Professional Documents

Culture Documents

Commissioning of Reactor

Commissioning of Reactor

Uploaded by

Souvik PaulCopyright:

Available Formats

You might also like

- FRAMO SYSTEM Drain and VentDocument3 pagesFRAMO SYSTEM Drain and VentjoelandrewpintoNo ratings yet

- Aerodynamics Questions and Suggested Answers 2Document5 pagesAerodynamics Questions and Suggested Answers 2ApikSanPewPewNo ratings yet

- SOP-Operating Procedure of Hydrogen Plant.Document17 pagesSOP-Operating Procedure of Hydrogen Plant.Sooraj Surendran Sugatha100% (1)

- Boilers SOPDocument18 pagesBoilers SOPPrakash WarrierNo ratings yet

- Procedure For Tank Washing and CleaningDocument3 pagesProcedure For Tank Washing and CleaningSachin Yadav54% (13)

- Boiler Commissioning and Operation Check ListDocument14 pagesBoiler Commissioning and Operation Check Listtsrinivasan5083100% (4)

- MINI STEAM POWER PLANT - Lab ManualDocument20 pagesMINI STEAM POWER PLANT - Lab Manualmelanie japay50% (6)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Startup of An Air Separation PlantDocument3 pagesStartup of An Air Separation Plantcymy0% (1)

- Turbine Startup ProcedureDocument8 pagesTurbine Startup ProcedureBrijesh Srivastav50% (2)

- Manual Starting and Desludging of PurifierDocument2 pagesManual Starting and Desludging of PurifierAnupGautam50% (2)

- Experiment 2 - Study of Packed Column DistillationDocument7 pagesExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Distillation ExperimentDocument6 pagesDistillation ExperimentJureen Flores BelicarioNo ratings yet

- P&IDDocument7 pagesP&IDTagabo AliNo ratings yet

- Rotary DrumDocument7 pagesRotary Drumjeas grejoy100% (1)

- Dean Stark Apparatus Lab ReportDocument9 pagesDean Stark Apparatus Lab ReportSouvik Paul0% (2)

- ULDocument12 pagesULt_kumaraguruNo ratings yet

- A Microscopic Model For An Ideal Gas Tutorials in Introductory Physics Homework AnswersDocument1 pageA Microscopic Model For An Ideal Gas Tutorials in Introductory Physics Homework Answersdreamsmasher100% (1)

- Aeration Commisioning - STPDocument7 pagesAeration Commisioning - STPdexterNo ratings yet

- Sop - STPDocument7 pagesSop - STPpulkitsharma17100% (1)

- Solvent Conversion Procedures: B. Preparation For Initial Start-UpDocument5 pagesSolvent Conversion Procedures: B. Preparation For Initial Start-UpEliasNo ratings yet

- HydrogenDocument10 pagesHydrogennuzulNo ratings yet

- Sop STPDocument5 pagesSop STPModi JayNo ratings yet

- Oxygen Concentrator Operation ManualDocument4 pagesOxygen Concentrator Operation ManualInge NecoNo ratings yet

- Important RegenerationDocument8 pagesImportant RegenerationrawadNo ratings yet

- BXPDocument53 pagesBXPkaranx16No ratings yet

- Manufacture OF Producer GasDocument36 pagesManufacture OF Producer GasSai PavanNo ratings yet

- Production OF Producer GasDocument19 pagesProduction OF Producer Gassaipa1No ratings yet

- Unit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemDocument13 pagesUnit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemMuhammad luqman100% (1)

- PREPARATION AND REGENERATION PROCEDURE OF REFORMER CATALYST 121211 REv 1 6 1-2014Document6 pagesPREPARATION AND REGENERATION PROCEDURE OF REFORMER CATALYST 121211 REv 1 6 1-2014dragofloresNo ratings yet

- Hydrophore SystemDocument4 pagesHydrophore SystemSWASTIK MISHRA50% (2)

- SOP Gas AbsorptionDocument19 pagesSOP Gas AbsorptionKevin EsmunaldoNo ratings yet

- Procedure For Aph Water WashingDocument3 pagesProcedure For Aph Water WashingSelvaNo ratings yet

- Boiler PreservationDocument3 pagesBoiler PreservationansudasinghaNo ratings yet

- I. Laboratory Procedure: Procedure (EQUIPMENT SET-UP)Document2 pagesI. Laboratory Procedure: Procedure (EQUIPMENT SET-UP)Chanel AnnNo ratings yet

- PartsDocument9 pagesPartsRosario SisniegasNo ratings yet

- Training Material of Boiler Operation: Drum and Internal DevicesDocument8 pagesTraining Material of Boiler Operation: Drum and Internal DevicesandreNo ratings yet

- Experiment No. 2Document7 pagesExperiment No. 2noteasytobebooNo ratings yet

- Centrifugal Pump (Various Air Handling Methods)Document21 pagesCentrifugal Pump (Various Air Handling Methods)karthick_mariner92No ratings yet

- Sop MeeDocument5 pagesSop MeeYogesh Dhekale100% (4)

- Ninh Binh Rua Hoa ChatDocument3 pagesNinh Binh Rua Hoa Chathuy LuongNo ratings yet

- Centrifugal Pump (Various Air Handling Methods)Document31 pagesCentrifugal Pump (Various Air Handling Methods)karthick_mariner92No ratings yet

- Gas Absorption Lab ReportDocument7 pagesGas Absorption Lab ReportShida ShamNo ratings yet

- WWE Filter Press OperationDocument4 pagesWWE Filter Press OperationMf LuiNo ratings yet

- Starting A Boiler From Dead Ship ConditionsDocument21 pagesStarting A Boiler From Dead Ship ConditionsrickNo ratings yet

- Line Up Turbine Aux. SystemDocument42 pagesLine Up Turbine Aux. SystemAmit Chauhan100% (3)

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Biocleaner - Manual de Operacion y MantenimientoDocument9 pagesBiocleaner - Manual de Operacion y MantenimientoFabian Ignacio Marquez OsorioNo ratings yet

- Accumulator and BOP Control Unit5 - Aly2Document65 pagesAccumulator and BOP Control Unit5 - Aly2Khaled Yazid100% (1)

- 4-Pneumatic and Electro Pneumatic Systems - 1Document58 pages4-Pneumatic and Electro Pneumatic Systems - 1akhilkrrish143No ratings yet

- Cek Mesin AnestesiDocument3 pagesCek Mesin AnestesiAchmad MustikaNo ratings yet

- Solutions: TankersDocument7 pagesSolutions: TankersKirtishbose ChowdhuryNo ratings yet

- Subsea - Page 4Document79 pagesSubsea - Page 4lulalala8888100% (2)

- Unit 4 - Part 1Document25 pagesUnit 4 - Part 1akhilkrrish143No ratings yet

- Boiler Q&A FurtherDocument7 pagesBoiler Q&A FurtherRachitNo ratings yet

- PURIFIERSDocument7 pagesPURIFIERSjames dogelioNo ratings yet

- Study of Vacuuming of Refrigeration SystemDocument2 pagesStudy of Vacuuming of Refrigeration Systemsantosh IndulkarNo ratings yet

- Midterm - Unit OpsDocument19 pagesMidterm - Unit OpsKrizzia Anne ShengNo ratings yet

- Janoel Lucañas 2a Aux Mach Ass. #3Document4 pagesJanoel Lucañas 2a Aux Mach Ass. #3Janoel LucañasNo ratings yet

- Research Work Week 14Document5 pagesResearch Work Week 14jonas lintagNo ratings yet

- Two Stage Reciprocating CompressorDocument8 pagesTwo Stage Reciprocating CompressorAmolSarpeNo ratings yet

- Boiler Emergencies - 2017Document10 pagesBoiler Emergencies - 2017RAJKUMAR100% (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Fuel Gases: Primary (Natural) Secondary (Artificial)Document5 pagesFuel Gases: Primary (Natural) Secondary (Artificial)Souvik PaulNo ratings yet

- Question PaperDocument1 pageQuestion PaperSouvik PaulNo ratings yet

- Foe EndsemDocument22 pagesFoe EndsemSouvik PaulNo ratings yet

- Process Equipment Design: PART-1Document5 pagesProcess Equipment Design: PART-1Souvik PaulNo ratings yet

- Startup Roadmap 3Document6 pagesStartup Roadmap 3Souvik Paul100% (1)

- 13 Numerical Solution of Ode'SDocument8 pages13 Numerical Solution of Ode'SSouvik PaulNo ratings yet

- Mean Metal TempsDocument1 pageMean Metal TempsSouvik PaulNo ratings yet

- Prediction of The Liquid Viscosity For Petroleum FractionsDocument4 pagesPrediction of The Liquid Viscosity For Petroleum FractionsSouvik PaulNo ratings yet

- Quiz Time!!!Document13 pagesQuiz Time!!!Souvik PaulNo ratings yet

- BHP To RPHDocument1 pageBHP To RPHSouvik PaulNo ratings yet

- Integral Transforms For EngineersDocument365 pagesIntegral Transforms For EngineersSouvik PaulNo ratings yet

- UPCSC Syllabus: UPSC Syllabus For Preliminary ExaminationsDocument7 pagesUPCSC Syllabus: UPSC Syllabus For Preliminary ExaminationsSouvik PaulNo ratings yet

- All Flowmeter Basics PDFDocument1 pageAll Flowmeter Basics PDFAtharva PathakNo ratings yet

- Drying ProcessDocument18 pagesDrying ProcessMuhammad AlghitanyNo ratings yet

- Ch1 Advanced Reservoir Engineering 2007Document78 pagesCh1 Advanced Reservoir Engineering 2007RrelicNo ratings yet

- Valve Spec - Cleaning ProjectDocument16 pagesValve Spec - Cleaning ProjectMahmud RezaNo ratings yet

- External Static Pressure Calculation SheetDocument2 pagesExternal Static Pressure Calculation SheetNidhin CletusNo ratings yet

- S-Zorb (Conophillips) : Prepared By: Sadia Urooj Submitted To: Sir Zeeshan ZakiDocument4 pagesS-Zorb (Conophillips) : Prepared By: Sadia Urooj Submitted To: Sir Zeeshan ZakiSadia UroojNo ratings yet

- Refrigeration CycleDocument29 pagesRefrigeration CycleNeil John BoloNo ratings yet

- IM Intermedia Energy - Gas Plan Project 2022 FebDocument14 pagesIM Intermedia Energy - Gas Plan Project 2022 FebCV Sunan Kali JagaNo ratings yet

- MC 10121131 9999Document34 pagesMC 10121131 9999Florentin BacnașuNo ratings yet

- HaloalkanesDocument6 pagesHaloalkanesDoc_CrocNo ratings yet

- Argon Pure GasDocument2 pagesArgon Pure GasRaghu Pathy100% (1)

- Bank 35Document6 pagesBank 35Tung PhungvanNo ratings yet

- Standard Design Manual For Steam Drum InternalsDocument17 pagesStandard Design Manual For Steam Drum Internalsahmed sobhy100% (1)

- Gas InsulatorDocument2 pagesGas InsulatorAbdurrahman shuaibNo ratings yet

- Phy 101 Surface Tension and Capillary EffectDocument30 pagesPhy 101 Surface Tension and Capillary EffectZainab YusufNo ratings yet

- General Information (Steering) - HMU Steering: Systems OperationDocument5 pagesGeneral Information (Steering) - HMU Steering: Systems OperationRezhaNo ratings yet

- CFD MissileCombustion Scramjet DRDL 001 PDFDocument9 pagesCFD MissileCombustion Scramjet DRDL 001 PDFSai Santhosh ManepallyNo ratings yet

- Warman International LTD.: 2700 R/minDocument1 pageWarman International LTD.: 2700 R/minFlávio Carvalho FlávioNo ratings yet

- Energy Conversion Technology 1: 2019-2020 Exercise Class 7 - 7.10.2019 - Thermochemical ConversionDocument3 pagesEnergy Conversion Technology 1: 2019-2020 Exercise Class 7 - 7.10.2019 - Thermochemical ConversionKristijanNo ratings yet

- Extcat FM200Document15 pagesExtcat FM200Mohamed FawzyNo ratings yet

- Upstream, Midstream, DownstreamDocument5 pagesUpstream, Midstream, DownstreamKALPITA50% (2)

- Conventional JacketsDocument4 pagesConventional JacketskayeNo ratings yet

- PRDS Valve: Different Options For UseDocument3 pagesPRDS Valve: Different Options For UseRahul GawaliNo ratings yet

- Tutorial 1Document4 pagesTutorial 1Kevin TanNo ratings yet

- Expansion ValveDocument23 pagesExpansion Valvemahmoud EissaNo ratings yet

- Matriculation Chemistry Hydrocarbon Part 2 AlkaneDocument30 pagesMatriculation Chemistry Hydrocarbon Part 2 Alkaneiki292No ratings yet

Commissioning of Reactor

Commissioning of Reactor

Uploaded by

Souvik PaulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commissioning of Reactor

Commissioning of Reactor

Uploaded by

Souvik PaulCopyright:

Available Formats

Commissioning of Reactor

Biogas holdup should not be emptied completely. About 3-4 days of storage is kept in the gas

holdup for recycle.

1. The manual trip valve for slurry outlet located at the outlet of the reactor is kept closed

and the bypass line for the removal of air is kept opened.

2. Slurry inlet line is opened and pressure inside the reactor is maintained at mostly

atmospheric pressure.

3. During filling, de-oxygenated air is purged through the recycle line to stop aerobic

digestion and settling of the slurry.

4. After filling up of the reactor with slurry for about four weeks, the reactor is de-

pressurized up-to 0.1 atm. abs. by vacuum pumps connected at the top of the reactor.

5. After reducing pressure, recycle line is purged with methane instead of de-oxygenated

air and pressure is allowed to reach atmospheric pressure.

6. Now, the reactor is allowed to operate and the pressure builds up over days in the

reactor.

7. pH controller and level controller is allowed to operate after almost half of the reactor

is filled with slurry.

Commissioning of buffer tank

1. Outlet trip valve is closed and the inlet line is opened. Air purge line of the buffer tank

is kept open.

2. After filling the buffer tank to about half level, pH controller and level controller is

operated.

3. The slurry is continuously recycled during filling up of the tank to stop settling of the

slurry.

4. After buffer tank is filled to desired level, the manual outlet trip valve is opened and

the level controller takes over for the automated operation.

Commissioning of purification unit

Purification units are filled with chemicals (FeCl3 and lime). After sufficient pressure is

developed in the reactor, outlet line for bio-gas of the reactor starts operating. After operating

pressure of the purification units are reached, outlet line of the purification unit is started.

Shutdown of the plant

Mechanical and hydro-mechanical pre-treatment units are shut-down and the buffer tank is

gradually emptied. After, the buffer tank is emptied, we stop the reactor. To stop the reactor,

impure bio-gas is taken out and the reactor is de-pressurized up-to 0.1 atm. As the bio-gas is

purged out, the slurry is also purged out and compressed air is purged from the recycle line to

stop settling of the slurry and the reactor is gradually emptied. As the impure bio-gas flow

stops, the purification units are also stopped and brought to atmospheric pressure and

compressed air is purged inside the purification units for cleaning of the units.

You might also like

- FRAMO SYSTEM Drain and VentDocument3 pagesFRAMO SYSTEM Drain and VentjoelandrewpintoNo ratings yet

- Aerodynamics Questions and Suggested Answers 2Document5 pagesAerodynamics Questions and Suggested Answers 2ApikSanPewPewNo ratings yet

- SOP-Operating Procedure of Hydrogen Plant.Document17 pagesSOP-Operating Procedure of Hydrogen Plant.Sooraj Surendran Sugatha100% (1)

- Boilers SOPDocument18 pagesBoilers SOPPrakash WarrierNo ratings yet

- Procedure For Tank Washing and CleaningDocument3 pagesProcedure For Tank Washing and CleaningSachin Yadav54% (13)

- Boiler Commissioning and Operation Check ListDocument14 pagesBoiler Commissioning and Operation Check Listtsrinivasan5083100% (4)

- MINI STEAM POWER PLANT - Lab ManualDocument20 pagesMINI STEAM POWER PLANT - Lab Manualmelanie japay50% (6)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Startup of An Air Separation PlantDocument3 pagesStartup of An Air Separation Plantcymy0% (1)

- Turbine Startup ProcedureDocument8 pagesTurbine Startup ProcedureBrijesh Srivastav50% (2)

- Manual Starting and Desludging of PurifierDocument2 pagesManual Starting and Desludging of PurifierAnupGautam50% (2)

- Experiment 2 - Study of Packed Column DistillationDocument7 pagesExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Distillation ExperimentDocument6 pagesDistillation ExperimentJureen Flores BelicarioNo ratings yet

- P&IDDocument7 pagesP&IDTagabo AliNo ratings yet

- Rotary DrumDocument7 pagesRotary Drumjeas grejoy100% (1)

- Dean Stark Apparatus Lab ReportDocument9 pagesDean Stark Apparatus Lab ReportSouvik Paul0% (2)

- ULDocument12 pagesULt_kumaraguruNo ratings yet

- A Microscopic Model For An Ideal Gas Tutorials in Introductory Physics Homework AnswersDocument1 pageA Microscopic Model For An Ideal Gas Tutorials in Introductory Physics Homework Answersdreamsmasher100% (1)

- Aeration Commisioning - STPDocument7 pagesAeration Commisioning - STPdexterNo ratings yet

- Sop - STPDocument7 pagesSop - STPpulkitsharma17100% (1)

- Solvent Conversion Procedures: B. Preparation For Initial Start-UpDocument5 pagesSolvent Conversion Procedures: B. Preparation For Initial Start-UpEliasNo ratings yet

- HydrogenDocument10 pagesHydrogennuzulNo ratings yet

- Sop STPDocument5 pagesSop STPModi JayNo ratings yet

- Oxygen Concentrator Operation ManualDocument4 pagesOxygen Concentrator Operation ManualInge NecoNo ratings yet

- Important RegenerationDocument8 pagesImportant RegenerationrawadNo ratings yet

- BXPDocument53 pagesBXPkaranx16No ratings yet

- Manufacture OF Producer GasDocument36 pagesManufacture OF Producer GasSai PavanNo ratings yet

- Production OF Producer GasDocument19 pagesProduction OF Producer Gassaipa1No ratings yet

- Unit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemDocument13 pagesUnit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemMuhammad luqman100% (1)

- PREPARATION AND REGENERATION PROCEDURE OF REFORMER CATALYST 121211 REv 1 6 1-2014Document6 pagesPREPARATION AND REGENERATION PROCEDURE OF REFORMER CATALYST 121211 REv 1 6 1-2014dragofloresNo ratings yet

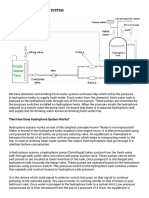

- Hydrophore SystemDocument4 pagesHydrophore SystemSWASTIK MISHRA50% (2)

- SOP Gas AbsorptionDocument19 pagesSOP Gas AbsorptionKevin EsmunaldoNo ratings yet

- Procedure For Aph Water WashingDocument3 pagesProcedure For Aph Water WashingSelvaNo ratings yet

- Boiler PreservationDocument3 pagesBoiler PreservationansudasinghaNo ratings yet

- I. Laboratory Procedure: Procedure (EQUIPMENT SET-UP)Document2 pagesI. Laboratory Procedure: Procedure (EQUIPMENT SET-UP)Chanel AnnNo ratings yet

- PartsDocument9 pagesPartsRosario SisniegasNo ratings yet

- Training Material of Boiler Operation: Drum and Internal DevicesDocument8 pagesTraining Material of Boiler Operation: Drum and Internal DevicesandreNo ratings yet

- Experiment No. 2Document7 pagesExperiment No. 2noteasytobebooNo ratings yet

- Centrifugal Pump (Various Air Handling Methods)Document21 pagesCentrifugal Pump (Various Air Handling Methods)karthick_mariner92No ratings yet

- Sop MeeDocument5 pagesSop MeeYogesh Dhekale100% (4)

- Ninh Binh Rua Hoa ChatDocument3 pagesNinh Binh Rua Hoa Chathuy LuongNo ratings yet

- Centrifugal Pump (Various Air Handling Methods)Document31 pagesCentrifugal Pump (Various Air Handling Methods)karthick_mariner92No ratings yet

- Gas Absorption Lab ReportDocument7 pagesGas Absorption Lab ReportShida ShamNo ratings yet

- WWE Filter Press OperationDocument4 pagesWWE Filter Press OperationMf LuiNo ratings yet

- Starting A Boiler From Dead Ship ConditionsDocument21 pagesStarting A Boiler From Dead Ship ConditionsrickNo ratings yet

- Line Up Turbine Aux. SystemDocument42 pagesLine Up Turbine Aux. SystemAmit Chauhan100% (3)

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Biocleaner - Manual de Operacion y MantenimientoDocument9 pagesBiocleaner - Manual de Operacion y MantenimientoFabian Ignacio Marquez OsorioNo ratings yet

- Accumulator and BOP Control Unit5 - Aly2Document65 pagesAccumulator and BOP Control Unit5 - Aly2Khaled Yazid100% (1)

- 4-Pneumatic and Electro Pneumatic Systems - 1Document58 pages4-Pneumatic and Electro Pneumatic Systems - 1akhilkrrish143No ratings yet

- Cek Mesin AnestesiDocument3 pagesCek Mesin AnestesiAchmad MustikaNo ratings yet

- Solutions: TankersDocument7 pagesSolutions: TankersKirtishbose ChowdhuryNo ratings yet

- Subsea - Page 4Document79 pagesSubsea - Page 4lulalala8888100% (2)

- Unit 4 - Part 1Document25 pagesUnit 4 - Part 1akhilkrrish143No ratings yet

- Boiler Q&A FurtherDocument7 pagesBoiler Q&A FurtherRachitNo ratings yet

- PURIFIERSDocument7 pagesPURIFIERSjames dogelioNo ratings yet

- Study of Vacuuming of Refrigeration SystemDocument2 pagesStudy of Vacuuming of Refrigeration Systemsantosh IndulkarNo ratings yet

- Midterm - Unit OpsDocument19 pagesMidterm - Unit OpsKrizzia Anne ShengNo ratings yet

- Janoel Lucañas 2a Aux Mach Ass. #3Document4 pagesJanoel Lucañas 2a Aux Mach Ass. #3Janoel LucañasNo ratings yet

- Research Work Week 14Document5 pagesResearch Work Week 14jonas lintagNo ratings yet

- Two Stage Reciprocating CompressorDocument8 pagesTwo Stage Reciprocating CompressorAmolSarpeNo ratings yet

- Boiler Emergencies - 2017Document10 pagesBoiler Emergencies - 2017RAJKUMAR100% (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Fuel Gases: Primary (Natural) Secondary (Artificial)Document5 pagesFuel Gases: Primary (Natural) Secondary (Artificial)Souvik PaulNo ratings yet

- Question PaperDocument1 pageQuestion PaperSouvik PaulNo ratings yet

- Foe EndsemDocument22 pagesFoe EndsemSouvik PaulNo ratings yet

- Process Equipment Design: PART-1Document5 pagesProcess Equipment Design: PART-1Souvik PaulNo ratings yet

- Startup Roadmap 3Document6 pagesStartup Roadmap 3Souvik Paul100% (1)

- 13 Numerical Solution of Ode'SDocument8 pages13 Numerical Solution of Ode'SSouvik PaulNo ratings yet

- Mean Metal TempsDocument1 pageMean Metal TempsSouvik PaulNo ratings yet

- Prediction of The Liquid Viscosity For Petroleum FractionsDocument4 pagesPrediction of The Liquid Viscosity For Petroleum FractionsSouvik PaulNo ratings yet

- Quiz Time!!!Document13 pagesQuiz Time!!!Souvik PaulNo ratings yet

- BHP To RPHDocument1 pageBHP To RPHSouvik PaulNo ratings yet

- Integral Transforms For EngineersDocument365 pagesIntegral Transforms For EngineersSouvik PaulNo ratings yet

- UPCSC Syllabus: UPSC Syllabus For Preliminary ExaminationsDocument7 pagesUPCSC Syllabus: UPSC Syllabus For Preliminary ExaminationsSouvik PaulNo ratings yet

- All Flowmeter Basics PDFDocument1 pageAll Flowmeter Basics PDFAtharva PathakNo ratings yet

- Drying ProcessDocument18 pagesDrying ProcessMuhammad AlghitanyNo ratings yet

- Ch1 Advanced Reservoir Engineering 2007Document78 pagesCh1 Advanced Reservoir Engineering 2007RrelicNo ratings yet

- Valve Spec - Cleaning ProjectDocument16 pagesValve Spec - Cleaning ProjectMahmud RezaNo ratings yet

- External Static Pressure Calculation SheetDocument2 pagesExternal Static Pressure Calculation SheetNidhin CletusNo ratings yet

- S-Zorb (Conophillips) : Prepared By: Sadia Urooj Submitted To: Sir Zeeshan ZakiDocument4 pagesS-Zorb (Conophillips) : Prepared By: Sadia Urooj Submitted To: Sir Zeeshan ZakiSadia UroojNo ratings yet

- Refrigeration CycleDocument29 pagesRefrigeration CycleNeil John BoloNo ratings yet

- IM Intermedia Energy - Gas Plan Project 2022 FebDocument14 pagesIM Intermedia Energy - Gas Plan Project 2022 FebCV Sunan Kali JagaNo ratings yet

- MC 10121131 9999Document34 pagesMC 10121131 9999Florentin BacnașuNo ratings yet

- HaloalkanesDocument6 pagesHaloalkanesDoc_CrocNo ratings yet

- Argon Pure GasDocument2 pagesArgon Pure GasRaghu Pathy100% (1)

- Bank 35Document6 pagesBank 35Tung PhungvanNo ratings yet

- Standard Design Manual For Steam Drum InternalsDocument17 pagesStandard Design Manual For Steam Drum Internalsahmed sobhy100% (1)

- Gas InsulatorDocument2 pagesGas InsulatorAbdurrahman shuaibNo ratings yet

- Phy 101 Surface Tension and Capillary EffectDocument30 pagesPhy 101 Surface Tension and Capillary EffectZainab YusufNo ratings yet

- General Information (Steering) - HMU Steering: Systems OperationDocument5 pagesGeneral Information (Steering) - HMU Steering: Systems OperationRezhaNo ratings yet

- CFD MissileCombustion Scramjet DRDL 001 PDFDocument9 pagesCFD MissileCombustion Scramjet DRDL 001 PDFSai Santhosh ManepallyNo ratings yet

- Warman International LTD.: 2700 R/minDocument1 pageWarman International LTD.: 2700 R/minFlávio Carvalho FlávioNo ratings yet

- Energy Conversion Technology 1: 2019-2020 Exercise Class 7 - 7.10.2019 - Thermochemical ConversionDocument3 pagesEnergy Conversion Technology 1: 2019-2020 Exercise Class 7 - 7.10.2019 - Thermochemical ConversionKristijanNo ratings yet

- Extcat FM200Document15 pagesExtcat FM200Mohamed FawzyNo ratings yet

- Upstream, Midstream, DownstreamDocument5 pagesUpstream, Midstream, DownstreamKALPITA50% (2)

- Conventional JacketsDocument4 pagesConventional JacketskayeNo ratings yet

- PRDS Valve: Different Options For UseDocument3 pagesPRDS Valve: Different Options For UseRahul GawaliNo ratings yet

- Tutorial 1Document4 pagesTutorial 1Kevin TanNo ratings yet

- Expansion ValveDocument23 pagesExpansion Valvemahmoud EissaNo ratings yet

- Matriculation Chemistry Hydrocarbon Part 2 AlkaneDocument30 pagesMatriculation Chemistry Hydrocarbon Part 2 Alkaneiki292No ratings yet