Professional Documents

Culture Documents

54 40 7020

54 40 7020

Uploaded by

Camilo ParedesCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 62TE P083B Fault CodeDocument4 pages62TE P083B Fault CodeossoskiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Quarry Wire Saw 11-75KW Machine Instruction ManualDocument64 pagesQuarry Wire Saw 11-75KW Machine Instruction Manualsandro100% (1)

- Valve Mounting Height PDFDocument6 pagesValve Mounting Height PDFgrisham018100% (1)

- LS32 Parts Manual 88298001-624 MNK Tro Bay PDFDocument53 pagesLS32 Parts Manual 88298001-624 MNK Tro Bay PDFAnh Vo0% (1)

- James Hardy's Self-Powered Water-Pump Generator.Document3 pagesJames Hardy's Self-Powered Water-Pump Generator.Naude VisserNo ratings yet

- MT900C enDocument7 pagesMT900C enJulian BlancoNo ratings yet

- 13 VersaBlue Adhesive Melters Models VA and VT - Parts List - VersaBlue A.20220720142147885Document90 pages13 VersaBlue Adhesive Melters Models VA and VT - Parts List - VersaBlue A.20220720142147885Yaswanth RajNo ratings yet

- ZJ Trans&XferDocument356 pagesZJ Trans&Xferoğuzhan_tekceNo ratings yet

- Cylinder Head & Cover (S-N 5260, 5261, 5258 & 5259) (V3300 DI T Kubota) (Tier II) - S250Document3 pagesCylinder Head & Cover (S-N 5260, 5261, 5258 & 5259) (V3300 DI T Kubota) (Tier II) - S250rjan7peNo ratings yet

- Pegson Crusher Bearing Product Luoyang JCB Bearing Technology CompanyDocument1 pagePegson Crusher Bearing Product Luoyang JCB Bearing Technology CompanyJusto Ernesto Gutierrez Schweitzer100% (1)

- 2006 ls430 Suspension Ecu Terminals PDFDocument4 pages2006 ls430 Suspension Ecu Terminals PDFbob loblawNo ratings yet

- Pegadora B Bq240Document79 pagesPegadora B Bq240AlbhertoalonsoNo ratings yet

- Mobil Industrial - Product Guide - 2015Document107 pagesMobil Industrial - Product Guide - 2015Massimiliano VolaNo ratings yet

- Fom Inspeksi Vibrasi PDFDocument2 pagesFom Inspeksi Vibrasi PDFHeza FirdausNo ratings yet

- SSP 265 Vehicle Electrics in Polo MY 02Document24 pagesSSP 265 Vehicle Electrics in Polo MY 02ภูเก็ต เป็นเกาะ100% (1)

- Optional Functions Basic FunctionsDocument68 pagesOptional Functions Basic Functionsjitesh.chauhanNo ratings yet

- Catalog Piese Brio250Document39 pagesCatalog Piese Brio250Sutu Cristi DanielNo ratings yet

- Equipment Deployment EmaarDocument8 pagesEquipment Deployment Emaaraliengineer953No ratings yet

- SENR33120001 - 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)Document2 pagesSENR33120001 - 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)CEVegaONo ratings yet

- Gv222ti - Gas Natural GLP PDFDocument2 pagesGv222ti - Gas Natural GLP PDFdaniloreisrochaNo ratings yet

- Operating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerDocument6 pagesOperating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerRonald Bienemi PaezNo ratings yet

- 4 PulleysDocument16 pages4 PulleysMahmoud HanafyNo ratings yet

- Engine Spare Parts StocksDocument10 pagesEngine Spare Parts StocksJahangir HosenNo ratings yet

- Slick Mag Overhaul ManualDocument64 pagesSlick Mag Overhaul Manualleather_nun100% (1)

- 18ME54 Turbo Machines Module 02 Question No 4a & 4bDocument15 pages18ME54 Turbo Machines Module 02 Question No 4a & 4bThanmay JSNo ratings yet

- VW Eos Maintenance PDFDocument75 pagesVW Eos Maintenance PDFNick P100% (1)

- CASE 2050M Dozer Spec SheerDocument4 pagesCASE 2050M Dozer Spec SheerPebi Legent100% (1)

- Engine Trip Detail Report (One Page) Engine Trip Detail Report (One Page)Document1 pageEngine Trip Detail Report (One Page) Engine Trip Detail Report (One Page)Cam51096No ratings yet

- 74311Document18 pages74311amdevaNo ratings yet

- Motor InvntryDocument41 pagesMotor InvntryChandu ChNo ratings yet

54 40 7020

54 40 7020

Uploaded by

Camilo ParedesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

54 40 7020

54 40 7020

Uploaded by

Camilo ParedesCopyright:

Available Formats

BULLETIN NO.

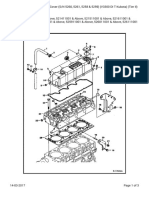

SERVICE PARTS LIST 54-40-7020

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS REVISED BULLETIN DATE

May 2006

CORDLESS CIRCULAR SAW

WIRING INSTRUCTION

STARTING

CATALOG NO. 0730-20 SERIAL NO. A57A SEE REVERSE SIDE

EXAMPLE:

00 0 Component Parts (Small #) Are Included 19 34

When Ordering The Assembly (Large #).

19a

NOTE:

Remove brush tubes (18) prior to removing 16

armature assembly (14) from left 11

handle halve (30). 1

20 47 18

14

Install brush tubes (18) into left 23

27 7

handle halve (30) only after

armature assembly (14) has 15

been secured into left 22

handle halve (30). 40 2 25

7

12 54

44

29 21 11 30 26

8 47 6

18

49

37 17 35

4

6

32 19a

28 43

29 19 31 42

52

38 33

45 Functionally

36

46 check the lower

50

guard #26, with the

51 39

saw set at full depth of

cut and 0° bevel. Place the

10 saw upside down with the shoe

34 63 28

31

34

35

horizontal. Fully retract the guard and

7 then release it. The guard must return briskly.

3

FIG. PART NO. DESCRIPTION OF PART NO.

55 REQ.

9 32 34-40-4480 O-Ring (1)

Apply 3.0 grams of "Y" grease, 41 33 34-60-0860 Retaining Ring - External (1)

No. 49-08-5270 to gear bore of 34 34-60-0920 Retaining Ring - External (2)

gearcase #24. The grease should be 35 38-50-1160 Spindle (1)

directed toward the pinion 5 48 24 36 40-50-0045 Guard Spring (1)

end of the armature. 37 40-50-0350 Spring (1)

56 38 40-50-8040 Spring (1)

59 39 42-38-0222 Rubber Bumper (1)

40 42-42-1020 Switch Lock-Out (1)

Apply a light film of 41 42-42-1030 Spindle Lock Button (1)

lubricant to the 60 42 43-34-0790 Inner Flange (1)

bearing bore of the 43 43-34-0795 Outer Flange (1)

gearcase before 57 44 44-10-0420 Guard Lever (1)

assembling the 53 45 44-10-0430 Depth Lever (1)

armature/bearing. 46 44-20-0650 Spindle Lock (1)

13 56 57 58 59

60 61 62 58 47 ------------- Connector Block Cover (1)

62 61 48 44-60-0740 Pivot Pin (1)

49 44-66-0560 Retaining Plate (1)

FIG. PART NO. DESCRIPTION OF PART NO. REQ. 50 45-04-0485 Bumper Screw (1)

1 02-04-1212 Ball Bearing (1) 51 45-06-0720 Felt Seal (1)

2 02-04-5130 Ball Bearing (1) 52 45-08-0395 Depth Shaft (1)

3 02-50-1640 Needle Bearing (1) 53 45-88-1515 Washer (1)

4 06-75-1010 Left Hand Screw (1) 54 45-88-5615 Wave Spring Washer (1)

5 06-75-5860 1/4-20 x 3/4 Screw (1) 55 49-96-0080 3/16 Hex Key (1)

6 06-82-5285 6-32 x .5 Pan Hd. Taptite Screw T-15 (5) 56 06-10-0660 1/4-20 x 1/2 Short Neck Carriage Bolt (1)

7 06-82-5314 10-24 x .5 Pan Hd. Taptite Screw T-25 (5) 57 45-88-1560 Washer (1)

8 06-82-7470 6-19 x .687 Plastite Torx Screw T-15 (8) 58 43-98-0730 Bevel Adjustment Knob (1)

9 06-82-7475 6-19 x .875 Plastite Torx Screw T-15 (4) 59 43-98-0720 Rip Fence Knob (1)

10 10-20-2840 Logo Label (1) 60 40-50-0650 Spring (1)

11 22-74-0510 Diode Assembly (1) 61 06-82-9605 10-32 x 3/8 CSK Machine Screw T-25 (4)

12 12-20-3340 Service Nameplate (1) 62 06-83-1600 10-32 x 3/8 Set Screw (1)

13 14-74-0310 Shoe Assembly (1) 63 14-46-2575 Gear Service Assembly (1)

14 16-01-2125 Armature (1) 49-22-1001 Rip Fence (Not Shown) (1)

15 18-01-2000 Field (1)

16 22-18-1240 Brush Assembly - Red (1) FIG. NOTE:

17 22-18-1245 Brush Assembly - Black (1) 2 Orient the ball bearing so that the seal faces the

18 22-20-0425 Brush Tube (2) commutator and the shield faces the shaft end.

19 22-32-0420 Brush Spring Clip (2)

19a 40-50-8745 Brush Spring (2) 3 Press needle bearing flush to .015 sub-flush in gearcase.

20 22-56-0975 Connector Block Assembly (1)

21 23-66-1005 Service Switch (1) 20,47 Concave side of connector block cover to face

22 23-94-4290 Leadwire Assembly - Red (1) connector block.

23 23-94-4295 Leadwire Assembly - Black (1)

24 28-14-0746 Gearcase (1) 26,33 Position retaining ring with rounded edge facing

25 28-20-1160 Upper Guard Cover (1) lower guard.

26 28-41-0955 Lower Guard (1)

27 31-05-0350 Baffle (1)

28 31-15-0601 Gearcase Cover (1)

29 31-44-2040 Right Handle Halve (1) MILWAUKEE ELECTRIC TOOL CORPORATION

30 31-44-2045 Left Handle Halve (1) 13135 W. LISBON RD., BROOKFIELD, WI 53005

31 32-75-1310 Spindle Gear (1) Drwg. 6

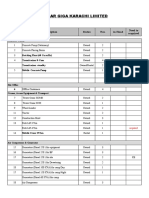

BLACK 23

RED 22

21

20

11

ORIENT DIODE #11 AS SHOWN.

CORRECT POLARITY IS CRITICAL

FOR PROPER TOOL FUNCTION.

! WARNING

SWITCH AND DIODE

ARE POLARITY

SENSITIVE

16 RED

If wired incorrectly,

switch and diode will

be damaged and

BLACK 17 Functionally check switch lock-out

destroyed! #40 by attempting to turn on tool by

applying a reasonable amount of

force, up to 8 lbs., to the switch

trigger #21. The tool must not turn

17 TO on. Release trigger. Actuate the

POSITIVE lock-out lever and apply a reason-

BLACK BATTERY ALL TERMINALS

BRUSH MUST BE

able amount of force to the switch

TO TOP CONNECTION

ASSEMBLY BRUSH ORIENTED AS trigger. The tool must turn on. While

TUBE 22 RED SHOWN IN the trigger is still in the "ON" position,

THESE VIEWS. release the lock-out. Release the

16 RED TO BOTTOM trigger. The tool must stop and the

BRUSH TUBE lock-out lever must again prevent

21 the actuation of the

17 BLACK switch. Repeat the

SWITCH

switch check two

BLACK 11 TO NEGATIVE

DIODE 11 BATTERY more times.

LEADWIRE DIODE

ASSY. 23 CONNECT-

ION

23

BLACK

SWITCH SWITCH LOCK-OUT

SWITCH DETAIL BACK VIEW

BRUSH WIRE

LEADWIRE TRAPS TRAPS

WIRES MAY BE PLACED IN

ANY ORDER IN THESE TRAPS

A

B

TERMINALS MUST BE LOCATED

BETWEEN 'A' AND 'B' FOR

WIRING SPECIFICATIONS BOTH BRUSH ASSEMBLIES.

Wire Wire Origin or

No. Color Gauge Length Terminals, Connectors and 1 or 2 End Wire Preparation

16 Red 22-18-1240 ----- Carbon brush assembly. TERMINAL DESCRIPTION

17 Black 22-18-1245 ----- Carbon brush assembly. Code Part No. Qnty.

22 Red 23-94-4290 ----- Leadwire assembly.

23 Black 23-94-4295 ----- Leadwire assembly.

22-74-0510 ----- Diode assembly.

BULK LEAD WIRE - BULLETIN NO. 58-01-0003

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 62TE P083B Fault CodeDocument4 pages62TE P083B Fault CodeossoskiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Quarry Wire Saw 11-75KW Machine Instruction ManualDocument64 pagesQuarry Wire Saw 11-75KW Machine Instruction Manualsandro100% (1)

- Valve Mounting Height PDFDocument6 pagesValve Mounting Height PDFgrisham018100% (1)

- LS32 Parts Manual 88298001-624 MNK Tro Bay PDFDocument53 pagesLS32 Parts Manual 88298001-624 MNK Tro Bay PDFAnh Vo0% (1)

- James Hardy's Self-Powered Water-Pump Generator.Document3 pagesJames Hardy's Self-Powered Water-Pump Generator.Naude VisserNo ratings yet

- MT900C enDocument7 pagesMT900C enJulian BlancoNo ratings yet

- 13 VersaBlue Adhesive Melters Models VA and VT - Parts List - VersaBlue A.20220720142147885Document90 pages13 VersaBlue Adhesive Melters Models VA and VT - Parts List - VersaBlue A.20220720142147885Yaswanth RajNo ratings yet

- ZJ Trans&XferDocument356 pagesZJ Trans&Xferoğuzhan_tekceNo ratings yet

- Cylinder Head & Cover (S-N 5260, 5261, 5258 & 5259) (V3300 DI T Kubota) (Tier II) - S250Document3 pagesCylinder Head & Cover (S-N 5260, 5261, 5258 & 5259) (V3300 DI T Kubota) (Tier II) - S250rjan7peNo ratings yet

- Pegson Crusher Bearing Product Luoyang JCB Bearing Technology CompanyDocument1 pagePegson Crusher Bearing Product Luoyang JCB Bearing Technology CompanyJusto Ernesto Gutierrez Schweitzer100% (1)

- 2006 ls430 Suspension Ecu Terminals PDFDocument4 pages2006 ls430 Suspension Ecu Terminals PDFbob loblawNo ratings yet

- Pegadora B Bq240Document79 pagesPegadora B Bq240AlbhertoalonsoNo ratings yet

- Mobil Industrial - Product Guide - 2015Document107 pagesMobil Industrial - Product Guide - 2015Massimiliano VolaNo ratings yet

- Fom Inspeksi Vibrasi PDFDocument2 pagesFom Inspeksi Vibrasi PDFHeza FirdausNo ratings yet

- SSP 265 Vehicle Electrics in Polo MY 02Document24 pagesSSP 265 Vehicle Electrics in Polo MY 02ภูเก็ต เป็นเกาะ100% (1)

- Optional Functions Basic FunctionsDocument68 pagesOptional Functions Basic Functionsjitesh.chauhanNo ratings yet

- Catalog Piese Brio250Document39 pagesCatalog Piese Brio250Sutu Cristi DanielNo ratings yet

- Equipment Deployment EmaarDocument8 pagesEquipment Deployment Emaaraliengineer953No ratings yet

- SENR33120001 - 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)Document2 pagesSENR33120001 - 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)CEVegaONo ratings yet

- Gv222ti - Gas Natural GLP PDFDocument2 pagesGv222ti - Gas Natural GLP PDFdaniloreisrochaNo ratings yet

- Operating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerDocument6 pagesOperating Instruction: Modification Instructions For Anti Polishing Ring in Cylinder LinerRonald Bienemi PaezNo ratings yet

- 4 PulleysDocument16 pages4 PulleysMahmoud HanafyNo ratings yet

- Engine Spare Parts StocksDocument10 pagesEngine Spare Parts StocksJahangir HosenNo ratings yet

- Slick Mag Overhaul ManualDocument64 pagesSlick Mag Overhaul Manualleather_nun100% (1)

- 18ME54 Turbo Machines Module 02 Question No 4a & 4bDocument15 pages18ME54 Turbo Machines Module 02 Question No 4a & 4bThanmay JSNo ratings yet

- VW Eos Maintenance PDFDocument75 pagesVW Eos Maintenance PDFNick P100% (1)

- CASE 2050M Dozer Spec SheerDocument4 pagesCASE 2050M Dozer Spec SheerPebi Legent100% (1)

- Engine Trip Detail Report (One Page) Engine Trip Detail Report (One Page)Document1 pageEngine Trip Detail Report (One Page) Engine Trip Detail Report (One Page)Cam51096No ratings yet

- 74311Document18 pages74311amdevaNo ratings yet

- Motor InvntryDocument41 pagesMotor InvntryChandu ChNo ratings yet