Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

131 viewsBase Valve Comp Wp4cs

Base Valve Comp Wp4cs

Uploaded by

demoracingedurace tech wp4cs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- VW 1.4L TSI Engine - SSP - 359Document64 pagesVW 1.4L TSI Engine - SSP - 359freefly286% (7)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Satelis Service Manual Body Panels PDFDocument83 pagesSatelis Service Manual Body Panels PDFdemoracingeduNo ratings yet

- Codigos Color Multimarca GiviDocument7 pagesCodigos Color Multimarca GividemoracingeduNo ratings yet

- Arbol CambioDocument1 pageArbol CambiodemoracingeduNo ratings yet

- Cuchillas TornoDocument4 pagesCuchillas TornodemoracingeduNo ratings yet

- All Models and Model Years (Except Xdiavel) Service Repair Bulletin Srv-Srb-18-030Document21 pagesAll Models and Model Years (Except Xdiavel) Service Repair Bulletin Srv-Srb-18-030demoracingeduNo ratings yet

- MC-10086369-5448 Gear Learning Procedure UpdateDocument3 pagesMC-10086369-5448 Gear Learning Procedure Updatedemoracingedu0% (1)

- Gear Position Indicator With Programmable Engine Speed and High Speed WarningDocument4 pagesGear Position Indicator With Programmable Engine Speed and High Speed WarningdemoracingeduNo ratings yet

- Triumph DatosDocument3 pagesTriumph DatosdemoracingeduNo ratings yet

- Instructions Bo Yes enDocument2 pagesInstructions Bo Yes endemoracingeduNo ratings yet

- Llimit 500auto ManualDocument162 pagesLlimit 500auto ManualdemoracingeduNo ratings yet

- 2018 250sx CC Setting List ForkDocument2 pages2018 250sx CC Setting List ForkdemoracingeduNo ratings yet

- 2007 Txtpro PartlistDocument70 pages2007 Txtpro PartlistdemoracingeduNo ratings yet

- 450sx 2005Document5 pages450sx 2005demoracingeduNo ratings yet

- Fork Notes WPDocument18 pagesFork Notes WPdemoracingeduNo ratings yet

- Daelim MRP Upgrade Step by StepDocument11 pagesDaelim MRP Upgrade Step by Stepdemoracingedu100% (1)

- Terminal Configurations: Terminal Battery Type Type Front Side TopDocument28 pagesTerminal Configurations: Terminal Battery Type Type Front Side TopdemoracingeduNo ratings yet

Base Valve Comp Wp4cs

Base Valve Comp Wp4cs

Uploaded by

demoracingedu0 ratings0% found this document useful (0 votes)

131 views8 pagesrace tech wp4cs

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentrace tech wp4cs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

131 views8 pagesBase Valve Comp Wp4cs

Base Valve Comp Wp4cs

Uploaded by

demoracingedurace tech wp4cs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

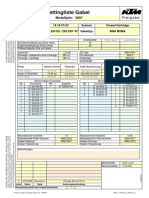

zene IP FMGV 280001 COMP WPECS

COMPRESSION GOLD VALVE INSTALLATION

FMGV 280601 WP 4CS

Dirt 28mm

Wekome to the wonderfill world of Gold Valving. To obtain your personal Custom Suspension

Settings:

[DVS Setup Sheet - If you haven't already, go to DVS Valving Search, insert your Access Code,

and rider data and print your DVS Setup Sheet. If you are using a RT Adjustable Compression

‘Base be sure to select YES LSV (Low Speed Valve).

CAUTION: IF YOU ARE UNFAMILIAR WITH REBUILDING AND REVALVING

FORKS, STOP!!! DO NOT PROCEED; SEEK OUT A QUALIFIED SUSPENSION

TECHNICIAN.

NOTE: All measurements are metric (for inches divide by 25.4). The valving list starts at the

piston face and goes towards the Base Plate. Valve specs are listed by (QUANTITY)

‘THICKNESS x DIAMETER. A number in parentheses means quantity. If there is no number in

parenthesis the quantity is one. Example: (2).15x30 means quantity two, 15 hundredths of a

‘millimeter thick by 30 millimeters in diameter.

The Left and Right Fork Leg are different. Keep all the components separate.

RT has a Spring Conversion Kit available for this fork that eliminates the Air Spring and replaces

it with a Coil Spring. Call for detail.

Tools Required

——__- |. In-Ib torque wrench that accurately measures 0 to 50 in-

lbs (0.58 kgm) (SnapOn Digital Torque Wrench shown)

|- Hi-Strength Loctite (included)

|- Mettic calipers and micrometer

2013

\VC1- This is the Compression Base Valve. As of this

printing there are 3 different types of Bottom-out Cups.

Fitouhwwnracetech compagatiteP%.20FMGV%4202808019%20COMPHs20WPACS, 18

22018

2014 v1

IPFMGY 200601 COMP wPecs,

12013 and 2014 v1 have valving shims.

12014 v2 has no valving shims.

12016 there is no Bottom-out Cup.

2014 v2

IVC2- Unscrew the Bottom-out Cup, in this case, with a

large screwdriver. This particular "Screwdriver" is made

lout ofa wood chisel.

IVC3- Remove the bottom-out cup. There are three

diferent styles of bottoming cups plus none,

itp tacetech compag atillP%20FMGV%202806019%20COMP%20WPACS.

28.

22018

IP FMGV 290001 COMP WPACS

[Notice that this time the Nut-Post unscrewed from the

|Compression Base Valve. Sometimes the Bottom-out Cup

|will unscrew from the Nut-Post. Either way is fine,

It occurs like this one you can just clean it up and

| reinstall it during reassembly.

IVC4- Remove the compression piston along with the

lvalving stack.

[Keep track of the bottom spacing shims. You will ikely

Ineed them when you build the new compression stack.

Stacks.

provided in the Gold Valve Kit.

VALVING STACK TYPES - SINGLE OR TWO STAGE

'VC5- You wil either be building a Single Stage or a Two Stage Stack. The difference is the

Crossover. The Crossover is a smaller diameter shim between the Lo-Speed and the Hi Speed

‘Note: The DVS Custom Setup Sheet displays individual shims and does not label Hi-Speed,

Crossover, and Lo-Speed. This is for your information only. Also you will not use all the shims

| Single Stage - made of

Lo-Speed Stack

Hi-Speed Stack

[There is NO Crossover

(it becomes one stack.)

|- Two Stage - made of

Lo-Speed Stack

Crossover

Hi-Speed Stack

[The Crossover Gap is visible

EF: (ee

itp tacetech compag atillP%20FMGV%202806019%20COMP%20WPACS.

38

22018

FMGV 280601 2014 V2 4CS 2 STAGE

FMGV 280601 2014 V2 4CS 2 STAGE

Li

remy ——— Shek Spring

ee check Pate aveenen

O-Ring

Compression

Gold Valve

SSS res sek

==

ae Stack

Spacing Shims.

Gompression Base

IP FMGV 280601 COMP WPécs

Vc6- Two Stage Example

(Single Stage is exactly the same except there is no

Crossover)

[Put the valving on the shaft in the reverse of the order

listed, starting with the last (smallest) shim of the Hi-

\Speed Stack.

[For Two Stage the total valving stack is made up of a:

ILo-Speed Stack

ICrossover and a

IHi-Speed Stack

(this is only an example - not your setting)

[The Total Valving Stack starting from the Gold

IValve piston face:

(4) .15x24 - Lo-Speed Stack

(1) .10x16 - Crossover (notice the smaller diameter)

(1) .10x24 - Hi-Speed Stack

(1) 10x22

(1) .10x20

(1) 10x18

(1) 10x16

(1) 10x15

(1) 10x14

(1) 10x13

(1) 10x12

\VC7- COMPRESSION BLEED HOLE

|No Compression Bled Holes are required on 4CS forks.

|VC8- SET THE TOTAL VALVING STACK

[THICKNESS (This is critical!)

itp tacetech compag atillP%20FMGV%202806019%20COMP%20WPACS.

48

22018

IP FMGV 280801 COMP WPéCS,

[Before installing the valving on the shaft build the Valving

[Stack and measure the total thickness. Make sure it is

[between 2.7 and 3.1mm thick. Ifit is not, re-use some

lof the original 40x18 Spacing Shims to get into this range.

IVC9- This conversion eliminates the Compression

[Adjuster at the top of the Left Fork Leg that doesn't do

Imuch anyway. Convert it to a Rebound Adjuster by

removing both Check Needles inside the Bottom-out

|Pistons.

[To get external compression adjustment RT has LSV

|Adjustable Compression Bases (FACB M3010001)

lavailable. If you have them use them at this time. Note -

lselect YES LSV (Low Speed Valve) in the DVS.

7 & @ 7

'VC10- Install the compression valving stack starting with

the packing shims.

itp tacetech compag atillP%20FMGV%202806019%20COMP%20WPACS.

58

22018

IP FMGV 290001 COMP WPACS

1VC11- Install the Gold Valve on the shaft. Then the

|Check Plate and Check Spring. Put a drop of Loctite on

Ithe female thread ofthe Nut post.

[Be sure the Check Plate is free and can move up and

ldown against the spring without binding. This can be done

lby blowing air into the feed port just above the top shim. A

IClip Tool can be used to manually open the valve ffom the

ltop as well.

'VC12- CAUTION! The threads can be damaged without

lextreme care. The Nut-Post must be torqued with a

ltorque wrench to 30 in-Ibs (2.5 ft-Ibs or 0,35 kgém), NO

IMORE! Do not take this step lightly.

|VC13- Install the original Bottom-out Valving Stack (if

required). Duplicate the original setup.

|As of this printing there are three different Bottom out Cup

designs. Duplicate the original setup. The Bottom-out Cup

|Assembly screws onto the Nut-Post. Use Loctite on the

lfemale thread and torque it to 30 in-Ibs.

VC14- Install the Bottom-out Cup (ifrequited).

itp tacetech compag atillP%20FMGV%202806019%20COMP%20WPACS.

68

22018 IP FMGV 280801 COMP WPéCS,

IVC1S- Using a large screwdriver, tighten the bottom-out

cup to 30 in-Ibs (2.5 ft-lbs or 0.35 kgm).

VC16- Two Stage

\vo16- Single Stage

‘SINGLE STAGE

COMPRESSION

‘TWO STAGE

COMPRESSION

[Notice the gap in the valving stack where the Crossover is,

Ihe Crossover Gap should be clearly visible.

VC17- Visually check your work.

[Hold the Compression Stack up to the light and look for

proper assembly. Ifthere are any problems, disassemble

the stack and look for burrs to surface and/or dirt in the

valving, Reassemble and check again.

On two-stage stacks make sure the Crossover Gap is

clearly visible.

itp tacetech compag atillP%20FMGV%202806019%20COMP%20WPACS.

22018 IP FMGV 280601 COMP WPécs

\Make sure the o-ring is on the Gold Valve.

IVC18- Make sure the shims that go next to the Gold

IValve completely cover the ports on both sides of the

piston! If the ports are not covered there will not be

lenough damping,

|This could be caused by a number of reasons. Please call

[Tech Support ifthis occurs and you cant figure it out.

}VC19- Return to the rebuild instructions and continue with

[Rebound Valving and Assembly.

racetech.com

tpt racetech compagetilalPY%20FMGV%202806019%20C OMP%20WPACS.

a8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- VW 1.4L TSI Engine - SSP - 359Document64 pagesVW 1.4L TSI Engine - SSP - 359freefly286% (7)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Satelis Service Manual Body Panels PDFDocument83 pagesSatelis Service Manual Body Panels PDFdemoracingeduNo ratings yet

- Codigos Color Multimarca GiviDocument7 pagesCodigos Color Multimarca GividemoracingeduNo ratings yet

- Arbol CambioDocument1 pageArbol CambiodemoracingeduNo ratings yet

- Cuchillas TornoDocument4 pagesCuchillas TornodemoracingeduNo ratings yet

- All Models and Model Years (Except Xdiavel) Service Repair Bulletin Srv-Srb-18-030Document21 pagesAll Models and Model Years (Except Xdiavel) Service Repair Bulletin Srv-Srb-18-030demoracingeduNo ratings yet

- MC-10086369-5448 Gear Learning Procedure UpdateDocument3 pagesMC-10086369-5448 Gear Learning Procedure Updatedemoracingedu0% (1)

- Gear Position Indicator With Programmable Engine Speed and High Speed WarningDocument4 pagesGear Position Indicator With Programmable Engine Speed and High Speed WarningdemoracingeduNo ratings yet

- Triumph DatosDocument3 pagesTriumph DatosdemoracingeduNo ratings yet

- Instructions Bo Yes enDocument2 pagesInstructions Bo Yes endemoracingeduNo ratings yet

- Llimit 500auto ManualDocument162 pagesLlimit 500auto ManualdemoracingeduNo ratings yet

- 2018 250sx CC Setting List ForkDocument2 pages2018 250sx CC Setting List ForkdemoracingeduNo ratings yet

- 2007 Txtpro PartlistDocument70 pages2007 Txtpro PartlistdemoracingeduNo ratings yet

- 450sx 2005Document5 pages450sx 2005demoracingeduNo ratings yet

- Fork Notes WPDocument18 pagesFork Notes WPdemoracingeduNo ratings yet

- Daelim MRP Upgrade Step by StepDocument11 pagesDaelim MRP Upgrade Step by Stepdemoracingedu100% (1)

- Terminal Configurations: Terminal Battery Type Type Front Side TopDocument28 pagesTerminal Configurations: Terminal Battery Type Type Front Side TopdemoracingeduNo ratings yet