Professional Documents

Culture Documents

Zeiss o Select

Zeiss o Select

Uploaded by

Sai Charan ChallapalliCopyright:

Available Formats

You might also like

- Ultrasonic Time of Flight Diffraction 1st Edition - SampleDocument19 pagesUltrasonic Time of Flight Diffraction 1st Edition - SampleSooraj Rajan67% (3)

- Keyence Instant MeasurmentDocument36 pagesKeyence Instant MeasurmentArun SreedharNo ratings yet

- OPMI-Lumera-i EN 32 010 0106IDocument8 pagesOPMI-Lumera-i EN 32 010 0106IEdward Valderrama0% (1)

- Intro To Vision Sensors ENDocument12 pagesIntro To Vision Sensors ENYogyBear43No ratings yet

- ROHM Optical Image Stabilization (OIS) Technical White PaperDocument13 pagesROHM Optical Image Stabilization (OIS) Technical White PaperavrelecNo ratings yet

- QS-LZ AFC Manual Vision Measuring SystemDocument1 pageQS-LZ AFC Manual Vision Measuring SystemTinh HàNo ratings yet

- As 94456 Im-7000 C 611G17 Us 1028-1 PDFDocument36 pagesAs 94456 Im-7000 C 611G17 Us 1028-1 PDFrishi sharmaNo ratings yet

- Profile Projector-KeyenceDocument36 pagesProfile Projector-Keyencebaskaran.marieNo ratings yet

- Measuring Microscope STM7 PDFDocument24 pagesMeasuring Microscope STM7 PDFRossie' Kumoro AldianNo ratings yet

- CM Operating Microscope PPDocument17 pagesCM Operating Microscope PPNizar Arif LazuardiNo ratings yet

- Microscopio Especular CEM-530 EspecifiacionesDocument4 pagesMicroscopio Especular CEM-530 EspecifiacionesFERNEY REYES MONSALVENo ratings yet

- Automated Defect Inspection System For CMOS Image Sensor With Micro Multi-Layer Non-Spherical Lens ModuleDocument12 pagesAutomated Defect Inspection System For CMOS Image Sensor With Micro Multi-Layer Non-Spherical Lens Module랑블루No ratings yet

- Optical Image Stabilization (OIS) : White PaperDocument13 pagesOptical Image Stabilization (OIS) : White PaperMike BrdnNo ratings yet

- Operating MicroscopeDocument26 pagesOperating MicroscopeAlfred Fredrick0% (1)

- Mitutoyo - Mikroskopy Pomiarowe Hyper MF I MF-U Serii - PRE1438 - 2015 ENDocument16 pagesMitutoyo - Mikroskopy Pomiarowe Hyper MF I MF-U Serii - PRE1438 - 2015 END.T.No ratings yet

- Mitutoyo - Mikroskopy Pomiarowe MF I MF-U - E14003 (4) - 2017 ENDocument40 pagesMitutoyo - Mikroskopy Pomiarowe MF I MF-U - E14003 (4) - 2017 END.T.No ratings yet

- En 60 020 0002iii Zeiss O-Inspect PDFDocument20 pagesEn 60 020 0002iii Zeiss O-Inspect PDFNPD TechnoringsNo ratings yet

- Catalogo Lumera T - ZEISSDocument8 pagesCatalogo Lumera T - ZEISSIgor Figueroa PizarroNo ratings yet

- Opmi Lumera TDocument8 pagesOpmi Lumera TBertha DuránNo ratings yet

- Xslicer-SMX 160 KVDocument16 pagesXslicer-SMX 160 KVDoanh NguyenNo ratings yet

- Instant Measurement: Image Dimension Measurement SystemDocument44 pagesInstant Measurement: Image Dimension Measurement SystemjongoskampretosNo ratings yet

- As 117014 TG 601061 WW GB 2021 1Document12 pagesAs 117014 TG 601061 WW GB 2021 1Srivatsava RajagopalanNo ratings yet

- Delta2 Brochure ENDocument4 pagesDelta2 Brochure ENEverton SarmentoNo ratings yet

- Advanced Microscopy Simplifi Ed: Bx53M/BxfmDocument28 pagesAdvanced Microscopy Simplifi Ed: Bx53M/BxfmRepresentaciones y Distribuciones FALNo ratings yet

- Industry PortfolioDocument1 pageIndustry PortfolioEnrique BelloNo ratings yet

- A-TN01 AutoSE Technical Note - HDDocument8 pagesA-TN01 AutoSE Technical Note - HDBecherescu DanNo ratings yet

- Brochure Hi-R NEO 900Document10 pagesBrochure Hi-R NEO 900Hazem Abu RamadanNo ratings yet

- Revo fc130 Rev11 OnlineDocument16 pagesRevo fc130 Rev11 Onlineevans DNo ratings yet

- ZeissDocument8 pagesZeisslurukataNo ratings yet

- Vision Sensor: SetupDocument16 pagesVision Sensor: SetupjulioNo ratings yet

- Eye GazeDocument8 pagesEye Gazeyashaswi_pnNo ratings yet

- Opmi Proergo BrochureDocument8 pagesOpmi Proergo BrochureMiriam SanchezNo ratings yet

- Swift PRO Brochure English LIT5428EN - 02Document6 pagesSwift PRO Brochure English LIT5428EN - 02ANo ratings yet

- HRK 7000A BrochureDocument6 pagesHRK 7000A BrochureRhuan CostaNo ratings yet

- Nidek ICE-1200Document6 pagesNidek ICE-1200QulrafMongkonsirivatanaNo ratings yet

- Zeiss Ultra OptimeterDocument13 pagesZeiss Ultra OptimeterLokesh kumar MeenaNo ratings yet

- Manual Grand SeikoDocument4 pagesManual Grand SeikoOscar Tovar50% (2)

- Discover Another Dimension: DSX500iDocument20 pagesDiscover Another Dimension: DSX500iRepresentaciones y Distribuciones FALNo ratings yet

- GX71 GX51 PDFDocument18 pagesGX71 GX51 PDFRepresentaciones y Distribuciones FALNo ratings yet

- Isprs Archives XLVI 2 W1 2022 395 2022Document6 pagesIsprs Archives XLVI 2 W1 2022 395 2022aliramezanidehajNo ratings yet

- Topógrafo MedmontDocument4 pagesTopógrafo MedmontgersonbartoloNo ratings yet

- Cali Opt Prox SensorDocument5 pagesCali Opt Prox SensorbehzadNo ratings yet

- MR Blue Tracer Blocker US Size 11 2019 1Document2 pagesMR Blue Tracer Blocker US Size 11 2019 1M.r SadrshiraziNo ratings yet

- Omron Healthcare ZFX C Manual de UsuarioDocument15 pagesOmron Healthcare ZFX C Manual de UsuarioJosé Manuel MoaNo ratings yet

- IC-8 IOL Physician BrochureDocument8 pagesIC-8 IOL Physician BrochureFederico LucidiNo ratings yet

- STM6 LM PDFDocument20 pagesSTM6 LM PDFRepresentaciones y Distribuciones FALNo ratings yet

- Iv C 611705 GB 1024-2Document16 pagesIv C 611705 GB 1024-2Jhon Kenneth GeneralesNo ratings yet

- gx71 gx51 en - Ver3 PDFDocument18 pagesgx71 gx51 en - Ver3 PDFAlina JumoleaNo ratings yet

- BX53MDocument28 pagesBX53MQA LAB ISMNo ratings yet

- PS - PSL Operation Manual 2013Document127 pagesPS - PSL Operation Manual 2013MatheusNo ratings yet

- AP74045 Rev1,0 PDFDocument38 pagesAP74045 Rev1,0 PDFgass2No ratings yet

- Instruction Manual: Vision Screening With The VS-V Pediatric Vision ScreenerDocument19 pagesInstruction Manual: Vision Screening With The VS-V Pediatric Vision ScreenerboboNo ratings yet

- Al ScanDocument4 pagesAl ScanGeorgie Alexandria MagidoNo ratings yet

- The Start Button: Eye TrackingDocument12 pagesThe Start Button: Eye Trackingevans DNo ratings yet

- Visuphor 500 Datenblatt en ZeissDocument4 pagesVisuphor 500 Datenblatt en ZeissgondamNo ratings yet

- Machine Vision For Visual TestingDocument22 pagesMachine Vision For Visual TestingMuhammad UmairNo ratings yet

- Optical InferometryDocument2 pagesOptical Inferometryajay ranaNo ratings yet

- OEC Brivo Essential: GE HealthcareDocument12 pagesOEC Brivo Essential: GE HealthcareThanh TrầnNo ratings yet

- Brivo Essential BrochureDocument12 pagesBrivo Essential BrochureLuis Fernando Garcia SNo ratings yet

- Personalized PDF Catalog Catalogue Generated January 29, 2018Document3 pagesPersonalized PDF Catalog Catalogue Generated January 29, 2018Sai Charan ChallapalliNo ratings yet

- Learn Sheet Metal Design Terminology Including Bend DeductionDocument4 pagesLearn Sheet Metal Design Terminology Including Bend DeductionSai Charan ChallapalliNo ratings yet

- Calculating Bend Allowance, Bend Deduction, and K-FactorDocument7 pagesCalculating Bend Allowance, Bend Deduction, and K-FactorSai Charan ChallapalliNo ratings yet

- Calculating Bend Allowance, Bend Deduction, and K-FactorDocument7 pagesCalculating Bend Allowance, Bend Deduction, and K-FactorSai Charan ChallapalliNo ratings yet

- RJ45 Mosaic 1Document5 pagesRJ45 Mosaic 1Alexandra MihaelaNo ratings yet

- Basler DECS-400 Instruction ManualDocument227 pagesBasler DECS-400 Instruction ManualileheNo ratings yet

- What'S New?: Learn How To Repair TV Panel With The Help of Cof Boardview Without Replace A TV PanelDocument17 pagesWhat'S New?: Learn How To Repair TV Panel With The Help of Cof Boardview Without Replace A TV PaneluzenNo ratings yet

- Advances in UHV Transmission and DistributionDocument24 pagesAdvances in UHV Transmission and DistributionsalehknNo ratings yet

- Five Tone PDFDocument2 pagesFive Tone PDFMasanobu TAKEMURANo ratings yet

- S-72 2211 Course OverviewDocument4 pagesS-72 2211 Course OverviewDaniel ManoleNo ratings yet

- PROCOLD S.R.L.: Distributed in Europe byDocument20 pagesPROCOLD S.R.L.: Distributed in Europe byChirila CristinelNo ratings yet

- Annex B Conveyor Schedule of Specs 20nov15Document3 pagesAnnex B Conveyor Schedule of Specs 20nov15Kalai SelvanNo ratings yet

- 110 - Power Distribution Wiring SchematicsDocument34 pages110 - Power Distribution Wiring SchematicsGedas GvildysNo ratings yet

- Band Theory-1 PDFDocument65 pagesBand Theory-1 PDFKamaljit RajkumarNo ratings yet

- Stand Alone PV System ComponentDocument142 pagesStand Alone PV System Componentbedilu77No ratings yet

- 4 Amps N-Channel MOSFET: 600voltsDocument5 pages4 Amps N-Channel MOSFET: 600voltsOliveira OliveiraNo ratings yet

- Wien-Bridge Oscillator With Low Harmonic DistortionDocument3 pagesWien-Bridge Oscillator With Low Harmonic DistortiontonypdfNo ratings yet

- TLICDocument3 pagesTLICHariharan BalasubramaniamNo ratings yet

- Plasma Monitor/Tuner: Service ManualDocument49 pagesPlasma Monitor/Tuner: Service Manualzhuzhu2010No ratings yet

- DEIFDocument6 pagesDEIFnhocti007No ratings yet

- Idm 50B: Multi-Standard ModemDocument4 pagesIdm 50B: Multi-Standard ModemRahmat Wahyu PratamaNo ratings yet

- SM 66Document39 pagesSM 66eys.automotricesNo ratings yet

- A 005Document7 pagesA 005sunnyliuNo ratings yet

- Project On Accounts ReceivableDocument61 pagesProject On Accounts ReceivableNilesh JhaNo ratings yet

- 03-AC-Solution-Critical, Graphical, Ass. ResonDocument5 pages03-AC-Solution-Critical, Graphical, Ass. ResonMd Rizwan AhmadNo ratings yet

- Support Wiki - Cable Pin-OutsDocument6 pagesSupport Wiki - Cable Pin-OutsfrancportNo ratings yet

- Type II CompensatorDocument10 pagesType II CompensatorTrương Văn TrọngNo ratings yet

- Rd-8132 20w Mcpa Ds 3-0-4 - Rep CombaDocument3 pagesRd-8132 20w Mcpa Ds 3-0-4 - Rep CombaJohn Williams Rosas SolierNo ratings yet

- Electric Poker Vibrators & Frequency ConvertersDocument8 pagesElectric Poker Vibrators & Frequency ConvertersIgor Halterbeck HalterbeckNo ratings yet

- Testing of DC MachinesDocument15 pagesTesting of DC MachinesMadhu TallapanenimadhuNo ratings yet

- kx-tg773x kx-tg254 kx-tg294 kx-tg774x kx-tg263 kx-tg273 Mul OmDocument88 pageskx-tg773x kx-tg254 kx-tg294 kx-tg774x kx-tg263 kx-tg273 Mul OmsungdkdNo ratings yet

- Wireless Transformer MonitoringDocument18 pagesWireless Transformer MonitoringKamlesh MotghareNo ratings yet

- Sliding Mode Control of DC-DC Converters: G. Spiazzi, P. Mattavelli, L. RossettoDocument10 pagesSliding Mode Control of DC-DC Converters: G. Spiazzi, P. Mattavelli, L. RossettoDuc NguyenNo ratings yet

Zeiss o Select

Zeiss o Select

Uploaded by

Sai Charan ChallapalliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zeiss o Select

Zeiss o Select

Uploaded by

Sai Charan ChallapalliCopyright:

Available Formats

ZEISS O-SELECT

Digital Measuring Projector

O_SELECT_EN_60_020_0003I.indd 1 4/23/2015 12:18:47 PM

// O-SELECT

MADE BY ZEISS

O_SELECT_EN_60_020_0003I.indd 2 4/23/2015 12:18:49 PM

The moment you get total certainty

at the push of a button.

This is the moment we work for.

O_SELECT_EN_60_020_0003I.indd 3 4/23/2015 12:18:50 PM

4

O_SELECT_EN_60_020_0003I.indd 4 4/23/2015 12:18:54 PM

Reliably measure

at the push of a button

ZEISS O-SELECT makes the optical measurement of 2D parts easy

and reliable. Thanks to fully automatic setting of both illumination

and focus, measuring errors due to operator influence are

eliminated. With the simple push of a button, ZEISS O-SELECT

evaluates the characteristics and documents the results –

also in a professional report if needed.

Fully automated

Position the part 1

Start the serial measurement 2

Reproducible, traceable results

and automated report output

O_SELECT_EN_60_020_0003I.indd 5 4/23/2015 12:18:58 PM

6

O_SELECT_EN_60_020_0003I.indd 6 4/23/2015 12:19:03 PM

Fields of application

Whether it is used in the automotive, electronic or plastic

processing industries, ZEISS O-SELECT provides precisely the

simplicity and reliability needed in today's industrial environment.

The digital measuring projector is particularly suitable for checking

the dimensional accuracy of distances, radii or angles. Common

test parts include punched and formed parts, or injection-molded

and laser-cut workpieces.

ZEISS O-SELECT measures characteristics like angles, distances and radii quickly and reliably.

O_SELECT_EN_60_020_0003I.indd 7 4/23/2015 12:19:18 PM

Automatically focused

Manual focusing can often lead to errors – all unnoticed by the

operator. The result: measuring errors of up to several micrometers.

To eliminate this source of error, ZEISS O-SELECT automatically

identifies the characteristics to be tested and sets the focal plane

accordingly. In other words, operator errors are eliminated.

ZEISS O-SELECT focuses automatically –

totally without operator intervention.

Telecentric optics

Standard camera lenses are based on the central perspective principle: the farther away an object

is, the smaller it is imaged on the sensor. A telecentric lens, on the other hand, does not change the

image magnification when the object is moved axially. This means that the dimensional accuracy can

be captured correctly, regardless of the distance to the object.

Center:

A standard, non-telecentric lens results

in a distortion of perspectives.

Right:

A telecentric lens ensures that the

perspectives remain undistorted.

O_SELECT_EN_60_020_0003I.indd 8 4/23/2015 12:19:26 PM

The centerpiece of the optical system is

low-distortion, telecentric ZEISS optics

with a high-resolution camera chip.

O_SELECT_EN_60_020_0003I.indd 9 4/23/2015 12:19:29 PM

Automatically the best light

Optical measurement can only succeed if the illumination is right.

To ensure that each characteristic is seen in the best possible light,

ZEISS O-SELECT offers a variable illumination system. The illumination

is set automatically to each characteristic, ruling out any possibility

of operator error.

Transmitted light Coaxial light, optional Ring light

(page 13)

Camera

Lens

Test object

Light source

ZEISS O-SELECT automatically and individually adjusts the intensity of each of the eight segments of the double ring light –

depending on the properties of the workpiece and the position of the characteristics

10

O_SELECT_EN_60_020_0003I.indd 10 4/23/2015 12:21:19 PM

Eight-segment double ring light for

variable reflected-light illumination

Mounting block for optional

coaxial light

Transmitted light for

maximum contrast

11

O_SELECT_EN_60_020_0003I.indd 11 4/23/2015 12:21:21 PM

Intelligent, compact and reliable

The efficient system for 2D geometries

The hardware and software of ZEISS O-SELECT are optimally

matched to ensure that 2D geometries can be tested with

outstanding speed and reliability. Its compactness and robustness

allow ZEISS O-SELECT to be installed at practically any location.

You can measure your test parts precisely where you need to –

whether in incoming inspection or in production.

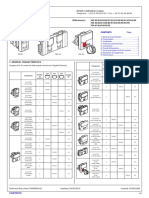

System components

The system consists of the measuring system, the touch display keyboard and the ZEISS O-SELECT

software. The external display offers clear benefits over a small, integrated display: a better overview,

better orientation and more detail. Its touch function further simplifies the operation of the system.

The software was specially developed for the ZEISS O-SELECT system and features a new, innovative

approach. This is a major benefit not only for inexperienced operators, but also for experts whose

workload will be lightened by the intelligent software.

Coaxial light as an option

Illumination coaxial to the optics is also available. This is recommended for measuring deep-lying

structures which would otherwise be concealed by shadow.

Machine size 402 mm x 510 mm x 727 mm (W x D x H)

Size of measuring field approx. 100 mm x 90 mm

System components Digital measuring projector, workstation, monitor screen,

ZEISS O-SELECT software

12

O_SELECT_EN_60_020_0003I.indd 12 4/23/2015 12:21:23 PM

High-resolution camera

Drive for the autofocus

Telecentric ZEISS optics

Double ring light, each

with eight segments

Optional coaxial light

Transmitted light

13

O_SELECT_EN_60_020_0003I.indd 13 4/23/2015 12:21:25 PM

The fastest way to get your results

With the ZEISS O-SELECT software

The ZEISS O-SELECT software combines ZEISS metrology know-

how with innovative, simple operation. Serial measurements are

performed at the press of the button – regardless of the operator.

Single measurements and measurement plans are no problem

with ZEISS O-SELECT software: because it is so easy to understand,

offers clear operator guidance and reduces workload.

Controllable via touch display

Control ZEISS O-SELECT via a touch display and you will experience a new

dimension in operator convenience. In many applications this means that the

use of a keyboard and mouse is no longer needed.

14

O_SELECT_EN_60_020_0003I.indd 14 4/23/2015 12:21:26 PM

89.2595

dia. 9.4746

14.9316

dia. 9.4791

79.6249

dia. 9.4958

°

33

.1

90

Results are projected beside the dimensioning arrows in the image.

The color code indicates immediately what values are within tolerance.

Measure directly in the image Clear orientation Serial measurement

The graphical user interface of ZEISS The intuitive user interface makes it easier at the press of a button

O-SELECT is a real innovation. As required for operators to navigate through the Parts for which a measuring plan has

functions and information are all just a software. It shows clearly what point they already been generated can be tested

mouse click away, measurement plans have reached and guides them through with ZEISS O-SELECT at the press of

can be generated at unparalleled speed. the entire run: from creating a new project a button. The system identifies the

You only see what you need. For most to the measurement plan and specifying positioned part and loads the appropriate

measurements, you will never have the measuring run, users are guided program automatically. The alignment

to leave the main window. Instead of throughout the entire process right up to is also automatic. ZEISS O-SELECT sets

navigating through sub-menus, you the report. the optimal illumination and focuses

measure directly in the image. automatically. This not only lightens the

operator's workload, but also makes the

measurement operator-independent and

reproducible. If required, the reliable result

is automatically output or printed in a

report.

15

O_SELECT_EN_60_020_0003I.indd 15 4/23/2015 12:21:26 PM

Click & Pick: Click on the features on

the right and the software will offer

possible characteristics to choose

from.

64

9.02

Y 4.3263

X 7.3261

Single measurements the easy way – Generate measurement plans

with Click & Pick It's just a small step from a single

Even unknown parts for which no measurement to a serial measurement.

measurement plan has been generated You proceed in the same way as for

can be measured quickly, easily and a single measurement and select the

reliably with ZEISS O-SELECT. Using an required characteristics in the image

automatically high-contrast and focused using the Click & Pick function.

image, ZEISS O-SELECT identifies possible No special knowledge is needed, as

features like circles and straight lines. the programming is totally intuitive,

and enjoyable too! During this, a

When you move over one of these measurement plan is already being

features with the mouse, you will receive generated in the background. All you

possible characteristics such as radii, have to do is save it – that's all there is

distances and angles. With a first Click to it.

you define an initial feature, and with

a second Pick you select one of the

suggested test features – all intuitively,

directly on the object. The measured value

then appears next to the dimensioning

arrow. This way, you receive all desired

dimensions of an unknown test part.

16

O_SELECT_EN_60_020_0003I.indd 16 4/23/2015 12:21:26 PM

One example of a report –

ZEISS O-SELECT also offers many other

templates.

Single measurement and Fully automatic serial Professional reports

measurement plan generation measurement It’s possible to record and evaluate

the measurements with the reporting

Position the part 1 Position the part 1 tool ZEISS PiWeb, integrated in the

measurement software. For the efficient

exchange of information, various

Start the single measurement 2 Start the serial measurement 2 report templates are available – from

the straightforward graphic report to

the detailed list report. This makes it

Select the characteristics 3 Result and report possible to generate reports practically

with Click & Pick without effort and without any in-

depth knowledge. One particularly

Result and report simple possibility is the one-click report

that outputs the current monitor view

in a report at the push of a button.

Save as a measurement plan 4 Templates with value displays in the

image and form plots make it easier to

understand the results. For the purpose

of process inspection, templates with

value flows and statistical parameters are

also available. And if needed, you can

also have a report of a specified format

automatically displayed, saved or printed.

17

O_SELECT_EN_60_020_0003I.indd 17 4/23/2015 12:21:28 PM

We make it visible

Optical inspection and measuring machines

ZEISS Industrial Metrology has set the quality standards and

spearheaded innovation in the industry for almost 100 years. In

the field of optics, ZEISS has set the pace for one and a half

centuries. Optical machines from ZEISS combine all of this know-

how and expertise. In other words, you receive optical inspection

and measuring machines that will impress you in every respect –

right from day one.

Optical testing and visualization Optical testing and measurement

ZEISS Smartzoom 5 ZEISS O-SELECT

Sensors optical (color camera) Sensors optical (grayscale camera)

Characteristics Visualization and dimensioning of Characteristics Size, form and location in the image with

characteristics in the image subpixel accuracy, automatic part

recognition; nominal/actual comparison

using CAD data

www.zeiss.com/smartzoom www.zeiss.com/o-select

18

O_SELECT_EN_60_020_0003I.indd 18 4/23/2015 12:21:30 PM

Optical and contact measurement

ZEISS O-INSPECT

Sensors contact scanning and optical

(grayscale camera)

Characteristics Size, form and location in 3D,

nominal/actual comparison using CAD data

www.zeiss.com/o-inspect

19

O_SELECT_EN_60_020_0003I.indd 19 4/23/2015 12:21:39 PM

Subject to change in design and scope of delivery and as a result of ongoing technical development.

DE_60_020_0003I Printed in Germany AW-CZ-IV/2015 Uoo

© Carl Zeiss Industrielle Messtechnik GmbH

Carl Zeiss

Industrielle Messtechnik GmbH Sales: +49 (0) 7364/ 20-6336

73446 Oberkochen Service: +49 (0) 7364/ 20-6337

Germany Fax: +49 (0) 7364/ 20-3870

Email: imt@zeiss.de

Internet: www.zeiss.com/imt

O_SELECT_EN_60_020_0003I.indd 22 4/23/2015 12:21:49 PM

You might also like

- Ultrasonic Time of Flight Diffraction 1st Edition - SampleDocument19 pagesUltrasonic Time of Flight Diffraction 1st Edition - SampleSooraj Rajan67% (3)

- Keyence Instant MeasurmentDocument36 pagesKeyence Instant MeasurmentArun SreedharNo ratings yet

- OPMI-Lumera-i EN 32 010 0106IDocument8 pagesOPMI-Lumera-i EN 32 010 0106IEdward Valderrama0% (1)

- Intro To Vision Sensors ENDocument12 pagesIntro To Vision Sensors ENYogyBear43No ratings yet

- ROHM Optical Image Stabilization (OIS) Technical White PaperDocument13 pagesROHM Optical Image Stabilization (OIS) Technical White PaperavrelecNo ratings yet

- QS-LZ AFC Manual Vision Measuring SystemDocument1 pageQS-LZ AFC Manual Vision Measuring SystemTinh HàNo ratings yet

- As 94456 Im-7000 C 611G17 Us 1028-1 PDFDocument36 pagesAs 94456 Im-7000 C 611G17 Us 1028-1 PDFrishi sharmaNo ratings yet

- Profile Projector-KeyenceDocument36 pagesProfile Projector-Keyencebaskaran.marieNo ratings yet

- Measuring Microscope STM7 PDFDocument24 pagesMeasuring Microscope STM7 PDFRossie' Kumoro AldianNo ratings yet

- CM Operating Microscope PPDocument17 pagesCM Operating Microscope PPNizar Arif LazuardiNo ratings yet

- Microscopio Especular CEM-530 EspecifiacionesDocument4 pagesMicroscopio Especular CEM-530 EspecifiacionesFERNEY REYES MONSALVENo ratings yet

- Automated Defect Inspection System For CMOS Image Sensor With Micro Multi-Layer Non-Spherical Lens ModuleDocument12 pagesAutomated Defect Inspection System For CMOS Image Sensor With Micro Multi-Layer Non-Spherical Lens Module랑블루No ratings yet

- Optical Image Stabilization (OIS) : White PaperDocument13 pagesOptical Image Stabilization (OIS) : White PaperMike BrdnNo ratings yet

- Operating MicroscopeDocument26 pagesOperating MicroscopeAlfred Fredrick0% (1)

- Mitutoyo - Mikroskopy Pomiarowe Hyper MF I MF-U Serii - PRE1438 - 2015 ENDocument16 pagesMitutoyo - Mikroskopy Pomiarowe Hyper MF I MF-U Serii - PRE1438 - 2015 END.T.No ratings yet

- Mitutoyo - Mikroskopy Pomiarowe MF I MF-U - E14003 (4) - 2017 ENDocument40 pagesMitutoyo - Mikroskopy Pomiarowe MF I MF-U - E14003 (4) - 2017 END.T.No ratings yet

- En 60 020 0002iii Zeiss O-Inspect PDFDocument20 pagesEn 60 020 0002iii Zeiss O-Inspect PDFNPD TechnoringsNo ratings yet

- Catalogo Lumera T - ZEISSDocument8 pagesCatalogo Lumera T - ZEISSIgor Figueroa PizarroNo ratings yet

- Opmi Lumera TDocument8 pagesOpmi Lumera TBertha DuránNo ratings yet

- Xslicer-SMX 160 KVDocument16 pagesXslicer-SMX 160 KVDoanh NguyenNo ratings yet

- Instant Measurement: Image Dimension Measurement SystemDocument44 pagesInstant Measurement: Image Dimension Measurement SystemjongoskampretosNo ratings yet

- As 117014 TG 601061 WW GB 2021 1Document12 pagesAs 117014 TG 601061 WW GB 2021 1Srivatsava RajagopalanNo ratings yet

- Delta2 Brochure ENDocument4 pagesDelta2 Brochure ENEverton SarmentoNo ratings yet

- Advanced Microscopy Simplifi Ed: Bx53M/BxfmDocument28 pagesAdvanced Microscopy Simplifi Ed: Bx53M/BxfmRepresentaciones y Distribuciones FALNo ratings yet

- Industry PortfolioDocument1 pageIndustry PortfolioEnrique BelloNo ratings yet

- A-TN01 AutoSE Technical Note - HDDocument8 pagesA-TN01 AutoSE Technical Note - HDBecherescu DanNo ratings yet

- Brochure Hi-R NEO 900Document10 pagesBrochure Hi-R NEO 900Hazem Abu RamadanNo ratings yet

- Revo fc130 Rev11 OnlineDocument16 pagesRevo fc130 Rev11 Onlineevans DNo ratings yet

- ZeissDocument8 pagesZeisslurukataNo ratings yet

- Vision Sensor: SetupDocument16 pagesVision Sensor: SetupjulioNo ratings yet

- Eye GazeDocument8 pagesEye Gazeyashaswi_pnNo ratings yet

- Opmi Proergo BrochureDocument8 pagesOpmi Proergo BrochureMiriam SanchezNo ratings yet

- Swift PRO Brochure English LIT5428EN - 02Document6 pagesSwift PRO Brochure English LIT5428EN - 02ANo ratings yet

- HRK 7000A BrochureDocument6 pagesHRK 7000A BrochureRhuan CostaNo ratings yet

- Nidek ICE-1200Document6 pagesNidek ICE-1200QulrafMongkonsirivatanaNo ratings yet

- Zeiss Ultra OptimeterDocument13 pagesZeiss Ultra OptimeterLokesh kumar MeenaNo ratings yet

- Manual Grand SeikoDocument4 pagesManual Grand SeikoOscar Tovar50% (2)

- Discover Another Dimension: DSX500iDocument20 pagesDiscover Another Dimension: DSX500iRepresentaciones y Distribuciones FALNo ratings yet

- GX71 GX51 PDFDocument18 pagesGX71 GX51 PDFRepresentaciones y Distribuciones FALNo ratings yet

- Isprs Archives XLVI 2 W1 2022 395 2022Document6 pagesIsprs Archives XLVI 2 W1 2022 395 2022aliramezanidehajNo ratings yet

- Topógrafo MedmontDocument4 pagesTopógrafo MedmontgersonbartoloNo ratings yet

- Cali Opt Prox SensorDocument5 pagesCali Opt Prox SensorbehzadNo ratings yet

- MR Blue Tracer Blocker US Size 11 2019 1Document2 pagesMR Blue Tracer Blocker US Size 11 2019 1M.r SadrshiraziNo ratings yet

- Omron Healthcare ZFX C Manual de UsuarioDocument15 pagesOmron Healthcare ZFX C Manual de UsuarioJosé Manuel MoaNo ratings yet

- IC-8 IOL Physician BrochureDocument8 pagesIC-8 IOL Physician BrochureFederico LucidiNo ratings yet

- STM6 LM PDFDocument20 pagesSTM6 LM PDFRepresentaciones y Distribuciones FALNo ratings yet

- Iv C 611705 GB 1024-2Document16 pagesIv C 611705 GB 1024-2Jhon Kenneth GeneralesNo ratings yet

- gx71 gx51 en - Ver3 PDFDocument18 pagesgx71 gx51 en - Ver3 PDFAlina JumoleaNo ratings yet

- BX53MDocument28 pagesBX53MQA LAB ISMNo ratings yet

- PS - PSL Operation Manual 2013Document127 pagesPS - PSL Operation Manual 2013MatheusNo ratings yet

- AP74045 Rev1,0 PDFDocument38 pagesAP74045 Rev1,0 PDFgass2No ratings yet

- Instruction Manual: Vision Screening With The VS-V Pediatric Vision ScreenerDocument19 pagesInstruction Manual: Vision Screening With The VS-V Pediatric Vision ScreenerboboNo ratings yet

- Al ScanDocument4 pagesAl ScanGeorgie Alexandria MagidoNo ratings yet

- The Start Button: Eye TrackingDocument12 pagesThe Start Button: Eye Trackingevans DNo ratings yet

- Visuphor 500 Datenblatt en ZeissDocument4 pagesVisuphor 500 Datenblatt en ZeissgondamNo ratings yet

- Machine Vision For Visual TestingDocument22 pagesMachine Vision For Visual TestingMuhammad UmairNo ratings yet

- Optical InferometryDocument2 pagesOptical Inferometryajay ranaNo ratings yet

- OEC Brivo Essential: GE HealthcareDocument12 pagesOEC Brivo Essential: GE HealthcareThanh TrầnNo ratings yet

- Brivo Essential BrochureDocument12 pagesBrivo Essential BrochureLuis Fernando Garcia SNo ratings yet

- Personalized PDF Catalog Catalogue Generated January 29, 2018Document3 pagesPersonalized PDF Catalog Catalogue Generated January 29, 2018Sai Charan ChallapalliNo ratings yet

- Learn Sheet Metal Design Terminology Including Bend DeductionDocument4 pagesLearn Sheet Metal Design Terminology Including Bend DeductionSai Charan ChallapalliNo ratings yet

- Calculating Bend Allowance, Bend Deduction, and K-FactorDocument7 pagesCalculating Bend Allowance, Bend Deduction, and K-FactorSai Charan ChallapalliNo ratings yet

- Calculating Bend Allowance, Bend Deduction, and K-FactorDocument7 pagesCalculating Bend Allowance, Bend Deduction, and K-FactorSai Charan ChallapalliNo ratings yet

- RJ45 Mosaic 1Document5 pagesRJ45 Mosaic 1Alexandra MihaelaNo ratings yet

- Basler DECS-400 Instruction ManualDocument227 pagesBasler DECS-400 Instruction ManualileheNo ratings yet

- What'S New?: Learn How To Repair TV Panel With The Help of Cof Boardview Without Replace A TV PanelDocument17 pagesWhat'S New?: Learn How To Repair TV Panel With The Help of Cof Boardview Without Replace A TV PaneluzenNo ratings yet

- Advances in UHV Transmission and DistributionDocument24 pagesAdvances in UHV Transmission and DistributionsalehknNo ratings yet

- Five Tone PDFDocument2 pagesFive Tone PDFMasanobu TAKEMURANo ratings yet

- S-72 2211 Course OverviewDocument4 pagesS-72 2211 Course OverviewDaniel ManoleNo ratings yet

- PROCOLD S.R.L.: Distributed in Europe byDocument20 pagesPROCOLD S.R.L.: Distributed in Europe byChirila CristinelNo ratings yet

- Annex B Conveyor Schedule of Specs 20nov15Document3 pagesAnnex B Conveyor Schedule of Specs 20nov15Kalai SelvanNo ratings yet

- 110 - Power Distribution Wiring SchematicsDocument34 pages110 - Power Distribution Wiring SchematicsGedas GvildysNo ratings yet

- Band Theory-1 PDFDocument65 pagesBand Theory-1 PDFKamaljit RajkumarNo ratings yet

- Stand Alone PV System ComponentDocument142 pagesStand Alone PV System Componentbedilu77No ratings yet

- 4 Amps N-Channel MOSFET: 600voltsDocument5 pages4 Amps N-Channel MOSFET: 600voltsOliveira OliveiraNo ratings yet

- Wien-Bridge Oscillator With Low Harmonic DistortionDocument3 pagesWien-Bridge Oscillator With Low Harmonic DistortiontonypdfNo ratings yet

- TLICDocument3 pagesTLICHariharan BalasubramaniamNo ratings yet

- Plasma Monitor/Tuner: Service ManualDocument49 pagesPlasma Monitor/Tuner: Service Manualzhuzhu2010No ratings yet

- DEIFDocument6 pagesDEIFnhocti007No ratings yet

- Idm 50B: Multi-Standard ModemDocument4 pagesIdm 50B: Multi-Standard ModemRahmat Wahyu PratamaNo ratings yet

- SM 66Document39 pagesSM 66eys.automotricesNo ratings yet

- A 005Document7 pagesA 005sunnyliuNo ratings yet

- Project On Accounts ReceivableDocument61 pagesProject On Accounts ReceivableNilesh JhaNo ratings yet

- 03-AC-Solution-Critical, Graphical, Ass. ResonDocument5 pages03-AC-Solution-Critical, Graphical, Ass. ResonMd Rizwan AhmadNo ratings yet

- Support Wiki - Cable Pin-OutsDocument6 pagesSupport Wiki - Cable Pin-OutsfrancportNo ratings yet

- Type II CompensatorDocument10 pagesType II CompensatorTrương Văn TrọngNo ratings yet

- Rd-8132 20w Mcpa Ds 3-0-4 - Rep CombaDocument3 pagesRd-8132 20w Mcpa Ds 3-0-4 - Rep CombaJohn Williams Rosas SolierNo ratings yet

- Electric Poker Vibrators & Frequency ConvertersDocument8 pagesElectric Poker Vibrators & Frequency ConvertersIgor Halterbeck HalterbeckNo ratings yet

- Testing of DC MachinesDocument15 pagesTesting of DC MachinesMadhu TallapanenimadhuNo ratings yet

- kx-tg773x kx-tg254 kx-tg294 kx-tg774x kx-tg263 kx-tg273 Mul OmDocument88 pageskx-tg773x kx-tg254 kx-tg294 kx-tg774x kx-tg263 kx-tg273 Mul OmsungdkdNo ratings yet

- Wireless Transformer MonitoringDocument18 pagesWireless Transformer MonitoringKamlesh MotghareNo ratings yet

- Sliding Mode Control of DC-DC Converters: G. Spiazzi, P. Mattavelli, L. RossettoDocument10 pagesSliding Mode Control of DC-DC Converters: G. Spiazzi, P. Mattavelli, L. RossettoDuc NguyenNo ratings yet