Professional Documents

Culture Documents

136 Sandblasting Cabinet

136 Sandblasting Cabinet

Uploaded by

Abdul RasyidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

136 Sandblasting Cabinet

136 Sandblasting Cabinet

Uploaded by

Abdul RasyidCopyright:

Available Formats

MAST

SAFE WORK PROCEDURE

Division: Analysis By: Date: Sep/12/2006

Department: Supervisor: Frequency: Hourly

Job Title: Auto Body Metal Approved By: JSA Number:

Job Title: Sandblasting Cabinet Job Performed By: Teacher and or students

REQUIRED PERSONAL PROTECTIVE EQUIPMENT: CSA approved safety boots/shoes, CSA approved safety glasses/goggles, hearing protection,

100% cotton coveralls

GENERAL NOTES: Operators must be trained by a teacher, demonstrate competency and receive pre-approval to operate this equipment, by the teacher/s

of the Auto Body Metal shop or Automotive Technology shop.

No matches, lighters or cell phones allowed in the shop area. Long hair should be tied back; strings and hoods from pullovers/sweaters should be removed or

tucked inside of coveralls. Long necklaces and or bracelets should be removed.

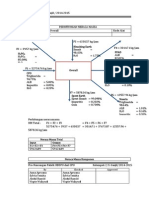

JOB SAFETY ANALYSIS:

Step Description Hazard Controls

1 Pre-operation walk around inspection of sand--- a) Operation injuring yourself or --b) a) & b) Remove any obstructive material from door

blaster and surrounding area.--Sandblaster side Operation injuring others--c) Slip around swing area.--c) Clean up sand from floor area to

door swing should be clear of obstructions. machine area. reduce slippage.--Ensure that the equipment is not

Ensure that the side door closes properly and damage - if damaged do not use, notify teacher right

that the latch secures door tight. away.

2 a) Check for exhaust fan operation. (In the a) Dust inhalation--b) Visibility a) Contact a teacher immediately if exhaust fan fails to

Auto Technology shop you must attach an start-up.--b) Contact teacher and report an inoperative

exhaust hose to the hose of the sand blaster).-- interior light.--c) If the cabinet inspection glass has

B) Check for cabinet light operation.--c) Check been eroded, ask a teacher to assist with its

glass for abrasive areas.-- replacement or ask teacher to have it replaced.

3 a) Open doors and inspect door seals.--b) a) Leakage onto floor - slips--b) Electrical a) Reseal leaking door--b) Repair ground on bead

Inspect bead gun for proper grounding.--c) static shock--c) Sand penetrating skin - gun--c) Replace gloves--

Inspect gloves to make sure they are not torn abrasion

or ripped.

Page 1 of 2 Print Date: Sep/12/2006

4 If sandblaster passes all inspections and Doors not sealed and secured - dust Make sure doors are sealed and secure.

everything is in good working order. --Turn on inhalation, leakage onto floor - slips.

light, ensure both doors are sealed and secure,

place hands in gloves hold bead gun with one

hand and with the other hand hold what you

are blasting. Press down on foot pedal with

foot, a mixture of air and sand will be forced

through the bead gun. Continue sandblasting

until you are satisfied, job completed.

5 Remove foot from foot pedal, and wait until Dust inhalation--Slip around machine area Wait until dust has settled before removing your

dust has settled before opening top door or work.--Clean up area of any sand that has fallen

side door to remove your work. Once work is around sandblaster.

removed, re-latch door/s. --Shut off light,

(disconnect exhaust hose-auto tech only).

Clean up any sand that has fallen around

sandblaster.

AUTHORIZED EMPLOYEE INFORMATION:

ID NUMBER: LAST NAME: FIRST NAME: REMARKS:

JOB HISTORY INFORMATION:

DATE: REMARKS:

Approval Signature: Date:

Page 2 of 2 Print Date: Sep/12/2006

You might also like

- Risk Assesment For Sand Blasting and PaintingDocument6 pagesRisk Assesment For Sand Blasting and PaintingRochdi Bahiri100% (11)

- 08 Stripping and Waxing floors-JOB PROCEDUREDocument2 pages08 Stripping and Waxing floors-JOB PROCEDUREDoo PLTGUNo ratings yet

- 97 Glass Removal and Replacement-JOB PROCEDUREDocument2 pages97 Glass Removal and Replacement-JOB PROCEDUREAmalia Dwi Aryanti100% (1)

- Passenger HoistDocument10 pagesPassenger HoistParshant SainiNo ratings yet

- Assignment 2 MaterialsDocument2 pagesAssignment 2 Materialspoornima patil100% (1)

- 08 Stripping and Waxing Floors-JOB PROCEDUREDocument2 pages08 Stripping and Waxing Floors-JOB PROCEDUREwahyu nugrohoNo ratings yet

- Cost Accounting 7 8 - Solution Manual Cost Accounting 7 8 - Solution ManualDocument27 pagesCost Accounting 7 8 - Solution Manual Cost Accounting 7 8 - Solution ManualMARIA100% (1)

- 136 Sandblasting CabinetDocument2 pages136 Sandblasting CabinetSunil SharmaNo ratings yet

- 136 Sandblasting CabinetDocument2 pages136 Sandblasting CabinetHazmi HanifNo ratings yet

- SandblastingDocument2 pagesSandblastingPeter Antony67% (3)

- Sand Blasting Cabinet Safe Work ProcedureDocument3 pagesSand Blasting Cabinet Safe Work ProcedureGhazi Kallel100% (1)

- 130 Metal-Inert Gas (MIG) WeldingDocument2 pages130 Metal-Inert Gas (MIG) Weldinglara cross100% (1)

- Method Statement For Crack RepairingDocument5 pagesMethod Statement For Crack RepairingZaheer Hussain100% (1)

- MEthdstatemet For GRP Pipe Puddle Flange Installation (Complete)Document13 pagesMEthdstatemet For GRP Pipe Puddle Flange Installation (Complete)Mdubdt100% (1)

- LESB-method Statement For KG ChapDocument4 pagesLESB-method Statement For KG ChapEzuan AdamNo ratings yet

- Guia 1.4.12 N2 Inspeccion de VentanaDocument8 pagesGuia 1.4.12 N2 Inspeccion de Ventanabalmore gironNo ratings yet

- 10 Work On Mud PumpsDocument5 pages10 Work On Mud PumpsdraghiceanuNo ratings yet

- 3.3 Cold Saw Operating ProcedureDocument3 pages3.3 Cold Saw Operating Procedurereza dian humkiNo ratings yet

- 08 Stripping and Waxing floors-JOB PROCEDURE - 2Document2 pages08 Stripping and Waxing floors-JOB PROCEDURE - 2sepri manerson sinagaNo ratings yet

- 08 Stripping and Waxing floors-JOB PROCEDUREDocument2 pages08 Stripping and Waxing floors-JOB PROCEDUREsoubhagya100% (1)

- 08 Stripping and Waxing Floors-JOB PROCEDURE - 2Document2 pages08 Stripping and Waxing Floors-JOB PROCEDURE - 2sepri manerson sinagaNo ratings yet

- Working Proceduer Soil Test Lot 328 PT (Version 2)Document1 pageWorking Proceduer Soil Test Lot 328 PT (Version 2)Widyardi SaputraNo ratings yet

- Module 2 Dozer OperationDocument16 pagesModule 2 Dozer OperationBaigalBaldandorjNo ratings yet

- PTS BarandasDocument8 pagesPTS Barandasjuan bastiasNo ratings yet

- Meta Blasting and PaintingDocument12 pagesMeta Blasting and Painting4gen_7No ratings yet

- 97 Glass Removal and Replacement-JOB PROCEDUREDocument2 pages97 Glass Removal and Replacement-JOB PROCEDURESarfarazNo ratings yet

- Interal Safety Audit . Shutdown Date: - / - / - Department: FM MechanicalDocument3 pagesInteral Safety Audit . Shutdown Date: - / - / - Department: FM MechanicalchandankrdumkaNo ratings yet

- Aros Site01Document24 pagesAros Site01R. Ayyanuperumal AyyanuperumalNo ratings yet

- Procedure For SandblastingDocument1 pageProcedure For SandblastingAlvene TagocNo ratings yet

- Polyglass VEHA - Surface Prep and Application ProcedureDocument6 pagesPolyglass VEHA - Surface Prep and Application Proceduresyed jeelani ahmedNo ratings yet

- Site Adhesion Test One Ayala Nov 19 2020 With PicsDocument5 pagesSite Adhesion Test One Ayala Nov 19 2020 With PicsMark TatonNo ratings yet

- Short Notes & MCQ On Metal Mine RegulationsDocument54 pagesShort Notes & MCQ On Metal Mine RegulationsSatyaraj KasireddiNo ratings yet

- SMP 19Document2 pagesSMP 19kishorekumarvNo ratings yet

- Concrete by Concrete Boom Placer JSA HSE ProfessionalsDocument2 pagesConcrete by Concrete Boom Placer JSA HSE ProfessionalsSamadov 13No ratings yet

- B Test SKD17 - GBDocument4 pagesB Test SKD17 - GBBruno de Almeida Gonçalves Gramado ParksNo ratings yet

- Waterproofing: Guide Book (DRAFT-R0)Document10 pagesWaterproofing: Guide Book (DRAFT-R0)Halaswamy SiddalingappaNo ratings yet

- Type 678 - Running Instructions: 1. EquipmentDocument18 pagesType 678 - Running Instructions: 1. EquipmentFabian MontoyaNo ratings yet

- B.tech Major Project Review 1Document17 pagesB.tech Major Project Review 1AMARDEEP SAHNo ratings yet

- C.1.3 Method Statement For Sand BlastingDocument7 pagesC.1.3 Method Statement For Sand Blastingagbon johnNo ratings yet

- JSA-excavation & RefillDocument7 pagesJSA-excavation & RefillArnfel Jamil Cabil100% (1)

- 2005 - 2009 Water Leak RepairsDocument5 pages2005 - 2009 Water Leak RepairsJuan CandiaNo ratings yet

- VW Eos Maintenance PDFDocument75 pagesVW Eos Maintenance PDFNick P100% (1)

- 2008 Nissan Teana J32 Service Manual-GWDocument26 pages2008 Nissan Teana J32 Service Manual-GWMrihexNo ratings yet

- Kleemann Handbook DRAFTDocument59 pagesKleemann Handbook DRAFTAleksandar RankovicNo ratings yet

- Ice Room Frost SB TTI Revised AB 5.20.19 20190604Document17 pagesIce Room Frost SB TTI Revised AB 5.20.19 20190604EMMANUEL MAYNo ratings yet

- MOS-VCM Tank TK 5102B Bottom Plate Blasting (Soil Side) at FSN Yard.Document7 pagesMOS-VCM Tank TK 5102B Bottom Plate Blasting (Soil Side) at FSN Yard.Rehanul HaqueNo ratings yet

- MOS-VCM Tank TK 5102B Bottom Plate Blasting (Soil Side) at FSN Yard.Document7 pagesMOS-VCM Tank TK 5102B Bottom Plate Blasting (Soil Side) at FSN Yard.Rehanul HaqueNo ratings yet

- Safe Operational Procedure: Excavator: Personal Protective Equipment (PPE)Document2 pagesSafe Operational Procedure: Excavator: Personal Protective Equipment (PPE)JamesNo ratings yet

- Method Statement 09.05.2019Document6 pagesMethod Statement 09.05.2019Shashank GinjupalliNo ratings yet

- Surface Treatment ProcedureDocument5 pagesSurface Treatment Proceduredeepan85No ratings yet

- JSA ExcavationDocument6 pagesJSA Excavationkermech21607100% (1)

- SWP - Excavator Safety LockoutDocument3 pagesSWP - Excavator Safety LockoutTushiro K. HimuraNo ratings yet

- Automatic SandblastersDocument34 pagesAutomatic SandblastersNjat HakimNo ratings yet

- 03 Washing Floors With An Auto-scrubber-JOB PROCEDUREDocument2 pages03 Washing Floors With An Auto-scrubber-JOB PROCEDUREmarvinNo ratings yet

- Inspection Spark TestingDocument4 pagesInspection Spark TestingAshish PattanaikNo ratings yet

- Caseway SC-94 TDSDocument2 pagesCaseway SC-94 TDSasinghNo ratings yet

- Embraer SatenaDocument5 pagesEmbraer SatenaOz TamayoNo ratings yet

- HAAP-JSA-SA-P&SCM Rev1.1Document11 pagesHAAP-JSA-SA-P&SCM Rev1.1Mubasshir WarsiNo ratings yet

- 143 - WaterleaksDocument11 pages143 - WaterleaksGedas GvildysNo ratings yet

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Tuv Rheinland Reference Case Risk Analysis Risk Evaluation Petrobrazi Refinery enDocument2 pagesTuv Rheinland Reference Case Risk Analysis Risk Evaluation Petrobrazi Refinery enAbdul RasyidNo ratings yet

- Curriculum Vitae: Personal DataDocument2 pagesCurriculum Vitae: Personal DataAbdul RasyidNo ratings yet

- Megans LawDocument1 pageMegans LawAbdul RasyidNo ratings yet

- Lampiran OverallDocument2 pagesLampiran OverallAbdul RasyidNo ratings yet

- Strilube 3125 TDSDocument2 pagesStrilube 3125 TDSchetanNo ratings yet

- 3 Mid PointDocument3 pages3 Mid PointIftitah TazkiyahNo ratings yet

- Journal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten VansteenkisteDocument17 pagesJournal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten Vansteenkisterisa agustinaNo ratings yet

- ELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsDocument51 pagesELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsItsClarence100% (2)

- Practice Problems 2012Document5 pagesPractice Problems 2012Anonymous Fj3YPHNo ratings yet

- Scope of WorkDocument2 pagesScope of WorkRameshbabu PeramNo ratings yet

- Therbligs Are 18 Kinds of Elemental Motions Used in The Study of Motion Economy in The WorkplaceDocument2 pagesTherbligs Are 18 Kinds of Elemental Motions Used in The Study of Motion Economy in The WorkplaceManonmani Mani100% (2)

- Methodist Dallas Medical Center ExpansionDocument6 pagesMethodist Dallas Medical Center ExpansionrappletonNo ratings yet

- C32400 PDFDocument76 pagesC32400 PDFjeffer rojasNo ratings yet

- Traulsen RLT - ALT Freezer DUTDocument2 pagesTraulsen RLT - ALT Freezer DUTwsfc-ebayNo ratings yet

- Petron Plustm Formula 7 Diesel Engine ConditionerDocument2 pagesPetron Plustm Formula 7 Diesel Engine ConditionerwellblablablaNo ratings yet

- Celebrating The Life Of: Arthur Kinyanjui KimaniDocument32 pagesCelebrating The Life Of: Arthur Kinyanjui KimaniKinuthia MathewNo ratings yet

- Fungi: Galactomannan and 1,3-β - Glucan Testing for the Diagnosis of Invasive AspergillosisDocument8 pagesFungi: Galactomannan and 1,3-β - Glucan Testing for the Diagnosis of Invasive AspergillosisntnquynhproNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance and SupplierDocument9 pagesSafety Data Sheet: Section 1: Identification of The Substance and Supplier12030440No ratings yet

- P3-F Grammar Revision For MidyearDocument10 pagesP3-F Grammar Revision For MidyearnewtonelifNo ratings yet

- Neck ExercisesDocument8 pagesNeck ExercisesAnthony Dinicolantonio100% (1)

- SR710 Tunnel Systems ReportDocument138 pagesSR710 Tunnel Systems ReportseriouscallerzonlyNo ratings yet

- Nursing TheoriesDocument198 pagesNursing TheoriesSamba SukanyaNo ratings yet

- Bulleh Shah's Poems ExplanationDocument4 pagesBulleh Shah's Poems Explanationmmuhammadwaleed786No ratings yet

- Sheep Diseases - The Farmers Guide - 2nd Edition - July 2015Document84 pagesSheep Diseases - The Farmers Guide - 2nd Edition - July 2015Raghu NathaNo ratings yet

- Drug Interaction TableDocument3 pagesDrug Interaction TableJason PattersonNo ratings yet

- MAKSHIKADocument5 pagesMAKSHIKAMSKCNo ratings yet

- Principles Practices and Pragmatics New Models of Coteaching Friend and CookDocument33 pagesPrinciples Practices and Pragmatics New Models of Coteaching Friend and CookEFL Classroom 2.0100% (1)

- Obsessive Love - WikipediaDocument3 pagesObsessive Love - WikipediaIslam AhmedNo ratings yet

- Homeopathic Remedies For 'Flu - Flow ChartDocument1 pageHomeopathic Remedies For 'Flu - Flow Chartisadore97% (32)

- Criminal Law 2008 Zone B PaperDocument5 pagesCriminal Law 2008 Zone B Paperశ్రీ లత Sri Lata100% (1)

- January 2020Document64 pagesJanuary 2020Eric Santiago100% (1)

- Zamil Product Brochure PDFDocument30 pagesZamil Product Brochure PDFZameer KhanNo ratings yet