Professional Documents

Culture Documents

Getting The Full Benefits of A Hazop

Getting The Full Benefits of A Hazop

Uploaded by

aymenkaramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Getting The Full Benefits of A Hazop

Getting The Full Benefits of A Hazop

Uploaded by

aymenkaramCopyright:

Available Formats

QUALITY OF HAZOPS

1 GETTING THE FULL BENEFITS OF A HAZOP

A Hazard and Operability Study (HAZOP) is a well-known risk analysis technique. It can be applied in any

industry, but is most widely used in the chemical, processing and energy industries. The method is based

on a structured, multi-discipline approach in a workshop setting, where the design, operation or system in

question is split into nodes (sub-systems), and a set of parameters and guidewords are used for

identification and evaluation of hazards. A HAZOP can be applied for a variety of systems and activities,

such as continuous or batch process systems, electrical systems, computer systems, modifications and

procedures. This article focuses on the application of HAZOP for process systems in the energy industry.

A HAZOP is a powerful tool, which can give valuable input about process risks in the design or operational

phase of a process facility. However, it is also evident that the outcome and success of the HAZOP

correlates with the skills and experience of the facilitation team and participants. The facilitation team,

consisting of a facilitator and scribe, is responsible for the efficiency, continuity, structure and quality of the

HAZOP. Through human interaction, a HAZOP combines process safety knowledge, operational experience,

and hazard identification expertise. Hence, it is important that the facilitation team is skilled and trained to

obtain highest possible quality of the HAZOP, focusing on process safety theory, knowledge about the

HAZOP methodology, and particularly workshop leadership skills to ensure that the expertise and

experience of the participants is fully utilized in a constructive manner.

Literature describing the HAZOP methodology is widely available, for instance through IEC 61882, “Hazard

and Operability studies (HAZOP studies) Application Guide” (2001-05), and through articles and books (e.g.

“HAZOP Guide to Best Practice”, 2nd ed. 2008, IChemE). This article presents experience-based advice on

how to ensure optimal outcome of a HAZOP with regards to effectiveness and brainstorming.

The article will focus on the three phases of a HAZOP where the facilitation team are usually involved

The preparation phase

The workshop

The documentation and reporting phase

The article will not go into details regarding close-out and follow up of HAZOP actions.

PREPARATION PHASE

The quality of a HAZOP depends on the efforts made during the planning of the HAZOP. During the last two

weeks prior to the HAZOP, it is recommended to perform the following activities:

Start-up meeting to agree on the battery limits and intention with the HAZOP. In the start-up

meeting, the participant list, agenda and venue for the HAZOP should be agreed. It is important that

the number of days for the HAZOP is set according to the scope of the HAZOP. Too limited time

available for a HAZOP can reduce the quality of the HAZOP.

The design should be frozen in good time before the HAZOP to ensure that the P&IDs used in the

HAZOP contain a minimum of drawing errors and other minor issues that might draw focus from

the risk identification process.

The facilitator should prepare or give input to a Terms of Reference (ToR), which should be

distributed to the HAZOP participants at least one week prior to the workshop. The ToR is an

agreement between the HAZOP participants on how to conduct the HAZOP. Hence, the document

describes the methodology, nodes, guidewords, participant list and agenda for the HAZOP. It is

important that all HAZOP participants read the ToR prior to the HAZOP, to be well prepared.

THE WORKSHOP

The HAZOP workshop is the core activity in a HAZOP process. The HAZOP workshop is a brainstorming

process, facilitated by the HAZOP facilitator, and documented by the HAZOP scribe. It should be both well

Copyright © 2015 ORS 1 (of 5)

QUALITY OF HAZOPS

prepared, organized and recorded in order to get the full benefits of the methodology. The following sections

gives guidance on how to optimize the outcome of a HAZOP.

Limiting the number of participants

A possible pitfall in a HAZOP is too many participants. In the workshop, all participants should be actively

sharing their experience and contributing in the risk assessment. Too many participants can limit the

discussions and creativity, as threshold to contribute increases. Further, it increases the likelihood for

participants not being focused. As a rule of thumb, a HAZOP should have a maximum of 15 participants,

including the facilitation team, to ensure a good group dynamic.

Operations do often have valuable input to design, related to use of the system. Hence, it is critical that

operations are attending the HAZOP. The following disciplines should attend a process HAZOP (with other

disciplines being called upon as necessary):

Process

Safety

Controls/Instrument

Operations

Facilitator

Scribe

Facilitation ground rules

An important role of the HAZOP facilitator is to ensure progress, optimal group dynamics and focus on the

intention of the HAZOP. The following ground rules for facilitation should be applied:

Always avoid more than one conversation at a time. It is the responsibility of the facilitator to stop

multiple participants from talking at once.

Ensure that all parties are actively contributing, and avoid that one party or discipline dominates the

discussions.

The facilitator should always summarize the discussions so that all participants can understand,

and agree, on the results from the HAZOP.

Lengthy discussion of solutions shall not be part of a HAZOP. A HAZOP is a tool for identification

and evaluation of hazards. Evaluating solutions are typically part of the HAZOP closeout.

The facilitator should facilitate the meeting, and avoid dominating it. This means that the

participants are responsible for the hazard identification, and suggesting actions for follow-up. The

HAZOP facilitator can stimulate the discussions using his/her own experience, but the facilitator

should not dictate hazards or actions without the participant’s acceptance. If the group cannot

reach consensus, the facilitator should however act as the final arbiter.

Respect the structure and the Terms of Reference. It is important that the facilitator is aligned with

the Terms of Reference at all times, unless otherwise agreed in the workshop.

It is the responsibility of the facilitator to ensure that the group is focused on the

parameter/guideword currently under review. It is normal that participants raise scenarios related

to guidewords/parameters not yet covered. This may especially be the case if the participant feels

that this scenario is a key scenario for the node. This impairs the structure of the HAZOP, and the

overall efficiency.

Avoid that discussions are more related to design review, rather than identification of hazards.

Discussions that are related to systems or hazards outside the scope for the meeting should be

aborted as fast as possible to avoid sidetracking.

Stop the discussions in the correct time. If a discussion is stopped by the facilitator too early, the

HAZOP may lose important experiences and input. If a discussion is stopped too late, it will have

impact on the progress and concentration of the group. A rule of thumb is that a discussion should

be stopped when sufficient information is provided to describe the core cause, consequence and

safeguards.

Copyright © 2015 ORS 2 (of 5)

QUALITY OF HAZOPS

The facilitator should ensure that the participants are sitting and staying focused during sessions.

The facilitator should stand in front of the group, and use a laser pen or pointer for guiding the

group through the nodes and P&IDs. Preferably, the group should be seated in a formation where all

participants can have eye contact, when discussing.

Ensure that there are frequent breaks. The concentration of a group is normally not lasting for more

than 60 minutes without breaks. A rule of thumb is breaks of 5-10 minutes every hour. Frequent

breaks will also ensure that the participants are more likely to follow the ground rules for the

HAZOP. This means that the participants focus on the discussions, avoid using phones/laptops or

having off-topic conversations.

A HAZOP-day should not last for more than 7 hours, as the assessment requires concentration and

creativity. It is also recommended that for longer HAZOPs to only schedule for 4 days of HAZOP per

week.

The role of the scribe

The scribe is a key role for a HAZOP. The progress, efficiency and quality of the HAZOP is highly dependent

on the skills and performance of the scribe. Further, the quality of the scribing in a HAZOP is depending on

the interactions between the facilitator and scribe.

The scribe and facilitator should be trained in working together as facilitator-scribe team. A scribe

without experience in scribing for the facilitator in question is not expected to perform well. The

dynamics and interactions (e.g. structure, speed, dynamic) between the facilitator and scribe

requires training.

The scribe should be experienced within process systems, to understand the discussions and to

quickly be able to document discussions and technical identifiers (e.g. tag numbers)

The scribe should be a fast writer. If the speed in the HAZOP is limited due to the efficiency of the

scribe, it may also affect the quality of the session as it could negatively influence the creativity and

dynamics of the discussions.

It is important that the participants can familiarize and agree with the recordings from the HAZOP. If

worksheets shall be shown during the HAZOP, it is recommended to have dual screens, one with the P&IDs

and one with the HAZOP worksheet. If worksheets shall not be shown, it is recommended to summarize the

key results, and actions, by the end of each node.

THE DOCUMENTATION AND REPORTING PHASE

Independent on methods selected for recording of HAZOPs, the HAZOP should be documented to ensure

that all assumptions, results and discussions are understandable for persons not attending the HAZOP.

Hence, all HAZOPs should be documented to ensure an auditable trail. The following sections give guidance

on means for ensuring a proper documentation.

HAZOP Worksheet

A HAZOP is documented using a worksheet (MS Excel, Word or a specific HAZOP software). The worksheet

should contain the following columns:

Node description: The node description should include clear boundaries for the node, and describe

relevant design and operating parameters within the node.

ID. Each identified deviation shall have a unique identifier.

Guideword / Parameter: Forming a meaningful deviation from the design intent.

Cause. Describes the initial cause for the deviations (E.g. Closure of a valve)

Consequence. As a base case, consequences should be described without taking safeguards into

account, unless there are inherent protection features (e.g. design pressure above maximum

possible pressure) If so, the consequence column should explain why there is no consequence from

the identified deviation to ensure an auditable trail (i.e why the design is considered inherently safe).

Copyright © 2015 ORS 3 (of 5)

QUALITY OF HAZOPS

Safeguards. All relevant safeguards should be listed for each deviation. It is important that

safeguards are properly discussed to ensure that they actually give some risk reduction for the

hazard considered. If a LOPA is planned subsequent to the HAZOP, it is recommended to spend

some time to define whether safeguards qualify as independent protection layers. E.g,, Alarms

should not be specified as safeguards unless the operator has time and instruction for a dedicated

response to mitigate the hazard. Normal operating procedures, normal inspection and maintenance

should not be recorded as safeguards in a HAZOP. However if special operating procedures or

inspection/maintenance routines are required, it should be noted.

Actions. Description of actions for follow-up.

Responsible: Responsible Company/Department/Person for following up and closing out the

HAZOP action

Comments. Important discussions, which do not fit in the other columns, shall be documented in

the comments field.

Methods of recording

The outcome and value of a HAZOP is linked to the accuracy and completeness of the recordings from the

HAZOP. As a rule of thumb, the HAZOP should be recorded such that persons not attending the HAZOP can

understand and relate to all identified hazards and deviations, to ensure an auditable trail of the HAZOP.

There are three main level of details for recording of a HAZOP:

HAZOP documented by exception

o HAZOP items (unique rows) are only created when actions are identified. This should not

be confused with HAZOP by exception, which means that only one out of two, or more,

identical process trains are HAZOPed completely, while the other train is HAZOPed by

exception from the first process train.

Intermediate recording

o All credible deviations and hazards are recorded. Causes that have the same consequence

and safeguards can be grouped.. To ensure an auditable trail, all parameters/guidewords

should be recorded, and “No credible scenarios identified” should be added for

parameters/guidewords without credible scenarios.

Full recording

o All causes for deviations or hazards are recorded, even if there is no significant causes or

consequences. Further, all causes should have a separate row (e.g. each valve that could

cause blockage, and therefore high pressure/low flow).

To ensure an auditable trail, performing HAZOPs documented by exception should be avoided. The decision

regarding intermediate or full recording depends on the phase/type of the project and time available for the

study. Full recording is more time consuming than intermediate recording.

Independent of selected level of recording, it is important that the recording follow key principles:

All actions/recommendations should be recorded such that they are understandable without

assessing all columns of the worksheet. This means that the record should specify what is the

action and why the action is raised.

All actions should be recorded such that they are possible to close-out, meaning that they should

have a defined point of closure.

The worksheet should always specify tag numbers

The P&IDs shall be marked-up with pointers for all action IDs to ease action close-out.

Drawing errors usually capture the focus of some participants even though they should not be discussed as

part of the HAZOP. A useful way to prevent spending much time on this is to have a project engineer mark

drawing errors on a clean set of P&IDs. Using this methodology, there is no need to describe the drawing

Copyright © 2015 ORS 4 (of 5)

QUALITY OF HAZOPS

errors in the HAZOP worksheet, but scanned versions of the P&IDs can be attached the HAZOP report to

ensure an auditable trail.

ENSURING A HIGH QUALITY HAZOP

A well-documented HAZOP should give clear recommendations for improving safety and optimizing design

where possible, and give a clear and auditable description of identified hazards of the system, design or

operation considered. However, it is important to emphasize that no matter how well executed a HAZOP is,

it can never be a “catch-it-all” for all conceivable hazards in a system, design or operation. As the HAZOP is

based on the expertise and experience of the participants, there may always be hazards that the team are

not able to identify (i.e. “unknown unknowns”), no matter how experienced the team is. Also, due to the

nature of the HAZOP, usually focusing particularly on design as represented on PFDs, mass and energy

balances, P&IDs, and C&Es, there will be hazard types that are more suitable to consider in other types of

risk assessments. Such hazards could be related to dropped objects, impacts, external fires, location of F&G

detectors and specific layout issues). Hence, the focus of a HAZOP should be process and operational

hazards.

The article is written jointly by Morten Nilstad Pettersen, Thomas Solberg Fylking and Richard Forss.

Copyright © 2015 ORS 5 (of 5)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jett Plasma Lift Medical Manual ENG - Akt - .9.9.15 PDFDocument27 pagesJett Plasma Lift Medical Manual ENG - Akt - .9.9.15 PDFMichaely Natali100% (1)

- Truck Crane Stc250 Ir2Document9 pagesTruck Crane Stc250 Ir2ahmadfarrizNo ratings yet

- IBM Infoprint Color 1454, 1464 Parts List, Service ManualDocument450 pagesIBM Infoprint Color 1454, 1464 Parts List, Service Manualhawker71No ratings yet

- Course Outline Det1013Document8 pagesCourse Outline Det1013KiddozesNo ratings yet

- Lessons Learned For Construction Administration of Higher Education Facilities - John Lewis - DataCom Design GroupDocument35 pagesLessons Learned For Construction Administration of Higher Education Facilities - John Lewis - DataCom Design GroupNajeeb Ahmad KhanNo ratings yet

- BSNL Industrial TrainingDocument37 pagesBSNL Industrial TrainingAnkit NagarNo ratings yet

- EsresumeDocument2 pagesEsresumeapi-253435147No ratings yet

- Abhishek SampleDocument4 pagesAbhishek SampleABHILASH KUMARNo ratings yet

- Resume of Abishek K PDFDocument4 pagesResume of Abishek K PDFGopu KrishnaNo ratings yet

- 3409Document5 pages3409Sohail AhmadNo ratings yet

- Plumbing BOQDocument13 pagesPlumbing BOQ85sunaNo ratings yet

- Vacon NXL PID Fire Mode ALFIFF32 Application ManuaDocument58 pagesVacon NXL PID Fire Mode ALFIFF32 Application ManuaTanuTiganuNo ratings yet

- Product Data: 16LJ Single-Effect, Low Temperature Hot Water Hermetic Absorption Liquid ChillerDocument32 pagesProduct Data: 16LJ Single-Effect, Low Temperature Hot Water Hermetic Absorption Liquid ChillersulphurdioxideNo ratings yet

- 12G, 14G, 16G, 120G, 130G and 140G Electrical System Motor GraderDocument2 pages12G, 14G, 16G, 120G, 130G and 140G Electrical System Motor Gradermirbek mairykovNo ratings yet

- HTML-365-385 Op y MantDocument375 pagesHTML-365-385 Op y MantGerardo MartinezNo ratings yet

- Intro To VulcanDocument242 pagesIntro To VulcanNik Agarwal67% (3)

- In Alk For Refinery MT BeDocument2 pagesIn Alk For Refinery MT BeChristianGuerreroNo ratings yet

- History PNRDocument6 pagesHistory PNRElla PondalisNo ratings yet

- Introduction To Flanges: Based On Pipe AttachmentDocument15 pagesIntroduction To Flanges: Based On Pipe AttachmentMohamed Al-OdatNo ratings yet

- Foundation KLD 29Document13 pagesFoundation KLD 29anzim kpNo ratings yet

- GRB100 Rev3Document0 pagesGRB100 Rev3comportNo ratings yet

- Rss Ranjith ShahiDocument35 pagesRss Ranjith Shahisabhari_ramNo ratings yet

- Series FB: Floating Ball ValveDocument12 pagesSeries FB: Floating Ball ValveCarlos Alberto Aguilera MendezNo ratings yet

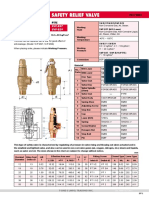

- Bronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Document1 pageBronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Shishan Ahmad100% (1)

- Engineering Case StudyDocument5 pagesEngineering Case StudyMitsui KonttoriNo ratings yet

- Faraday Rotation NewDocument28 pagesFaraday Rotation NewdrtanilbabuNo ratings yet

- Silenciador Tipo ResidencialDocument1 pageSilenciador Tipo ResidencialAngeloNo ratings yet

- BswallDocument14 pagesBswallIdrus IsmailNo ratings yet

- A Guide To Advanced Functional VerificationDocument208 pagesA Guide To Advanced Functional VerificationMohammad Seemab AslamNo ratings yet

- Tutorial Chapter 5Document5 pagesTutorial Chapter 5Nur Aqilah Ainaa Binti SahrolNo ratings yet