Professional Documents

Culture Documents

Determination of The Torque-Speed Characteristic of Induction Motor in Electric Machinery Education

Determination of The Torque-Speed Characteristic of Induction Motor in Electric Machinery Education

Uploaded by

Robin PengCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual de Taller Kawasaki Vullcan 1500Document423 pagesManual de Taller Kawasaki Vullcan 1500MELVIN PACHECO100% (2)

- Working Environment: Norsok StandardDocument52 pagesWorking Environment: Norsok StandardFoad MirzaieNo ratings yet

- SKF Baker Time RiseDocument3 pagesSKF Baker Time RiseFernando NavarroNo ratings yet

- Inst IndexDocument3 pagesInst IndexblessonfrancisNo ratings yet

- Mechanical Relay-Type PDFDocument17 pagesMechanical Relay-Type PDFSaleCvetkovicNo ratings yet

- 3 StepsDocument15 pages3 StepsJericoNo ratings yet

- Indian Electricals Cost SheetDocument1 pageIndian Electricals Cost SheetPratul BatraNo ratings yet

- Boq CMW Fac 11Document27 pagesBoq CMW Fac 11Somaia Al-AkrasNo ratings yet

- Ethylene Dichloride (Edc) / Vinyl Chloride Monomer (VCM) : Customer Process BrochureDocument4 pagesEthylene Dichloride (Edc) / Vinyl Chloride Monomer (VCM) : Customer Process Brochurerkapoor584199No ratings yet

- Gestión de Mantenimiento"Document3 pagesGestión de Mantenimiento"Sandy Polo CardenasNo ratings yet

- The Innovations Arrived From 1860Document2 pagesThe Innovations Arrived From 1860NicolasNo ratings yet

- Two (2) Storey Residential BuildingDocument10 pagesTwo (2) Storey Residential BuildingAlly Son de LagdamenNo ratings yet

- Procurement PlanDocument7 pagesProcurement PlanEr. Satya Narayan ShahNo ratings yet

- Aixam Despiece RecambiosDocument338 pagesAixam Despiece RecambiosjaumegusNo ratings yet

- Gov. Pablo Borbon Campus II, Alangilan, Batangas City, Philippines 4200 WWW - Batstate-U.edu - PH Telefax: (043) 300-4044 Locs. 106-108Document6 pagesGov. Pablo Borbon Campus II, Alangilan, Batangas City, Philippines 4200 WWW - Batstate-U.edu - PH Telefax: (043) 300-4044 Locs. 106-108Olibear ArellanoNo ratings yet

- TOR Implementation of Building CodeDocument5 pagesTOR Implementation of Building CodeNepali KanchooNo ratings yet

- Martinal LEO - Product RangeDocument6 pagesMartinal LEO - Product RangeAdamMitchellNo ratings yet

- FormulasDocument13 pagesFormulasSandeep SinghNo ratings yet

- AIA Contract Documents-Availability by Family (2017)Document6 pagesAIA Contract Documents-Availability by Family (2017)ed booker100% (1)

- g223 Compression PlatensDocument1 pageg223 Compression Platensطه اللوذعيNo ratings yet

- Remanufactured Wabco ECUs & Actuators - H L SmithDocument2 pagesRemanufactured Wabco ECUs & Actuators - H L SmithYoùssef ModesteNo ratings yet

- Ysio Max ENDocument12 pagesYsio Max ENcurduroyNo ratings yet

- List of Architectural BooksDocument29 pagesList of Architectural BooksVirendra Kumar GajbhiyeNo ratings yet

- Agip Rotra JD-F Sae 80W PDFDocument2 pagesAgip Rotra JD-F Sae 80W PDFJan HendriksNo ratings yet

- 156-EG-100 Rev1Document44 pages156-EG-100 Rev1Tony StatelovNo ratings yet

- Goodyear ZSG-4 Airship F HBDocument146 pagesGoodyear ZSG-4 Airship F HBEnrico Furlan100% (1)

- 4Document1 page4Leanna Abdul WahabNo ratings yet

- Developing Thecurriculum Chapter14Document16 pagesDeveloping Thecurriculum Chapter14Nadjwa ArryfaNo ratings yet

- DR Karima OmanDocument6 pagesDR Karima OmanKarimaNo ratings yet

Determination of The Torque-Speed Characteristic of Induction Motor in Electric Machinery Education

Determination of The Torque-Speed Characteristic of Induction Motor in Electric Machinery Education

Uploaded by

Robin PengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determination of The Torque-Speed Characteristic of Induction Motor in Electric Machinery Education

Determination of The Torque-Speed Characteristic of Induction Motor in Electric Machinery Education

Uploaded by

Robin PengCopyright:

Available Formats

Determination of the Torque-Speed Characteristic

of Induction Motor in Electric Machinery

Education

Rade Buinac, Veselko Tomljenović

Electrical engineering department, Polytechnic of Zagreb

Konavoska 2, Zagreb, Croatia

rade.buinac@tvz.hr

Abstract - The paper describes the measuring method for the motor. The starting torque of the motor is slightly

determination of the torque-speed characteristic of an larger than its full-load torque, so this motor will start

induction machine used in electric machinery classes carrying any load that it can supply at full power [4].

performed at the Polytechnic of Zagreb. The torque-speed

characteristic is determined by recording and The torque-speed characteristic is required in order to

differentiating speed signal during the starting. Data is predict behavior of induction machines in electrical motor

gathered using a measuring system based on a simple digital drives [1]. It should be measured as accurately as possible,

acquisition card, and processed in custom software, built while the selection of which method to apply depends on

with LabVIEW, on a personal computer. Advantages and the characteristics of both the machine and the testing

shortages of this sort of measurement compared with other facilities [3].

measuring methods are given, and measuring equipment

deployment and software development are described. Main scope of the paper is the implementation of a

new measuring method into laboratory exercises and

integration of two methods in one exercise. It shortly

I. INTRODUCTION describes two of the methods outlined in IEEE standard

The induction motor torque-speed characteristic gives test procedure for polyphase induction motors and

information on the dependence of induced mechanical generators [3], one of which had been used in the

torque on mechanical speed. Sometimes this characteristic exercises, and the new one, recently included. Main

is called torque-slip characteristic, where slip is defined as technical aspects of the methods are described in the

speed relative to synchronous speed expressed as a paper, as well as the deployment of the measuring

fraction of synchronous speed. equipment, development of the software needed for

measurements and data processing, and the expected

Typical torque-speed curve of a squirrel-cage benefits in class.

induction motor given in Figure 1 provides information

about the operation of induction motor. The induced II. LABORATORY EXCERSISES

torque of the motor is zero at synchronous speed. The

curve is nearly linear in normal operating conditions Laboratory exercises are performed in the summer

which are between pullout speed and synchronous speed semester of the second year of study, after the students

[6]. Maximum possible torque the machine can induce is have taken the “Electrical machines I” course, and

called the pullout torque or the breakdown torque and it therefore have certain knowledge about electric machinery

limits the short-time overload capability of the motor [7]. which enables them to be more self-confident in

It is usually two or three times the rated full-load torque of individual work in the laboratory. The subject is divided

in six exercises which follow the classroom lectures, and

help students gain better understanding through practical

work with electric machinery and measuring equipment.

All of the exercises are done in small groups of maximum

seven students whose scope is to perform the tasks under

the guidance of the teaching assistant. Each individual

exercise lasts two academic hours during which students

have to take notes which will be the base for reports they

have to generate in order to successfully complete the

course. Reports are based on the guidelines given in the

printed material for all of the exercises. The concept of

producing reports documenting work in the laboratory is

an old and proven method in engineering disciplines

education, especially because of the importance of

technical reports in engineering. This was one of the

Figure 1. Typical torque-speed characteristic of an induction machine

MIPRO 2013/CE 895

guiding concepts in the integration of the new measuring report, the torque-speed characteristic, and the current as

technique, described later in the article, into existing function of speed characteristic need to be drawn.

program of laboratory exercises.

Torque-speed characteristic is the title and the central III. IMPLEMENTATION OF THE NEW METHOD

part of the report produced after the exercise described in Another method for obtaining data for a torque-speed

this article. Students use measuring equipment under the curve of an induction machine outlined in the IEEE

supervision of the teaching assistant and, following his Standard 112-1996 [3] is the Acceleration method. In this

directions, and guidelines given in the manual, take notes method the value of acceleration is determined at various

and finally draw the torque-speed characteristic. As speeds, and the torque at each speed is determined from

mentioned earlier, there are several methods for the acceleration of the mass of the rotating parts. Torque is

determination of the torque-speed characteristic of an calculated as follows:

induction machine. Four of them are described in [3]. The

method that has been used so far is based on direct

measurement of the torque and speed. Electric generator 2π dn

T =J⋅ ⋅ (1)

dynamometer is directly coupled to the tested engine. 60 dt

Dynamometer housing is made free to rotate and

connected to the weight transducer by the torque arm. where T is the torque in Nm

Speed is measured by inductive transducer mounted on

the shaft of the dynamometer. The students control the J is the moment of inertia of rotating

load and the speed of the motor by controlling the field parts in kg·m2

windings voltage of the electric generator dynamometer n is the speed in min-1.

connected to a large resistor. Measurement is performed at

reduced voltage maintained using a variable-voltage The accelerating time should be long enough so that

transformer. Equipment setup for this exercise can be seen electrical transient effects in the instruments and in the

in Figure 2. motor do not distort the torque-speed curve [3], and long

enough to ensure successful measurement of the necessary

Measuring points are taken depending on speed, number of data points. Detailed explanation can be found

ranged from locked-rotor to synchronous speed. in the literature [1] and [2]. The benefits of acceleration

Experience has proven a dozen points are enough, with method are short starting period and small heating of the

preference of choosing more points in higher speeds motor, which allow repeating of the experiment, and the

range. Alongside speed, at each point the operator, i.e. the ability to perform the tests at rated voltage.

students, measure the torque, phase voltage, current, and

real power. During the production of the report, in order to The measuring technique in laboratory exercises is

establish values of current, voltage and torque at rated based on the acceleration method, but it is not performed

values, the students need to calculate them from the values under no load conditions. There are two reasons for such

measured at reduced voltage. As the final goal of the modification of the method. Primary reason for adding the

load is increasing the duration of accelerating time to the

value ten times larger than electromagnetic time constant

which represents the duration of electrical transient

effects. To avoid the influence of the transient effect on

the torque-speed characteristic, motor should be reversed,

meaning it should be rotated manually in the reverse

direction to that expected when the motor is energized [2].

This can be performed using the electric generator

dynamometer working as a motor. Using the

dynamometer as additional load obviates the time-

consuming activity of uncoupling the motors after the first

part of the exercise, allowing students to be more

individual in the laboratory work. Accurate measurements

of speed and acceleration are essential requirements [3]

for this method, so the data acquisition system should be

fast enough, in terms of sampling rate, to record speed,

voltage and current, which also may be of interest. Speed

transducer used in acceleration method should be a

tachometer. It is necessary to have information about the

rotation direction because of the reversing before

energizing the machine. The measuring system should be

able to record the speed, perform mathematical operations

including differentiating to determine acceleration and

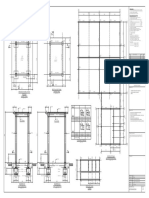

Figure 2. Equipment setup in laboratory exercises for direct display the results during the measurement and after the

measurement of the torque and speed processing.

896 MIPRO 2013/CE

IV. MEASURING SYSTEM

Measuring system is a product of Veski Inc. from

Zagreb, consisting of measurement/acquisition device and

a personal computer equipped with corresponding

software. The system is designed for measurement,

preparation, acquisition, storage, processing, and data

presentation of voltages, currents and speeds for rotating

machinery under 5 kW of power. It is adjusted for

measuring the currents up to 10 A, voltages up to 500 V

and speeds up to 60000 min-1. Sampling rate is 48 kHz

which is high enough to enable obtaining the speed by

differentiation, i.e. to avoid the coarseness of quantization.

The acquisition device is connected to the PC via a USB

port. This data acquisition device is used to measure

different physical quantities, some of which are

mechanical, and some electrical. Using appropriate

measuring transducers this device may be used for

measuring any type of quantity, whether mechanical,

chemical, etc. The software determines its functionality

and the way it emulates traditional electronic

instrumentation. This concept is called virtual

instrumentation, and it is one of the main advantages of a

system such as this. The block scheme of the measuring

system including the software is given in Figure 3.

Figure 3. Equipment setup in laboratory exercises for acceleration

Acquisition device is modular, and composed of method

modules for signal adaptation (voltage and current

transducers, resistors), data acquisition card, and power source to the acquisition device. In this method, motor is

supply. Device has three inputs, for voltages and currents connected directly to the power grid, so the (3-phase)

of each phase, additional input sockets for tachometer variable voltage transformer should be disconnected and

signal, measuring signal control sockets, and a USB motor should be started directly on line (DOL).

socket. The deployment of measuring system is simple Tachometer should be connected to the sockets

and intuitive for people with small experience in electrical provided for speed measurement. Equipment setup should

measurements, so it can be done by the students follow the one given in Figure 4. Software deployment, on

themselves during the exercises. During the equipment the other hand, provided some challenges and it should be

deployment, leads should be connected from the voltage carefully monitored when performed by the students.

V. SOFTWARE

Software for the measuring system was developed

using LabVIEW, programming tool designed for

developing applications in test and measurement,

automation, instrumentation control, data acquisition and

processing [10]. This tool was chosen because

applications for measurement are developed much faster

in LabVIEW than with traditional programming

languages. Rich user interfaces imitating parts of

conventional measuring instrumentation and equipment

are included in the program. This is important for

electrical engineering students who have some experience

in working with electronic instrumentation. User

interfaces reminding the students of an oscilloscope,

ammeter, 7-segment numeric display, knobs, button, dials,

etc. provide the students with familiar surroundings, and

hopefully giving them an insight to another possible

application of the personal computer, not just the Internet

and fun they are used to [8]. Although LabVIEW is

declared to be compatible with different operating

systems, software installation on unsupported Linux

distributions was not simple, and some issues had to be

resolved without the official support from the

manufacturer, National Instruments. Installation and

Figure 4. Block scheme of the measuring system following software development under MS Windows went

smoothly. One of the dominating distinctions between

MIPRO 2013/CE 897

Figure 6. Block diagram of the Measurement and storage VI

LabVIEW and other programming languages is the subVIs colored pale red.

dataflow paradigm, a programming paradigm in which

functions are not executed in a determined order, but The Acquisition VI starts communication with the

following the arrival of data to a certain function. Thus, hardware and opens a link to the DataSocket server – a

the order of execution of functions does not have to be the protocol used by LabVIEW for sharing data between

same every time we start the program. Source code in programs and computers. This VI uses two standard

LabVIEW is written, or better, drawn as a block diagram. subVIs for communication establishment and data

Functions are represented by blocks and nodes acquisition. The Measurement and storage VI converts

interconnected with wires. An example of a block diagram signals received, maintaining the last five seconds of the

is given in Figure 5. Objects in LabVIEW are called signal during live recording in the buffer [9] and, at the

user’s command, stores data to the hard drive. Processing

virtual instruments (VIs) and the structure of an

application is often built up of several or more VIs. SubVI and (graphical) presentation is performed in a VI bearing

is a object large enough to be a VI, but used by VIs of that name. The result of the software analysis, the torque-

higher rank to perform a specific function. Software speed curve can be seen on Figure 6. The result given is

developed for the torque-speed characteristic smoothed and polynomial interpolated using least square

determination purposes has three main VIs and four method, so the students are left to discuss precision and

subVIs, two of which are custom made, and two are accuracy with the teaching assistant. This seems to be a

integral part of the LabVIEW package. Figure 3 shows the good "trick" to interest the students more for electrical

structure of the VIs, with main VIs colored white, and measurements problems.

XY Graph 4

18

16

14

12

Moment Nm

10

8

6

4

2

0

0 200 400 600 800 1000 1200 1400 1600

brzina okr/min

Figure 5. The torque-speed characteristic drawn by the software

898 MIPRO 2013/CE

VI. CONLUSION REFERENCES

Implementation of the new method in the exercises has [1] S. Štefanko, M. Pužar, “Measurement of Torque-slip Curve of

Induction Motors during Starting” Automatika, Zagreb, vol. 33,

several benefits. Students will notice that it is possible to pp. 41-46, April 1992.

measure the same physical quantity in several ways, get [2] B. Szabados, R.D. Findlay, G.M. Obermeyer, R.

familiar with some of the computer tools used in E. Draper, "Measurement of the torque-speed characteristics of

contemporary electrical engineering, and be able to run induction motors using an improved new digital approach", IEEE

the software and make simple modifications themselves. Transactions on Energy Conversion, Vol. 5, No. 3, pp. 565–571,

September 1990

This would be encouraged in order to help better

[3] IEEE Std 112-1996, "IEEE Standard Test Procedure for Polyphase

understanding of the electric machinery and the Induction Motors and Generators", pp. 31-34

measuring techniques. Teamwork would be important as [4] Stephen J. Chapman, Electric Machinery Fundamentals, 2nd ed.,

a desirable quality during the performance of this McGraw-Hill Inc., New York, 1991

exercise, preparing the future engineers, at least a bit, for [5] M. Fruk, D. Maršić, G. Malčić, “Mjerenje brzine vrtnje pomoću

their future work in a team. Students' reactions to the new programirljivog logičkog kontrolera”, MIPRO 2008: Proceedings,

method are to be tested through a questionnaire and vol. 2 (CTS&CIS), pp. 102–107, Croatian Society MIPRO,

Rijeka, May 2008

through laboratory reports comparison between several

[6] I. Mandić, V. Tomljenović, M. Pužar, "Sinkroni i asinkroni

generations in order to qualitatively evaluate električni strojevi", textbook, Polytechnic of Zagreb, Electrical

improvements in students' knowledge and skills. Without engineering department, Zagreb, 2012

careful investigation, however, it can be stated that their [7] A.E. Fitzgerald, C. Kingsley, S.D. Umans, "Electric machinery",

competence in electrical measurements and their skills in 5th SI ed., McGraw-Hill, London, 1992

computer usage are improved through work with the [8] M. Krznaric, R. Buinac, "Can online learning help Croatian ESL

students achieve better fluency", MIPRO 2010: Proceedings, vol.

newly deployed equipment. 4 (CE), pp.876-879, Croatian Society MIPRO, Rijeka, May 2010

ACKNOWLEDGMENT [9] R. Buinac, Measuring the torque-slip characteristic of an induction

machine from starting, diploma thesis, Polytechnic of Zagreb,

R.B. would like to thank Boris Meško for his help with Zagreb, 2012

the measurement system, Mato Fruk for his advice and [10] Jeffrey Travis, Jim Kring, LabVIEW for Everyone, Person

support, and Marija Krznarić for her commitment and help Education, Upper Saddle River, New Jersey, 2007

with almost everything.

MIPRO 2013/CE 899

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual de Taller Kawasaki Vullcan 1500Document423 pagesManual de Taller Kawasaki Vullcan 1500MELVIN PACHECO100% (2)

- Working Environment: Norsok StandardDocument52 pagesWorking Environment: Norsok StandardFoad MirzaieNo ratings yet

- SKF Baker Time RiseDocument3 pagesSKF Baker Time RiseFernando NavarroNo ratings yet

- Inst IndexDocument3 pagesInst IndexblessonfrancisNo ratings yet

- Mechanical Relay-Type PDFDocument17 pagesMechanical Relay-Type PDFSaleCvetkovicNo ratings yet

- 3 StepsDocument15 pages3 StepsJericoNo ratings yet

- Indian Electricals Cost SheetDocument1 pageIndian Electricals Cost SheetPratul BatraNo ratings yet

- Boq CMW Fac 11Document27 pagesBoq CMW Fac 11Somaia Al-AkrasNo ratings yet

- Ethylene Dichloride (Edc) / Vinyl Chloride Monomer (VCM) : Customer Process BrochureDocument4 pagesEthylene Dichloride (Edc) / Vinyl Chloride Monomer (VCM) : Customer Process Brochurerkapoor584199No ratings yet

- Gestión de Mantenimiento"Document3 pagesGestión de Mantenimiento"Sandy Polo CardenasNo ratings yet

- The Innovations Arrived From 1860Document2 pagesThe Innovations Arrived From 1860NicolasNo ratings yet

- Two (2) Storey Residential BuildingDocument10 pagesTwo (2) Storey Residential BuildingAlly Son de LagdamenNo ratings yet

- Procurement PlanDocument7 pagesProcurement PlanEr. Satya Narayan ShahNo ratings yet

- Aixam Despiece RecambiosDocument338 pagesAixam Despiece RecambiosjaumegusNo ratings yet

- Gov. Pablo Borbon Campus II, Alangilan, Batangas City, Philippines 4200 WWW - Batstate-U.edu - PH Telefax: (043) 300-4044 Locs. 106-108Document6 pagesGov. Pablo Borbon Campus II, Alangilan, Batangas City, Philippines 4200 WWW - Batstate-U.edu - PH Telefax: (043) 300-4044 Locs. 106-108Olibear ArellanoNo ratings yet

- TOR Implementation of Building CodeDocument5 pagesTOR Implementation of Building CodeNepali KanchooNo ratings yet

- Martinal LEO - Product RangeDocument6 pagesMartinal LEO - Product RangeAdamMitchellNo ratings yet

- FormulasDocument13 pagesFormulasSandeep SinghNo ratings yet

- AIA Contract Documents-Availability by Family (2017)Document6 pagesAIA Contract Documents-Availability by Family (2017)ed booker100% (1)

- g223 Compression PlatensDocument1 pageg223 Compression Platensطه اللوذعيNo ratings yet

- Remanufactured Wabco ECUs & Actuators - H L SmithDocument2 pagesRemanufactured Wabco ECUs & Actuators - H L SmithYoùssef ModesteNo ratings yet

- Ysio Max ENDocument12 pagesYsio Max ENcurduroyNo ratings yet

- List of Architectural BooksDocument29 pagesList of Architectural BooksVirendra Kumar GajbhiyeNo ratings yet

- Agip Rotra JD-F Sae 80W PDFDocument2 pagesAgip Rotra JD-F Sae 80W PDFJan HendriksNo ratings yet

- 156-EG-100 Rev1Document44 pages156-EG-100 Rev1Tony StatelovNo ratings yet

- Goodyear ZSG-4 Airship F HBDocument146 pagesGoodyear ZSG-4 Airship F HBEnrico Furlan100% (1)

- 4Document1 page4Leanna Abdul WahabNo ratings yet

- Developing Thecurriculum Chapter14Document16 pagesDeveloping Thecurriculum Chapter14Nadjwa ArryfaNo ratings yet

- DR Karima OmanDocument6 pagesDR Karima OmanKarimaNo ratings yet