty elastomers have been developed to

meet a wide range of applications and operating environments. Their properties vary widely in terms of their

elasticity, temperature range, strength, hardness, compatibility, environmental resistance, etc. Natural rubber is

preferred in many products because of its superior building tack, green stock strength, and better processability,

high strength in non-black formulations, hot tear resistance, retention of strength at elevated temperatures, better

resilience, low heat build-up, fatigue resistance, and better dynamic properties [4]. Anti-vibration mountings,

Recent Advances in Structural Engineering, RASE2013 Page 8

American Journal of Engineering Research (AJER) 2013

flexible couplings, bridge bearings, rail pads, power transmission and conveyer belts, rubber covered rollers,

cable covering, automobile components, hoses, tubing, lining of tanks, extruded products, and components for

domestic and industrial machinery are some of the industrial and engineering rubber products. Flooring, gloves,

adhesive for pressure sensitive tapes, door/barrier mats and footwear are the familiar examples of household

rubber products.

Nitrosamines are found in rubber articles that are vulcanised with very common traditional accelerators

such as tetra methyl thiuram disulphide (TMTD) [5]. These vulcanisates have been tested positive as mutagens

and are carcinogenic [5, 6]. Other accelerators and sulphur donors that form hazardous nitrosamines are tetra

methyl thiuram monosulphide (TMTM), N- oxydiethylene dithiocarbamyl Nl- oxydiethylene sulphenamide

(OTOS) and N- oxydiethylene – 2- benzothiazole sulphenamide (MBS) [7]. Nitrosamines are produced mostly

during curing and post curing process of rubber. Nitrosamines are formed by the reaction of secondary amines

with nitrogen oxides [8] as shown in the equation:

RRINH + N2O3 RRINNO + HNO2

Binary accelerator formulations involve the use of two different accelerators in the system, often

leading to improved properties. In many cases a synergistic behaviour is observed leading to better vulcanisate

properties in the combined system than expected by the rule of mixtures [9]. Tetra benzyl thiuramdisulphide

(TBzTD) which is not carcinogenic has been developed as a non-regulated or safe nitrosamine producing

accelerator [10] to replace thiurams such as TMTD. TBzTD is a fast curing accelerator in natural rubber and

provides longer scorch times than TMTD [11].

This paper reports the preliminary investigations on the effect of combinations of TBzTD and a primary amine

based sulfenamide (tertiary butyl benzothiazole sulfenamide (TBBS)) as non – regulated safe binary

accelerating system for the efficient vulcanisation of natural rubber.

II. EXPERIMENTAL SECTION

2.1 Materials used

Natural rubber (ISNR-5) used in this study was obtained from the Rubber Research Institute of India

(Kottayam, Kerala). The antioxidant N-(1,3-Dimethyl butyl)-N1-phenyl-p-phenylene diamine i.e. 6PPD

(Mernox 6C), the accelerators TBBS (Mercure TBBS), TMTD (Mercure TMT) and TBzTD (Mercure TBzTD)

were supplied by Merchem Ltd , Kochi, Kerala. The structure of TBzTD is:

Zinc oxide, stearic acid and sulphur were supplied from Associated Rubber Chemicals, Kochi.

2.2 Compounding and testing

The formulations employed for the study are shown in Table 1. The compounding of NR was done on a

two roll open mill as per ASTM D 3184-89.The rheographs of the mixes and their cure characteristics were

obtained using Rubber Processing Analyser.The test specimens were prepared by molding in an electrically

heated hydraulic press at 150 oC for the optimum cure time. Tensile and tear strength were measured according

to ASTM D 412 and ASTM D 624 respectively using a Shimadzu Universal Testing Machine, at a cross head

speed of 500 mm/min. The ageing of the samples were done in a hot air oven at 70 oC and 100 oC for 24 hours

according to ASTM D 572-99 to determine the influences of elevated temperature and time on tensile

properties. The hardness (Shore A) of the samples was determined using Mitutoyo hardmatic hardness tester

according to ASTM D 2240-03. Compression set at constant strain was measured according to ASTM D 395 .

The flex resistances of the vulcanisates were determined using De Mattia flexing machine as per ASTM D 813-

95. Rebound resilience was determined by vertical rebound method according to ASTM D 2632-01.The cross

link densities of the vulcanisates were determined by the Flory- Rehner equation using the equilibrium swelling

data [12-16].

Recent Advances in Structural Engineering, RASE2013 Page 9

American Journal of Engineering Research (AJER) 2013

Table1. Formulation of mixes

Ingredients C C1 C2 C3

NR (g) 100 100 100 100

ZnO (phr) 5.0 5.0 5.0 5.0

Stearic acid (phr) 2.0 2.0 2.0 2.0

6PPD (phr) 1.0 1.0 1.0 1.0

TBBS (phr) 1.5 1.5 1.5 1.5

TMTD (phr) 2.0 - - -

TBzTD (phr) - 2.0 2.2 2.4

Sulphur (phr) 0.3 0.3 0.3 0.3

III. RESULTS AND DISCUSSION

3.1 Cure characteristics

The rheographs of the mixes cured at 150 oC are shown in Fig. 1 and the optimum cure time and scorch

time are shown in Table 2.The value of the scorch time of the compound containing 2.2 phr TBzTD ( mix C2) is

almost the same as that of compound containing 2.0 phr TMTD (mix C). As the concentration of TBzTD

increases from 2.0 (mix C1) to 2.4 (mix C3) the optimum cure time is reduced considerably. The optimum cure

time of the mix C2 is low; therefore, more cross links are formed in shorter time [17]. The Cure Rate Index

(CRI) which is a measure of the speed with which the cure reaction is taking place, is given by the equation:

CRI 100 ( t90 t10)

where t90 and t10 are the optimum cure time and scorch time respectively. The CRI values increases with

increasing concentration of TBzTD and shows high value for the mix C2.

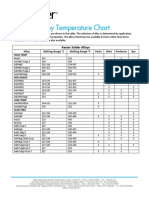

Table 2. Optimum cure time and scorch time of mixes cured at 150 o C

Properties C C1 C2 C3

Scorch Time t10 (min) 2.96 5.10 2.89 4.95

Optimum Cure Time t90 (min) 6.82 10.41 7.17 9.83

Cure Rate Index (CRI) 25.91 18.83 23.36 20.49

Fig 1. Rheographs of the mixes cured at 150oC

3.2 Mechanical properties

The stress - strain curves of the vulcanisate samples are shown in Fig. 2. Tensile properties of the

samples are tabulated in Table 3. Tensile strength of the control vulcanisate C was found to be 17.43 MPa. The

tensile strength values are in the order C1 < C < C3 < C2 in agreement with the aim of this work, i.e. developing

Recent Advances in Structural Engineering, RASE2013 Page 10

American Journal of Engineering Research (AJER) 2013

a non carcinogenic, nitrosamine – safe vulcanisate with properties comparable to that of the control vulcanisate.

The tensile strength values are in exact correlation with the chemical cross link density values shown later in

this article. It could be seen that the modulus values increases with increase in concentration of TBzTD and it

shows a maximum at a dosage of 2.2 phr. This is in accordance with the cross link density values.

The tear strength of the samples C, C1, C2 and C3 are shown in Table 3. Tear strength indicates the

capacity of the vulcanisates to resist cutting, chipping and tearing actions during service. From the result it was

observed that the samples C1 and C3 have almost the same tear strength and that for C2 is high. Hardness (Shore

A) of the samples C, C1, C2 and C3 are shown in Table 3. Hardness is a measure of modulus of elasticity at low

strain [18]. The hardness value remains practically unchanged. This indicates that the hardness is not adversely

affected by the addition of the safe accelerator.

Figure 2: Stress-Strain curves of the samples

Compression set of rubber vulcanisates results from rearrangement of the network structure,

degradation of polymer chains, debonding of polymer- filler attachments, etc. It is dependent on the type of the

polymer, nature of cross links, type of filler and its quantity [19 – 21]. Measurement of set under compression

provides a practical evaluation of either the creep or the stress relaxation of rubber. A high state of cure is found

to reduce set. Compressions set value of the vulcanisate containing TMTD is 14%. The compression set of the

vulcanisates prepared from the compounds containing TBzTD are almost similar to that of the control

vulcanisate containing TMTD.

Table 3. Properties of the rubber vulcanisates

Properties C C1 C2 C3

Tensile strength(MPa) 17.43 14.52 19.55 18.97

Modulus at 300% elongation (MPa) 1.61 1.32 1.46 1.39

Elongation at break(%) 1071 1084 1230 1354

Tear strength (N/mm) 25.37 24.13 26.71 24.96

Hardness (Shore A) 29 28 31 31

Rebound resilience (%) 65 62 65 66

Crosslink density x105 (moles/g rubber 3.93 3.64 7.09 6.10

hydrocarbon)

Flex crack resistance of elastomer vulcanisates is the ability to sustain numerous flexing cycles without

the occurrence of cracks in the surface from stress and ozone attack [22]. The number of test cycles required for

the control sample for the initiation of crack growth was found to be about 2 lakhs. In the case of the samples

C1, C2 and C3 containing TBzTD crack growth initiation was not observed even after 2 lakhs flexing cycles.

Rebound resilience of the samples C, C1, C2 and C3 are shown in Table 3.The values are in the order C3 > C >

C1 with marginal difference. The Control sample C and C2 have the same rebound resilience values.

Recent Advances in Structural Engineering, RASE2013 Page 11

American Journal of Engineering Research (AJER) 2013

The stress –strain properties of the vulcanisates after aging for 24 hours at 70 oC and 100 oC are shown

in Table 4. In all the cases the stress – strain properties improved marginally after aging at 70 oC. After aging at

100 oC the vulcanisate C, C2 and C3 shows marginal improvement in the properties. The improvement in

properties on thermal aging may be due to the conversion of the small percentage of the polysulphidic crosslinks

formed initially in the vulcanisate to monosulphidic and disulphidic linkages [3, 9,23].

Table 4. Tensile properties of the rubber vulcanisates after ageing

Tensile strength (MPa) Modulus at 300% elongation Elongation at break (%)

Sample (MPa)

700C 1000C 700C 1000C 700C 1000C

C 17.54 17.75 1.62 2.12 995 863

C1 14.95 14.8 1.44 1.73 1084 967

C2 20.64 19.19 1.62 2.04 1082 906

C3 19.08 19.46 1.55 1.95 1069 1016

The cross link densities of the vulcanisates calculated from the equilibrium swelling measurements in

toluene are shown in Table 3. The crosslink densities are in the order C1 < C < C3< C2. Cross link density is an

important parameter, which can be related to the physical properties of rubber vulcanisate [24]. The results of

the study cited above show that the mechanical properties of the samples such as tensile strength, hardness and

rebound resilience are in accordance with the cross link density. The study establishes that in natural rubber

vulcanisates it is possible to develop equivalent and even superior crosslink densities and the mechanical

properties by replacing TMTD which is known to be carcinogenic with marginally high dosage of TBzTD

which is non-regulated and safe.

IV. CONCLUSION

The use of TBzTD instead of TMTD in a natural rubber compound for engineering applications

containing an efficient vulcanization system results in better scorch safety. The dosage of TBzTD in a

vulcanisate equivalent to that of the dosage of TMTD in the cure system in the control vulcanisate shows

marginally inferior mechanical properties and cross link density. However the vulcanisate containing 10%

higher dosage of TBzTD shows mechanical properties, aging resistance and cross link density comparable to

that of the control. TBzTD is a safe (non-carcinogenic) substitute for TMTD in the compounds for the

manufacture of rubber engineering components ranging from small automotive mounts and bushes through anti-

seismic devices to large marine fenders

REFERENCES

[1] A.D.Roberts, Natural Rubber Science and Technology(Oxford University Press, Oxford, USA, 1988)

[2] R.N.Datta, Rubber Curing Systems, Rapra Review Reports, 12, ,2002, 3-13 .

[3] M.Morton, Rubber Technology (Chapman& Hall, London, UK, 1995).

[4] Abraham K., Asian Rubber Handbook and Directory( Dhanam Publications (P) Ltd., Kochi,India,

2005).

[5] L.Fishbein, Potential Industrial Carcinogens and Mutagens( Elsevier Scientific Publishing Company,

Netherlands,1979).

[6] E.R.Vieira, N.J.Pierozan and V.Lovison,Brazilian Archives of Biology and Technology, 49, 2006, 73-

77.

[7] M.J.Forrest, Food contact rubbers 2- products, migration and regulation, Rapra review Reports, 16,

2006, 69.

[8] M.D.Gernon, C.Trumpfheller, Chem. Educator, 8 ,2003, 112.

[9] A.S.Aprem, K. Joseph, T.Mathew, V. Altstaedt and S.Thomas, European Polymer Journal, 39, 2003,

1452 .

[10] D.B.Seeberger, Rubber World, 1990.

[11] M.P.Ferrandino, J.A.Sanders and S.W.Hong, Rubber World, 1996.

[12] G.Byran and G.W.Welding, Techniques of Polymer Science, Society of Chemical Industries, 17 ,1963,

75.

[13] A.D.T.Gorton and T.D.Pendle, Nat. Rubber Technol.7,1976, 77.

[14] B.Ellis and G.W.Welding, Rubber Chem Technol,.37,1964, 571.

[15] P.J.Flory and J. Rhener, J Chem Phys, 11, 1943, 5120.

[16] A.S.Aprem, K. Joseph and S.Thomas, J Applied Polymer Science, 91, 2004, 1070.

[17] A.M.Sadequl, U.S.Ishiaku, H.Ismail and B.T. Poh, Eur.Polym. J., 34, 1998, 51 – 57.

Recent Advances in Structural Engineering, RASE2013 Page 12

American Journal of Engineering Research (AJER) 2013

[18] T.H.Ferrigno, Principles of filler selection and use in handbook of fillers and reinforcements for

plastics(Harry S Katz and John V Milewski (Ed.), Van Nostrand Reinhold Company, Newyork, USA,

1978).

[19] K.M.George, P.V.Pillai and N.M.Mathew, Indian Journal of Natural Rubber Research, 4, 1991, 26.

[20] H.J.Janh and H.H.Bertram, Rubber Chemistry and Technology, 46, 1973, 305.

[21] J.R.W.White and S.K.De, Rubber Technologist’s Handbook(Rapra Technology Ltd, Shawbury, UK,

2001).

[22] P.A.Ciullo and N. Hewitt, The Rubber Formulary( Noyes Publications/ William Andrew Publishing,

LLC, NewYork, USA,1999).

[23] V.Pimolsiriphol, P.Saeoui and C.Sirisinha, Polymer-Plastics Technology and Engineering,46, 2007,

113 – 121.

[24] M.R.Krejsa and J.L.Koenig, Elastomer Technology Handbook (CRC Press Boca Raton, Florida, USA,

1993).

Recent Advances in Structural Engineering, RASE2013 Page 13

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Catalytic ReactorsDocument40 pagesCatalytic ReactorsClinton Thomson100% (1)

- An Accelerator Free Peroxide Vulcanization TechniqueDocument17 pagesAn Accelerator Free Peroxide Vulcanization TechniqueClinton ThomsonNo ratings yet

- HLLDocument40 pagesHLLClinton ThomsonNo ratings yet

- KSWCFC Application 2Document2 pagesKSWCFC Application 2Clinton ThomsonNo ratings yet

- University of Kerala: Time Table For The Sixth Semester B.Tech Degree ExaminationDocument2 pagesUniversity of Kerala: Time Table For The Sixth Semester B.Tech Degree ExaminationClinton ThomsonNo ratings yet

- Us 2975151Document4 pagesUs 2975151Clinton ThomsonNo ratings yet

- Photocatalytic Water Treatment Using Tio: Clinton Thomson Guided by 7614 Saibi.RDocument1 pagePhotocatalytic Water Treatment Using Tio: Clinton Thomson Guided by 7614 Saibi.RClinton ThomsonNo ratings yet

- 212Document12 pages212cu1988No ratings yet

- Structural MechanicsDocument5 pagesStructural MechanicsManish Shashikant DharekNo ratings yet

- REG 162 Introduction of Structure: School of Housing, Building and PlanningDocument38 pagesREG 162 Introduction of Structure: School of Housing, Building and Planningabhishek chibNo ratings yet

- CVEN1300 Engineering Mechanics: Total Number of Questions: 10 Submission DateDocument6 pagesCVEN1300 Engineering Mechanics: Total Number of Questions: 10 Submission DatedavidNo ratings yet

- TOPIC 31 Option CDocument5 pagesTOPIC 31 Option Cisma watiNo ratings yet

- Sample Questions 3Document4 pagesSample Questions 3MA KAYE NICCA DALLUAYNo ratings yet

- HDRB 1Document24 pagesHDRB 1Shritej nirmalNo ratings yet

- Cheng 2018Document11 pagesCheng 2018Patel TosifNo ratings yet

- Ohamed Sathak A.J. College of Engineering, Chennai Internal Assessment Test-IDocument1 pageOhamed Sathak A.J. College of Engineering, Chennai Internal Assessment Test-IDamo Daran GNo ratings yet

- CCX 2.2Document458 pagesCCX 2.2sovsepNo ratings yet

- Microstructural Evolution of 2.25Cr-1Mo-0.25V Submerged-Arc Weld PDFDocument15 pagesMicrostructural Evolution of 2.25Cr-1Mo-0.25V Submerged-Arc Weld PDFBurag HamparyanNo ratings yet

- Tos MCQDocument19 pagesTos MCQRIYA AhujaNo ratings yet

- Permissible Stresses in Concrete and SteelDocument3 pagesPermissible Stresses in Concrete and SteelDesign TDLCCS50% (2)

- Creep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperDocument5 pagesCreep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperpicottNo ratings yet

- Reinforced Concrete Design 1 Design of SlabDocument14 pagesReinforced Concrete Design 1 Design of SlabLi ChianNo ratings yet

- International Journal of Refractory Metals & Hard Materials: ArticleinfoDocument8 pagesInternational Journal of Refractory Metals & Hard Materials: ArticleinfoAndres TorresNo ratings yet

- Lec 28Document18 pagesLec 28elene shopovaNo ratings yet

- Aluminum 413 FDocument2 pagesAluminum 413 Ftanto_deep_15No ratings yet

- Design of Cold-Formed Steel Structures (To Australian/New Zealand Standard AS/NZS 4600:2005)Document8 pagesDesign of Cold-Formed Steel Structures (To Australian/New Zealand Standard AS/NZS 4600:2005)teguh andriantoNo ratings yet

- 2-Analytical Investigations On Stiffened Steel and Carbon Fibre Reinforced Polymer Cylindrical Submarine Pressure HullDocument10 pages2-Analytical Investigations On Stiffened Steel and Carbon Fibre Reinforced Polymer Cylindrical Submarine Pressure HullChinkuNo ratings yet

- Ucalgary 2019 Varughese KeziaDocument188 pagesUcalgary 2019 Varughese KeziavaranaNo ratings yet

- Alloy Temperature ChartDocument2 pagesAlloy Temperature ChartDaymer AularNo ratings yet

- Mechanical Properties: Element Content (%)Document2 pagesMechanical Properties: Element Content (%)SANNI KUMARNo ratings yet

- 107 Weldox 700 Uk Data SheetDocument2 pages107 Weldox 700 Uk Data SheetAnurag JainNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- Chapter 41 - Conduction of Electricity in SolidsDocument11 pagesChapter 41 - Conduction of Electricity in SolidsVV Cephei100% (1)

- Experiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMDocument5 pagesExperiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMSudhakar LavuriNo ratings yet

- Adhesives: Prepared By: - LT VineetaDocument9 pagesAdhesives: Prepared By: - LT VineetagoddamitNo ratings yet

- Plaxis 20Document24 pagesPlaxis 20Smail ZennoucheNo ratings yet

- The Effect of Heat Treatment On Mechanical Properties and Corrosion Behavior of AISI420 Martensitic Stainless SteelDocument6 pagesThe Effect of Heat Treatment On Mechanical Properties and Corrosion Behavior of AISI420 Martensitic Stainless Steelanon_506964735No ratings yet