Professional Documents

Culture Documents

Handling Procedure Electrostatic Discharge Sensitive Devices (ESD)

Handling Procedure Electrostatic Discharge Sensitive Devices (ESD)

Uploaded by

BALAJIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handling Procedure Electrostatic Discharge Sensitive Devices (ESD)

Handling Procedure Electrostatic Discharge Sensitive Devices (ESD)

Uploaded by

BALAJICopyright:

Available Formats

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the

Company with the authority to grant

such permission.

Handling Procedure

Electrostatic Discharge Sensitive Devices

(ESD)

Mo/Yr

Revisions Rev:

Letter E.O. Number - Description Date

Used On Contract#:

Your Company Name

Prepared By: Date

Your Dept: Date

Your Dept: Date YOUR PROCEDURE NAME

Your Dept: Date Your Procedure #

Your Dept: Date Size: A CAGE: Your Form # (mo.yr) 1 of 11

Your Company Logo

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

1.0 Purpose..............................................................................................................................................................................................3

2.0 Scope..................................................................................................................................................................................................3

3.0 Discussion..........................................................................................................................................................................................3

4.0 Responsibility...................................................................................................................................................................................3

4.1 Personnel..................................................................................................................................................................................3

4.2 Supervisor/Training Requirements...........................................................................................................................................3

4.3 Non-Company Personnel.........................................................................................................................................................4

5.0 Definitions.........................................................................................................................................................................................4

6.0 ESDS Identification..........................................................................................................................................................................5

6.1 ESDS ID requirements.............................................................................................................................................................5

6.2 ESDS Device Designation........................................................................................................................................................6

7.0 ESDS Device Handling Procedures................................................................................................................................................6

7.1 ESDS Device Handling............................................................................................................................................................6

7.2 Receiving Inspection Handling................................................................................................................................................6

7.3 ESDS Device Transportation...................................................................................................................................................7

7.4 Shipment of ESDS Device........................................................................................................................................................7

7.5 Specific Handling Procedures..................................................................................................................................................7

7.6 Low Humidity Operation..........................................................................................................................................................8

8.0 Static Safeguarded Work Station/Zone Requirements.................................................................................................................9

8.1 Static Safeguarded Work Stations............................................................................................................................................9

8.2 ESDS Device Work Zone Requirement.....................................................................................................................................9

9.0 ESDS Work Zone Operations.......................................................................................................................................................10

9.1 Personnel Grounding.............................................................................................................................................................10

9.2 Personnel Apparel..................................................................................................................................................................10

9.3 ESD Shop Coats.....................................................................................................................................................................10

9.4 Prohibited materials...............................................................................................................................................................11

9.5 Paperwork..............................................................................................................................................................................11

9.6 Ionized Air..............................................................................................................................................................................11

9.7 Equipment grounding (Electrical).........................................................................................................................................12

9.8 Hand Tools.............................................................................................................................................................................12

9.9 ESD Shielding Bags...............................................................................................................................................................12

10.0 Work Station and Equipment Calibration..................................................................................................................................12

10.1 Calibration of Work Station...................................................................................................................................................12

10.2 Equipment Checks..................................................................................................................................................................13

11.0 Potential Damage.............................................................................................................................................................................13

Your Company Name REV CAGE DOC#: 2 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

1.0 Purpose

To define minimum requirements for effective electrostatic discharge (ESD) control.

Adherence to this procedure will provide adequate protection for ESD sensitive devices during

handling and storage processes. MIL-STD-1686B and MIL-HDBK-263A provided guidance

for preparing this procedure.

2.0 Scope

This procedure is specifically written for the handling of an ESD sensitive circuit card but may

be applied to any ESD sensitive device included in any process as deemed applicable by the

Responsible Authority (RA).

3.0 Discussion

All processing of an ESD sensitive device or of a subassembly or assembly containing an ESD

sensitive device must be completed with the intent of providing maximum protection against

electrostatic discharge. Even though care must be exercised in the handling of the device,

thought must be given to the actual application of the ESD sensitive device. For instance, a

circuit card could be used in a variety of atmospheric and weather conditions, thus, as long as a

static discharge is not induced, the device should be capable of surviving in any atmosphere.

4.0 Responsibility

4.1 Personnel

All personnel who handle ESD sensitive parts and assemblies must be trained and certified in

ESDS handling techniques. Training and certification should be updated on an "as needed"

basis. Each person should handle and protect the components according to this procedure.

Each person is responsible for the testing and maintenance of their Static Safe Work station.

This will include actual operation by testing to insure specification compliance. Application of

this procedure begins by receiving an ESDS item and is inclusive of all handling and storage

operations involving ESDS components through shipment of the assembly.

4.2 Supervisor/Training Requirements

All lead operators, supervisors, or other personnel who directly oversee or manage individuals

who handle ESD sensitive parts and/or assemblies shall have ESD training. They will also

ensure that ESD training is provided (for employees) and that a system is established for proper

handling and storage of ESD sensitive components. This is inclusive of maintaining a proper

workstation environment (i.e., handling equipment, tooling, etc.) to ensure minimum ESD

exposure.

Your Company Name REV CAGE DOC#: 3 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

4.3 Non-Company Personnel

Customers, Government representatives, or other non-Company personnel (i.e., security guards)

who have access to any area within the Company where ESD type components or assemblies

may be present shall have ESD training.

5.0 Definitions

Anti static (Anti-stat) - Unable to drain a charge within a few minutes. Has low enough

resistivity (109 to 1014 ohms/sq) to resist formation of static charge when rubbed, but not capable

of preventing the build up of a voltage along or across the surface. (blue or pink bags, bubble

wrap)

Electrostatic Discharge (ESD) - A transient, or rapid transfer of charge, between bodies at

different electrostatic potentials (voltages), either:

a) caused by direct contact,

b) by arc-over due to the items being close, or

c) induced by an electrostatic field.

Electrostatic Discharge Sensitive (ESDS) - Susceptible to damage or destruction by

electrostatic discharge, usually from melting of a microscopic segment of semiconductive

material.

ESDS Device (component, part) - Any component whose structure incorporates: (a) very thin

insulating layers between conductive materials, (b) very small junction areas, or (c) very thin

layers of a conductive material or any combination of these structures. This is inclusive of any

assembly containing such devices, although once installed in a container (or other appropriate

Faraday cage) slightly different handling procedures may be used.

ESDS Device Zone - An identified zone where there are exposed ESDS devices present.

A high level of static awareness should be maintained.

Electrostatic Field - An electric field developed between two items at different voltages

Faraday Cage - a container in which ESDS devices are no longer considered sensitive

Insulator - Able to generate an electrostatic potential on its surface. Because of its high

resistive nature it requires very long periods of time to lose its charge. Resistivity for this

material is greater than 1014 ohms/sq.

Resistivity (Surface) - A measure of resistance across the surface of a conductive mat, tabletop,

floor, etc. The measurement is made in units of ohms/sq. What this means is for every square

piece of conductive material the electrical resistance from along one side to the opposite side

will measure the same no matter how big the square piece is, this the value of ohms/sq.

The lower the value of resistivity, the easier and quicker it is to drain away the static charge.

Static Conductive - Able to drain an electrostatic charge very rapidly, the range of resistivity

for this material is less than 105ohms/sq. Because of its low resistivity it has a high current

carrying capacity.

Static Dissipative - Able to drain a charge in a few seconds to a few minutes. The range of

resistivity for this material is 105 ohms to 1015 ohms/sq. (i.e., most ESD mats)

Your Company Name REV CAGE DOC#: 4 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

Static Protective - Materials characterized by static-conductive and antistatic properties,

provides shielding from electrostatic fields, electrostatic discharge, and from frictional charge

generation.

Static Safe - This is any material with resistivity less than 1014 ohms/sq. characterized by its

ability to not generate a charge, and (except for antistatic, above) can remove static charge from

conductive items (including employees). It creates an environment that has a lower risk of

charge build up within a Static Safe Perimeter. This is a general term including antistatic, static

dissipative, static conductive, static shielding, and static protective.

Static Safe Perimeter - A radius of 12 inches around an ESDS device that shall not have an

electric field that exceeds ±100 volts, as measured with an ESD field meter.

Static Shielding - Able to shield the product from direct contact with electrostatic discharge,

and from breakdowns caused by a near electrostatic field. Shields are conductive or have a

conductive layer buried inside.

Static Table Mat - A flexible work surface composed of vinyl or rubber with an added

component to allow static to drain from its surface to ground via a connected ground cord.

There are two styles of mats used at Static Safeguarded Work Stations:

a) Multilayered - with conductive middle layer, a dissipating top layer, and an insulating (or

dissipating in some models) bottom layer.

b) Single layered - Homogeneous - No conductive middle layer, rather the entire mat is

uniformly resistive.

6.0 ESDS Identification

The remainder of this document is as comprehensive as

the above content but has been truncated for demo.

6.1 ESDS ID requirements

All ESDS devices or assemblies containing ESDS components must be readily identified and

… as necessary:

a) …

b) …

c) …

d) …

e) …

6.2 ESDS Device Designation

An ESDS device or component may reach a point during production where the assembled

components are no longer considered ESD sensitive. This is true when the device is enclosed in

… with the following exceptions:

1-…

Your Company Name REV CAGE DOC#: 5 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

2-…

3-…

Note: Work within the …

7.0 ESDS Device Handling Procedures

7.1 ESDS Device Handling

The handling procedures for ESDS devices have two basic requirements:

1-…

2-…

These requirements are met with daily wrist strap checks and with periodic checks and

monitoring of static safeguarded workstations.

ESDS devices include both discrete components (individual parts) and assemblies having these

components. Special handling procedures will apply to:

-…

-…

-…

7.2 Receiving Inspection Handling

When any item is received that indicates an ESDS device may be present, it shall have …

7.3 ESDS Device Transportation

ESDS devices or assemblies will be transported to the ESD Workstation using the unopened

container that the device was received in. If the device needs to be transported outside the ESD

Workstation area, the device …

7.4 Shipment of ESDS Device

When packaging an ESDS device for return shipment, keep it in the static shielding bag that it

was received in, unless the bag was damaged. Close the bag using staples or other suitable

method. The outside shipping container …

7.5 Specific Handling Procedures

ESDS devices should be kept in contact with a grounded surface. Where grounded surface

contact cannot be maintained, keep the device's contacts shorted together with static conductive

or dissipative material until ready for test, installation, etc. Once ESDS devices have been

installed, …

Before handling ESDS devices, an individual shall …

While handling an ESDS device, always …

Minimize physical handling of an ESDS device. Hold the device …

Your Company Name REV CAGE DOC#: 6 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

Warning: When working where 120 volts or more may be present, always …

7.5.1 The circuit cards used in a container will be kept in the original shipping carton until

needed for inspection, testing, or assembly. The cards may be kept in …

While handling the ESDS device, maintain a static dissipation path for the device and

operator by continuous contact to ground using a grounded wrist strap. When not in

process, the cards shall …

7.6 Low Humidity Operation

When the relative humidity drops below …, the following precautions must be taken:

-…

-…

-…

-…

-…

-…

-…

8.0 Static Safeguarded Work Station/Zone Requirements

8.1 Static Safeguarded Work Stations

Static Safeguarded Work Stations shall include:

-…

-…

-…

Basically, a properly grounded ESD mat with the connections for operator wrist straps along

with …

8.2 ESDS Device Work Zone Requirement

Work zones that will be used for ESDS device processing will consist of the workstation

described in para 8.1 above along with the immediate surrounding area. The immediate

surrounding area is defined as …

The work zone shall include the following requirements:

1) …

2) …

3) …

4) …

5) …

6) …

7) …

8) …

Your Company Name REV CAGE DOC#: 7 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

9.0 ESDS Work Zone Operations

9.1 Personnel Grounding

For processes in which an operator stays at a fixed location and handles an ESDS device, an

electrical connection from operator to work surface (wrist strap to mat ground connection) is

required at all times. The resistance from the operator's body surface to ground shall be …

Warning: When working where 120 volts or more may be present, always …

9.2 Personnel Apparel

Clothing and its movement on the operator is a significant source of static generation during the

handling process. Clothing made of … The following will minimize the static generation

within the Static Safe Perimeter.

-…

-…

-…

-…

9.3 ESD Shop Coats

All personnel working on ESDS devices in an area identified as a Static Safeguarded Work

Station or personnel who will be in the ESD work zone while ESDS devices are present must

wear an ESD shop coat. In order to properly block static fields from clothing, the operator must

…

9.4 Prohibited materials

High static generating materials must not be allowed in the ESD Work Zone when ESDS

devices are exposed. In general, this means that the following items shall be removed from the

work zone …

-…

-…

a) …

b) …

c) …

d) …

e) …

-…

9.5 Paperwork

Paper and wood products with normal humidity conditions (over 30% relative humidity) do not

pose a problem with ESDS devices in the area. These type products absorb water out of the air

and therefore tend not to build up static. As a normal precautionary measure, only paperwork

Your Company Name REV CAGE DOC#: 8 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

needed for the ongoing process will be allowed in the ESD work zone while ESDS devices are

exposed. Do not place an ESDS device on top of …

9.6 Ionized Air

Excessive static charge must be neutralized by providing a flow of ionized air over the affected

work area and equipment when one or more of the following exist:

-…

-…

-…

-…

As a standard rule, an air ionizer will be used to …

9.7 Equipment grounding (Electrical)

All electrical equipment used in the processing of ESDS devices must have a connection

directly to ground unless …

9.8 Hand Tools

All hand tools must be either conductive or dissipative (with the use of dissipative handle

coatings), or …

9.9 ESD Shielding Bags

The standard bag for all ESD protection will be the ESD shielding bag. This bag is dark or

silver tinted, and is slightly see through. Any shielding bag shall be discarded if found to be

damaged, has …

10.0 Work Station and Equipment Calibration

Equipment required:

-…

-…

-…

-…

All equipment shall be …

10.1 Calibration of Work Station

Place the 5# weight in the center of the ESD mat. Measure the resistance, with the resistance

meter, from the weight to the mat's grounding connector. The value should be less than …

For the next measurement the operator must…

The static field meter shall be pointed at the mat. The meter shall be an inch or two from the

mat according to the meter's instructions. Turn on the meter and verify a zero volt reading.

With the meter still on, point the meter at the different objects within the work station area,

paying particular attention to … If a voltage of more than ±100 volts is found, turn the meter

Your Company Name REV CAGE DOC#: 9 of 10

Your Procedure #

This document may not be disclosed or reproduced in whole or in part without prior written permission from a representative of the Company with the authority to grant

such permission.

off and repeat this procedure for that one item. If the second reading is still over ±100 volts,

and an air ionizer is located at the workstation, turn the meter off, turn the ionizer on and wait

for 30 seconds. Turn off the ionizer since this can affect the meter readings, repeat the

measurement, if the item is still over ±100 volts it must be …

10.2 Equipment Checks

Using the ohmmeter or DMM, measure the resistance from the tip of the soldering iron to the

ground prong of the power plug. The value must be less than …

11.0 Potential Damage

If an ESDS device is exposed to a significant field or discharge, the device might fail

immediately or have a latent failure. In the latter case, the device may function normally but for

a shorter lifetime.

If an ESDS device is handled by an ungrounded person, that person will hold the device in one

hand and place the other hand on a conductive mat for …

If an ESDS item has been exposed to a possibly damaging ESD field or environment, bring it

…

Your Company Name REV CAGE DOC#: 10 of 10

Your Procedure #

You might also like

- Multi V 2 Trouble Shooting Guide BookDocument173 pagesMulti V 2 Trouble Shooting Guide Booktafadzwa simbi100% (2)

- Method Statement Installation of Duct BankDocument63 pagesMethod Statement Installation of Duct BankGerry Dwi Putra100% (2)

- Equipment Sizing Criteria TDEDocument32 pagesEquipment Sizing Criteria TDEEngr. Anees Ahmad100% (1)

- Technical Specification For TankDocument19 pagesTechnical Specification For Tankhelard68100% (1)

- Electronic Signatures Management SOP SampleDocument10 pagesElectronic Signatures Management SOP SampleAnton Mymrikov0% (2)

- Form 8Document1 pageForm 8BALAJI100% (1)

- Crisis Management Log: Name: Position: Crisis Situation: Time Started: - Time CompletedDocument1 pageCrisis Management Log: Name: Position: Crisis Situation: Time Started: - Time CompletedBALAJINo ratings yet

- Sop Sheet Metal Shear Foot OperatedDocument2 pagesSop Sheet Metal Shear Foot OperatedBALAJI100% (1)

- Tip: To Quickly Find Your Search Term On This Page, Press CTRL+F or - F (Mac) and Use The Find BarDocument34 pagesTip: To Quickly Find Your Search Term On This Page, Press CTRL+F or - F (Mac) and Use The Find BarBALAJINo ratings yet

- MSDS Coffee PDFDocument3 pagesMSDS Coffee PDFBALAJI100% (2)

- Working Principle of Vibration SensorDocument1 pageWorking Principle of Vibration Sensorsdf5er4633% (3)

- Corrective Action Plan 111 399Document3 pagesCorrective Action Plan 111 399BALAJINo ratings yet

- Lab Preparing Chem Stds 80 74 DemoDocument17 pagesLab Preparing Chem Stds 80 74 DemoBALAJI100% (1)

- R10 - MK700192 - CI110E Siemens Generator InspectionDocument6 pagesR10 - MK700192 - CI110E Siemens Generator InspectionSalmanEjazNo ratings yet

- R10 - MK700192 - CI100E Generator IR Measurement of StatorDocument7 pagesR10 - MK700192 - CI100E Generator IR Measurement of StatorSalmanEjazNo ratings yet

- Passive Fire Protection of Structures, Cables and Equipment: Construction SpecificationDocument15 pagesPassive Fire Protection of Structures, Cables and Equipment: Construction SpecificationMartinAlexisGonzálezVidalNo ratings yet

- 00251034BFPT85210 Cdfe00 11 PDFDocument11 pages00251034BFPT85210 Cdfe00 11 PDFcrNo ratings yet

- Zero Acceptance Number Sampling Plan 57 372 DemoDocument5 pagesZero Acceptance Number Sampling Plan 57 372 DemoBALAJINo ratings yet

- Zeml-2010b Eng LC Oqp QaDocument97 pagesZeml-2010b Eng LC Oqp QaAchmad AkbarNo ratings yet

- 00250600dest4207s Exco00 15Document12 pages00250600dest4207s Exco00 15Mohammed HijaziNo ratings yet

- Services Rig Survey ReportDocument3 pagesServices Rig Survey ReportKuOneMohdAzrulNo ratings yet

- Central Laundry - Potable Water Plan and Isometric Views: Onshore PlantDocument1 pageCentral Laundry - Potable Water Plan and Isometric Views: Onshore PlantUtkucan KILIÇNo ratings yet

- Technical Spec EVC Pump - R0Document18 pagesTechnical Spec EVC Pump - R0AyahKenzie100% (1)

- 30a100dbqb23060 - Exde00 - 65 - Quality Control Plan For Electrical Installation WorksDocument68 pages30a100dbqb23060 - Exde00 - 65 - Quality Control Plan For Electrical Installation Workssamuel madisonNo ratings yet

- Drywall Work Installatin Method StatementDocument10 pagesDrywall Work Installatin Method Statementtumelo makgabutlaneNo ratings yet

- EC-B-54.00-01a: Mechanical Commissioning of Operating SystemsDocument50 pagesEC-B-54.00-01a: Mechanical Commissioning of Operating SystemsjaimemecaNo ratings yet

- Paew Aiec 1 2017 PQP DraftDocument45 pagesPaew Aiec 1 2017 PQP DraftPopescu OctavianNo ratings yet

- Acceptance Test Procedure: Add To CartDocument6 pagesAcceptance Test Procedure: Add To CartBALAJINo ratings yet

- Maamoura and Baraka Development Project: Ex-Co 0 16/03/2010 Final Issue GJ HS HTDocument7 pagesMaamoura and Baraka Development Project: Ex-Co 0 16/03/2010 Final Issue GJ HS HTAHMED AMIRANo ratings yet

- Ma'Aden Engineering Manual: Piping MaterialsDocument21 pagesMa'Aden Engineering Manual: Piping Materialssameer ejaazNo ratings yet

- EMX 00 E BAU - en DO 050-A En-Lightning Protection General ConceptDocument29 pagesEMX 00 E BAU - en DO 050-A En-Lightning Protection General ConceptRichardLemusNo ratings yet

- Waste Management Plan: A-18290 Supply and Installation of Intelligent Access Control SystemDocument16 pagesWaste Management Plan: A-18290 Supply and Installation of Intelligent Access Control Systemsherazk330No ratings yet

- Business Case Template-1Document21 pagesBusiness Case Template-1earl58100% (2)

- CMS 80294 en V2Document20 pagesCMS 80294 en V2vijayNo ratings yet

- ControlledDocument6 pagesControlledvg_vvgNo ratings yet

- Fdocuments - in HRSG Erection Manual Vendor Sur V 99ha 191003raDocument104 pagesFdocuments - in HRSG Erection Manual Vendor Sur V 99ha 191003ramr proposal85No ratings yet

- S-000-1654-0250v - A - 0010 Hs S e Ins TR U CT Ion S To Su B-C On Trac T OrsDocument59 pagesS-000-1654-0250v - A - 0010 Hs S e Ins TR U CT Ion S To Su B-C On Trac T OrsjenniferNo ratings yet

- 6 RC2 30 Vess JSS 95 000 0610Document16 pages6 RC2 30 Vess JSS 95 000 0610Shaaban NoamanNo ratings yet

- Investigation Report 05.12.2017 Lifting Operation Failure During Tower Erection Investigatigations by Arber DoganiDocument35 pagesInvestigation Report 05.12.2017 Lifting Operation Failure During Tower Erection Investigatigations by Arber DoganiArber DoganiNo ratings yet

- Ofis 23059 Qa Pro NDT 00 01 RT ProcedureDocument97 pagesOfis 23059 Qa Pro NDT 00 01 RT ProcedureanandNo ratings yet

- Reimbursment Form For ExpenseDocument1 pageReimbursment Form For ExpenseForenTec Engineers RanchiNo ratings yet

- UV IQP ZEMA-0004B Rev310Document29 pagesUV IQP ZEMA-0004B Rev310api-19973846No ratings yet

- Engineering 0001 Standard For General Electrical Design - OnshoreDocument35 pagesEngineering 0001 Standard For General Electrical Design - Onshoremarin cristianNo ratings yet

- MOP For NULL-0 Encryption in Cisco MMEDocument12 pagesMOP For NULL-0 Encryption in Cisco MMEkdmu123No ratings yet

- Maamoura and Baraka Development Project: Flare Rack Foundation Calculation NoteDocument17 pagesMaamoura and Baraka Development Project: Flare Rack Foundation Calculation NoteAHMED AMIRANo ratings yet

- 5 RC2 30 Vess JSD 95 000 0400Document15 pages5 RC2 30 Vess JSD 95 000 0400Shaaban Noaman100% (1)

- 2.9a Plant Equipment - Bulldozer ChecklistDocument2 pages2.9a Plant Equipment - Bulldozer ChecklistNoel OlivarNo ratings yet

- Contractor Information - CIDocument2 pagesContractor Information - CIRathnayakaNo ratings yet

- 2.9c Plant Equipment - Bobcat ChecklistDocument2 pages2.9c Plant Equipment - Bobcat ChecklistNoel OlivarNo ratings yet

- 250600DWQRD0087 Exde01 11Document11 pages250600DWQRD0087 Exde01 11Mohammed HijaziNo ratings yet

- Prediction of CO2 Corrosion Rate TZK Gas Line Rev0Document14 pagesPrediction of CO2 Corrosion Rate TZK Gas Line Rev0Mohamed KAICH100% (1)

- Reference Calculation Structure HarmonicsDocument40 pagesReference Calculation Structure HarmonicsBALASUBRAMANIAM MEGHANADHNo ratings yet

- EMX - 00 - 008b - 007 - TP - 001-A - En-Grid CodeTest Procedure Plant CapabilityDocument56 pagesEMX - 00 - 008b - 007 - TP - 001-A - En-Grid CodeTest Procedure Plant CapabilityRichardLemusNo ratings yet

- Contractors Registration Board: Application Form For First Registration As Contractors By-Law 3 (1) (A)Document17 pagesContractors Registration Board: Application Form For First Registration As Contractors By-Law 3 (1) (A)Hubert MubofuNo ratings yet

- Method Statement For Concrete Repair Works.Document9 pagesMethod Statement For Concrete Repair Works.Munaku TafadzwaNo ratings yet

- D-10A-B Vessel RequisitionDocument2 pagesD-10A-B Vessel Requisitionjajangsuryadilaga76No ratings yet

- PL-SPE-1-13-00 Spec Riser Coat RevA2Document16 pagesPL-SPE-1-13-00 Spec Riser Coat RevA2RamNo ratings yet

- CTR012036 - MSA - SPECTRUM ELECTRICAL INDUSTRIES LIMITED (T40000652) - CompilsignedDocument58 pagesCTR012036 - MSA - SPECTRUM ELECTRICAL INDUSTRIES LIMITED (T40000652) - CompilsignedAbhinav GuptaNo ratings yet

- Observaciones Preventivas de SeguridadDocument28 pagesObservaciones Preventivas de SeguridadRocoDrillo 315No ratings yet

- Certification Program PlanDocument18 pagesCertification Program PlanFendy FendersonNo ratings yet

- 3225.XX - dfrv.10XXX - 00 - P&ID Desktop Reveiw ReportDocument74 pages3225.XX - dfrv.10XXX - 00 - P&ID Desktop Reveiw ReportMorgan SidesoNo ratings yet

- Sow of New BuildingDocument77 pagesSow of New Buildingغزوان العبداللهNo ratings yet

- SHE 5.0.57 PER 13 (1) (B) Pressure Equipment InspectorDocument1 pageSHE 5.0.57 PER 13 (1) (B) Pressure Equipment InspectorVicky LandmanNo ratings yet

- S-000-1654-0110v - A - 0010 Safety Task Analysis Risk TalkDocument10 pagesS-000-1654-0110v - A - 0010 Safety Task Analysis Risk Talkle huyNo ratings yet

- DWA-00-HS-MS - 0002 - Rev000 - MS&RA For MV FO Cable Laying, Jointing, Termination and TestingDocument22 pagesDWA-00-HS-MS - 0002 - Rev000 - MS&RA For MV FO Cable Laying, Jointing, Termination and TestingAnandu AshokanNo ratings yet

- SAIPEM MS Grounding & Lightning ProtectionDocument20 pagesSAIPEM MS Grounding & Lightning Protectionsyam prasad100% (1)

- Variables Influencing the Severity of IPO Underpricing: An Empirical Analysis of the German MarketFrom EverandVariables Influencing the Severity of IPO Underpricing: An Empirical Analysis of the German MarketNo ratings yet

- Batteries Handling Disposal ProcedureDocument17 pagesBatteries Handling Disposal ProcedureBALAJINo ratings yet

- Certificate TC 5750 PDFDocument1 pageCertificate TC 5750 PDFBALAJINo ratings yet

- FMEA ExampleDocument4 pagesFMEA ExampleBALAJINo ratings yet

- Template ProcedureDocument3 pagesTemplate ProcedureBALAJINo ratings yet

- GHTF Sg3 n99 8 Guidance On Quality 990629Document48 pagesGHTF Sg3 n99 8 Guidance On Quality 990629BALAJINo ratings yet

- Emirates Authority For Standardization & Metrology (ESMA) : UAE Draft Standard (DS1)Document8 pagesEmirates Authority For Standardization & Metrology (ESMA) : UAE Draft Standard (DS1)BALAJINo ratings yet

- Hazardous Waste Display BoardDocument3 pagesHazardous Waste Display BoardBALAJINo ratings yet

- Mandatory ProceduresDocument2 pagesMandatory ProceduresBALAJINo ratings yet

- 2.7 - Generic Confidentiality Agreement I - v1Document1 page2.7 - Generic Confidentiality Agreement I - v1BALAJINo ratings yet

- W304 What Is The Decision RuleDocument59 pagesW304 What Is The Decision RuleBALAJINo ratings yet

- Misc - Multiple Choice Quiz TemplateDocument11 pagesMisc - Multiple Choice Quiz TemplateBALAJINo ratings yet

- FMEA ExampleDocument4 pagesFMEA ExampleBALAJINo ratings yet

- Nescafe in CupDocument5 pagesNescafe in CupBALAJINo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument26 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksBALAJINo ratings yet

- Intercontinental Coffee Trading Inc.: 110 West A Street, Suite 110 San Diego, Ca 92101Document2 pagesIntercontinental Coffee Trading Inc.: 110 West A Street, Suite 110 San Diego, Ca 92101BALAJINo ratings yet

- Instant Coffee Granules Specification Summary: Coagulase Positive StaphylococciDocument4 pagesInstant Coffee Granules Specification Summary: Coagulase Positive StaphylococciBALAJINo ratings yet

- Ambient StorageDocument1 pageAmbient StorageBALAJINo ratings yet

- Draft Notice Comments Pesticides MRL 08-08-2017Document46 pagesDraft Notice Comments Pesticides MRL 08-08-2017BALAJINo ratings yet

- 3323Document222 pages3323BALAJINo ratings yet

- Myhaccp Hazard Factsheet: Category: MicrobiologicalDocument1 pageMyhaccp Hazard Factsheet: Category: MicrobiologicalBALAJINo ratings yet

- Edc 3Document10 pagesEdc 329viswa12No ratings yet

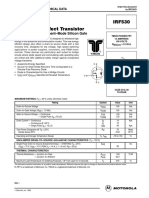

- Irf530 DDocument8 pagesIrf530 DnooneezNo ratings yet

- Department of Electronics and Communication Engineering Faculty of Engineering and Technology, SRM UniversityDocument6 pagesDepartment of Electronics and Communication Engineering Faculty of Engineering and Technology, SRM UniversityShubham Kumar GuptaNo ratings yet

- VIGIDocument1 pageVIGIBambang Suwito WibowoNo ratings yet

- .Asus X45a RG PDFDocument5 pages.Asus X45a RG PDFNgipik Komp Pati50% (2)

- Bobina DanfossDocument16 pagesBobina DanfossHenrique TnkaNo ratings yet

- Pioneer dvr-540h-s 640h-s rrv3453 (ET)Document13 pagesPioneer dvr-540h-s 640h-s rrv3453 (ET)AXO2000No ratings yet

- Mémoire PDFDocument55 pagesMémoire PDFAbouZakaria100% (1)

- Light P2 Questions 5054Document42 pagesLight P2 Questions 5054Muhammad FaisalNo ratings yet

- Available Fault Current Calculation: E I kVA X 1000 Trans. FLADocument7 pagesAvailable Fault Current Calculation: E I kVA X 1000 Trans. FLAAdil AberkanNo ratings yet

- A-9150 Manual enDocument32 pagesA-9150 Manual enVojtkó JózsefNo ratings yet

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranNo ratings yet

- Twido Twdlmda20drt Manual EspañolDocument10 pagesTwido Twdlmda20drt Manual Españoljoel_garcia_leeNo ratings yet

- SPH4U Sample Test - Electric & Magnetic Fields+KeyDocument13 pagesSPH4U Sample Test - Electric & Magnetic Fields+KeyssshhawnNo ratings yet

- HiFi Choice - Audia Flight FL Three SDocument2 pagesHiFi Choice - Audia Flight FL Three SJohnNo ratings yet

- PrimerCube MotherBoard V10 v2 (Bill of Materials)Document1 pagePrimerCube MotherBoard V10 v2 (Bill of Materials)PRED4T0R85No ratings yet

- Check Glow Plug SystemDocument5 pagesCheck Glow Plug SystemNicoletaNo ratings yet

- Cold Load Pick-Up - Theory and Industry PracticesDocument30 pagesCold Load Pick-Up - Theory and Industry PracticesamirrezafeyziNo ratings yet

- CMSS 2207: Superior Accelerometer, Side ExitDocument2 pagesCMSS 2207: Superior Accelerometer, Side ExitMuhammad luthfi fadilahNo ratings yet

- Clubdediagramas - Invertec V270 ServDocument70 pagesClubdediagramas - Invertec V270 ServGilberto Marcano100% (1)

- Dual Source Energy Meter EM 6438Document4 pagesDual Source Energy Meter EM 6438jaikolangaraparambilNo ratings yet

- MQ07 enDocument22 pagesMQ07 enmabruk12No ratings yet

- Electrical Power Solution and Solar Power System (1) (Autosaved)Document71 pagesElectrical Power Solution and Solar Power System (1) (Autosaved)tin mg mgNo ratings yet

- Laser NotesDocument39 pagesLaser NotesAvinashNo ratings yet

- B1 105 2012 PDFDocument11 pagesB1 105 2012 PDFZeckrey JikurunNo ratings yet

- Module Data Sheet: Valve Position Module (Amd)Document10 pagesModule Data Sheet: Valve Position Module (Amd)Wasim AhmedNo ratings yet

- Electromagnetic Wave TheoryDocument75 pagesElectromagnetic Wave TheoryLen Cardona Bagunas100% (1)

- Superlux HD681 EVODocument14 pagesSuperlux HD681 EVOGeorge TschulevinhoNo ratings yet