Professional Documents

Culture Documents

Centrifugation, Guide PDF

Centrifugation, Guide PDF

Uploaded by

Grymjoe Angin EmasCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MGT162 Individual AssignmentDocument12 pagesMGT162 Individual AssignmentNURSABRINA WAN HARMADI100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Quick Ref Table For V-Notch Weir, 0 To 64 L/s oDocument3 pagesQuick Ref Table For V-Notch Weir, 0 To 64 L/s osultanbona99100% (1)

- SWRPG Starship VehicleSheetsDocument2 pagesSWRPG Starship VehicleSheetsPatrick J Smith100% (1)

- Assignment 3Document7 pagesAssignment 3Midhun MNo ratings yet

- Family Relations - 2004 - Cobb - Development of The Attitudes About Romance and Mate Selection ScaleDocument10 pagesFamily Relations - 2004 - Cobb - Development of The Attitudes About Romance and Mate Selection Scaleaqsa randhawaNo ratings yet

- Prism4 SuccinctlyDocument111 pagesPrism4 SuccinctlyHorácio GasparNo ratings yet

- Hydroforce Olympus M200 ManualDocument44 pagesHydroforce Olympus M200 ManualNestor Marquez-DiazNo ratings yet

- Scantron OPSCAN 4ES Brochure From AXIS ITDocument2 pagesScantron OPSCAN 4ES Brochure From AXIS ITKhan Mohammad Mahmud HasanNo ratings yet

- Protocol - 21-01-2022Document14 pagesProtocol - 21-01-2022systacare remediesNo ratings yet

- Case Study Class 12 Physics ImportantDocument5 pagesCase Study Class 12 Physics Importantdivanshu2006yadavNo ratings yet

- ADIDSE Learning Plan 1 (Sets and Cardinality)Document2 pagesADIDSE Learning Plan 1 (Sets and Cardinality)Maron QuiambaoNo ratings yet

- August Lock Installation ManualDocument12 pagesAugust Lock Installation ManualeyaoNo ratings yet

- 07-09-2022 - Inspection Checklist - JMI - AygazDocument1 page07-09-2022 - Inspection Checklist - JMI - AygazMd Sahabul IslamNo ratings yet

- Further Reading Practice TestsDocument19 pagesFurther Reading Practice TestsGia Quỳnh 7/1No ratings yet

- MIT15 S12F18 Ses1Document43 pagesMIT15 S12F18 Ses1Nikhil PatelNo ratings yet

- EQC ACR User Manual Rev07 Apr2010 FinalDocument107 pagesEQC ACR User Manual Rev07 Apr2010 FinalHans SchellmannNo ratings yet

- Code Resource PackDocument38 pagesCode Resource PackSurnainaNo ratings yet

- Installation and O&M of Offshore Renewable Energy Systems: Location: ONLINE Webinar Course ScheduleDocument1 pageInstallation and O&M of Offshore Renewable Energy Systems: Location: ONLINE Webinar Course ScheduleazbNo ratings yet

- The NEC3 Engineering and Construction Contract - A Comparative Analysis - Part 1 - Energy and Natural Resources - United KingdomDocument7 pagesThe NEC3 Engineering and Construction Contract - A Comparative Analysis - Part 1 - Energy and Natural Resources - United Kingdomiqbal2525No ratings yet

- GUIDELINESDocument3 pagesGUIDELINESRenalyn de VillarNo ratings yet

- Insight Release NotesDocument28 pagesInsight Release NotesChris FavreNo ratings yet

- SThree Annual Report 2022Document129 pagesSThree Annual Report 2022Barnaby BensonNo ratings yet

- Chapter 4 Notes BME 2023 Feb 14Document181 pagesChapter 4 Notes BME 2023 Feb 14gamingendless003No ratings yet

- Mahle Air Filter (Primary) For CaterpillarDocument12 pagesMahle Air Filter (Primary) For Caterpillarsuraj pandeyNo ratings yet

- Raw Material CatalogueDocument6 pagesRaw Material CatalogueKhalil EbrahimNo ratings yet

- FICHA TECNICA TOTEM DIGITAL Totem 55 Specs Thin I7 8gb 128gbDocument1 pageFICHA TECNICA TOTEM DIGITAL Totem 55 Specs Thin I7 8gb 128gbEdwin Diaz TorresNo ratings yet

- Tourism EssayDocument2 pagesTourism EssayAnnae CampbellNo ratings yet

- Lhotka UEB To EBAE Comparison Manual 2015Document69 pagesLhotka UEB To EBAE Comparison Manual 2015Karel BrgNo ratings yet

- ConclusionDocument5 pagesConclusionAntonette PunsalanNo ratings yet

- Revised RFQ Kochi OceanariumDocument90 pagesRevised RFQ Kochi OceanariumEjas Halu Mohammed100% (1)

Centrifugation, Guide PDF

Centrifugation, Guide PDF

Uploaded by

Grymjoe Angin EmasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifugation, Guide PDF

Centrifugation, Guide PDF

Uploaded by

Grymjoe Angin EmasCopyright:

Available Formats

ARTICLE BACK TO BASICS

Centrifugation:

a guide to equipment

use and maintenance

With increased emphasis now placed on work-based learning and the

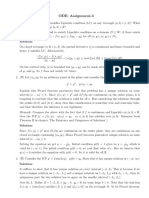

20 50 20000

need for trainees and support workers to receive a solid grounding in 18 45 15000

16 40

laboratory techniques, The Biomedical Scientist once again goes back to 14 10000

35

12 30000

basics. This first in a series of articles sees Peter Riddle consider the use 30

20000

6000

10 25 10000

and maintenance of laboratory centrifuges.

9 5000 4000

8 20 3000

The centrifuge is ubiquitous in biomedical Earth’s gravitational force and is known as 7 18 2000

laboratories and a basic knowledge of the the relative centrifugal field (RCF) or, more 6 15 1000 2000

theory of centrifugation is more than useful. commonly, the ‘g’ force. 14 500

Centrifuge performance can be classified as 5

low-speed, high-speed and ultra-speed. Usual RELATIVE CENTRIFUGAL FIELD 12

200 1000

applications include the separation of serum The RCF generated by a rotor depends on 4 10 100

or plasma from red blood cells, the separation the speed of the rotor in revolutions per 9

of precipitated solids from the liquid phase minute (rpm) and the radius of rotation 50

3 8 500

of a mixture, or the separation of liquids of (ie the distance from the axis of rotation).

7 20

varying density. The equations that permit calculation of the

RCF from a known rpm and radius of 6 10

PRINCIPLES OF CENTRIFUGATION rotation, and calculation of the rpm from a

Particles suspended in a fluid move, under known RCF and radius are shown in Table 1. 2 5 3 200

the influence of gravity, towards the bottom The RCF value can also be obtained using

of a vessel at a rate that depends, in general, a nomogram (Fig 1). Using a straight-edged Inches cm Relative Revolutions

on their size and density. Centrifugation is ruler, line up the known rotating radius centrifugal per minute

a technique designed to utilise centrifugal (distance from the centre of the rotor to the field (xg)

forces, which are greater than the force of bottom of the centrifuge bucket) on the left

gravity, to speed up the sedimentation rate with the known rpm on the far right and read Fig 1. Nomogram used to convert

of particles. This is achieved by spinning the RCF value where the line crosses the revolutions per minute to relative

the vessel containing the fluid and particles graph in the centre. Most manufacturers centrifugal field (xg), and vice versa.

about an axis of rotation so that the particles include a nomogram in the instruction

experience a force acting away from the axis. manual; however, most modern centrifuges there are instruments with a temperature

The force is measured in multiples of the now have the facility to swap the figure control facility. Most instruments now include

displayed on the control panel between rpm a sensor that will detect any imbalance when

Table 1. Calculations used to convert and RCF, making manual calculation the rotor is running and cut off power to the

rpm to RCF, and vice versa. unnecessary. drive mechanism if imbalance is present.

Low-speed instruments are used to separate

RCF = 11.18 x r (rpm/1000)2

LOW-SPEED INSTRUMENTS serum or plasma from red blood cells, and to

rpm = 299.07 √RCF/r Low-speed centrifuges have maximum rotor harvest and purify chemical precipitates,

r: radius (cm) speeds of less than 10,000 rpm, which do not intact cells, nuclei, large mitochondria and

require the rotors to be run in a vacuum, and large plasma-membrane fragments.

76 THE BIOMEDICAL SCIENTIST FEBRUARY 2013

ARTICLE

HIGH-SPEED INSTRUMENTS door-locking mechanism manually to

In general, high-speed centrifuges are retrieve the samples. Manufacturers’

capable of rotor speeds up to 21,000 instructions should be checked for

rpm, although the new generation of the exact procedure required.

super-speed instruments are capable

of rotor speeds of 30,000 rpm, Refrigerator

in which RCFs of 120,000 xg are A centrifuge generates heat as

possible. These instruments require it rotates and if samples are

refrigeration systems to overcome the temperature labile then a refrigerated

heat generated by the friction of the centrifuge should be used. Some

spinning rotor, and the higher-speed centrifuges enable the rotor and

machines must incorporate vacuum chamber to be precooled before a

systems. High-speed centrifuges are run.

used in the separation of a number of

cell constituents and in the isolation Braking system

and purification of viruses. Braking devices are incorporated

to provide rapid rotor deceleration.

ULTRACENTRIFUGES Modern instruments have an

Ultracentrifuges are capable of electrical braking system that

speeds in excess of 30,000 rpm functions by reversing the polarity

and RCFs of over 600,000 xg. of the electrical current to the

RSP

They can be used in the isolation motor. Other machines may have

and purification of membrane Owing to their aerodynamic construction, fixed-angle rotors a mechanical brake.

components such as the endoplasmic can attain much higher speeds.

reticulum and Golgi membrane, CENTRIFUGE TUBES

endosomes, ribosomes, DNA and RNA. Motor It is advisable to use a conical-bottomed

Once again, refrigeration and vacuum In general, centrifuge motors are high-torque, tube in a swing-out bucket rotor for the

systems are necessary. series-wound DC motors, the rotation of which sedimentation of cells. This tube type will

increases as the voltage is increased. The rotor retain the pellet of cells more effectively as the

INSTRUMENT COMPONENTS shaft is driven directly or through a gyro, supernatant is removed. All tubes for use with

Rotor although occasionally a pulley system is used. high-speed rotors are round-bottomed. Pyrex

The design of most centrifuges allows the Electrical contact to the commutator is provided glass tubes can withstand forces of around

drive system to accept rotors of different sizes by graphite brushes, which gradually wear down 2000 xg, while Corex tubes can be used up to

and capacities, although most instrument as they press against the commutator turning 12,000 xg. Polycarbonate or polyallomer are

rotors are now capable of accepting a large at high speed, and thus should be replaced at the most common plastic tubes in use but

range of tube sizes through the use of specified intervals. Modern centrifuges have great care must be taken when using organic

adaptors. Rotors have three basic designs: induction drive motors that have no brushes to solvents. Manufacturers usually provide

horizontal, in which the tubes are carried change. The shaft of the motor turns through extensive information about solvent, salt

in buckets that can swing outwards to a sleeve bearings located at the top and bottom and pH resistance, as well as sterilisation

horizontal position and can operate at speeds of the motor. Most instruments contain sealed procedures.

to about 3000 rpm; fixed angle, in which the bearings that are permanently lubricated, while

sample tubes are held at a fixed angle to the others require periodic application of oil or PREVENTIVE MAINTENANCE

vertical position and can attain much higher grease. r If the bearings on the upper and lower

speeds (approximately 7000 rpm) because The speed of the centrifuge is controlled ends of the motor shaft are not of the

of the aerodynamic construction of the rotor; by a potentiometer that raises and lowers the sealed type then they should be lubricated

and vertical, in which the tubes are fixed voltage supplied to the motor. The calibrations as per the manufacturer’s instructions.

in the vertical position. In general, the on the speed control are often only relative r Brushes should be removed regularly and

horizontal rotor offers advantages to the voltage increments and should never be taken checked for wear; they should be replaced

clinical laboratory because sedimentation of as accurate indicators of speed. Therefore, if they are worn to more than one-half of

large particles (eg red blood cells) is efficient periodic recalibration is required. their original length. When reinserting

at low force and because a flat sediment is used brushes, replace them in the same

produced. Imbalance detector orientation. New brushes should be broken

The load on the rotor should always be Some instruments have an internal imbalance in by slowly accelerating the unloaded unit

balanced before operating the centrifuge, detector that monitors the rotor during to mid-speed and then allowing it to run

particularly when using high-speed operation, causing automatic shutdown if for a period of time.

instruments in which the buckets and caps rotor loads are severely out of balance. r The rotor, buckets and shields or carriers

are often numbered so that they can be should be examined for signs of

matched on opposite sides of the rotor. Tachometer mechanical stress (eg cracks, corrosion).

The load must be balanced both by equal A tachometer indicates the speed in rpm. Most r Some manufacturers etch the expiry date

mass and by centres of gravity across the modern centrifuges use electronic tachometers, on the rotor and this should be checked

centre of rotation. Thus, it is important not in which a magnet rotates around a coil to periodically.

to run the centrifuge with buckets, carriers produce a current that can be measured. r Regularly lubricate the contact areas

or shields missing from the unit, and not to between the centrifuge buckets and the

exceed the maximum rated speed of the Safety lid pins.

rotor in use. Most modern rotors have Modern centrifuges must have a door-locking r Regularly check the condition of the

microprocessor-controlled automatic rotor mechanism to prevent the lid from being O-ring on the tie-down nut on top of the

identification so that it is impossible to set opened while the instrument is running. If rotor, and replace it if worn or damaged.

the speed beyond the safety limit for that there is a power failure or the safety latch fails r Always follow a manufacturer’s specific

rotor. for some reason it may be necessary to trip the instructions. r

FEBRUARY 2013 THE BIOMEDICAL SCIENTIST 77

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MGT162 Individual AssignmentDocument12 pagesMGT162 Individual AssignmentNURSABRINA WAN HARMADI100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Quick Ref Table For V-Notch Weir, 0 To 64 L/s oDocument3 pagesQuick Ref Table For V-Notch Weir, 0 To 64 L/s osultanbona99100% (1)

- SWRPG Starship VehicleSheetsDocument2 pagesSWRPG Starship VehicleSheetsPatrick J Smith100% (1)

- Assignment 3Document7 pagesAssignment 3Midhun MNo ratings yet

- Family Relations - 2004 - Cobb - Development of The Attitudes About Romance and Mate Selection ScaleDocument10 pagesFamily Relations - 2004 - Cobb - Development of The Attitudes About Romance and Mate Selection Scaleaqsa randhawaNo ratings yet

- Prism4 SuccinctlyDocument111 pagesPrism4 SuccinctlyHorácio GasparNo ratings yet

- Hydroforce Olympus M200 ManualDocument44 pagesHydroforce Olympus M200 ManualNestor Marquez-DiazNo ratings yet

- Scantron OPSCAN 4ES Brochure From AXIS ITDocument2 pagesScantron OPSCAN 4ES Brochure From AXIS ITKhan Mohammad Mahmud HasanNo ratings yet

- Protocol - 21-01-2022Document14 pagesProtocol - 21-01-2022systacare remediesNo ratings yet

- Case Study Class 12 Physics ImportantDocument5 pagesCase Study Class 12 Physics Importantdivanshu2006yadavNo ratings yet

- ADIDSE Learning Plan 1 (Sets and Cardinality)Document2 pagesADIDSE Learning Plan 1 (Sets and Cardinality)Maron QuiambaoNo ratings yet

- August Lock Installation ManualDocument12 pagesAugust Lock Installation ManualeyaoNo ratings yet

- 07-09-2022 - Inspection Checklist - JMI - AygazDocument1 page07-09-2022 - Inspection Checklist - JMI - AygazMd Sahabul IslamNo ratings yet

- Further Reading Practice TestsDocument19 pagesFurther Reading Practice TestsGia Quỳnh 7/1No ratings yet

- MIT15 S12F18 Ses1Document43 pagesMIT15 S12F18 Ses1Nikhil PatelNo ratings yet

- EQC ACR User Manual Rev07 Apr2010 FinalDocument107 pagesEQC ACR User Manual Rev07 Apr2010 FinalHans SchellmannNo ratings yet

- Code Resource PackDocument38 pagesCode Resource PackSurnainaNo ratings yet

- Installation and O&M of Offshore Renewable Energy Systems: Location: ONLINE Webinar Course ScheduleDocument1 pageInstallation and O&M of Offshore Renewable Energy Systems: Location: ONLINE Webinar Course ScheduleazbNo ratings yet

- The NEC3 Engineering and Construction Contract - A Comparative Analysis - Part 1 - Energy and Natural Resources - United KingdomDocument7 pagesThe NEC3 Engineering and Construction Contract - A Comparative Analysis - Part 1 - Energy and Natural Resources - United Kingdomiqbal2525No ratings yet

- GUIDELINESDocument3 pagesGUIDELINESRenalyn de VillarNo ratings yet

- Insight Release NotesDocument28 pagesInsight Release NotesChris FavreNo ratings yet

- SThree Annual Report 2022Document129 pagesSThree Annual Report 2022Barnaby BensonNo ratings yet

- Chapter 4 Notes BME 2023 Feb 14Document181 pagesChapter 4 Notes BME 2023 Feb 14gamingendless003No ratings yet

- Mahle Air Filter (Primary) For CaterpillarDocument12 pagesMahle Air Filter (Primary) For Caterpillarsuraj pandeyNo ratings yet

- Raw Material CatalogueDocument6 pagesRaw Material CatalogueKhalil EbrahimNo ratings yet

- FICHA TECNICA TOTEM DIGITAL Totem 55 Specs Thin I7 8gb 128gbDocument1 pageFICHA TECNICA TOTEM DIGITAL Totem 55 Specs Thin I7 8gb 128gbEdwin Diaz TorresNo ratings yet

- Tourism EssayDocument2 pagesTourism EssayAnnae CampbellNo ratings yet

- Lhotka UEB To EBAE Comparison Manual 2015Document69 pagesLhotka UEB To EBAE Comparison Manual 2015Karel BrgNo ratings yet

- ConclusionDocument5 pagesConclusionAntonette PunsalanNo ratings yet

- Revised RFQ Kochi OceanariumDocument90 pagesRevised RFQ Kochi OceanariumEjas Halu Mohammed100% (1)