Professional Documents

Culture Documents

Metric-8 12466 1 PDF

Metric-8 12466 1 PDF

Uploaded by

Riana ZammitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric-8 12466 1 PDF

Metric-8 12466 1 PDF

Uploaded by

Riana ZammitCopyright:

Available Formats

Hex Bolts

Tensile / Yield / Shear Strength

Tightening Torque

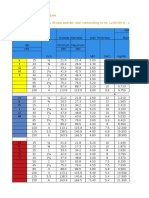

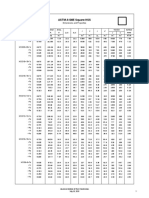

HEX BOLTS - RECOMMENDED TIGHTENING TORQUE

CLASS 8.8

Tensile Proof Shear

Size Pitch Stress Area Core Area Recommended Tightening Torque

Strength Strength Strength

(mm) (mm²) (mm²) (kN) (kN) (kN) Plain (Nm) Zinc (Nm) HDG (Nm)

M6 1.00 20.1 17.9 16.1 11.7 8.6 9.1 6.4 19.1

M8 1.25 36.6 32.8 29.3 21.2 15.7 22.1 15.5 46.4

M10 1.50 58.0 52.3 46.4 33.6 25.1 43.7 30.6 91.8

M12 1.75 84.3 76.2 67.4 48.9 36.6 76.3 53.4 160.2

M14 2.00 115.0 104.7 92.0 66.7 50.3 121.4 85.0 254.9

M16 2.00 157.0 144.0 125.6 91.1 69.1 189.4 132.6 397.8

M18 2.50 192.0 175.0 159.4 115.2 84.0 269.6 188.7 566.1

M20 2.50 245.0 225.0 203.3 147.0 108.0 382.0 268.0 803.0

M22 2.50 303.0 281.0 251.5 181.8 134.9 520.0 364.0 1092.0

M24 3.00 353.0 324.0 293.0 211.8 155.5 661.0 463.0 1388.0

M27 3.00 459.0 427.0 381.0 275.4 205.0 967.0 677.0 2030.0

M30 3.50 561.0 519.0 465.6 336.6 249.1 1313.0 919.0 2757.0

M33 3.50 694.0 647.0 576.0 416.4 310.6 1786.0 1250.0 3751.0

M36 4.00 817.0 759.0 678.1 490.2 364.3 2294.0 1606.0 4818.0

M39 4.00 976.0 912.0 810.1 585.6 437.8 2969.0 2078.0 6235.0

M42 4.50 1120.0 1050.0 929.6 672.0 504.0 3670.0 2568.0 7705.0

M48 5.00 1470.0 1380.0 1220.1 882.0 662.4 5504.0 3853.0 11558.0

M56 5.50 2030.0 1910.0 1684.9 1218.0 916.8 8867.0 6207.0 18621.0

M64 6.00 2680.0 2520.0 2224.4 1608.0 1209.6 13379.0 9365.0 28095.0

Note:

The tightening torque values given in the above table serve only as a guide. A k factor of 0.2 has been used which assumes

threads are plain finish, burr free with a light oil coating. It should be noted that these figures are based on the first tightening of

single assemblies in isolation.

Please refer to AS4100 for correct tightening methods of AS1252, as the above figures do not apply.

v.1.5

August 2007 Quality Fasteners Since 1935

You might also like

- Assassins Creed Odyssey - Inventory - Hash IDDocument27 pagesAssassins Creed Odyssey - Inventory - Hash IDAditya Arya75% (4)

- Simulative Calculation and Optimal Design of Scissor Lift MechanismDocument4 pagesSimulative Calculation and Optimal Design of Scissor Lift MechanismLuis Alfonso González Vergara88% (8)

- One Steel CatalogueDocument32 pagesOne Steel CatalogueVivek33% (3)

- The Tactical Athlete A Product of 21st Century.2Document6 pagesThe Tactical Athlete A Product of 21st Century.2fggffsdgNo ratings yet

- AITAS 8th Doctor SourcebookDocument192 pagesAITAS 8th Doctor SourcebookClaudio Caceres100% (14)

- Bolt, Nut, WasherDocument9 pagesBolt, Nut, WasherAndri EkoNo ratings yet

- Bolt Weight CalDocument10 pagesBolt Weight CalvpjagannaathNo ratings yet

- Din 929 PDFDocument1 pageDin 929 PDFprathmesh238No ratings yet

- FM 5 31 Booby Traps Field ManualDocument131 pagesFM 5 31 Booby Traps Field ManualJason Tang100% (2)

- Adeptus Custodes DatasheetsDocument2 pagesAdeptus Custodes DatasheetsLuke R. CordeNo ratings yet

- The Tower of LondonDocument12 pagesThe Tower of Londonlasc roxanaNo ratings yet

- Chinas Super Psychics Paul Dong OCR SDDocument131 pagesChinas Super Psychics Paul Dong OCR SDlex100% (4)

- HTD Shcs 12.9 T TorqueDocument1 pageHTD Shcs 12.9 T TorqueChandru Vel100% (1)

- HTD HXB cl10.9 Tight TorqDocument1 pageHTD HXB cl10.9 Tight Torqaegean227No ratings yet

- Bolt Torque Cl4.6-Tight-TorqDocument1 pageBolt Torque Cl4.6-Tight-TorqMir AsifNo ratings yet

- HTD Ss HXB Tight TorqDocument1 pageHTD Ss HXB Tight TorqMuddasar AhmadNo ratings yet

- HTD Ss HXB Tight TorqDocument1 pageHTD Ss HXB Tight TorqTony CefaiNo ratings yet

- Impact Wrenches: Optimal Torque of BoltDocument6 pagesImpact Wrenches: Optimal Torque of BoltFarjad KhanNo ratings yet

- Tabela Torques de ApertoDocument8 pagesTabela Torques de ApertoEduardo Figueiredo BertassoNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- Service DataDocument12 pagesService DataGianni DaBolognaNo ratings yet

- Standard Metric Bolt Shank DimensionsDocument4 pagesStandard Metric Bolt Shank DimensionsVIVEK YADAVNo ratings yet

- P3 50x50 D125 40 M GrafDocument2 pagesP3 50x50 D125 40 M GrafGilmar BastidasNo ratings yet

- Gi Pipe Size Is 1239Document4 pagesGi Pipe Size Is 1239sshnvlNo ratings yet

- Screw DimensionDocument2 pagesScrew DimensionAbhijeet SinghNo ratings yet

- Torque SpecificationsDocument2 pagesTorque SpecificationsTigerNo ratings yet

- Shear Stress Vs Shear StrainDocument12 pagesShear Stress Vs Shear StrainAbrar AfzalNo ratings yet

- Torque Settings: Section 1 - General InformationDocument1 pageTorque Settings: Section 1 - General InformationNikNo ratings yet

- Table-1 Properties of Rolled Steel SectionsDocument40 pagesTable-1 Properties of Rolled Steel Sectionsramanathan appu0% (1)

- MBL WireDocument1 pageMBL WireThanh Anh MaiNo ratings yet

- Slings Weight-Breaking-LoadDocument1 pageSlings Weight-Breaking-LoadNed VasicNo ratings yet

- Specific Steel WireDocument1 pageSpecific Steel WireThanh Anh MaiNo ratings yet

- Dây Cuaroa 5M Quy Cách Tham Khảo Bảng TraDocument1 pageDây Cuaroa 5M Quy Cách Tham Khảo Bảng Trathanggimme.phanNo ratings yet

- @tspkco: Construction: 6x19 / 6x36 Group IWRC Construction: 6x19 / 6x36 Group Fibre Core (Document1 page@tspkco: Construction: 6x19 / 6x36 Group IWRC Construction: 6x19 / 6x36 Group Fibre Core (amirhosseinNo ratings yet

- Standard Metric and USA Bolt Shank Dimensions: MM MMDocument2 pagesStandard Metric and USA Bolt Shank Dimensions: MM MMLan MendietaNo ratings yet

- ASTM A1085 Square HSS: Surface Area Design Wall Thickness, T Nominal Wt. Area, Shape TorsionDocument3 pagesASTM A1085 Square HSS: Surface Area Design Wall Thickness, T Nominal Wt. Area, Shape TorsionamadhubalanNo ratings yet

- Assembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners of SteelDocument7 pagesAssembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners of SteelMurshidi MarzukiNo ratings yet

- Electrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMDocument1 pageElectrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMccorp0089No ratings yet

- Proof Load, Yield & Tensile Strength Chart MetricDocument1 pageProof Load, Yield & Tensile Strength Chart MetricAnonymous YWS7ndsiNo ratings yet

- Orrcon Steel Chequer PlateDocument1 pageOrrcon Steel Chequer PlateOliver HermosaNo ratings yet

- Sifat-Sifat Penampang Pipa Fy 1600 kg/cm2: Diam. Thick. A P V I WDocument7 pagesSifat-Sifat Penampang Pipa Fy 1600 kg/cm2: Diam. Thick. A P V I WNovly IbrahimNo ratings yet

- WDS Torque ChartDocument9 pagesWDS Torque ChartThaharNo ratings yet

- Bolt Pro PDFDocument4 pagesBolt Pro PDFWaqar FaziNo ratings yet

- Hex Bolts - Minimum Tensile StressDocument4 pagesHex Bolts - Minimum Tensile StressWaqar FaziNo ratings yet

- Specifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Document3 pagesSpecifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Manish StauffenbergNo ratings yet

- 21-Stainless Steel Aisi 304 (A2) PDFDocument1 page21-Stainless Steel Aisi 304 (A2) PDFItx MinhasNo ratings yet

- JIS G3444 Tube For General StructureDocument1 pageJIS G3444 Tube For General StructurelukmanNo ratings yet

- A1085 Dimensions and Properties Round HssDocument3 pagesA1085 Dimensions and Properties Round HssRaul Flores BegazoNo ratings yet

- 0 Converter UnitsDocument1 page0 Converter Unitsenid38No ratings yet

- Datasheet 6x19 Fibre Core GalvanisedDocument1 pageDatasheet 6x19 Fibre Core GalvanisedKurnia Adi WibowoNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocument3 pagesDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius Elbowswenfang leeNo ratings yet

- ANSI B16.9 Elbow PDFDocument3 pagesANSI B16.9 Elbow PDFRamadan RashadNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocument3 pagesDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsHai lm5No ratings yet

- Elbow 2Document3 pagesElbow 2robert_candra_tarunaNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocument3 pagesDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsRAFAEL BRAVONo ratings yet

- 4 Steel Pipe Sans 719Document1 page4 Steel Pipe Sans 719Roddy TeeNo ratings yet

- Tourqe Value 8.8Document1 pageTourqe Value 8.8MAKNo ratings yet

- Profile IPEDocument4 pagesProfile IPEscarto08No ratings yet

- Bolt Weight CalDocument10 pagesBolt Weight CalwahyuokkNo ratings yet

- Din 59410Document8 pagesDin 59410Fitra BagusNo ratings yet

- Katalog MKM GSW - Jisg3537Document1 pageKatalog MKM GSW - Jisg3537Lintang SamuderaNo ratings yet

- Cable Lug Heavy Duty Brochure67Document1 pageCable Lug Heavy Duty Brochure67alberth michaelNo ratings yet

- Mechanical Thread TablesDocument38 pagesMechanical Thread TablesbarcristianNo ratings yet

- Buttweld 7Document1 pageButtweld 7abhi_libra14No ratings yet

- Reinforcement Abstract As On 04.05.2015Document5 pagesReinforcement Abstract As On 04.05.2015Nirmalya SenNo ratings yet

- Mechanical Engineering: 1.plain Washers, Black: Metric SeriesDocument7 pagesMechanical Engineering: 1.plain Washers, Black: Metric SeriesRathnakrajaNo ratings yet

- Tension Wire ChartDocument1 pageTension Wire Chartlaspsieca100% (1)

- SCK Cell Fenders: DimensionsDocument1 pageSCK Cell Fenders: DimensionsVivekNo ratings yet

- Corner Arch FenderDocument1 pageCorner Arch FenderVivekNo ratings yet

- 09 Materials HandlingDocument32 pages09 Materials HandlingVivekNo ratings yet

- OneSteel Metalcentre KYS Catalogue April 14Document96 pagesOneSteel Metalcentre KYS Catalogue April 14VivekNo ratings yet

- STAUFF Accumulators - BladderDocument16 pagesSTAUFF Accumulators - BladderVivekNo ratings yet

- Daily Use ContainersDocument2 pagesDaily Use ContainersVivekNo ratings yet

- Orkot Marine Bearings Engineering Manual enDocument32 pagesOrkot Marine Bearings Engineering Manual enVivekNo ratings yet

- Container Details PDFDocument2 pagesContainer Details PDFVivekNo ratings yet

- Niche Cpaelites - RAWDocument24 pagesNiche Cpaelites - RAWMartin ForthewinNo ratings yet

- Juanita MoodyDocument5 pagesJuanita MoodyJohn GreenewaldNo ratings yet

- Battery Rodgers - WikipediaDocument3 pagesBattery Rodgers - Wikipedian4k4No ratings yet

- Catalogue: Your Reliable Partner in Global DefenceDocument128 pagesCatalogue: Your Reliable Partner in Global DefenceAlex Viray Lucinario100% (1)

- Excerpts From XDocument1 pageExcerpts From Xapi-227744493No ratings yet

- Collaborative Timeline DatabaseDocument19 pagesCollaborative Timeline Databaseraniaisha449No ratings yet

- Cloudspire Reference Sheet - Heirs 2.0Document2 pagesCloudspire Reference Sheet - Heirs 2.0Sam TamNo ratings yet

- World Boss Schedule BDO SEA 16/08/2018Document1 pageWorld Boss Schedule BDO SEA 16/08/2018shugara100% (1)

- Stemming The Tide, May 1965 To October 1966Document436 pagesStemming The Tide, May 1965 To October 1966Bob Andrepont100% (1)

- Primary and Secondary Sources WorksheetDocument2 pagesPrimary and Secondary Sources WorksheetSteven RodriguezNo ratings yet

- Boricubos - The Lost IslesDocument138 pagesBoricubos - The Lost Islesguilherme gui100% (4)

- Albania, A New Nation in An Old World - Scribner's Magazine (1922) - V. I. Paradise, H. CampbellDocument21 pagesAlbania, A New Nation in An Old World - Scribner's Magazine (1922) - V. I. Paradise, H. Campbellxhibi100% (3)

- The Hundred Day Reform, 1898Document8 pagesThe Hundred Day Reform, 1898Ramita Udayashankar75% (4)

- The Knight in Rusty ArmourDocument37 pagesThe Knight in Rusty ArmourPedro Perez Brandão100% (2)

- Shrine of The Jaguar PrincessDocument56 pagesShrine of The Jaguar PrincessJupp KowalskiNo ratings yet

- Wong Douglas - The Deceptive Hands of Wing Chun PDFDocument63 pagesWong Douglas - The Deceptive Hands of Wing Chun PDFTyarel El Angel Caido100% (3)

- Visualizing The Bill of RightsDocument2 pagesVisualizing The Bill of Rightsapi-328120679No ratings yet

- Bigul Booklet 16 Fasivaad Kya Hai Aur Isse Kaise LarenDocument232 pagesBigul Booklet 16 Fasivaad Kya Hai Aur Isse Kaise LarenSarthak NayakNo ratings yet

- Russian Navy-Future DevelopmentDocument14 pagesRussian Navy-Future DevelopmentAlexandra SieaNo ratings yet

- Fairmont Army Air FieldDocument28 pagesFairmont Army Air FieldCAP History LibraryNo ratings yet

- 1 Player S Handbook OEFDocument250 pages1 Player S Handbook OEFEthanNo ratings yet

- History of BangladeshDocument82 pagesHistory of Bangladeshtaohidafnan4No ratings yet

- ICE 8203 - Calenhad A Beacon of GondorDocument50 pagesICE 8203 - Calenhad A Beacon of GondorRobert100% (3)