Professional Documents

Culture Documents

Diesel Engine Lubricants Their Selection and Utilization With Particular Reference To Oil Alkalinity

Diesel Engine Lubricants Their Selection and Utilization With Particular Reference To Oil Alkalinity

Uploaded by

rpumacayovCopyright:

Available Formats

You might also like

- (Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠDocument12 pages(Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠMauricio Solano DiazNo ratings yet

- Controlling WearDocument2 pagesControlling WearJavier NarváezNo ratings yet

- Understanding Lqs ReportsDocument6 pagesUnderstanding Lqs Reportsjuanete29No ratings yet

- 20 HFL 0356 - Whitepaper - Used Oil Analysis Tech Bulletin Whitepaper - v5Document7 pages20 HFL 0356 - Whitepaper - Used Oil Analysis Tech Bulletin Whitepaper - v5DANIEL ZORRONo ratings yet

- Diesel Emissions - A Breath of Fresh Air P2Document10 pagesDiesel Emissions - A Breath of Fresh Air P2STEVENNo ratings yet

- Study On Durability of Engine & Engine Oil in Presence of ContaminantsDocument14 pagesStudy On Durability of Engine & Engine Oil in Presence of ContaminantsAnandNo ratings yet

- Properties of LubricantDocument6 pagesProperties of LubricantEl Sayed ZakariaNo ratings yet

- Technical Topic - Developing Turbine Oils Beyond RPVOTDocument3 pagesTechnical Topic - Developing Turbine Oils Beyond RPVOTdhavit wijayantoNo ratings yet

- TT Developing Turbine OilsDocument2 pagesTT Developing Turbine Oilssatya_chagantiNo ratings yet

- Ozhllii!iieri': Electro-MotiveDocument3 pagesOzhllii!iieri': Electro-MotiveVladimir ArsicNo ratings yet

- Lubrication Systems 9Document38 pagesLubrication Systems 9shimi yayNo ratings yet

- Watson 2009Document11 pagesWatson 2009Steve OoiNo ratings yet

- Is It Time To Change Your OilDocument6 pagesIs It Time To Change Your Oilarchie zambranoNo ratings yet

- Remaining Service Life (RSL) Assessment of Engine Oil in Rock ExcavatorsDocument10 pagesRemaining Service Life (RSL) Assessment of Engine Oil in Rock ExcavatorsAjay MahawerNo ratings yet

- Guía de Inspección GDY106-85Document7 pagesGuía de Inspección GDY106-85Adolfo DonairesNo ratings yet

- Lubricant GlossaryDocument8 pagesLubricant GlossaryAli KhanNo ratings yet

- Lubricants 10 00162Document14 pagesLubricants 10 00162hanyNo ratings yet

- Transformer: Oil Condition MonitoringDocument6 pagesTransformer: Oil Condition MonitoringKhushdeep SohiNo ratings yet

- Need For Lubrication in An I.C. EngineDocument6 pagesNeed For Lubrication in An I.C. EngineDrChandrakant KothareNo ratings yet

- Sabp G 022Document8 pagesSabp G 022Hassan MokhtarNo ratings yet

- Impact of Low Viscosity Engine Oil On Performance, Fuel Economy and Emissions of Light Duty Diesel EngineDocument6 pagesImpact of Low Viscosity Engine Oil On Performance, Fuel Economy and Emissions of Light Duty Diesel EngineChemilomNo ratings yet

- Cylinder Lubrication Timed InjectionDocument6 pagesCylinder Lubrication Timed Injectionapi-3701567100% (1)

- Oils I:: Electrical Insulating Characterization and Pre-Treatment of Transformer OilsDocument13 pagesOils I:: Electrical Insulating Characterization and Pre-Treatment of Transformer OilsRamesh GopalanNo ratings yet

- Lubrication Systems: A. Principies of Engine LubricationDocument36 pagesLubrication Systems: A. Principies of Engine LubricationMiguelNo ratings yet

- Lubricating Oil Purification TestingDocument9 pagesLubricating Oil Purification Testingapi-3701567No ratings yet

- Lubrication Systems For Turbomachinery by Fredrick B. WilcoxDocument4 pagesLubrication Systems For Turbomachinery by Fredrick B. Wilcoxkamal arabNo ratings yet

- Turbine Oil Analysis Report Interpretation - June15 TLTDocument7 pagesTurbine Oil Analysis Report Interpretation - June15 TLTAnibal Rios100% (1)

- Lubricattng Oil For Marine EnginesDocument5 pagesLubricattng Oil For Marine Enginesemmsh71No ratings yet

- Lubricant Performance and Turbochargers Analysis For Alternate Fuel TestsDocument16 pagesLubricant Performance and Turbochargers Analysis For Alternate Fuel Testsgigi23901No ratings yet

- 21-Q1-1021 New Oil - Flushed Oil3-1 - REVISED 4 April 2021 CleanDocument7 pages21-Q1-1021 New Oil - Flushed Oil3-1 - REVISED 4 April 2021 CleanMuhammed ThanzeelNo ratings yet

- MI1760Document6 pagesMI1760Fabricio DelgadoNo ratings yet

- Experimental Investigation of Lubricating Properties of Engine OilDocument4 pagesExperimental Investigation of Lubricating Properties of Engine OilAnthony CamarenaNo ratings yet

- Improving Rolling Mill Lube Oil PDFDocument4 pagesImproving Rolling Mill Lube Oil PDFRaj Kumar SinghNo ratings yet

- Lubrication Applications: 11-1. IntroductionDocument28 pagesLubrication Applications: 11-1. IntroductionFmc U'fuçador100% (2)

- Determination of Oil Drain Period in Naval Ship Diesel EngineDocument10 pagesDetermination of Oil Drain Period in Naval Ship Diesel EngineRodrigoNo ratings yet

- Temperature Dependent Kinematic Viscosity of Different Types of Engine OilsDocument8 pagesTemperature Dependent Kinematic Viscosity of Different Types of Engine OilsSoliman AlostaNo ratings yet

- Guide To Electric Motor Bearing LubricationDocument7 pagesGuide To Electric Motor Bearing LubricationUber_Konstruktor100% (2)

- SAE Grades-Oil ViscosityDocument4 pagesSAE Grades-Oil ViscosityMathew John100% (2)

- LUB OILS NOHAB W25 W25SG W25DF 9193911800eDocument2 pagesLUB OILS NOHAB W25 W25SG W25DF 9193911800eLIVIA100% (2)

- Testing Engine Oil Specifications and Properties and Its Effects On The Engines Maintenance and PerformanceDocument10 pagesTesting Engine Oil Specifications and Properties and Its Effects On The Engines Maintenance and PerformanceMAZ TechNo ratings yet

- Sae 982674Document16 pagesSae 982674Tudor RatiuNo ratings yet

- Guide To EM Bearing LubricationDocument12 pagesGuide To EM Bearing LubricationAnonymous alQXB11EgQ100% (1)

- Guide To Electric Motor Lubrication ExxonDocument0 pagesGuide To Electric Motor Lubrication Exxont_syamprasad100% (1)

- Steam Turbine Oil Eyeopening ArticleDocument15 pagesSteam Turbine Oil Eyeopening ArticleRajeswaran NatarajanNo ratings yet

- Practical Assessment No. 4: College of Maritime Studies Marine Engineering DepartmentDocument13 pagesPractical Assessment No. 4: College of Maritime Studies Marine Engineering DepartmentKimberly Hosmillo ImperialNo ratings yet

- Application of Surfactants in The Petroleum Industry: Those Uses AreDocument4 pagesApplication of Surfactants in The Petroleum Industry: Those Uses AreGeeva Prasanth ANo ratings yet

- Submarine Main Propulsion Diesels - Chapter 7Document32 pagesSubmarine Main Propulsion Diesels - Chapter 7Michael ChungNo ratings yet

- 208 ArticleText 2482 4 10 202012291Document9 pages208 ArticleText 2482 4 10 202012291Santosh IngoleNo ratings yet

- Exxon Aviation Oil EEDocument2 pagesExxon Aviation Oil EEJeefNo ratings yet

- Global DHD 1Document15 pagesGlobal DHD 1sanbao72No ratings yet

- 2000 5000i 8000 9000i Section 6Document100 pages2000 5000i 8000 9000i Section 6diego428No ratings yet

- Fuel Specification Guide: Shell Marine ProductsDocument6 pagesFuel Specification Guide: Shell Marine ProductsVilius BukysNo ratings yet

- Secondscopusa285113 079Document10 pagesSecondscopusa285113 079Renukutla SandeepNo ratings yet

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- Steam Turbine Maintenance Maintenance InstructionsDocument11 pagesSteam Turbine Maintenance Maintenance Instructionsdreamboy87No ratings yet

- 21st Annual CMF PlusDocument26 pages21st Annual CMF PlusGaurav ChauhanNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyFrom EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNo ratings yet

- Lubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6From EverandLubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6Rating: 5 out of 5 stars5/5 (1)

- TIBU6253-00 - Damage To C175 Engine Wiring Harnesses in 793F, 795F, and 797F Off-Highway Trucks (1408)Document3 pagesTIBU6253-00 - Damage To C175 Engine Wiring Harnesses in 793F, 795F, and 797F Off-Highway Trucks (1408)rpumacayovNo ratings yet

- Event Codes 793F-797FDocument14 pagesEvent Codes 793F-797FrpumacayovNo ratings yet

- Pre Plan Semana 34Document6 pagesPre Plan Semana 34rpumacayovNo ratings yet

- Ho SheetDocument66 pagesHo SheetrpumacayovNo ratings yet

- APLs CARDocument1 pageAPLs CARrpumacayovNo ratings yet

- Film TV Treatment TemplateDocument6 pagesFilm TV Treatment TemplateYaram BambaNo ratings yet

- Liebherr Vehicle CardDocument16 pagesLiebherr Vehicle CardArimbi GembiekNo ratings yet

- Visvesvaraya Technological University Application For Issue of Duplicate Marks Cards (DMC)Document1 pageVisvesvaraya Technological University Application For Issue of Duplicate Marks Cards (DMC)Harshkumar KattiNo ratings yet

- TE1 Terminal CircuitDocument2 pagesTE1 Terminal Circuitcelestino tuliaoNo ratings yet

- Rivera December Staar Eoc TA Testing PPDocument55 pagesRivera December Staar Eoc TA Testing PPOlga RenteriaNo ratings yet

- Delta Ia-Plc DVP-PLC PM en 20140804Document749 pagesDelta Ia-Plc DVP-PLC PM en 20140804Ali PadaryamNo ratings yet

- KL202232 PSRPT 2022-05-18 18.01.51Document19 pagesKL202232 PSRPT 2022-05-18 18.01.51Thuy AnhNo ratings yet

- Astrolabe Free Chart From HTTP - AlabeDocument2 pagesAstrolabe Free Chart From HTTP - AlabeArijit AcharyaNo ratings yet

- TH-RevsedDocument22 pagesTH-RevsedTaimoor HassanNo ratings yet

- Rubrics CE ORIENT Written ReportDocument2 pagesRubrics CE ORIENT Written ReportjocelNo ratings yet

- Design of Basic ComputerDocument29 pagesDesign of Basic ComputerM DEEPANANo ratings yet

- Kami 3Document2 pagesKami 3KumarNo ratings yet

- Group 2 - Tinder's AlgorithmDocument3 pagesGroup 2 - Tinder's AlgorithmKarinNo ratings yet

- MTC 17022021063931Document1 pageMTC 17022021063931Ahmed LepdaNo ratings yet

- Guide To Iso 9001 2015 PDFDocument15 pagesGuide To Iso 9001 2015 PDFahmed nawaz100% (2)

- B.Lib SyllabusDocument17 pagesB.Lib SyllabussantoshguptaaNo ratings yet

- Current Transformer - PACT RCP-4000A-1A-D95 - 2904921: Key Commercial DataDocument4 pagesCurrent Transformer - PACT RCP-4000A-1A-D95 - 2904921: Key Commercial DataЮрий ЛобановNo ratings yet

- FINAL REQ Psych 212 PDFDocument2 pagesFINAL REQ Psych 212 PDFM GiNo ratings yet

- Citation XDocument25 pagesCitation XlocoboeingNo ratings yet

- Virginia SatirDocument12 pagesVirginia SatirGuadalupe PérezNo ratings yet

- .Choose The Correct Answer For The Following Questions From The Given AlternativesDocument3 pages.Choose The Correct Answer For The Following Questions From The Given AlternativesAlemayehu OreboNo ratings yet

- Ats22 User Manual en Bbv51330 02Document85 pagesAts22 User Manual en Bbv51330 02Catalin PelinNo ratings yet

- Activity Heal The Environmentpermentilla-Michael-Ray-E.Document1 pageActivity Heal The Environmentpermentilla-Michael-Ray-E.Michael Ray PermentillaNo ratings yet

- Chapter 1 Vocabulary and Study GuideDocument3 pagesChapter 1 Vocabulary and Study GuideArman OmadtoNo ratings yet

- Sublime VocabularyDocument6 pagesSublime VocabularyHum Nath BaralNo ratings yet

- Chief Minister's Good Governance Fellowship: Case Study Questions For Shortlisted CandidatesDocument20 pagesChief Minister's Good Governance Fellowship: Case Study Questions For Shortlisted CandidatesRajeev SagiNo ratings yet

- Detailed Lesson Plan DLP Format DATE LeaDocument4 pagesDetailed Lesson Plan DLP Format DATE LeaPablo JimeneaNo ratings yet

- WellPlan ReportDocument34 pagesWellPlan ReportElmar CahangirovNo ratings yet

- Wrench Time PaperDocument4 pagesWrench Time PaperJair TNo ratings yet

Diesel Engine Lubricants Their Selection and Utilization With Particular Reference To Oil Alkalinity

Diesel Engine Lubricants Their Selection and Utilization With Particular Reference To Oil Alkalinity

Uploaded by

rpumacayovOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diesel Engine Lubricants Their Selection and Utilization With Particular Reference To Oil Alkalinity

Diesel Engine Lubricants Their Selection and Utilization With Particular Reference To Oil Alkalinity

Uploaded by

rpumacayovCopyright:

Available Formats

717

DIESEL ENGINE LUBRICANTS : THEIR SELECTION AND

UTILIZATION WITH PARTICULAR REFERENCE TO OIL

ALKALINITY

By A. Dyson, M.A.*, L. J. Richards, B.Sc. (Eng.), Wh.Sc..f., and K. R. Williams, B.Sc.$

The main functions of heavy-duty lubricating-oil additives are to control engine fouling,

bearing corrosion, and wear of liners and piston rings. Alkalinity is desirable for the

control of wear and is one of the major requirements for the avoidance of piston fouling

when conventional organo-metallic additives are used. In a well-balanced oil, sufficient

dispersive power and oxidation stability may be incorporated to ensure adequate piston

cleanliness and freedom from bearing corrosion provided that the alkalinity level is satis-

factory.

The alkalinity level falls during service, and for satisfactory performance with certain

types of additive in common use it must be kept above a minimum value. For these

additives equations are given which enable the variation of the alkalinity level with time

in given circumstances to be predicted approximately. The most satisfactoryarrangementis

to use an oil containing sufficient alkalinity so that the concentrationnever falls below the

critical value. The oil-change period is then determined by other considerations, for

example, contamination with abrasives. If an oil of lower alkalinity-concentration is used,

then the equations developed permit an approximate estimate of the oil-change period,

determined solely from the aspect of additive effectiveness. The applicationof these results

to engines with separate cylinder lubrication is discussed.

Thus oils, and, where appropriate, oil-change periods, may be selected on a rational

basis instead of by trial and error.

INTRODUCTION

ABOUTTWENTY YEARS AGO it was found that the addition of

certain materials to the lubricating oil could alleviate ring

sticking and other difficulties which were being encountered

in the operation of high-speed Diesel engines. From these

early beginnings a new class of Diesel-engine lubricant was

developed and it is now common practice to use oils of this

type, called ‘heavy duty’, in Diesel engines; in fact some

highly rated engines will not run on straight mineral oils.

In the early days of these oils there were sometimes com-

plaints that they gave little or no benefit over the straight

mineral oils then in common use. On the other hand many

users were completely satisfied with the new oils and found

that they gave reduced engine wear and reduced fouling and

consequently longer engine life. Fig. 1 shows examples

typical of the range of results observed.

Experience showed that different grades of heavy-duty

The MS. of this paper was first received at the Institution on 27th

3ub 1956. For a report of the meeting, in London, at which this

paper was presented, see p . 740. Fig. I . Typical Examples of Differences in Piston Condition

* Research Physicist, :Shell’ Group, Thornton Research Centre. Which Can Arise from Improper and Proper Use of

t Research Engineer, Shell’ Group, Thornton Research Centre.

$ Research Physicist, ‘Shell’ Group, Thornton Researoh Centre. Heavy-duty Oil

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

7 18 A. DYSON, L. J. RICHARDS, AND K. R. WILLIAMS

lubricating oil were required for differing engines and diffuse through the film and attack cylinder liners and piston

operating conditions. This was recognized in the MIL-L- rings, causing severe corrosive wear (Broeze and Wilson

2104A, Supplement I and Series I1 Specifications defined 1948-49)*.

by the ability of the oil to pass a series of tests on a Cater- The relation between dispersivepower and piston fouling

pillar engine run at three different levels of severity. These is rather more complicated, and dispersive power and alka-

tests are widely acccptcd and have in general proved satis- linity interact together (Denison and Kavanagh 1955). The

factory yardsticks of oil performance. Furthermore, engine lacquers and insoluble resins which act as binders of the

manufacturers have, as a result of their test-bed and field s a t produced during combustion and form a major part

experience, been able to define the grade of lubricant of many engine deposits are thought to be formed by the

required in a unit run under specified operating conditions polymerization of oxidation products of the fuel or of the

in terms of these performance levels. For a particular lubricating oil. Some of these oxidation products are acidic

grade of oil they have recommended oil-change periods and may be rendered innocuous by reaction with alkaline

appropriate to various operating conditions. However, this additive. Moreover, some deposits arc formed by the reac-

plbccss of oil selection and oil-change period recommenda- tion between lubricating-oil components and the sulphur

tion is a purely empirical one. It had, of course, been acid produced in the combustion chamber, which may also

recognized for a long time that the oil contaminants, such catalyse the polymerization referred to above. Neutraliza-

as insolubles and fuel dilution, should not be allowed to tion of the sulphur acids by the alkaline additive therefore

exceed a certain value. However, experience showed that in helps to keep the piston clean. Dispersive power is still

many cases with heavy-duty lubricants satisfactory engine needed to avoid deposition in the engine of insoluble con-

cleaxiliness and wear levels were not obtained, despite quite taminants, either soot from the combustion chamber or

low levels of contamination present in the oil when it was products from the neutralization reactions discussed above.

drained from the engine. It was evident that some other Oxidation stability is necessary for the conml of the

factor was determining the necessity for oil change. corrosion of sensitive bearing metals. The oil f ilm on the

Laboratory examination of used-oil samples showed that cylinder walls is exposed to very high local temperatures

the additive was being used up or depleted in service and and may oxidize to give some corrosive products which are

that depletion of the additive often made oil change ncces- liable to attack copper-lead bearings. This process may be

sary. It was therefore decided to embark upon an extensive retarded or prevented by making the oil more stable to

investigation in an attempt to define in a rational manner oxidation.

the factors effccting additive depletion. From the results It has been seen that alkalinity is necessary both to reduce

obtained in this investigation it was hoped that it would corrosive wear and to keep the piston clean, and in practice

prove possible to predict the grade of heavy-duty lubricant sufficient dispersive power and oxidation stability may be

and oil-change period required by a Diesel engine under maintained in an oil to ensure satisfactory performance so

given operating conditions. long as there is an adequate reserve of alkalinity.

This paper describes work which has shown how It therefore seems that in such cases, allralinity could be

additive depletion is relatcd to engine design and operating used as a criterion of the effectiveness of a heavy-duty oil

conditions. It also shows how with certain classes of during its life and evidence will be presented to show that

additive lubricants oil-change periods, as determined by this is indeed the case.

considerations of additive depletion, may be related to In order to relate the performance of an oil to its W t y ,

certain readily defined parameters. a method of measurement applicable to a used oil is required.

I n principle a suitable method is to titrate the oil against a

P R O P E R T I E S REQUIRED IN A strong acid, that is to measure the quantity of add required

HEAVY-DUTY OIL to neutralize the alkaline additive in a given quantity of the

Before considering in detail what happens to the additive lubricating oil. Many practical difficulties arise, however.

in a heavy-duty oil when it is used in a Diesel engine, it is An electrometric indication of the end point is necessary,

relevant to consider the properties which are improved or together with careful selection of the reagents and of the

conferred on a mineral oil by the presence of heavy-duty reaction medium. These difficulties will not be discussed in

additives. l h c y are alkalinity, dispersive power, and this paper. It may be necessary to vary the procedure

oxidation stability. according to the particular additive or combination of

Those aspects of the performance of a Diesel engine additives employed.

most lkely to give trouble and which the heavy-duty oil The result is conventionally expressed as the number of

is expected to control are corrosive wear of cylinder liners, milligrammes of potassium hydroxide chemically equivalent

and piston rings; piston fouling (ring sticking, piston to the alkalinity contained in 1 gramme of oil, or mg. KOH

lacquer, oil ring plugging) ;and bearing corrosion. per gramme for short.

Alkalinity combats the corrosive wear of cylinder liners It is perhaps worthy of mention at t h i s point that it was

and piston rings. When conventional fuels are burnt, at one time thought that the performance of a used oil could

sulphur oxides and the corresponding acids are produced, be estimated from its sulphated ash or additive metal

and enter the oil film in the cylinder walls. Alkaline additives content. However, neither of these characteristics is a

in the oil film may neutralize these acids before they can * An alphaberial list of references i s given in Appmdix ZV.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

DIESEL ENGINE LUBRICANTS : THEIR SELECTION AND UTILIZATION 719

measure of the alkalinity of a used oil, since additive metal covered by different types of deposit are estimated visually

may remain in solution or in suspension in the oil after the and multiplified by a merit figure for that type of deposit.

additive has been neutralized in doing its job. The merit figure depends on the colour and nature of the

Such used additive is still detectable directly or in the deposit, a perfectly clean surface obviously having the

form of its sulphate, and both field and laboratory studies highest merit figure. The sum of these products of per-

have confirmed the lack of correlation between these pro- centage area and merit figure gives the rating for the par-

perties and the actual performance of the oil. ticular section of the piston. These sectional ratings are

suitably weighted and combined to give an overall piston

WHAT HAPPENS TO THE PISTON A S THE rating. A perfectly clean piston would have an overall rating

ALKALINITY IS NEUTRALIZED of 10, a very dirty one would be rated at 0. Fig. 3 shows the

As the engine is run, additive is neutralized and the state at various times of the individual areas of the piston

alkalinity of the oil decreases. The piston remains clean, which are combined to give the overall rating shown in

however, until the base number reaches a certain critical Fig. 2. Each part starts getting dirty at about the same time,

value, after which the piston becomes dirty quite rapidly. but in general the top of the piston is rather more sensitive

This is illustrated in Fig. 2, which shows the variation of than the skirt. It is interesting to note that when a fresh

FRESH CHARGE FRESH CHARGE

J BASE OIL

-,

ADDITIVE OIL

.-

OF ADDITIVE OIL

10

BASE OIL

A.

ADDITIVE OIL OF ADDITIVE OIL

+

N

=-lo

Y

a

-

0

u

Z 6

l-

a

t

mI: 4

Ln

z 2

z

i

0 10 20 30 40

2

U

10

NUMBER OF 16-HOUR PERIODS RUN

Fig. 2. Alkalinity and Piston Cleanliness Ratings at 16-hour

Intervals During an Engine Run Using Fuel Containing 6

I per cent Sulphur

o No. 1 piston, cleaned after every period. 4

+ No. 2 piston, not cleaned after period 3.

2

alkalinity and piston cleanliness with time during a long

runusing a fuel containing 1 per cent sulphur in a laboratory 0

Diesel engine. Chromium-plated compression rings were 0 10 20 30 40

NUMBER OF 16-HOUR PERIODS RUN

used in this experiment and the run-in was slow. The oil

consumption was relatively high, about 2 per cent of the Fig. 3. Sectional Piston-area Cleanliness Merit Ratings at

fuel consumption, and so much fresh additive was intro- Intervals During an Engine Run Using Fuel Containing

duced with the make-up oil that the alkalinity decreased 1 per cent Sulphur

only slowly. After some time the consumption was made up a x Top land.

with straight mineral-oil in order to accelerate the drop in o Other lands.

allralinity. b x Topskirt.

The state of the piston is described on an arbitrary scale. o Lowerskirt.

Each section of the piston is considered in turn,ring grooves c x Topringgrooves.

and lands, skirt, etc. For each section the relative areas o Other ring grooves.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

720 A. DYSON, L. J. RICHARDS, AND K. R. WILLIAMS

heavy-duty oil is charged to the engine, the piston skirt

and the lands are cleaned up but the grooves stay dirty.

This indicates that the additive can stop further deposition

but that the removal of deposits already formed depends on

a mechanical rubbing action.

MINIMUM ALKALINITY REQUIRED FOR A

CLEAN PISTON

In the particular case discussed above, the piston stayed

clean as long as the alkalinity remained above about 0.3 mg.

KOH per gramme. However, the high oil-consumption due

to the very slow mming-in of the compression rings is

believed to have influenced the result. From observations

of the behaviour of a number of different Diesel engines 3 -2 u4 8

running under widely different conditions, it is possible to ALKALINITY REMAINING AT END OF TEST-

derive a working rule. This states that the piston will MG. KOH PER GRAMME

remain clean provided that the alkalinity exceeds a critical Fig. 5. Piston Cleanliness Against Residual Alkalinity at

value which has been found to be approximately propor- End of Test fur Various Fuel Sulphur Contents

tional to the sulphur content of the fuel. For example, the

value for a certain class of additive is about 1 mg. KOH per Each point represents the mean result of three runs with different

oil viscosities.

gramme for every 1 per cent sulphur. As is shown later in

this section, the critical level might be expected to vary with

engine design or operating conditions, and although the previous experiment. The critical alkalinity level is seen to

stated value is adequate for most engines, higher minimum be between 1.5 and 2-5 mg. KOH per gramme.

additive concentrations are sometimes necessary to ensure Fig. 5 shows the result of a comparison of different oils

freedom fiom ring-sticking. This paper is concerned mainly containing different concentrations of alkaline additive with

with the behaviour of oils containing additives of this type, different fuels. The piston cleanliness rating is plotted

against the alkalinity remaining at the end of test. It will

be observed that for alkalinities above about 1 mg. KOH

per gramme there is very little difference in engine con-

dition between the fuels of 0.2 and 1.0 per cent by weight

of sulphur. Fig. 6 shows a similar comparison at different

values of the fuel consumption for a constant fuel sulphur

NUMBER OF 40-HOUR PERIODS RUN

F&. 4. Alkalinity and Top-ring Groove Cleanliness Rating

During an Engine Run Using Fuel Containing 2.8 per

cent Wezght Sulphur

x

-

0

-ox Alkalinity.

Top-ring groove rating.

Periods 1-4 in this figure correspond to periods 5-8 in Fig. 8.

but the procedure given below for the selection of oils,and,

where appropriate, oil-change periods, may easily be

modified to apply to the case of additives with different

I 2 3

requirements. ALKALINITY REMAINING AT END OF TEST-

Fig. 4 shows the variation of piston cleanliness and MG. KOH PER GRAMME

alkalinity with time during an experiment similar to the Fig. 6. Piston Cleanliness Against Residual Alkalinity at

one described previously except that the fuel contained 2.8 End of Test for Various Fuel Inputs

per cent by weight of sulphur. This level of sulphur was

adopted to magnify the influence of this factor on additive 0 Fuel input 0.50

per min.

02.

o Fuel input 0.75

per min.

02.

depletion and does not represent a present-day or probable x Fuel input 1.00 per min.

02.

distillate fuel. The rings were well run in and the oil- Each point represents the mean result of four runs with different

consumption rate was about 40 per cent of that in the combinations of Iubricant viscosity and jacket temperature.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

DIESEL ENGINE LUBRICANTS : THEIR SELECTION AND UTILIZATION 721

Thus quite a high-alkalinity concentration must be main- rates of the order of 0.1 pint per hr. The circulation rate

tained if a fuel of high-sulphur content is used. The reason tends to decrease with increasing oil viscosity, but it appears

for the relation between fuel-sulphur content and the critical to be independent of engine speed and load within the range

value of the alkalinity level is believed to be as follows. Oil investigated (500-1,500 r.p.m.). It seems to be independent

is splashed up on to the cylinder-bore surface and some of of oil consumption within the range normally encountered,

it finds its way into the ring-belt area. While it is there some although the circulation rate was found to be rather higher

of the additive is neutralized by acids formed when the fuel in one case where slow runnhg-in of chromium-plated

is burnt. Some of the oil is consumed but the rest eventually compression rings was accompanied by excessive oil con-

drains back into the crankcase. Thus the oil 'returning to sumption. Circulation rates estimated by this method show

the crankcase contains less additive than that splashed up reasonable agreement with those obtained by other methods

on the cylinder bore and this causes the loss of alkalinity (Edgar 1957).

observed as the engine is run. The oil in the ring-belt area CORROSIVE WEAR A N D ALKALINITY

thus contains less alkalinity than that in the crankcase, but

it is the concentration of alkaline additive in the ring-belt The criterion for the minimum alkalinity required in the

area which controls the deposit formation on the piston. crankcase oil has been established only in relation to piston

cleanliness. It has been found, however, that the action of

the alkaline additive in reducing corrosive wear normally

NEUTRALIZING ACIDS

ADDED AT RATE oL lasts at least until the piston has become dirty. This is

OIL CONSUMED RATE R

CYLINDER ZONE

ALKALINITY CONCENTRATION CI

011 ClRCULATlpN

t P \

CRANKCASE ZONE OIL ~ A K E - U RATE

P R

WEIGHT OF OIL L2

ALKALINITY CONCENTRATION Cz

' I I NUMBER OF 40-HOUR PERIODS RUN

F&. 7. Model of Oil Circulation System to Ring-belt Zone

Fig. 8. Alkalinity and Wear Rate at 40-hour Intervals

During an Engine Run Using Fuel Containing 2.8 per

cent by Wezght of Sulphur

A simplified model illustrating these points is shown in

Periods 5-8 in this f i v e correspond to periods 1-4 in Fig. 4.

Fig. 7. The flow of oil up to the ring-belt zone and back

is represented by a circulation rate P. The difference in illustrated in Fig. 8 which shows the piston-ring wear rates

concentration of the alkaline additive in the ring-belt zone in the experiment for which the piston cleanliness was

and in the crankcase may be shown to be approximately shown in Fig. 4.

equal to a/P, where a is the rate of addition of the acid Fig. 9 shows the results of experiments using a fuel con-

which neutralizes the additive, and may be calculated from taining 1 per cent by weight of sulphur. In this case the top

the observed rate of loss of alkalinity in the crankcase ring was made radioactive by exposure in a neutron pile

(Appendix 111). Therefore if some effective additive is to at Harwell. The wear products from this ring enter the oil

be present in the oil in the ring-belt zone its concentration film on the cylinder walls and drain down to the crankcase.

in the crankcase oil must be at least a/lJ which is the Oil from the crankcase is continuously circulated past a

required critical alkalinitylevel. The effective oil-circulation scintillation counter, a very sensitive detector of radiation,

rate P may thus be calculated. Details of the calculations and the curve of counting rate against engine running-time

are given in Appendix 111. is automatically plotted by means of a recorder. The

The results obtained for two direct-injection four-stroke counting rate is proportional to the concentration in the oil

Diesel engines of about 1.5 litres capacity give circulation of radioactive wear products, that is, to the total top-ring

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

722 A. DYSON, L. J. RICHARDS, AND K. R. WILLIAMS

conditions and to the additive combination in use, then

deposits will probably be formed in the ring grooves,

although these will not be worse than those experienced

with a straight mineral oil. I t has been shown above that

these deposits will not be removed by subsequent operation

with alkalinity concentrations above the critical level. This

emphasizes the importance of never allowing the alkalinity

concentration to fall below the critical level, particularly in

the case of engines sensitive to ring-groove deposits.

Measurement of alkalinity concentration in used oils is

1 1 1 1 1 1 1 1 1 1 1 not a simple matter, however, and specialized equipment

and skilled workers are required. The standard methods

given in the literature have been found to require modifica-

tion when used for this purpose. The necessary laboratory

facilities are not available to most engine operators, and if

they are available they are very expensive. Furthermore, it

is often desired to make recommendations in advance for

oils for specific situations, as a process of trial-and-error

is not regarded very favourably by the operators on whose

engines the errors are committed.

It is therefore desirable to predict the variation of

alkalinity with time. It will be shown later that this may

be done provided that information is available on the alka-

linity of the fresh oil, the engine characteristics, and the

running conditions, etc. Most of the remainder of this paper

is concerned with this particular problem.

ENGINE RUNNING TIME-HOURS

Fig. 9. Alkalinity and Wear Rate During Four Diflerent VARIATION O F ALKALINITY WITH TIME

Engine Runs with Additive Oil DURING A TYPICAL ENGINE R U N

”>

o Three different continuous runs.

0

Run during day only, shut down at night.

The variation in the allralinity of the crankcase oil with time

during an engine run in the absence of oil make-up is

illustrated in Fig. 10. For the classes of additive dealt with,

it has been found that in these conditions, the curve of

alkalinity against time is curved downward as in curve I.

wear which has taken place. The slope thus corresponds to This is to be expected if the effective rate of neutralization

the wear rate. Suitable corrections must be applied for is constant, as the volume of oil present in the crankcase

radioactive decay and for losses due to oil consumption, decreases as oil is consumed. It is possible to correct for this

etc., and the corrected wear rates are then plotted as shown

in Fig. 9.

In both these instances the full anti-wear effect of the oil

is evident for the whole of the period during which some

alkalinity is maintained in the crankcase oil.

RECOMMENDING OILS A N D OIL-CHANGE

P E R I O D S I N T H E IDEAL C A S E

So far, the stage has been reached at which a definite

recommendation may be given to Diesel engine operators

concerning the selection of oils and oil-change periods.

These should be arranged so that the alkalinity concentra-

tion never falls below a critical level estimated as x mg.

KOH per gramme for each 1 per cent sulphur content of

the fuel, where x depends on the particular formulation

used. In this way piston cleanlinessis maintained, corrosive ENGINE RUNNING TIME

wear is controlled, and in a suitably formulated oil the Fig. 10. Variation of Alkalinity with Engine Running

oxidation stability maintained at a level sufficient to avoid Time in the Absence of Make-up

the corrosion of copper-lead bearings.

If at any time the alkalinity concentration is allowed to I Observed alkalinities.

I1 Alkalinities which would have been observed in the absence of

fall below the critical level appropriate to the operating oil consumption.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

DIESEL ENGINE LUBRICANTS : THEIR SELECTION AND UTILIZATION 723

effect and to draw curve 11, which represents the alkalinity

which would have been observed in the absence of oil con-

sumption. This line is usually straight, that is, the rate of

loss of alkalinity due to neutralization by acid is in fact

independent of the alkalinity of the oil. The rate of the

neutralization reaction may thus be characterized by a rate

of addition of neutralizing acid which is independent of

initial alkalinity level or of time during an engine run.

Additives other than those of the class considered may

behave differently, for example, the neutralization rate may

increase with increasing alkalinity concentration. However,

in the range of most practical importance, up to 2 mg.

KOH per gramme, the rates of neutralization of all the

additives of which the authors have experience are approxi-

mately the same under similar conditions.

RATE OF NEUTRALIZATION OF ALKALINITY

DURING A RUN

For a given engine working at constant speed the rate of

addition of neutralizing acid has been found to be propor- x -x Initial additive content equivalent to 1.6 mg. KOH

per gramme.

tional to the fuel sulphur throughput, that is, to the product

0-0 Initial additive content equivalent to 3.2 mg. KOH

of the fuel consumption rate (quantity per unit time) and per gramme.

of the fuel sulphur content. It appears to be almost in- 0- 0 Initial additive content equivalent to 6.4mg. KOH

dependent of other factors such as oil viscosity and tem- per gramme.

perature and coolant temperature, within the limits which

better agreement at low values of the fuel sulphur content

have been studied in the laboratory up to the present time.

Fig. 11 shows the relation between neutralization rateis obtained if a value of 0.1 is arbitrarily added to the

measured fuel sulphur content, expressed in percentage

and fuel consumptionat constant speed and sulphur content,

while Fig. 12 shows the effect of fuel sulphur content atweight. Secondly, the neutralization rate with the fuel of

constant speed and fuel consumption. the highest sulphur content does depend slightly on the

Concerning Fig. 12, two qualifications must now be initial alkalinity of the oil. This is really a consequence

made to the simple statement that the neutralization rateof the breakdown of the condition discussed under the

is proportional to the fuel sulphur throughput. Firstly, head ‘Minimum Alkalinity Required for a Clean Piston’,

that the- oil circulating round the ring-belt area should

contain some available alkalinity. There is then sufficient

‘0

X

1CQ

I alkalinity to cope with all the acids present, and further

increases in the allralinity content of the oil have very little

effect on corrosive wear and on piston fouling.

a

(L

If this condition breaks down there is an excess of acid

I

IS0 in the ring-belt zone, and this will neutralize all the base

w

that is supplied to it, that is, the neutralization rate will

z depend on the alkalinity present in the oil. Some of the

3

U excess of unneutralized acid will cause corrosive wear and

5

P

piston fouling, and these will be worse, the lower the alka-

I100 linity concentration in the oil. This was found to be so,

s Fig. 5 is a plot of the piston cleanliness results of the same

+

j

I

experiment, and the relative sensitivity of the piston

I-

vt

cleanliness to additive concentration with the fuel of the

d highest sulphur content can be seen. Any remaining excess

z

acid may drain to the crankcase and cause wasteful neutrali-

zation there.

It has been seen above that the rate of neutralization of

alkalinity is proportional to the fuel sulphur throughput for

a given engine working at a given speed, subject to the two

- 1

I 0.6 I qualifications. The ratio between the observed neutraliza-

FUEL THROUGH r OF ENGINE-oz PER

tion rate and the chemical equivalent of the fuel sulphur

Fig. 11. Variation of Rate of Neutralization with Fuel throughput will be called the conversion ratio, and denoted

Throughput by y per cent. That is to say, only y per cent of the fuel

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

724 A. DYSON, L. J. RICHARDS, AND K. R WILLIAMS

sulphur which enters the combustion chamber actually distance between the top of the piston and the cylinder

reacts with the additive present in the lubricating oil. It is head, and N the engine speed.

shown in Appendix I that ifthis is known, then the variation The area of the oil film available for absorption of these

of the allralinity with time during an engine run may be sulphur oxides is proportional to XU,and the rate of entry

predicted from a knowledge of other quantities such as fuel of the sulphur acids into the oil film is therefore propor-

and oil consumption which may easily be measured or tional to

estimated. Thus it is important to know the magnitude of F!3

the conversion ratio in Merent cases. The experimental -

method of the determination of the conversion ratio is XN

illusuated in Appendix 11. The time available for the.absorption is proportional to

1/N, and the whole process is repeated with a frequency

proportional to N . The value of y would therefore be

VALUE O F THE CONVERSION FACTOR IN expected to be inversely proportional to XN,other things

VARIOUS CASES being equal.

The following values of the conversion ratio, expressed as a The data on the four-stroke direct-injection trunk engines

percentage, have been observed in a series of Diesel engines show some indications that the conversionfactory decreases

ranging from 3 to 15 inches in bore and from 250 to 2,000 with increasing values of XN,but not so rapidly as predicted

r.p.m. in speed. Each value represents an engine of a by the simple theory outlined above. It will be appreciated

Merent type, and several supercharged engines are that XN does not vary very much from one engine to

included. The arbitrary addition of 0.1 per cent by weight another, so that experimental verification is rather difficult.

to the measured fuel sulphur content has been made in each Tests with varying speeds in the same engine have indicated

case. These values apply to a range of heavy-duty oil that the conversion factor decreases with increasing speed,

formulations, though not necessarily to all of them: but again less rapidly than predicted by the simple theory.

Direct-injection four-stroke trunk engines: 0.090, 0.075, EFFECT O F ADDITION O F MAKE-UP

0.082, 0.080, 0.061, 0.067, 0.077, 0.041, 0.069. In Fig. 10 it was shown that in the absence of oil consump-

Pre-chamber four-stroke uunk engines: 0.155, 0.098, tion, the variation of alkalinity with time in an engine run

0.130, 0.147. would be linear for the class of additive considered in this

Direct-injection two-stroke uunk engines: 0.055, 0.095, paper. The effect of oil consumption is to make the line

0.108. curve downward. During a long run, make-up is added at

Direct-injection four-stroke engine with separate cylinder intervals and this gives a ‘saw-tooth’ curve of the form

feed: 0.074. shown in Fig. 13, curve I. If make-up is added very often,

so that in effect there is a continuous addition of maka-up

It appears that prechamber engines are more severe fiom to balance the continuous loss of oil through consumption,

the depletion aspect in their demands on heavy-duty curve I is smoothed out to give curve 11. It is shown in

lubricating oil than are their direct-injection counterparts. Appendix I that the forms of these curves may be calculated,

Insufficient data have been obtained to make a categorical given a knowledge of the following factors: conversion

statement aboutdirect-injection two-stroke enginesalthough ratio, fuel consumption, fuel sulphur-content, oil con-

the evidence available suggests that this type of engine is sumption, oil charge.

intermediate in severity between four-stroke direct-

injection and prechamba engines.

It will also be apparent from the above figures that there

is still a wide variation within these classes of engine,

however. The data on direct-injection four-stroke trunk

engines are barely adequate for a statistical investigation

while the data on the other classes of engine are inadequate

at the present time. The conversion factor appears to

increase with increasing swirl or turbulence in the cylinder.

On theoretical grounds y would be expected to depend

on engine dimensions and speed. An argument which is

often advanced is that the concentration of sulphur acids

during the working stroke is pmportional to

ENGINE RUNNING TIME

Fs

XZYN Fig. 13. Vuriutionof Alkalinity with Engim Running

Time Showing Effectof Addition of Make-up

where F is the fuel consumption, quantity per unit time,

S the fuel sulphur content, X the bore, Y the effective ---- I1I Make-up added at discrete intervals.

Continuous addition of make-up.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

DIESEL ENGINE LUBRICANTS : THEIR SELECTION AND UTKLIZATION 725

All these may easily be measured or estimated except the

conversion ratio. This may be known from the experiments

on the same engine, but if it is not known then it is suggested

that the best estimates at present available are the means

of the values given above for the various classes of engine:

Direct-injection four-stroke engines 0.07 per cent

Prechamber four-stroke engines . 0.13 per cent

Direct-injection two-stroke engines 0.10 per cent

If the alkalinity concentration of the make-up oil is high

enough, the continuous curve tends towards a limiting

value after some time, while the saw-tooth curve oscillates

between two limiting values, corresponding to the con-

centrations just before, and just after, make-up. An example

of the experimental verification of the relations derived

theoretically in Appendix I is given in Appendix 11.

If C, is the alkalinity concentration in the make-up oil,

y the conversion ratio per cent, S the fuel sulphur content

per cent by weight, f the ratio of the fuel consumption to

the oil consumption, and Q a safety factor depending on the

make-up procedure, then the limiting value of the alkalinity FUEL SULPHUR CONTENT-PER CENT WEIGHT

concentration after a long time is Fig. 14. Fuel Sulphur Content Against Oil Consumption

C,-A’ Required for Indefinite Oil-drain Period

where A’ = 0*35yfQ(S+0.1) Initial alkalinity level of oil, mg. KOH per gramme.

In practice, the allralinity concentration of the make-up

oil is usually the same as that in the initial oil charge, so that If an oil of lower initial alkalinity content than that

the final value of the drop in alkalinity concentration is indicated by the above considerations is used, then an oil-

simply A’. In these circumstances, the drop is 85 per cent change period dictated by considerations of additive

of A‘ after the engine has consumed a quantity of oil equal effectivenessmay be calculated from the equations given in

to twice the original oil charge, or 95 per cent of A’ after Appendix I. However, slight variations in the quantities

it has consumed three times the original charge. In such involved may lead to large variations in the calculated oil-

cases the oil may be selected by means of the simple equa- change period.

tion already given, as explained in the following section. It is emphasized that oil must still be changed when

indicated by other considerations, for example, contamina-

RECOMMENDATIONS OF OILS A N D OIL- tion with fuel, coolant, or abrasives.

CHANGE P E R I O D S FOR INDIVIDUAL C A S E S In some cases the oil-change period dictated by these

If the limiting value of the allralinity concentration is not other considerations may not be long compared with the

less than the critical value, 1 mg. KOH per gramme for time necessary to consume a volume of oil equal to that of

each 1 per cent of sulphur in the fuel, for the class of addi- the original crankcase charge. The minimum alkalinity level

tive considered, then the oil-change period will not be of the oil for the maintenance of additive effectiveness

limited by the exhaustion of the additive. The minimum throughout the oil-change period is then no longer deter-

alkalinity level of the fresh d l is thus given by mined by the formulae given above, but must be evaluated

by means of the equations given in Appendix I.

C, =.S+A’

It is important to note that raising the sulphur content of

= S+O*35yQf(S+O*l) fuel does not necessarily entail any disadvantages in the

Thus for a given type of engine with a given make-up operation of an engine, and frequently it may well be more

practice, y Q is fixed, and a family of curves may be con- economic to use a fuel of higher sulphur content (even if, as

structed, giving the alkalinity concentration in the fresh may sometimes be the case, it is desirable to use an oil of

oil necessary for any combination of fuel sulphur content higher additive content). In many cases it is not necessary

and fuel/oil consumption ratio. This is illustrated in Fig. 14. to match an increase in fuel sulphur content with a higher

In practice it is obviously uneconomic to market a large additive content in the lubricating oil. MIL-L-2104A oils

number of oils differing only slightly in alkalinity content. give satisfactory results with fuels of up to 1per cent sulphur

Thus convenient ‘steps’ in additive concentration are in many applications in which oil-change period is not

adopted for marketing purposes and the various brand limited by additive exhaustion but by oil contamination.

references can replace the actual alkalinity levels given in The most familiar examples of this occur in automotive

the figure. For those concerned with specific recommenda- operation, in which engines generally have an oil-

tions in the field this facilitates considerably the selection consumption rate of around 1 per cent of the fuel consump-

of the most suitable oil for a given application. tion and under conditions of normal use, MIL-L-2104A

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

726 A. DYSON, L. J. RICHARDS, AND K. R. WILLIAMS

oils give an indefinite oil-change period with fuels containing presence of water may react with alkaline additives. One

up to 1 per cent by weight of sulphur. These sulphur levels possible mechanism for the entry of sulphur acids into the

could be appreciably higher or, alternatively, the oil con- oil and the subsequent reaction with alkaline additives is

sumptions appreciably lower, when oils of level Supple- that sulphur dioxide enters the interface between oil and

ment I are used. combustion gases and diffuses into the oil where it may be

Owing to the low conversion ratio for the neutralization neutralized by the additive. Some experiments on the

of the alkalinity in the lubricating oil, it is always more diffusion and reaction rate of sulphur dioxide in films of oil

economic to incorporate the alkalinity in the oil than in the undertaken in the chemical laboratory show that this is

fuel. far too slow to account for the observed reaction rate, about

1,000 times too slow, in fact. It is therefore necessary to look

OILS FOR THE SPECIAL CASE O F for another picture of what happens.

SEPARATELY LUBRICATED CYLINDERS The lubricating oil of a trunk engine is found to contain

A typical problem is that of marine engines. These are a proportion of the non-volatile combustion products of any

usually big engines with separate cylinder lubrication, and substance which may have been added to the fuel. Thus in a

there is an increasing tendency towards the use of heavy gasoline engine between 5 and 10 per cent of the lead

fuels with high sulphur contents. An oil of very high supplied with the fuel may afterwards be found in the

alkalinity content is required to reduce the severe corrosive lubricating oil, or in the sludge trapped by the lubricating-

wear and piston fouling encountered under these conditions. oil filter. Some experiments have been undertaken using

Let R be the rate of supply of oil to the cylinders, C the leaded fuel in Diesel engines, with similar results. One

alkalinity concentration of the oil supplied to the cylinder, obvious sulphur-containing material of moderately low

F the rate of fuel consumption, in the same units as R, and volatility likely to be present in the combustion chamber is

S the fuel sulphur content, per cent by weight. sulphuric acid. It is known that even a few parts per million

The rate of supply of alkalinity must balance the rate of of sulphur trioxide present in water vapour (which need

neutralization by sulphur acids, thus not be saturated) will condense as strong sulphuric acid

CR = 0.35yFS (Appendix I) (Johnstone 1929). Thus sulphur trioxide formed by com-

bustion of the sulphur in the engine may be expected to

The limited data available in engines of this class suggest

condense with water vapour, which is always present from

that y may be put equal to 0.08 per cent approximately, and

combustion of hydrogen in the fuel, to form droplets of

CR = 0.028FS sulphuric acid which will behave as the low-volatile materials

The ratio of oil supply to fuel consumption normally varies referred to above. That is to say, about one-tenth of the

between 0.2 and 0-6per cent, so that the value of C required sulphuric acid formed will appear in the lubricating oil. If

varies between 14s and 4.7s.For a fuel containing 3 per it is assumed that of the total sulphur burnt in the engine

cent sulphur the alkalinity concentration required may be 1 per cent is converted to sulphur trioxide then about 0.1

as much as 42 mg. KOH per gramme, which is many times per cent of the fuel sulphur would appear in the lubricant

that required for a series I1 crankcase oil. as sulphuric acid which would neutralize the alkaline

Since a marine lubricant must be capable of dealing with additive so accounting for the observed values of Y . It must

the worst possible case, an alkalinity concentration of the be stressed that orders of magnitude are being considered

order of 40-50 mg. KOH per gramme is necessary. Although throughout this section, and that an error of 2 or 3 to 1 is

at first sight it might seem possible to obtain sufficient tolerable.

alkalinity by using high concentrations of conventional The figure of 1 per cent conversionof sulphur to sulphuric

additives, possibly coupled with a higher rate of oil delivery, acid, which is the crux of this argument, may be thought

this would be too expensive to present a practicable solution low, as rather higher proportions of sulphur as trioxide have

to the problem. One method of providing the necessary been reported in exhaust gases. However, it seems that

alkalinity, which has been very successful, is to use an oxidation of sulphur dioxide to sulphur trioxide may occur

emulsion of a strong aqueous solution of an alkaline material after the gas has left the engine, and that the composition of

in the cylinder oil (van der Zijden and Kelly 1956). the exhaust gas does not necessarily relate to conditions on

the cylinder walls (van der Zijden, van Hinte, and van den

THEABSOLUTEVALUEOFTHE Ende 1950). In these circumstances the postulated mecha-

CONVERSION RATIO nism of additive depletion seems reasonable.

The main argument of the paper has now been concluded That sulphuric acid is the main factor causing depletion

but it is tempting to speculate on the factors underlying the is borne out by the experimental observation that at least

order of magnitude of the values found for the conversion half of the neutralization products are sulphates. Sulphuric

ratio y. Since the observed rate of alkalinity neutralization acid would cause corrosive wear and aggravate piston

is approximately proportional to the sulphur throughput of fouling unless it were neutralized by the alkaline additive.

the engine, it seems likely that the oxides of sulphur and Such neutralization is practicable, as in the oil fdm on the

the corresponding acids are responsible for neutralizing the cylinder walls there will normally be an excess of alkalinity

additive. over the small amount of sulphuric acid formed. An oil-film

Sulphur dioxide is soluble in lubricating oils, and in the thickness of about 1 micron would be suffcient.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

DIESEL ENGINE LUBRICANTS: THEIR SELECTION AND UTILIZATION 727

However, some sulphur dioxide or sulphurous acid a given engine so permitting the most economic application

probably enters the oil film.Fortunately the rate of reaction of the lubricating oil. Further evidence is being accumulated

with alkaline additive seems to be very slow, and most of the continuously, and as time goes on it is hoped that predic-

sulphur dioxide must evaporate from the oil film when the tions may be made with greater accuracy. In order to do

gas pressure in the cylinder is released at the end of this it may well be necessary to take into account detailed

the working stroke. Fortunately, again, the sulphur dioxide factors in the engine design to an extent not possible at the

or sulphurous acid does not seem to do much harm in the present moment.

form of corrosive wear or piston fouling, at least under the It is hoped that this paper will have given food for

conditions prevailing in most Diesel engines. thought particularly in connexion with the most economic

It should be emphasized that most of the views expressed use of additive-type oils so that neither additive nor base

in this section are purely speculative in that direct evidence oil is needlessly wasted. This end can best be achieved by

in their support is very difficult to obtain. selecting an oil with an adequate level of performance from

considerations of anti-wear, cleanliness, and stability to

CONCLUSIONS permit the oil-drain period to be determined by the level

It is evident from the work described that it is possible to of contamination. In the case of installations or railroads

relate additive depletion to various engine-design and where very efficient filtration coupled with frequent oil-

engine-operating factors and thereby ensure satisfactory analysis is practised almost indefinite sump-change periods

results with additive-type lubricants. Furthermore, it has are possible.

been shown that when heavy-duty oils are used over In conclusion it is suggested that the differences of rates

extended periods, the deterioration in engine condition is of depletion with different types of combustion system

not necessarily a gradual process permitting considerable merit further examination and consideration by engine

latitude in oil-drain practice, but may be a relatively rapid designers.

one which can lead to catastrophic results in severely rated

engines. The proper selection of oils and oil-change periods ACKNOWLEDGEMENTS

is therefore very important. Thanks are due to the directors of ‘Shell’ Research, Ltd.,

With many heavy-duty oil formulations the concentra- for permission to publish this paper. The co-operation of

tion of alkalinity may be used as a criterion of the effective- many colleagues, in particular Mr. J. Hughes and Mr. R.

ness of the additives. The allralinity level falls during Smith, is gratefully acknowledged.

service and for satisfactory operation it must be kept above

a certain minim- value.

The variation of the alkalinity concentration with time APPENDIX I

during an engine run may be predicted approximately. The

quantities concerned: fuel and oil consumption rates, fuel P R E D I C T I O N OF THE V A R I A T I O N OF A L K A L I N I T Y

W I T H T I M E D U R I N G AN E N G I N E R U N

sulphur contents, oil charge, etc., are easily measured or

estimated, and the calculations are relatively simpIe to carry Definitions of Symbols Used.

out. y per cent Conversion ratio, that is, the ratio between the rate of

The initial rate of neutralization depends on the fuel- neutralization of additive in the crankcase and the

chemical equivalent of the fuel sulphur throughput.

sulphur throughput, but after the engine has been running F Fuel-consumption rate, quantity per unit time or

for some time the alkalinity concentration depends strongly distance.

on the oil-consumption rate. Two-stroke engines and four- S per cent Fuel sulphur content, with an arbitrary addition of

stroke engines with prechambers, give higher neutralization 0.1 per cent by weight.

rates than do four-stroke direct-injection engines. Thus the R Oil-consumption rate, quantity per unit time or

distance (same units as F).

neutralization rate tends to increase with increasing com- L Oil charge.

bustion-chamber swirl. M Rate of addition of make-up, same units as R.

Although most of the work has been done using medium- t Running time or distance since the last oil-change.

and high-speed Diesel engines and distillate fuels the con- tl Time interval between successive additions of make-

up oil.

clusions are thought to be valid if fuels containing residual q = Rtl/Lo Make-up added in each individual operation expressed

components are used. Furthermore, similar theoretical con- as a fraction of the nominal oil charge.

siderations appear to apply to the separate cylinder lubrica- C Alkalinity concentration of the crankcase oil, mg.

tion of large engines such as marine-type Diesel engines. KOH per gramme.

The results are only approximate, but have already proved Chi M t y concentration of the make-up oil, mg.

KOH per gramme.

successful in predicting e n g i n e 4 requirements. It is

Subscript 0 refers to the initial state. It will also be convenient

interesting to note that the oil-change periods calculated to use the following quantities:

from the above considerations have nearly always been in A = 0.35yFS/R

line with the engine manufacturers’ recommendations. D = A log, (1 -4)

However, such recommendations are of necessity general F, R, L, and t must be in consistent units.

in nature and the methods described in this paper make it A has the dimensions of concentration and the numerical

possible to take into account the particular circumstances of coefficientis appropriate to its expressionin mg. KOH per gramme.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

728 A. DYSON, L. J. RICHARDS, AND K, R. W I L L U S

Rate of Neutralizaria. The fuel sulphur throughput is The limiting value of C(b),the lowest alkalinity concentration

reached during the make-up period, is

-FS units of sulphur per unit of oil per unit of time

looL

CM-A'

This is equivalent to A' = AQ = -- 0.35yFS log, (1 -4)

where

FS 112 R 4

looLX 32 units KOH per unit of oil per unit of time

For the case of continuous make-up, the asymptotic value of C

FS 112 was

or x 32 x 1,OOO mg. KOH per gramme per Unit of time C, =CM-A

The rate of neutralization is y per cent of this, The important condition is that C should never fall below a

critical value, and interest is therefore concentrated on the lowest

value reached during a make-up period.

Thus Q may be regarded as a correction factor for the make-up

E

.- 0.3y mg. KOH per gramme per unit of time

practice. The variation of this factor with q, the amount added at

each individual make-up expressed as a fraction of the nominal

crankcase-charge, is given in Table 1.

Continuous Addizion of Make-up. It is assumed that the oil

consumed carries with it an amount of alkalinity equal to the Table I . Variation of Correction Factor wilh Make-up

product of the amount of oil lost and the alkalinity concentration

in the crankcase at that time. Most of the oil is lost from the Expressed as a Fraction of Nm'nal Crankcase Charge

cylinder zone where the alkalinity concentration is less than in

the crankcase. In Appendix 111 it will be shown that this does not q l Q

affect the form of the curves of alkalinity against running time.

It is further assumed that F, R, and M are approximately 0.1 1.06

constant when averaged over intervals of time short compared 0.2 1.12

0.3 1.19

with r itself. 0.4 1.28

The balance of total alkalinity in the crankcase gives 0.5 1.39

d

;rt(LC) = M C M - R C - O O ~ ~ ~ F S

but L = Lo -(R -M)t and hence

dC

[Lo-(R--M)~]~+MC = MC~-0'35yFs . (1)

Two alternative values of M will now be considered in turn.

(1) No make-up. M = 0 and equation (1) becomes

dC

(b-Rr);iS- = -0.35yFS

The solution to this with C = COat t = 0 is

where A = 0.35yFS/R.

(2) Make-up equal to the oil consumption. Equation (1) with

M = R becomes

dC

L z +RC = RCM-0.35yFS

where L is now constant, = &.

The solution is

c = cM-A+(A-cM+co)C(-~) . . (3)

where again A = 0.35yFSIR.

Addition of Make-up in Discrete Amounts at Intervals. The

make-up period t l and the rate of oil consumption R will be

assumed to be constant.

If the alkalinity concentration at the end of the nth period, that

is, after time t = ntl is C(b, n) before make-up and C(a, n) after

make-up, then consideration of the neutralization process gives

C(b, n) = C(a, n -1)+D, from equation (2)

0.35yFS log, (1 -q)

where D=

R

Rt

q = 1- 0.1 1.11

L

0.3 1.36

1

Consideration of the make-up process gives

0.4 1.51

C(a, n) = (1 -q)C(b, n) +qcM 0.5 1.70

Thus it may be shown that

C(b, n) = cM+(l-q)"-'(co-c~)+[1-(1-q)"lD/q

C(a, n) = cM+(l-~)"(cO-~M)+[l-(l-q)"lD(l-~)/q Recmendations for Oils and Oil-change Periods. The alkalinity

. . . (4) concentration CMrequired in the make-up oil in order that the oil-

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

DIESEL ENGINE LUBRICANTS : THEIR SELECTION AND UTILIZATION 729

change period should not be limited by exhaustion of the additive Table 4. Alkalinity Concmtration Mg. KOH per Grarnme

has already been given in the text : of Oil Sample

CM-(O.~~YFSQ/R) =S

CM E: S(1+0*35yfQ) . . . . (5) Run No. 1 RunNo.2 I RunNo.3 I RunNo.4

where f = FIR. This applies if the oil-change period is long

compared with the time required to consume a volume of oil equal

to the original crankcase charge. Time,

-

Alka- Time,

-I I

Time, Alka-

If an oil of lower alkalinity-concentration is used, the oil-change hours linity hours hours linity

period T, determined solely by considerations of additive exhaus- -

tion, may be calculated from the equations given below. The same 50 1.66 45 50 2.42

equations may be used to determine the alkalinity concentrations 100 1a75 180 100 1.93

200 1-27 360 150 1.73

in the fresh oil CMand Coyfor a value of the oil-change period T 400 0-45 430 300 1*29

dictated by other considerations, in the case where T is not long 580 0.10 475 400 0.75

compared with the time required to consume a quantity of oil 550 500 0.39

equal to the original crankcase charge. 650 600 0.12

(a) Continuous make-up: I

The intercept at x = 1 obviously gives CO.It is advisable to

from equation (3) with C = S. treat COas an unknown quantity, to be determined experimentally.

(b) Make-up at constant intervals: The initial oil charge is usually mixed with a certain amount of oil

from the previous charge, particularly in field tests as opposed to

T=- 2.303L [(F)]

QR log S-CM+AQ

CO-CM +AQ

4

1

where Q = --log, (1 -q)

labomtory tests.

If the make-up is added at constant intervals, and if samples are

available either just before, or just after, the addition of make-up,

from equations (4) with Ccb, nl = S. equations (4) may be used. However, if the make-up is not known

(c) Rate of oil consumption negligible, that is, RT small compared to be regukr, then equations (3) should be used as in the present

with L: example. The effect of sampling at different positions in the make-

up cycle will increase the scatter of the points.

A statistical analysis shows that there is no evidence that the

relation between alkalinity concentration and x is different in run 2

from equation (1) with R = 0 = MyC = S.

APPENDIX I1

VARIATION OF A L K A L I N I T Y W I T H E N G I N E R U N N I N G T I M E :

A N EXAMPLE OF EXPERIMENTAL RESULTS FROM A

FIELD TEST

This example illustrates the verification of the formula developed

in Appendix I and the determination of the conversion ratio.

Small samples of the crankcase lubricating oil were taken at intervals

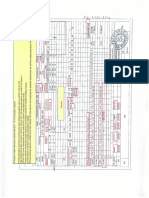

from a 900-b.h.p. engine employed on power-house duties. The

operating conditions are given in Table 3.

Table 3. Engine Operatinn Conditions

Mean fuel consumption

Mean oil consumption

.

.

302 pints per hr.

4.4 pints per hr.

Oil charge .

Fuel sulphur content

.

.

240 gallons = 1,920 pints

First and last 3 hour of each g-hour

period, 0.7 per cent. Remaining

8 hours, 2.5 per cent by weight

The effective mean fuel sulphur content was therefore

0.7+8 X2-5 = 2.3

9

and the addition of the arbitrary correction of 0-1per cent by

weight increases this to 2-4 per cent by weight.

The alkalinity determinations on the samples gave the results

shown in Table 4.

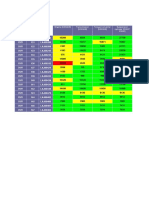

These results are plotted in Fig. 15 in the form of a graph of 0.2 0.4 0.6 0.8 1.0

alkalinity concentration against the quantity EXP (- R f/L)

x = e(-RtlL)

where R is the oil consumption rate, t the engine running time,

Fig. 15. Variation of Alkalinity with Time During

and L the sump charge. Four Runs on a Power-house Engine

It appears from equation (3) that this should give a straight x Run No. 1 RunNo.3

line, the intercept at x = 0 giving 0 RunNo.2) Run No. 4}

CM-A R Oil consumption rate.

and the slope giving t Engine running time.

A -cM +cO L Crankcase oil charge.

Downloaded from pme.sagepub.com at PENNSYLVANIA STATE UNIV on May 9, 2016

730 A. DYSON, L. J. RICHARDS, AND K. R. WILLIAMS

from that in run 1. Similarly, the relation in run 3 does not differ where t is the engine running time. The balance of alkalinity in the

significantly from that in run 4. The relation in runs 1 and 2, crankcase gives

however, differs significantly from that in runs 3 and 4. There is dcz = RCo-PCz+(P-R)C,

no evidence that these relations are not linear. L27T

The residual mean square about the two regression lines is The exact solutions to these equations are rather cumbersome,

0.0127 with 19 deg. of freedom, and the corresponding standard but an approximate solution may be obtained very simply if L I ,

deviation estimate is 0.11 mg. KOH per gramme. These error the quantity of oil in the ring-belt zone, is a s s h e d to be very

estimates may be compared with a mean square of Oa018 estimated small. This gives

from a laboratory determination of the repeatability of the analytical C2-C1 = L !

procedure, and of an estimate of the residual variance about the I’

regression lines of 0.0027 with 51 deg. of freedom from a typical

laboratory e q i n e experiment. The higher error variance estimate

obtained here no doubt reflects the lack of control of the make-up where 02 = a l ( l - R / P )

procedure as discussed above and also variations of fuel and oil

consumption rates with time. However, the linearity of the The solution for C2 if CZ = COat time t = 0 is

relation confirms the applicability of the equations developed in

Appendix I.

The regression equations connecting the alkalinity concentration Comparison with equation (3) shows that the effective rate of

with x are neutralization of allralinity in the crankcase is

runs 1 and 2, 2.79~-0.62 02 al(l-R/P)

runs 3 and 4, 3.19~-0.53 These approximate solutions may be shown to hold after a time

The alkalinity concentration in the make-up oil was 3.4 mg. long compared with

KOH per gramme, so the estimates of A arc 4.0for runs 1 and 2 Ll L2

and 3.9 for runs 3 and 4. These are obtained by equating the P(LI +L2)

intercept at x = 0 to If Cmin is the minimum alkalinity concentration in the crankcase

CM-A oil to ensure a clean piston, then

The initial concentrations COare estimated from the intercepts a1

Cmin = p

at x = 1, and the values are 2.2 for runs 1 and 2 and 2.7 for runs 3

and 4. The oil of the initial charge was nominally identical with

the make-up oil and it is suspected that considerable mixing with and

the previous oil charge had taken place. Between 20 and 35 per

cent of the oil in the crankcase at the beginning of the run must Thus p-R= %

have been left over from the previous charge if this explanation is Cmin

correct, assuming that this oil contained no alkalinity or acidity. from which (P-R) may be calculated from 0 2 , the observed rare

An alternative explanation is that the rate of neutralization of of neutralization of alkalinity in the crankcase, and Cmin, the

fresh alkalinity at the start of the run (less than 50 hours) was very critical alkalinity concentration in the crankcase for a clean piston.

much more rapid than during the later stages (more than 50 hours’ In practice, the piston cleanliness merit rating is plotted against

running time). However, this phenomenon has never been the ratio C / D , where C is the alkalinity concentration in the crank-

observed in carefully controlled taboratory tests. case oil and D is the depletion rate. The value of this ratio when