Professional Documents

Culture Documents

(Pilot/ Ignitor Assembly at Rear of Grate) : Downloaded From Manuals Search Engine

(Pilot/ Ignitor Assembly at Rear of Grate) : Downloaded From Manuals Search Engine

Uploaded by

grwgOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Pilot/ Ignitor Assembly at Rear of Grate) : Downloaded From Manuals Search Engine

(Pilot/ Ignitor Assembly at Rear of Grate) : Downloaded From Manuals Search Engine

Uploaded by

grwgCopyright:

Available Formats

g.

Check condition of the ceramic logs for large cracks,

fissures or missing pieces.

h. Check the wires for melting, loose or broken connections.

i. Check the aluminum pilot tubing for pinching or cracking.

j. Check the gas connections and fittings for looseness.

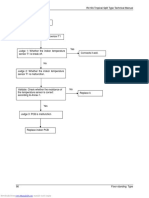

(Pilot/ ignitor assembly at rear of grate)

(Gas connections at rear of unit)

Annual Routine Maintenance: should be completed by qualified gas service or HVAC technician in addition to above.

1. Remove logs carefully (logs are fragile); inspect for large cracks, fissures or missing pieces.

a. Take note of log position for replacement (see page 7).

b. Place the logs on a blanket or newspapers to protect surfaces.

c. Vacuum/scoop the slag from the burner trays.

d. Clean the pilot/ignitors, being careful not to damage the wire tips or ceramic insulators.

e. Clean the flame sensor tip with emery cloth.

f. Check the ignition brackets for tightness and alignment with top edge of burn tray.

g. Check the wire connections to the ignitors for corrosion, cracking or looseness.

h. Vacuum the firebox floor and hearth burner (if applicable) to remove soot, dust carbon and old mineral

wool.

i. In systems with hearth effect burners, check all connections to the burner and the pilot/igniter assembly as

above.

j. If firebox walls are also to be restored, first vacuum, then wash the masonry firebox walls at this time, if

desired, using a damp sponge and cleanser.

k. Replace the black copper slag on the firebox floor or fill hearth effects burner to edge (refer to attached

photos for material positions).

Page 5 of 16

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Road Construction Quality Control Plan Sample PDFDocument26 pagesRoad Construction Quality Control Plan Sample PDFQaqc AbbasNo ratings yet

- Annexure 3 External Inspection ChecklistDocument5 pagesAnnexure 3 External Inspection Checklistankur100% (1)

- Repairs in Marine BoilersDocument9 pagesRepairs in Marine BoilersSwarg VibhaNo ratings yet

- Tank in Service Inspection ChecklistDocument8 pagesTank in Service Inspection ChecklistAhmadiBinAhmad100% (3)

- Tubing Storage, Handling and TransportDocument5 pagesTubing Storage, Handling and TransportYougchu Luan100% (2)

- Ite M Completed Comments: Tank Out-Of-Service Inspection ChecklistDocument14 pagesIte M Completed Comments: Tank Out-Of-Service Inspection Checklistmindbag100% (1)

- IMG - 0150 PSME Code 2008 142Document1 pageIMG - 0150 PSME Code 2008 142Arwyn BermasNo ratings yet

- Proceso de Soldadura PVC George FisherDocument10 pagesProceso de Soldadura PVC George FisherMarco Antonio Hernandez MotaNo ratings yet

- Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019Document1 pageTable 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019MehoNo ratings yet

- Preventive Maintenance ChecklistDocument2 pagesPreventive Maintenance ChecklistAnonymous 6gB0helNo ratings yet

- Section 5. Visual Corrosion Inspection Guide For AircraftDocument2 pagesSection 5. Visual Corrosion Inspection Guide For AircraftblackhawkNo ratings yet

- Drydocking InspectionDocument26 pagesDrydocking Inspectiondan_artimofNo ratings yet

- Location: Date of InspectionDocument1 pageLocation: Date of InspectionMohan VadiveluNo ratings yet

- Homeowner's Maintenance GuideDocument14 pagesHomeowner's Maintenance GuideMartín MalinawanNo ratings yet

- Part2 Secs6-7Document10 pagesPart2 Secs6-7Alexis GaitanNo ratings yet

- Plakabox BrochureDocument12 pagesPlakabox BrochurerajragavanNo ratings yet

- IMG - 0152 PSME Code 2008 144Document1 pageIMG - 0152 PSME Code 2008 144bnqr584bNo ratings yet

- Interface April 2004: SPF Gun and Foam From A Portable Foam KitDocument7 pagesInterface April 2004: SPF Gun and Foam From A Portable Foam KityosNo ratings yet

- Seasonal Checklist ENDocument2 pagesSeasonal Checklist ENdraNo ratings yet

- 33-590011-1 - Section 5Document3 pages33-590011-1 - Section 5Fábio FariaNo ratings yet

- Flex InstallDocument5 pagesFlex Installlinga007No ratings yet

- Verde 1 Eng 2019Document14 pagesVerde 1 Eng 2019SOPHIA TOLIANo ratings yet

- Fire Suppression System Initiative ChecklistDocument4 pagesFire Suppression System Initiative ChecklistMarcio BritoNo ratings yet

- How To Read Steel Ladle WearDocument7 pagesHow To Read Steel Ladle WearIcaro GavaNo ratings yet

- Bull Nose Ref FailureDocument1 pageBull Nose Ref FailurejagrutNo ratings yet

- CO2 4.5 KG Fire ExtinguisherDocument2 pagesCO2 4.5 KG Fire ExtinguishervivekvpsfeNo ratings yet

- Passive Fire Proofing For Buildings andDocument8 pagesPassive Fire Proofing For Buildings andTeknik produksi wikonNo ratings yet

- Expanse Al 600Document4 pagesExpanse Al 600raza102No ratings yet

- SW Vs Kammprofile GsktsDocument4 pagesSW Vs Kammprofile GsktsFilipNo ratings yet

- 05 Root End Filling MaterialsDocument30 pages05 Root End Filling MaterialsAbhinav Jagdish Nainani100% (1)

- Illustration and Analysis of Seal Face Damage PatternsDocument12 pagesIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсNo ratings yet

- Section 3. InspectionDocument4 pagesSection 3. Inspectionrobiny100% (1)

- GC Column Installation, Conditioning, Storage, and MaintenanceDocument5 pagesGC Column Installation, Conditioning, Storage, and MaintenanceHana RofidahNo ratings yet

- 1414665118314-Ti Mi 0039 PDFDocument15 pages1414665118314-Ti Mi 0039 PDFmithun 46No ratings yet

- Maintaining Your Home.: Bathrooms & KitchensDocument8 pagesMaintaining Your Home.: Bathrooms & Kitchenslxradley281677No ratings yet

- Steam Turbine Maintenance: Vibration DampersDocument2 pagesSteam Turbine Maintenance: Vibration Dampersdreamboy87No ratings yet

- Structural Apr24Document2 pagesStructural Apr24Nathsteph Delos ReyesNo ratings yet

- Part2 Sec3 pg27-33Document7 pagesPart2 Sec3 pg27-33Alexis GaitanNo ratings yet

- TEPA Gina SealsDocument16 pagesTEPA Gina SealsCristian Menéndez FernándezNo ratings yet

- Q ServicesDocument1 pageQ ServicesPrincess DimayacyacNo ratings yet

- Butterfly DamperDocument2 pagesButterfly Damperdeion29No ratings yet

- Operation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationDocument6 pagesOperation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationIrvansyah RazadinNo ratings yet

- Installation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesDocument6 pagesInstallation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesÁlvaro Martínez FernándezNo ratings yet

- Emcekrete: Ready To Use, Free Flow, High Strength, Non-Shrink GroutDocument2 pagesEmcekrete: Ready To Use, Free Flow, High Strength, Non-Shrink GroutFaisal AbbasNo ratings yet

- Annual Boiler Tuneup Checklist: Fading FiberglassDocument1 pageAnnual Boiler Tuneup Checklist: Fading FiberglasssamsonNo ratings yet

- The Fatigue Behavior of 55 3 Filament Wo PDFDocument5 pagesThe Fatigue Behavior of 55 3 Filament Wo PDFM.Sreeram SanjayNo ratings yet

- Ccsdeckfillinstr RCDocument1 pageCcsdeckfillinstr RCAndres CastilloNo ratings yet

- Sow-Bucaf Library Building26092018191533Document4 pagesSow-Bucaf Library Building26092018191533Adam SebastianNo ratings yet

- Shearing Blind Rams SBRDocument8 pagesShearing Blind Rams SBRDavid OrtegaNo ratings yet

- FORGED - Gate, Globe & Check Valve Manual - Xomox SanmarDocument20 pagesFORGED - Gate, Globe & Check Valve Manual - Xomox SanmarSaibabu SaiNo ratings yet

- 6KramerFurnaceMaintenance PDFDocument3 pages6KramerFurnaceMaintenance PDFcarrialdi100% (1)

- Expanseal Putty: Hand Applied Polymer Modified Bitumen SealantDocument4 pagesExpanseal Putty: Hand Applied Polymer Modified Bitumen Sealantmuhammad aliNo ratings yet

- Plastiseal : Rubber-Bitumen Cold Applied Joint SealantDocument4 pagesPlastiseal : Rubber-Bitumen Cold Applied Joint SealantzeroicesnowNo ratings yet

- BestpracticesDocument2 pagesBestpracticesClaudio VieiraNo ratings yet

- PLEXCO Bulletin No. 105-Y Yellowpipe 2406 Fusion ProceduresDocument15 pagesPLEXCO Bulletin No. 105-Y Yellowpipe 2406 Fusion ProceduresOctavio fnNo ratings yet

- Haxo 1990Document27 pagesHaxo 1990Ericke Nandita MaharaniNo ratings yet

- TM 9-1005-211-34 Pistol .45 Caliber Automatic 1911A1 2 of 2 Jun 1964Document27 pagesTM 9-1005-211-34 Pistol .45 Caliber Automatic 1911A1 2 of 2 Jun 1964sappernco1No ratings yet

- Underwater Burning: ProceduresDocument24 pagesUnderwater Burning: ProceduresDavidNo ratings yet

- Corrosion RingsDocument1 pageCorrosion RingsAhmed Al-TememiNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- TempDocument1 pageTempgrwgNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- 8.3 MOV-96CN1-C: Exploded View Tropical Split Type Technical ManualDocument1 page8.3 MOV-96CN1-C: Exploded View Tropical Split Type Technical ManualgrwgNo ratings yet

- Sound Levels Tropical Split Type Technical ManualDocument1 pageSound Levels Tropical Split Type Technical ManualgrwgNo ratings yet

- Movavi PDF Edi Tor: Getti NG Started: Vi EwDocument2 pagesMovavi PDF Edi Tor: Getti NG Started: Vi EwgrwgNo ratings yet

- 11.4 P2 Malfunction: Downloaded From Manuals Search EngineDocument1 page11.4 P2 Malfunction: Downloaded From Manuals Search EnginegrwgNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- 8.5 MOV-120CN1-C: Exploded View Tropical Split Type Technical ManualDocument1 page8.5 MOV-120CN1-C: Exploded View Tropical Split Type Technical ManualgrwgNo ratings yet

- Tropical Split Type Technical Manual Electric CharacteristicsDocument1 pageTropical Split Type Technical Manual Electric CharacteristicsgrwgNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- 8.2 MOV-76HN1-C: Exploded View Tropical Split Type Technical ManualDocument1 page8.2 MOV-76HN1-C: Exploded View Tropical Split Type Technical ManualgrwgNo ratings yet

- 15×20 Rectangular Hole: Foundation of The Outdoor UnitDocument1 page15×20 Rectangular Hole: Foundation of The Outdoor UnitgrwgNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- 11.1 E1 Malfunction: Downloaded From Manuals Search EngineDocument1 page11.1 E1 Malfunction: Downloaded From Manuals Search EnginegrwgNo ratings yet

- Features: Features R410A Tropical Split Type Technical ManualDocument1 pageFeatures: Features R410A Tropical Split Type Technical ManualgrwgNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- A. Wooden Structure: Tropical Split Type Technical Manual Installation of Indoor UnitsDocument1 pageA. Wooden Structure: Tropical Split Type Technical Manual Installation of Indoor UnitsgrwgNo ratings yet

- 11.2 E2 Malfunction: Downloaded From Manuals Search EngineDocument1 page11.2 E2 Malfunction: Downloaded From Manuals Search EnginegrwgNo ratings yet

- 10.4 MFA-96HRN1: R410A Tropical Split Type Technical Manual Exploded ViewDocument1 page10.4 MFA-96HRN1: R410A Tropical Split Type Technical Manual Exploded ViewgrwgNo ratings yet

- Part 4 Installation: Troubleshooting Tropical Split Type Technical ManualDocument1 pagePart 4 Installation: Troubleshooting Tropical Split Type Technical ManualgrwgNo ratings yet

- Troubleshooting: R410A Tropical Split Type Technical Manual TroubleshootingDocument1 pageTroubleshooting: R410A Tropical Split Type Technical Manual TroubleshootinggrwgNo ratings yet

- Troubleshooting: R410A Tropical Split Type Technical Manual TroubleshootingDocument1 pageTroubleshooting: R410A Tropical Split Type Technical Manual TroubleshootinggrwgNo ratings yet

- Installation of Outdoor Units: 3.1 Important: Construction CheckpointsDocument1 pageInstallation of Outdoor Units: 3.1 Important: Construction CheckpointsgrwgNo ratings yet

- Mounting and Instruction Manual: DK SeriesDocument1 pageMounting and Instruction Manual: DK SeriesgrwgNo ratings yet

- 11.10 MHB-96CRN1: Exploded View R410A Tropical Split Type Technical ManualDocument1 page11.10 MHB-96CRN1: Exploded View R410A Tropical Split Type Technical ManualgrwgNo ratings yet

- Specifications Tropical Split Type Technical ManualDocument1 pageSpecifications Tropical Split Type Technical ManualgrwgNo ratings yet

- Service Space: Electric Control Box Inspection HoleDocument1 pageService Space: Electric Control Box Inspection HolegrwgNo ratings yet

- Symptoms Causes Handling Methods: Downloaded From Manuals Search EngineDocument1 pageSymptoms Causes Handling Methods: Downloaded From Manuals Search EnginegrwgNo ratings yet

- Cold Clean-Out Block: PurposeDocument2 pagesCold Clean-Out Block: PurposeAlson LeeNo ratings yet

- Well Design ConsiderationsDocument30 pagesWell Design ConsiderationsarytriNo ratings yet

- 1995 Mitsubishi Galant VR V6 OverheatingDocument2 pages1995 Mitsubishi Galant VR V6 OverheatingRoullete Santos ChipongianNo ratings yet

- Meachanically Fastened Roofing Single Ply Membranes PDFDocument32 pagesMeachanically Fastened Roofing Single Ply Membranes PDFclaitonborgesNo ratings yet

- Sports and Building AerodynamicsDocument13 pagesSports and Building AerodynamicsMaria Cielo VarelaNo ratings yet

- 11-IM-240ANE-HC Specification SheetDocument2 pages11-IM-240ANE-HC Specification SheetGibron MakhdoomiNo ratings yet

- Limitless Perfection.: Lindner Partition Wall Systems - The Ultimate in Quality, The Most Extensive RangeDocument24 pagesLimitless Perfection.: Lindner Partition Wall Systems - The Ultimate in Quality, The Most Extensive RangeCarim NahabooNo ratings yet

- PWC ProposalDocument2 pagesPWC ProposalJohn Ralph VegaNo ratings yet

- 1.0 Purlins DesignDocument10 pages1.0 Purlins Designklynchelle100% (1)

- SBSDocument18 pagesSBSjaswinder singhNo ratings yet

- Cast Iron Material Comparison Chart ASTM CompilationDocument1 pageCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaNo ratings yet

- Construction Techniques, Equipment and Practice: M.Sathish Kumar, AP/CivilDocument18 pagesConstruction Techniques, Equipment and Practice: M.Sathish Kumar, AP/CivilJeya LakhsmiNo ratings yet

- 05-State of Stress in 3D 8.4.16 (8 Files Merged) PDFDocument347 pages05-State of Stress in 3D 8.4.16 (8 Files Merged) PDFChandra Bhushan Choubey100% (1)

- Manual (Aitech) : ON Accreditation of Innovative Technologies For HousingDocument48 pagesManual (Aitech) : ON Accreditation of Innovative Technologies For HousingJohn Ray Esmama CalasicasNo ratings yet

- Introduction To Waterborne Paints & Coatings Rheology: Technical DocumentDocument46 pagesIntroduction To Waterborne Paints & Coatings Rheology: Technical DocumentAPEX SON100% (1)

- Series 44 45 4M DelVal HPButterfly ValvesDocument8 pagesSeries 44 45 4M DelVal HPButterfly ValvesProcess Controls & ServicesNo ratings yet

- Crystals 09 00389 PDFDocument10 pagesCrystals 09 00389 PDFVeeturiVarunNo ratings yet

- Fabrication, Supply, Erection, Installation and Commissioning of Non Regenerative Type Demineralisation Plant and Online Polishing PlantDocument40 pagesFabrication, Supply, Erection, Installation and Commissioning of Non Regenerative Type Demineralisation Plant and Online Polishing Plantmangal deo pathakNo ratings yet

- Waterproof Range PainterDocument38 pagesWaterproof Range PainterPankaj KumarNo ratings yet

- Name: Johnson Ongeri Registration Number: Bds/08/15 University: Moi University College: College of Health and Sciences Course: Title: Presented ToDocument5 pagesName: Johnson Ongeri Registration Number: Bds/08/15 University: Moi University College: College of Health and Sciences Course: Title: Presented ToEuro UndisaNo ratings yet

- Febe1000a - Introduction To Materials - Rock-To-metal - Notes - Week 5 - 06042021Document48 pagesFebe1000a - Introduction To Materials - Rock-To-metal - Notes - Week 5 - 06042021uziNo ratings yet

- Shell Gas Compressor Oil S3 PYDocument2 pagesShell Gas Compressor Oil S3 PYBen Karthiben NathanNo ratings yet

- V-Series Refrigerators: VR ModelsDocument2 pagesV-Series Refrigerators: VR ModelsCJ10aNo ratings yet

- AD (DP) All Project Teams and Contract Managers 22 August 2013Document11 pagesAD (DP) All Project Teams and Contract Managers 22 August 2013BQ HeNo ratings yet

- RCC54 Circular Column ChartingDocument13 pagesRCC54 Circular Column ChartingvaideehNo ratings yet

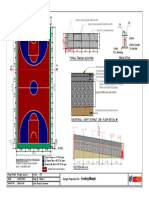

- Godrejj - Manjri-Tennis Court Dated 24.03.23Document1 pageGodrejj - Manjri-Tennis Court Dated 24.03.23Shlok JoshiNo ratings yet

- Thurne Teknik Rupture Disc Sizing ToolDocument2 pagesThurne Teknik Rupture Disc Sizing ToolRendy .KNo ratings yet

- Kil2315 - 200 - 0001 - Rev00 - Platform and Stairs General Arrangement 3Document1 pageKil2315 - 200 - 0001 - Rev00 - Platform and Stairs General Arrangement 3NiemNo ratings yet

- Reuse of Water Treatment Plant Sludge in Brick ManufacturingDocument8 pagesReuse of Water Treatment Plant Sludge in Brick ManufacturingA Nicole Rodríguez OportoNo ratings yet