Professional Documents

Culture Documents

Charge Cal

Charge Cal

Uploaded by

Ankit Garach0 ratings0% found this document useful (0 votes)

36 views1 pageThe document describes two methods for calculating amounts needed for alloying and furnace performance. It provides an example calculation for determining the amount of carbon needed when the desired and obtained carbon contents and purity are given. It also gives an example calculation for determining a furnace's thermal efficiency based on the stock weight, specific heat, initial and final temperatures, fuel calorific value and consumption.

Original Description:

charge calculation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes two methods for calculating amounts needed for alloying and furnace performance. It provides an example calculation for determining the amount of carbon needed when the desired and obtained carbon contents and purity are given. It also gives an example calculation for determining a furnace's thermal efficiency based on the stock weight, specific heat, initial and final temperatures, fuel calorific value and consumption.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

36 views1 pageCharge Cal

Charge Cal

Uploaded by

Ankit GarachThe document describes two methods for calculating amounts needed for alloying and furnace performance. It provides an example calculation for determining the amount of carbon needed when the desired and obtained carbon contents and purity are given. It also gives an example calculation for determining a furnace's thermal efficiency based on the stock weight, specific heat, initial and final temperatures, fuel calorific value and consumption.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

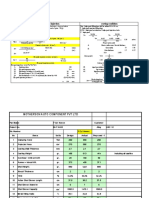

ALLOYING: CHARGE CALCULATION

( )

AMOUNT TO BE ADDED =

Example: Carbon content desired = 2.6%, Carbon content obtained= 2.1%,

Purity of carbon = 98%, total weight of cast iron = 2000kg

Solution:

( )

AMOUNT of Carbon =

=

CALCULATING FURNACE PERFORMANCE

Thermal efficiency of furnace =

Heat in the stock = Q = m x Cp (t1 – t2)

Q = Quantity of heat of stock in kCal

m = Weight of the stock in kg

Cp= Mean specific heat of stock in kCal/kg oC

t1 = Final temperature of stock in oC

t2 = Initial temperature of the stock before it enters the furnace in oC

Example

m = Weight of the stock = 6000 kg

Cp= Mean specific heat of stock = 0.12 kCal/kg oC

t1 = Final temperature of stock = 1340 oC

t2 = Initial temperature of the stock = 40 oC

Calorific value of oil = 10000 kCal/kg

Fuel consumption = 368 kg/hr

Solution:

Heat in the stock Q = m x Cp (t1 – t2) = 6000 kg X 0.12 X (1340 – 40)

= 936000 kCal

Efficiency = (heat input / heat consumed) x 100

= [936000 / (368 x 10000)] x 100 = 25.43%

Heat loss = 100% - 25% = 75%

You might also like

- The Perkins Cove Yacht Company CaseDocument9 pagesThe Perkins Cove Yacht Company CaseVSRI1993No ratings yet

- Tipos de Tratamientos PDFDocument1 pageTipos de Tratamientos PDFJose PerezNo ratings yet

- Body ModelDocument145 pagesBody ModelDipika PandaNo ratings yet

- LPDC Flow SimulationDocument5 pagesLPDC Flow SimulationDavid JendraNo ratings yet

- Cost-Benefit AnalysisDocument2 pagesCost-Benefit AnalysisNISREEN WAYANo ratings yet

- Steel and Pipes For Africa Price ListDocument1 pageSteel and Pipes For Africa Price ListLazuardhy Vozika Futur100% (1)

- F A X TSS: Cutting ForceDocument3 pagesF A X TSS: Cutting ForcesachinNo ratings yet

- Ev ThreadDocument1 pageEv ThreadGurjeevAnandNo ratings yet

- Project: TML (Emc) : Part No 1A014117 Customer TMLDocument2 pagesProject: TML (Emc) : Part No 1A014117 Customer TMLShrikant YashNo ratings yet

- TML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeDocument7 pagesTML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeChandrajeet ShelkeNo ratings yet

- Flexible Electronics: Presented by Ashwin.k 4SN14EC704Document16 pagesFlexible Electronics: Presented by Ashwin.k 4SN14EC704Aswin PrEmrajNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- PVC R RateDocument2 pagesPVC R RateKaushal LahotiNo ratings yet

- Rolling & Extrusion Case StudyDocument20 pagesRolling & Extrusion Case StudyMahmoud KassabNo ratings yet

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanNo ratings yet

- RP Tools & Materials PricelistDocument18 pagesRP Tools & Materials PricelistJose Antonio Siñani VilteNo ratings yet

- CostTable Materials 2022Document7 pagesCostTable Materials 2022shaffin jeba shinuNo ratings yet

- GD & T Tolerance Stack UpDocument19 pagesGD & T Tolerance Stack UpHemantNo ratings yet

- Summary-Costing Sheet For Shell & Tube Heat ExchangerDocument19 pagesSummary-Costing Sheet For Shell & Tube Heat ExchangerAnonymous LKi1w1uNo ratings yet

- Cost Estimate For Tricked Out 14 X 14 CabinDocument3 pagesCost Estimate For Tricked Out 14 X 14 CabinAlex Tango FuegoNo ratings yet

- E-Coat Inputs: A) Part InformationDocument5 pagesE-Coat Inputs: A) Part InformationAnjan MalusareNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Foundry Progress (Apr To Sep)Document6 pagesFoundry Progress (Apr To Sep)Junaid MuzafferNo ratings yet

- Iron and Steel Products Update 27mac2014Document13 pagesIron and Steel Products Update 27mac2014mfakhrudNo ratings yet

- Material: NRE Pricing Sheet Quantity CostDocument1 pageMaterial: NRE Pricing Sheet Quantity CostAnonymous VRspXsmNo ratings yet

- Tip Speed Calculation: RPM CalculationDocument13 pagesTip Speed Calculation: RPM CalculationNishant InamdarNo ratings yet

- 110 KG CastingsDocument4 pages110 KG CastingsGurudutta MishraNo ratings yet

- 1.1 1.2 Mechanical Items 1.3 Seal Tanks 1.4 Mechnical Equipments (Pumps +pipe Line + Fittings Etc)Document14 pages1.1 1.2 Mechanical Items 1.3 Seal Tanks 1.4 Mechnical Equipments (Pumps +pipe Line + Fittings Etc)yv singlaNo ratings yet

- GeneralDocument39 pagesGeneralDeerendra KaranthNo ratings yet

- Machining Line Quote-NewDocument1 pageMachining Line Quote-NewJimmyNo ratings yet

- Properties FCD 50Document5 pagesProperties FCD 50dwi Kuntoro100% (1)

- Costing Details of Alf3 EquipmentsDocument4 pagesCosting Details of Alf3 EquipmentsSarah DeanNo ratings yet

- Problems On Cost SheetDocument4 pagesProblems On Cost SheetAnand Dabasara0% (1)

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Basic Heat TreatmentDocument8 pagesBasic Heat TreatmentAnonymous VRspXsmNo ratings yet

- You Enter Information Only in The Shaded CellsDocument9 pagesYou Enter Information Only in The Shaded CellsEmba MadrasNo ratings yet

- Uk / India ISO en Ac-France Germany Italy Uni USA USA Japan Aa / Astm SAE LM0 LM2Document13 pagesUk / India ISO en Ac-France Germany Italy Uni USA USA Japan Aa / Astm SAE LM0 LM2Emba MadrasNo ratings yet

- Far LZ400895Document10 pagesFar LZ400895Soubhagya BeheraNo ratings yet

- Position of Hi Speed Injection Casting ConditionDocument4 pagesPosition of Hi Speed Injection Casting ConditionVishal RajputNo ratings yet

- Relining BP 2008-09 - FinalDocument14 pagesRelining BP 2008-09 - Finalanon-714066100% (2)

- Sample CostDocument6 pagesSample Costnath81No ratings yet

- CSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListDocument1 pageCSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListJosemar PorfirioNo ratings yet

- Stamping Die Solution Overview Updated 01142011Document36 pagesStamping Die Solution Overview Updated 01142011HerberPerazaNo ratings yet

- PCB Cti ValuesDocument4 pagesPCB Cti ValuesmadslayersNo ratings yet

- CostingDocument64 pagesCostingEmba MadrasNo ratings yet

- Unit 3 MCQ MPDocument11 pagesUnit 3 MCQ MPSandip AwaghadeNo ratings yet

- CostTable Fasteners 2022Document17 pagesCostTable Fasteners 2022shaffin jeba shinuNo ratings yet

- 14.72 KL PP FRP TankDocument24 pages14.72 KL PP FRP TankmaheshdgavaliNo ratings yet

- Tailor Welded BlanksDocument52 pagesTailor Welded BlanksYuvaraj YuvarajNo ratings yet

- Commercial VehicleDocument12 pagesCommercial VehicleAsif ShaikhNo ratings yet

- CalculationDocument14 pagesCalculationLipika KanojiaNo ratings yet

- China Manufacturing CalculatorDocument18 pagesChina Manufacturing CalculatorBilal AkramNo ratings yet

- Incremental Forming in Tailor Welded BlanksDocument24 pagesIncremental Forming in Tailor Welded BlanksSitanshu S0% (1)

- Template For Quoting Sheet Metal PartsDocument100 pagesTemplate For Quoting Sheet Metal PartsCarlos RetamozaNo ratings yet

- Design and Analysis of Progressive Tool For An Automobile ComponentDocument9 pagesDesign and Analysis of Progressive Tool For An Automobile ComponentAnna100% (1)

- 2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeDocument1 page2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeKARTICK PRASADNo ratings yet

- 96.rivet Cost Estimation TemplateDocument1 page96.rivet Cost Estimation TemplateVenkateswaran venkateswaranNo ratings yet

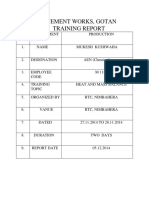

- JK Cement Works, Gotan Training ReportDocument17 pagesJK Cement Works, Gotan Training ReportMohamed Osama RagaaNo ratings yet

- Energy Performance Assessment of FurnacesDocument14 pagesEnergy Performance Assessment of FurnacesCatinca GeorgianaNo ratings yet

- Reactor:: Energy BalanceDocument4 pagesReactor:: Energy BalanceSanjay KumarNo ratings yet

- Technical Monograph 39: A Reliable Base For High Nickel EquipmentDocument8 pagesTechnical Monograph 39: A Reliable Base For High Nickel EquipmentAnkit GarachNo ratings yet

- MMO in ConcreteDocument7 pagesMMO in ConcreteAnkit GarachNo ratings yet

- Deposition of (Ti, Ru) O and (Ti, Ru, Ir) O Oxide Coatings Prepared by Sol-Gel Method On TitaniumDocument7 pagesDeposition of (Ti, Ru) O and (Ti, Ru, Ir) O Oxide Coatings Prepared by Sol-Gel Method On TitaniumAnkit GarachNo ratings yet

- AcademicCalender11 12Document1 pageAcademicCalender11 12Ankit GarachNo ratings yet

- CP ManualDocument48 pagesCP ManualFaddy Faris100% (7)