Professional Documents

Culture Documents

TABLE 3 Alloy Content

TABLE 3 Alloy Content

Uploaded by

Laurence Sarmiento0 ratings0% found this document useful (0 votes)

12 views1 pageThis document outlines the alloy content and tensile requirements for steel grades 42, 50, 55, 60, and 65. Table 3 specifies the allowable element content ranges for different alloy types. Table 4 provides the minimum yield point, tensile strength, and elongation requirements for each grade. Footnotes further define specimen orientation, exceptions for certain shapes, and adjustments for wider plates.

Original Description:

Snippet 2

Original Title

A 572_A 572M - 04-2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the alloy content and tensile requirements for steel grades 42, 50, 55, 60, and 65. Table 3 specifies the allowable element content ranges for different alloy types. Table 4 provides the minimum yield point, tensile strength, and elongation requirements for each grade. Footnotes further define specimen orientation, exceptions for certain shapes, and adjustments for wider plates.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views1 pageTABLE 3 Alloy Content

TABLE 3 Alloy Content

Uploaded by

Laurence SarmientoThis document outlines the alloy content and tensile requirements for steel grades 42, 50, 55, 60, and 65. Table 3 specifies the allowable element content ranges for different alloy types. Table 4 provides the minimum yield point, tensile strength, and elongation requirements for each grade. Footnotes further define specimen orientation, exceptions for certain shapes, and adjustments for wider plates.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

A 572/A 572M – 04

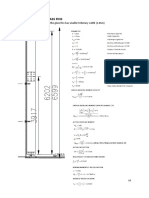

TABLE 3 Alloy Content

Heat

TypeA Elements

Analysis, %

1 ColumbiumB 0.005–0.05C

2 Vanadium 0.01–0.15

3 ColumbiumB 0.005-0.05C

Vanadium 0.01–0.15

Columbium plus vanadium 0.02–0.15D

5 Titanium 0.006-0.04

Nitrogen 0.003–0.015

Vanadium 0.06 max

A

Alloy content shall be in accordance with Type 1, 2, 3, or 5 and the contents

of the applicable elements shall be reported on the test report.

B

Columbium shall be restricted to the following thicknesses and sizes unless

killed steel is furnished. Killed steel shall be confirmed by a statement of killed steel

on the test report, or by a report on the presence of a sufficient quantity of a strong

deoxidizing element, such as silicon at 0.10 % or higher, or aluminum at 0.015 %

or higher. See table below.

C

Product analysis limits = 0.004 to 0.06 %.

D

Product analysis limits = 0.01 to 0.16 %.

Maximum Plate, Bar,

Sheet Maximum Structural

Grades Piling, Zees, and Rolled Shape Flange or Leg

Tee Thicknesses, in. [mm] Thickness,

in. [mm]

42, 50, and 55 3⁄4 1.5

[290, 345, and [20] [40]

380]

60 and 65 1⁄2 1

[415 and 450] [13] [25]

TABLE 4 Tensile RequirementsA

Minimum Elonga-

Yield Point, min Tensile Strength, min

tion, % B,C,D

Grade

in 8 in. in 2 in.

ksi [MPa] ksi [MPa]

[200 mm] [50 mm]

42 [290] 42 [290] 60 [415] 20 24

50 [345] 50 [345] 65 [450] 18 21

55 [380] 55 [380] 70 [485] 17 20

60 [415] 60 [415] 75 [520] 16 18

65 [450] 65 [450] 80 [550] 15 17

A

See specimen Orientation under the Tension Tests section of Specification

A 6/A 6M.

B

Elongation not required to be determined for floor plate.

C

For wide flange shapes over 426 lb/ft [634 kg/m], elongation in 2 in. [50 mm]

of 19 % minimum applies.

D

For plates wider than 24 in. [600 mm], the elongation requirement is reduced

two percentage points for Grades 42, 50, and 55 [290, 345, and 380], and three

percentage points for Grades 60 and 65 [415 and 450]. See elongation require-

ment adjustments in the Tension Tests section of Specification A 6/A 6M.

You might also like

- Flexo Printing Troubleshooting GuideDocument27 pagesFlexo Printing Troubleshooting GuideSathiya Raj100% (2)

- Material Steel StandardsDocument25 pagesMaterial Steel StandardssamadhankadamNo ratings yet

- Several New Aspects of Indigo ChemistryDocument34 pagesSeveral New Aspects of Indigo ChemistryAnonymous hkDxd8L0% (1)

- Chemical Process Industries (Reviewer)Document78 pagesChemical Process Industries (Reviewer)Emier VillanuevaNo ratings yet

- A 808 - A 808M - 00 Qtgwoc9boda4ts1sruqDocument3 pagesA 808 - A 808M - 00 Qtgwoc9boda4ts1sruqdelta lab sangliNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument5 pagesSteel Castings, Carbon, For General ApplicationMeethaq AbedNo ratings yet

- Sa 283Document3 pagesSa 283AnilNo ratings yet

- ASME NOTES - Part25Document1 pageASME NOTES - Part25Head copperNo ratings yet

- A 595 - 98 R02 Qtu5ns1sruqDocument5 pagesA 595 - 98 R02 Qtu5ns1sruqLimberhtNo ratings yet

- Structural Carbon Steel Plates of Improved Toughness: Standard Specification ForDocument2 pagesStructural Carbon Steel Plates of Improved Toughness: Standard Specification ForDarwin DarmawanNo ratings yet

- ASTM A572 Tensile RequirementsDocument1 pageASTM A572 Tensile RequirementsDave MulvihillNo ratings yet

- Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocument4 pagesPressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDiegoNo ratings yet

- H99sec2asa 516Document2 pagesH99sec2asa 516Fermín VallejoNo ratings yet

- Especificação Padrão CN-A860Document2 pagesEspecificação Padrão CN-A860Osvaldo Junges BomfimNo ratings yet

- Astm A283Document2 pagesAstm A283Ahmad Udin100% (1)

- Data Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enDocument2 pagesData Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enkanteron6443No ratings yet

- ASTM A514 GR B Data Sheet 2012 04 01 PDFDocument2 pagesASTM A514 GR B Data Sheet 2012 04 01 PDFMarco BacianNo ratings yet

- ASTM Standard (Vol 1.04) A 131 - A131M - 94Document5 pagesASTM Standard (Vol 1.04) A 131 - A131M - 94astrogildoNo ratings yet

- Astm A36 Asme Sa36Document3 pagesAstm A36 Asme Sa36Mohamed IsmailNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- A 455 - A 455M - 01 Qtq1ns9bndu1ts1sruqDocument4 pagesA 455 - A 455M - 01 Qtq1ns9bndu1ts1sruqMd Ahtesham DanishNo ratings yet

- Astm A573 - A573m - 13Document2 pagesAstm A573 - A573m - 13Panneer BalashanmuganNo ratings yet

- GB700 88Document8 pagesGB700 88JJGM120No ratings yet

- Astm A453 Grade 660 Class B SpecificationDocument4 pagesAstm A453 Grade 660 Class B Specificationashishkumarpadhy.cetNo ratings yet

- Rules For Materials and Welding 2021 AmendmentsDocument29 pagesRules For Materials and Welding 2021 AmendmentsSUEZSHIPYARD QCNo ratings yet

- ASTM A514 Grade S: General Product DescriptionDocument2 pagesASTM A514 Grade S: General Product DescriptionAGUSTINNo ratings yet

- Cast Steel Grades ChartDocument2 pagesCast Steel Grades ChartMajdi JerbiNo ratings yet

- GB700-88 Carbon Structural SteelsDocument7 pagesGB700-88 Carbon Structural SteelsyuNo ratings yet

- ASTM A672 Grade CC 60 EFW Pipe SuppliersDocument4 pagesASTM A672 Grade CC 60 EFW Pipe SuppliersRELIABLE PIPES & TUBESNo ratings yet

- Ductile Iron Casting Specfications and Details All Standards PDFDocument15 pagesDuctile Iron Casting Specfications and Details All Standards PDFSiriusNo ratings yet

- API 2W50 Data Sheet 2012 04 01Document2 pagesAPI 2W50 Data Sheet 2012 04 01Alfon Tampubolon100% (1)

- Astm A572 Grade 50Document1 pageAstm A572 Grade 50Luis67% (3)

- GB 700 88Document5 pagesGB 700 88trungNo ratings yet

- Plate Asme Sa516 Grade 70Document10 pagesPlate Asme Sa516 Grade 70Deaz AmbrsNo ratings yet

- SA 283 Grade CDocument1 pageSA 283 Grade CHandri YantoNo ratings yet

- Sa 283Document3 pagesSa 283ismaelarchilacastilloNo ratings yet

- Astm A 515 PDFDocument5 pagesAstm A 515 PDFsenthil4youNo ratings yet

- Draft SLS 26-2nd Revison - 2019-06-2811 00000003Document15 pagesDraft SLS 26-2nd Revison - 2019-06-2811 00000003Krishantha Jayawardene100% (1)

- Astm A560Document5 pagesAstm A560MAX ALBERTO JUAREZ AVALOSNo ratings yet

- Astm A675 A675m 14Document2 pagesAstm A675 A675m 14ayushiengpvtltdNo ratings yet

- Astm A517 GR B: General Product DescriptionDocument2 pagesAstm A517 GR B: General Product Descriptionjuan vargas tarazonaNo ratings yet

- Caracteristicas API 2HGr50 PDFDocument3 pagesCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNo ratings yet

- Bureau of Indian Standards: Cold-Rolled Steel Strips For SpringsDocument10 pagesBureau of Indian Standards: Cold-Rolled Steel Strips For SpringsPaviter SinghNo ratings yet

- Agenda 2022Document47 pagesAgenda 2022CAD CAE MELNo ratings yet

- Asme Sa203Document4 pagesAsme Sa203MargaritaNo ratings yet

- Kapitel 01 DINO Techn TeilDocument12 pagesKapitel 01 DINO Techn TeilLê Đức BảoNo ratings yet

- Astm A563Document5 pagesAstm A563poerwntiNo ratings yet

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocument6 pagesHigh Strength Fine Grained Structural Steel, Quenched and TemperedkazdanoNo ratings yet

- Steel Standards: ASTM A252 ASTM A500 CSA G40.21Document1 pageSteel Standards: ASTM A252 ASTM A500 CSA G40.21Candra YuniartoNo ratings yet

- PNS49Document14 pagesPNS49jbcast86No ratings yet

- High Strength Fine Grained Structural Steel Quenched and TemperedDocument6 pagesHigh Strength Fine Grained Structural Steel Quenched and TemperedAugusto BerdetteNo ratings yet

- Ferrotitanium: Standard Specification ForDocument2 pagesFerrotitanium: Standard Specification ForPaulo GalvãoNo ratings yet

- Sunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesDocument6 pagesSunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcessanjeettirkeyNo ratings yet

- Asme Section II A Sa-202 Sa-202mDocument4 pagesAsme Section II A Sa-202 Sa-202mAnonymous GhPzn1xNo ratings yet

- Extracto Norma ASTM A792Document2 pagesExtracto Norma ASTM A792Christian Latorre VielmaNo ratings yet

- ASTM A255 20aDocument12 pagesASTM A255 20aakshayb123No ratings yet

- Kapitel 01 DINO Techn TeilDocument12 pagesKapitel 01 DINO Techn TeilPetros IosifidisNo ratings yet

- F 560 - 98 - Rju2mc1sruqDocument5 pagesF 560 - 98 - Rju2mc1sruqAdrian GonzalezNo ratings yet

- API 2hgr50Document3 pagesAPI 2hgr50Jym GensonNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Loadings: Dead LoadDocument3 pagesLoadings: Dead LoadLaurence SarmientoNo ratings yet

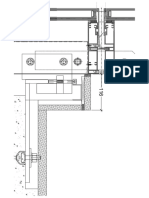

- Check For Upper ConnectionDocument3 pagesCheck For Upper ConnectionLaurence SarmientoNo ratings yet

- Check For The Anchorage To ConcreteDocument11 pagesCheck For The Anchorage To ConcreteLaurence SarmientoNo ratings yet

- Front Bracket Check: LC 1.0DL + 1.5WL+ (1.35DL Lessens The Tension On The Anchor Thus Is Not Governing)Document10 pagesFront Bracket Check: LC 1.0DL + 1.5WL+ (1.35DL Lessens The Tension On The Anchor Thus Is Not Governing)Laurence SarmientoNo ratings yet

- Bottom Bracket Design: For The Analysis of The Thru Bolt, See The Pervious SectionDocument6 pagesBottom Bracket Design: For The Analysis of The Thru Bolt, See The Pervious SectionLaurence SarmientoNo ratings yet

- Standards & Software ReferencesDocument4 pagesStandards & Software ReferencesLaurence SarmientoNo ratings yet

- Steel FrameDocument2 pagesSteel FrameLaurence SarmientoNo ratings yet

- Verification For The Front GlassDocument6 pagesVerification For The Front GlassLaurence SarmientoNo ratings yet

- Check For Glass Fin SupportDocument7 pagesCheck For Glass Fin SupportLaurence SarmientoNo ratings yet

- Project Integration Management: U U U U U U U U U UDocument3 pagesProject Integration Management: U U U U U U U U U ULaurence SarmientoNo ratings yet

- Check For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Document5 pagesCheck For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Laurence SarmientoNo ratings yet

- Intro To Pmbok PDFDocument3 pagesIntro To Pmbok PDFLaurence SarmientoNo ratings yet

- Project Environ PmbokDocument5 pagesProject Environ PmbokLaurence SarmientoNo ratings yet

- Roles of The PMDocument6 pagesRoles of The PMLaurence SarmientoNo ratings yet

- Load Share FactorDocument1 pageLoad Share FactorLaurence SarmientoNo ratings yet

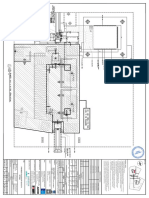

- Det 1020 PDFDocument1 pageDet 1020 PDFLaurence SarmientoNo ratings yet

- 2.14. Check For Steel Beam at Above Revolving Door: StaadDocument2 pages2.14. Check For Steel Beam at Above Revolving Door: StaadLaurence SarmientoNo ratings yet

- Cleat and SupportDocument2 pagesCleat and SupportLaurence SarmientoNo ratings yet

- Bracket FemDocument3 pagesBracket FemLaurence SarmientoNo ratings yet

- Glass Nominal ThicknessDocument1 pageGlass Nominal ThicknessLaurence SarmientoNo ratings yet

- 2.7. Check For Steel TransomDocument2 pages2.7. Check For Steel TransomLaurence SarmientoNo ratings yet

- Ucw Section BracketDocument1 pageUcw Section BracketLaurence SarmientoNo ratings yet

- Effective Wind Speed: Standard MethodDocument1 pageEffective Wind Speed: Standard MethodLaurence SarmientoNo ratings yet

- Formal Report Expt 8Document5 pagesFormal Report Expt 8Jemille Anne Maranan MoroñaNo ratings yet

- Republic of The Philippines Isabela State University Echague, IsabelaDocument11 pagesRepublic of The Philippines Isabela State University Echague, Isabelaaileen eustaquioNo ratings yet

- CBSE Previous Year Question Papers Compartment Exam Class 12 Chemistry All India 2017 AnswerDocument22 pagesCBSE Previous Year Question Papers Compartment Exam Class 12 Chemistry All India 2017 AnswerManisha ParveenNo ratings yet

- Arsenic Inorganic Canadian Soil Quality Guidelines For The Protection of Environmental and Human Health enDocument7 pagesArsenic Inorganic Canadian Soil Quality Guidelines For The Protection of Environmental and Human Health enTrevor FranklinNo ratings yet

- Food Chain Web and Nutrient Cycle EcoDocument41 pagesFood Chain Web and Nutrient Cycle EcoMonica F. GardoseNo ratings yet

- Analysis of Ice CreamDocument7 pagesAnalysis of Ice CreamUsman GhaniNo ratings yet

- Interpret DiffractogramDocument4 pagesInterpret DiffractogramastikaprasiddhaNo ratings yet

- SiphonDocument45 pagesSiphonNguyễn KỳNo ratings yet

- CUI - Coating GuideDocument1 pageCUI - Coating GuideNageswara Rao BavisettyNo ratings yet

- Construction and Building Materials: A. Mohammed, J.G. Sanjayan, W.H. Duan, A. NazariDocument7 pagesConstruction and Building Materials: A. Mohammed, J.G. Sanjayan, W.H. Duan, A. NazariahmadNo ratings yet

- Bda 30502 Sem 2 1213Document5 pagesBda 30502 Sem 2 1213Iskandar BellNo ratings yet

- Experiment 4 Aldehydes and KetonesDocument6 pagesExperiment 4 Aldehydes and KetonesJules Adrian NadelaNo ratings yet

- Organic Reaction and Reaction Mechanism (Lec) PDFDocument8 pagesOrganic Reaction and Reaction Mechanism (Lec) PDFRochelle Joyce AalaNo ratings yet

- Extraction and Recrystallization of CaffeineDocument3 pagesExtraction and Recrystallization of CaffeineTommy BetyNo ratings yet

- Heterocyclic CompdsDocument27 pagesHeterocyclic Compdsgurukumar100% (1)

- MSDS KathonDocument8 pagesMSDS KathonSuresh RamasamyNo ratings yet

- Electrospun Nanofiber Affinity Membranes For Water Treatment REVIEW 2022Document22 pagesElectrospun Nanofiber Affinity Membranes For Water Treatment REVIEW 2022Manu SharmaNo ratings yet

- Proofex GPXDocument2 pagesProofex GPXVenkata RaoNo ratings yet

- Poison and AntidoteDocument5 pagesPoison and Antidoterelaxedits2No ratings yet

- P 65 List 062819Document22 pagesP 65 List 062819Nguyễn Tiến DũngNo ratings yet

- Curing Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodDocument13 pagesCuring Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodNam Phạm VănNo ratings yet

- List Obat BaksosDocument1 pageList Obat BaksosRaden Mas Nur HaryonoNo ratings yet

- Personal Care Formulary - 2015Document28 pagesPersonal Care Formulary - 2015Evelina Kassabova100% (4)

- Chemistry Form 5 DoneDocument7 pagesChemistry Form 5 DoneTee Xin RuiNo ratings yet

- AIGA 053 - 13 Code of Practice FluorineDocument38 pagesAIGA 053 - 13 Code of Practice FluorineIvonn OchoaNo ratings yet

- 4003 Chemistry Section Topic by TopicDocument32 pages4003 Chemistry Section Topic by Topicpercymtetwa25No ratings yet

- Isolation of Lymphoid Cells: - Antigen-Antibody Interactions - Antigen-Antibody Based ExperimentsDocument111 pagesIsolation of Lymphoid Cells: - Antigen-Antibody Interactions - Antigen-Antibody Based ExperimentsSivarama KrishnanNo ratings yet