Professional Documents

Culture Documents

AMSOIL DOMINATOR® Coolant Boost

AMSOIL DOMINATOR® Coolant Boost

Uploaded by

amsoildealerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AMSOIL DOMINATOR® Coolant Boost

AMSOIL DOMINATOR® Coolant Boost

Uploaded by

amsoildealerCopyright:

Available Formats

Buy Wholesale FREE Shipping Offer

CALL 800-956-5695 M-F, 7 a.m.-7 p.m. Central

Give Customer Number: 1642716 - https://hdoil.co

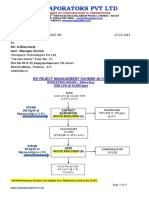

D A T A B U L L E T I N

DOMINATOR ® Coolant Boost

Provides Effective Heat Transfer and

Enhanced Corrosion Protection

Racers demand lower engine operating temperatures in order to

achieve maximum efficiency and horsepower on the track. Many racers

use straight water as a coolant, which invites damaging radiator and

water-pump corrosion. AMSOIL DOMINATOR® Coolant Boost (RDCB)

provides racers and motorists with significantly lower engine operating

temperatures, quicker warm-up times and advanced corrosion protec-

tion.

DOMINATOR Coolant Boost is formulated with proprietary tiered-sur-

factant technology, providing quick and effective heat transfer inside

radiators and cylinder heads and resulting in reduced operating tem-

peratures, more efficient operation, increased horsepower and signifi- • Reduces engine temps

cantly reduced engine warm-up times in cold weather and before a race. up to 25˚F

Coolant Boost also contains a robust mixture of corrosion inhibitors that

protect the radiator, heater core, water pump, cylinder heads, engine • Helps vehicles warm-up

an average of 54% faster

block and intake manifold from the damaging effects of corrosion.

Engine Warm-up Reduction Test

To test DOMINATOR Coolant Boost’s ability to reduce engine warm-up times, the product was added to an antifreeze/water mixture in

a V-8 test engine. The engine was run at idle until it reached a prescribed temperature of either 120ºF or 180ºF. Ambient temperature

was maintained at 30ºF to simulate winter conditions.

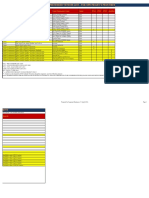

Engine Warm-up Time Reduction 30˚F TO 120˚F 30˚F TO 180˚F

Warm-up with 50/50 Antifreeze/Water Only . . . . . . . . . . . . . . . . . . . . . . 6.3 Min.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.4 Min.

Warm-up with Coolant Boost Added . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2 Min. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3 Min.

Temperature Reduction Dynamometer Test

To test temperature-reduction capabilities, controlled engine dynamometer (dyno) tests were performed on a 350 cubic inch Chevy*

engine with an aluminum block and cylinder heads. In each phase of testing, the engine was operated at 4,500 rpm until coolant

temperature stabilized. As benchmarks for the test, straight water stabilized at 220˚F and a 50/50 antifreeze/water mixture stabilized

at 228˚F.

Temperature Reduction (in degrees Fahrenheit) DOMINATOR COOLANT BOOST

Mixed with 50/50 Antifreeze/Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8˚F reduction

Mixed with Straight Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25˚F reduction

Cast Aluminum Alloys Corrosion Test

The Cast Aluminum Alloys Corrosion Test (ASTM D4340) measures corrosion protection properties in modern automobile and

high-performance race engines with aluminum cylinder heads. A cast aluminum puck was heated to 275˚F at 28 PSI and exposed

to the test coolant mixture for one week. Weight loss of less than 1.0 mg is required to pass the test.

ASTM D4340 DOMINATOR COOLANT BOOST

(in straight water) WATER ONLY

Weight loss in mg (1.00 max). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.06 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.97

Buy Wholesale FREE Shipping Offer

* All trademarked images are the property of their respective owners and may be registered marks in some countries. No affiliation or endorsement claim, express or implied, is made

CALL 800-956-5695 M-F, 7 a.m.-7 p.m. Central

by their use. All products advertised here are AMSOIL-engineered for use in the applications shown.

Give Customer Number: 1642716 - https://hdoil.co

Buy Wholesale FREE Shipping Offer

CALL 800-956-5695 M-F, 7 a.m.-7 p.m. Central

Give Customer Number: 1642716 - https://hdoil.co

Corrosion Test in Glassware

In the Corrosion Test in Glassware (ASTM D1384), six metal coupons constructed of the most common metals in automotive cooling

systems were totally immersed in aerated coolant mixtures for 336 hours at 190˚F. Each test was performed three times to determine

the average weight change for each metal. The ASTM sets the allowable weight loss maximums for each metal.

ASTM D1384

ALLOWABLE DOMINATOR COOLANT BOOST WATER

(in straight water) ONLY

Copper weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 max. . . . . . . . . . . . . . . . . . . . 1. . . . . . . . . . . . . . . . . . . . . 25

Solder weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . . 62

Brass weight loss (mg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . . 23

Steel weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 max. . . . . . . . . . . . . . . . . . . . 1. . . . . . . . . . . . . . . . . . . . . 18

Cast iron weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . . 29

Cast aluminum weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . . 91

Simulated Service Corrosion Test

In the Simulated Service Corrosion Test (ASTM D2570), six metal coupons constructed of the most common metals in automotive

cooling systems were exposed to ASTM corrosive water designed to simulate hard and corrosive water in degraded coolant for

1,064 hours at 190°F. Coolant was maintained at a temperature and flow rate equivalent to the operating conditions seen in most

passenger vehicles. Corrosive weight loss suffered during the test determines the additive’s corrosion protection properties. The

ASTM sets the allowable weight loss maximums for each metal.

ASTM D2570

ALLOWABLE DOMINATOR COOLANT BOOST WATER

(in straight water) ONLY

Copper weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 max. . . . . . . . . . . . . . . . . . . . 3. . . . . . . . . . . . . . . . . . . . . 66

Solder weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . 120

Brass weight loss (mg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 max. . . . . . . . . . . . . . . . . . . . 2. . . . . . . . . . . . . . . . . . . . . 59

Steel weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . . 54

Cast iron weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . 117

Cast aluminum weight loss (mg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 max. . . . . . . . . . . . . . . . . . . . 0. . . . . . . . . . . . . . . . . . . . . 89

Recommendations In applications using Coolant Boost with antifreeze/water

Use DOMINATOR® Coolant Boost with racing applications mixtures, add Coolant Boost once per year or every 30,000

using straight water as coolant and automotive applications miles, whichever comes first. Follow coolant manufacturer

using antifreeze mixtures. recommendations for coolant change intervals.

Directions: With engine off and cool, make sure cooling AMSOIL PRODUCT WARRANTY

system is filled with selected coolant. Shake bottle and pour AMSOIL products are backed by a Limited Liability Warranty.

calculated amount of Coolant Boost into radiator. Start engine, For complete information visit www.amsoil.com/warranty.aspx.

turn heat on high and run for 15 minutes.

Dosage: For straight water applications, add 2 fl. oz. of Coolant

Boost per quart of water. In antifreeze mixtures, add 1 fl. oz. of

Coolant Boost per quart of antifreeze.

Frequency: In applications using Coolant Boost with straight

water, drain and re-fill the coolant system and add Coolant

Boost once per year.

AMSOIL products and Dealership information are

available from your local full-service AMSOIL Dealer.

Buy Wholesale FREE Shipping Offer

AMSOIL INC., 925 Tower Ave., Superior, WI 54880 • 715-392-7101 • Printed in the USA. CALL 800-956-5695 M-F, 7 a.m.-7 p.m. Central G2785 4/16

© 2016, AMSOIL INC. All rights reserved. The AMSOIL logo is a registered trademark of AMSOIL INC.

Give Customer Number: 1642716 - https://hdoil.co

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Jis G 4305-2012 (Jssa-Jsa)Document48 pagesJis G 4305-2012 (Jssa-Jsa)quochunguic88% (8)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AGT Merged TrainingDocument116 pagesAGT Merged Trainingbilo198450% (2)

- Guideline For Weld Reject Rate Reduction: Table of ContentsDocument14 pagesGuideline For Weld Reject Rate Reduction: Table of ContentsMohammad Irfandi100% (1)

- October 2017 AMSOIL Dealer EditionDocument24 pagesOctober 2017 AMSOIL Dealer EditionamsoildealerNo ratings yet

- AVON Catalog Campaign 2 - 2020Document106 pagesAVON Catalog Campaign 2 - 2020amsoildealerNo ratings yet

- Avon Catalog Campaign 7 2020Document114 pagesAvon Catalog Campaign 7 2020amsoildealerNo ratings yet

- January 2017 AMSOIL Dealer EditionDocument24 pagesJanuary 2017 AMSOIL Dealer EditionamsoildealerNo ratings yet

- September 2018 AMSOIL Dealer EditionDocument24 pagesSeptember 2018 AMSOIL Dealer EditionamsoildealerNo ratings yet

- April 2018 AMSOIL Dealer EditionDocument24 pagesApril 2018 AMSOIL Dealer EditionamsoildealerNo ratings yet

- Winter 2019 AMSOIL Preferred Customer EditionDocument44 pagesWinter 2019 AMSOIL Preferred Customer EditionamsoildealerNo ratings yet

- August 2019 AMSOIL Dealer EditionDocument24 pagesAugust 2019 AMSOIL Dealer EditionamsoildealerNo ratings yet

- September 2019 AMSOIL Dealer EditionDocument28 pagesSeptember 2019 AMSOIL Dealer EditionamsoildealerNo ratings yet

- January 2018 AMSOIL Dealer EditionDocument24 pagesJanuary 2018 AMSOIL Dealer EditionamsoildealerNo ratings yet

- AMSOIL Catalog Massachusetts AMSOIL DealerDocument28 pagesAMSOIL Catalog Massachusetts AMSOIL DealeramsoildealerNo ratings yet

- MSC Materials Science Nanotechnology Syllabus MSU BarodaDocument12 pagesMSC Materials Science Nanotechnology Syllabus MSU BarodaSoumalyaBhowmikNo ratings yet

- Bio CNGDocument23 pagesBio CNGHarshini JayaprakashNo ratings yet

- Indicators of Sustainability To The MineDocument544 pagesIndicators of Sustainability To The Minegeominamb100% (1)

- Roland JWX-30 Set UpDocument62 pagesRoland JWX-30 Set UpDragos Manzateanu0% (1)

- COATEXDocument10 pagesCOATEXHelene Di marcantonioNo ratings yet

- MCQ Questions For Class 10 Science Acids Bases and Salts With Answers - Learn CBDocument19 pagesMCQ Questions For Class 10 Science Acids Bases and Salts With Answers - Learn CBMaana Ajmera100% (1)

- Project Report On Cellular Light Weight ConcreteDocument21 pagesProject Report On Cellular Light Weight ConcreteVishal Kumar100% (1)

- Cux Commercial Evaporator Catalogue 2010Document4 pagesCux Commercial Evaporator Catalogue 2010Rodrigo GonçalvesNo ratings yet

- T Beam DesignDocument10 pagesT Beam DesignUma Shankar Yaligar86% (7)

- Norma Astm E23 Ensayo CharpyDocument28 pagesNorma Astm E23 Ensayo CharpyVanesa Avellaneda OrtizNo ratings yet

- Tugas 1 Menara Bahan Isian Lengkap - KomangDocument3 pagesTugas 1 Menara Bahan Isian Lengkap - KomangKomang SadiaNo ratings yet

- Buitems: Assignment Civil Engg DrawingDocument6 pagesBuitems: Assignment Civil Engg DrawingHarun RasulNo ratings yet

- Conbextra GP1 PDFDocument4 pagesConbextra GP1 PDFabhay_joshi2002No ratings yet

- Business Comm ProjectDocument17 pagesBusiness Comm ProjectHassan AliNo ratings yet

- Samsung Evaporator Technical Details Aug 17 PDFDocument9 pagesSamsung Evaporator Technical Details Aug 17 PDFkumarNo ratings yet

- Rasgas Preferred Vendor List - For Opd Project Procurement: Pvl1 Pvl2 Pvl3 QualifiedDocument2 pagesRasgas Preferred Vendor List - For Opd Project Procurement: Pvl1 Pvl2 Pvl3 Qualifiedvysakh51No ratings yet

- Esr-4372 Hvu2 PDFDocument22 pagesEsr-4372 Hvu2 PDFDiana Rodrìguez GonzálezNo ratings yet

- NDT & WeldingDocument3 pagesNDT & WeldingSoham SahaNo ratings yet

- Combined Bearing/Freewheel - CSK - CSK..2RS - Stieber ClutchDocument2 pagesCombined Bearing/Freewheel - CSK - CSK..2RS - Stieber ClutchborischechenkoNo ratings yet

- Welding Processes - Chapter 31Document109 pagesWelding Processes - Chapter 31xharpreetx100% (1)

- How To Replace An ABS Control UnitDocument53 pagesHow To Replace An ABS Control UnitاحمدميدوNo ratings yet

- ARIJIT GUHA Road Development in India August2016Document42 pagesARIJIT GUHA Road Development in India August2016Goutam ChakrabortyNo ratings yet

- Confined Space: An Overview of OSHA Standards and Confined Space HazardsDocument35 pagesConfined Space: An Overview of OSHA Standards and Confined Space HazardsIssac BennyNo ratings yet

- LanoDocument8 pagesLanosakalidhasavasanNo ratings yet

- Avantis 70 Aluminium Windows and Doors - Sapa Building SystemDocument12 pagesAvantis 70 Aluminium Windows and Doors - Sapa Building SystemSapa Building SystemNo ratings yet

- Eurovent Certification Part 1 PDFDocument54 pagesEurovent Certification Part 1 PDFameeri143No ratings yet