Professional Documents

Culture Documents

Hot Work Permit

Hot Work Permit

Uploaded by

jitheshsvCopyright:

Available Formats

You might also like

- Fire Technology and Arson Investigation. Power Point PresentationDocument75 pagesFire Technology and Arson Investigation. Power Point PresentationPs Seven Neutron79% (14)

- TM 31-210 Improvised Munitions Handbook v3Document273 pagesTM 31-210 Improvised Munitions Handbook v3poisonknives100% (8)

- 14-03-00 Daily Pre-Task Plan (PTP)Document3 pages14-03-00 Daily Pre-Task Plan (PTP)JorgeNo ratings yet

- Hot Work Permit WordDocument3 pagesHot Work Permit Wordmush0025No ratings yet

- Safety Hot Work ProgramDocument10 pagesSafety Hot Work ProgramkevinNo ratings yet

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- Accident Investigation Form SampleDocument2 pagesAccident Investigation Form Sample811 - 813100% (2)

- Emergency Plan For Rescue From HeightsDocument9 pagesEmergency Plan For Rescue From HeightsMuhammad Shamaran AbdullahNo ratings yet

- Permit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedDocument3 pagesPermit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedJohn BusherNo ratings yet

- Hot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Document6 pagesHot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Wee Soon ChaiNo ratings yet

- EHS 2-F5 PTW Demolition Rev1Document2 pagesEHS 2-F5 PTW Demolition Rev1Lee Xiao YuNo ratings yet

- Jsa 2Document5 pagesJsa 2Muddassir Baig MirzaNo ratings yet

- Permit To Work EOH-SP-FORM 531.01Document2 pagesPermit To Work EOH-SP-FORM 531.01Brad EubankNo ratings yet

- Electrical Work Checklist: Saline Water Desalination Plant On The West CoastDocument1 pageElectrical Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- 18A - FO - Permit To Work LogDocument2 pages18A - FO - Permit To Work Lograjesh_rathNo ratings yet

- JHA - Plumbing WorksDocument1 pageJHA - Plumbing WorksBilly Joe BreakfastNo ratings yet

- Monthly Ladder Inspection ChecklistDocument1 pageMonthly Ladder Inspection ChecklistSalu BahiNo ratings yet

- Daily Safety ChecklistDocument4 pagesDaily Safety ChecklistKalyan ReddyNo ratings yet

- VR-ForM-F06.10 (Hot Work Permit Request Form)Document1 pageVR-ForM-F06.10 (Hot Work Permit Request Form)imtz2013No ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- 11.07.09 Working at Height (TD Repair)Document1 page11.07.09 Working at Height (TD Repair)Hamdi Rafiek100% (1)

- Noise MonitoringDocument7 pagesNoise Monitoringshahrul rollNo ratings yet

- HSE 09 Hotwork PermitDocument1 pageHSE 09 Hotwork PermitBa N Nhim100% (1)

- Task Risk AssesmentDocument6 pagesTask Risk Assesmentum erNo ratings yet

- Draft PTWDocument1 pageDraft PTWmohamad nur saufiNo ratings yet

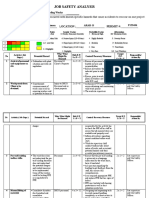

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- Excavaten Work PermitDocument1 pageExcavaten Work Permitasem sawalmehNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- Confined Space Entry PermitDocument2 pagesConfined Space Entry PermitradeepNo ratings yet

- Monthly Store Inspection ReportDocument1 pageMonthly Store Inspection ReportgkNo ratings yet

- Format - Task Based Hazard Identification & Risk AssessmentDocument2 pagesFormat - Task Based Hazard Identification & Risk AssessmentMohammad Asif100% (1)

- Loto Standard Operating Procedure Sop - Loto - : Lockout PointsDocument2 pagesLoto Standard Operating Procedure Sop - Loto - : Lockout PointsK3L ULP Tanjung RedebNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- MW-OPS-SP-3.6.13F1 Work Authorization Permit FormDocument3 pagesMW-OPS-SP-3.6.13F1 Work Authorization Permit FormGabriel Tan100% (1)

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Project EHS KPI - 24 Agustus 2013Document1 pageProject EHS KPI - 24 Agustus 2013Crystin Rotua Hasmi PanjaitanNo ratings yet

- Updated FMT05 MOM Safety Committee Jan-22Document3 pagesUpdated FMT05 MOM Safety Committee Jan-22anil kumarNo ratings yet

- 10-F20 Fuel Driven Equipment InspectionDocument3 pages10-F20 Fuel Driven Equipment InspectionSn AhsanNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Safety OfficerDocument16 pagesSafety OfficerAzad pravesh khanNo ratings yet

- HSE 13 Lifting Operation PermitDocument1 pageHSE 13 Lifting Operation PermitBa N Nhim100% (1)

- General Work Permit FormatDocument1 pageGeneral Work Permit FormatprabhuNo ratings yet

- 08n Safety Action PlanDocument103 pages08n Safety Action PlanMohammed MinhajNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- HIRA RCC Work (3) Approed by ClientDocument11 pagesHIRA RCC Work (3) Approed by ClientHARSHADNo ratings yet

- Heat-Stress-Management-Training-Program-Samir 11 R4Document28 pagesHeat-Stress-Management-Training-Program-Samir 11 R4Sheri DiĺlNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Ptw-Lifting Operation (Daily) : General Information OMC Permit NoDocument2 pagesPtw-Lifting Operation (Daily) : General Information OMC Permit NoPHP DEVELOPERNo ratings yet

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaNo ratings yet

- PLT - H&S - Project HIRA - (R 13) 191125Document115 pagesPLT - H&S - Project HIRA - (R 13) 191125soubhagyaNo ratings yet

- Jsa FormDocument5 pagesJsa FormRio HandokoNo ratings yet

- Permit To WorkDocument1 pagePermit To WorkMohammed KadhimNo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- JHA For Demolition of Hume PipeDocument2 pagesJHA For Demolition of Hume Pipeneecon techNo ratings yet

- 7-26 Scaffold Procedure (RV)Document7 pages7-26 Scaffold Procedure (RV)Lee JungNo ratings yet

- OHSE Project HIRA - Fencing Work - R 01Document8 pagesOHSE Project HIRA - Fencing Work - R 01Pankaj SinghNo ratings yet

- Confined Space Entry Risk AssessmentDocument9 pagesConfined Space Entry Risk Assessmentkoketso0% (1)

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Hot Work Permit ChecklistDocument1 pageHot Work Permit ChecklistDhanraj PatilNo ratings yet

- Chola MS Risk - Corporate ProfileDocument40 pagesChola MS Risk - Corporate ProfilejitheshsvNo ratings yet

- Mcete 104 Urban Transportation PlanningDocument2 pagesMcete 104 Urban Transportation PlanningjitheshsvNo ratings yet

- Buchholz RelayDocument2 pagesBuchholz RelayjitheshsvNo ratings yet

- JR East Railway MapDocument1 pageJR East Railway MapjitheshsvNo ratings yet

- Indonesia'S Export and Import Developments in February 2019Document6 pagesIndonesia'S Export and Import Developments in February 2019WennyKurniawatiNo ratings yet

- Rumaila ProjectDocument10 pagesRumaila ProjectJalal AlbadriNo ratings yet

- FSM (BPCL)Document15 pagesFSM (BPCL)Prabhat Kumar ChoubeyNo ratings yet

- 06-250 Old Farm EquipmentDocument191 pages06-250 Old Farm EquipmentJoseph Thomas Weber Jr.No ratings yet

- Riello Rls M MX Ts0064uk03 Rev1Document32 pagesRiello Rls M MX Ts0064uk03 Rev1weweqweqwNo ratings yet

- Advances in Chromatographic Analysis of Hydrocarbon Gases in Drilling Fluids - The Application of Semi-Permeable Membrane Technology To High Speed TCD Gas ChromatographyDocument9 pagesAdvances in Chromatographic Analysis of Hydrocarbon Gases in Drilling Fluids - The Application of Semi-Permeable Membrane Technology To High Speed TCD Gas ChromatographyNA NANo ratings yet

- ECOTRONS Turbo VZ21 Technical SpeclDocument16 pagesECOTRONS Turbo VZ21 Technical SpeclMauricio López AyalaNo ratings yet

- Action Plan Flame DetectorDocument2 pagesAction Plan Flame DetectorardipangulihiNo ratings yet

- JJMIE 41 09 Modified SOIDocument8 pagesJJMIE 41 09 Modified SOIED LiNo ratings yet

- Inventory Management ReportDocument24 pagesInventory Management Reportmahi5061100% (1)

- Fractional Distillation Is The Separation of A Mixture Into Its Component PartsDocument4 pagesFractional Distillation Is The Separation of A Mixture Into Its Component PartsMariana MarchenaNo ratings yet

- Brochure DUNGS Automatic Gas Burner ControlDocument4 pagesBrochure DUNGS Automatic Gas Burner ControlNestramiNo ratings yet

- Continued Success in A High Subsurface Risk Environment The Cendor StoryDocument1 pageContinued Success in A High Subsurface Risk Environment The Cendor StorymnoriegalNo ratings yet

- User Manual For Push Mower Model 02BDocument40 pagesUser Manual For Push Mower Model 02BshayetftNo ratings yet

- Sunval: Combined AssetsDocument9 pagesSunval: Combined AssetsWilliam MookNo ratings yet

- Countermeasure For SurgingDocument3 pagesCountermeasure For SurgingParthiban Nagarajan100% (1)

- Greenwald 1956Document5 pagesGreenwald 1956oreamigNo ratings yet

- Pinay Scientist Creates Lamp That Runs On SaltwaterDocument6 pagesPinay Scientist Creates Lamp That Runs On SaltwaterSamuel SeriñaNo ratings yet

- Fire Code Illustrated Commentary Salvage Shops &yardsDocument30 pagesFire Code Illustrated Commentary Salvage Shops &yardsMohammedNo ratings yet

- Tribolube 64Document2 pagesTribolube 64JasonNo ratings yet

- An Atmospheric Crude Tower RevampDocument6 pagesAn Atmospheric Crude Tower RevampMarlon Arteaga100% (1)

- All About SKV Welding: (A Complete Guide On AT Welding For P.Way Engineers / Officers)Document132 pagesAll About SKV Welding: (A Complete Guide On AT Welding For P.Way Engineers / Officers)radhakrishnangNo ratings yet

- VELVEX - AdditivesDocument11 pagesVELVEX - AdditivesVaradrajan jothi100% (1)

- Chapter 5 Rock MechanicsDocument59 pagesChapter 5 Rock MechanicsjcNo ratings yet

- Xp13000Eh Generator: User ManualDocument66 pagesXp13000Eh Generator: User ManualANGEL MALAVERNo ratings yet

- Perforation Job DesignDocument8 pagesPerforation Job DesignAfnan Mukhtar SyauqiNo ratings yet

- GEA31885 TM2500 Brochure PDFDocument8 pagesGEA31885 TM2500 Brochure PDFThanapaet RittirutNo ratings yet

- Contador de ParticulasDocument3 pagesContador de Particulascesar6huhNo ratings yet

Hot Work Permit

Hot Work Permit

Uploaded by

jitheshsvOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Work Permit

Hot Work Permit

Uploaded by

jitheshsvCopyright:

Available Formats

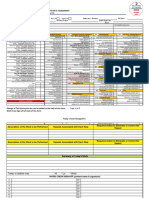

HOT WORK PERMIT

(Format 1, NFPA Format)

Date :

Building :

Department :

Floor :

Work to be done :

Special precautions :

Is fire watch :

required?

The location where this work is to be done has been examined, necessary precautions

taken, and permission is granted for this work (see other side also)

Permit expires :

Signed :

(Permit Authorizing

Individual)

Time started :

Time completed :

FINAL CHECK

Work area and all adjacent areas to which sparks and heat might have spread

(including floors above and below and on opposite side of wall(s)) were inspected 30

minutes after the work was completed and were found fire safe.

Signed :

(Permit Authorizing

Individual)

Page 1

ATTENTION

Before approving any hot work permit the PAI shall inspect the work area and confirm

that all precautions have been taken to prevent in accordance with NFPA 51 B.

PRECAUTIONS

Sprinklers in service

Hot work equipment in good repair

WITHIN 35FEET OF WORK

Floors swept clean of combustibles

Combustible floors wet down, covered with damp sand, metal or other shields

All wall and floor openings covered

Covers suspended beneath work to collect sparks

WORK ON WALLS OR CEILINGS

Construction non combustible and without combustible covering

Combustibles moved away from opposite side of wall

WORK ON ENCLOSED EQUIPMENT

(Tanks, containers, ducts, dust collectors, etc.,)

Equipment cleaned of all combustibles

Containers purged of flammable vapors

FIRE WATCH

To be provided during and 30 minutes after operation

Supplied with a fully charged and operable fire extinguisher

Trained in use of equipment and in sounding fire alarm

FINAL CHECK

To be made 30 minutes after completion of any operation unless fire watch is provided.

Signed (Permit Authorizing Individual):

Page 2

HOT WORK PERMIT

(Format 2, Factory Mutual Engineering corporation)

This Hot work permit is required for any operation involving open flames or producing

heat and / or sparks. This includes, but is not limited to brazing, cutting, grinding,

soldering, thawing pipe, Torch – Applied Roofing and Cadwelding

INSTRUCTIONS

1. Verify precautions listed at right (or do not proceed with work)

2. Complete and retain the permit

Hot work being done by (Employee / Contractor), In case of Contractor Name of the

contractor______________

Date :

Job No :

Location / Building & :

floor

Nature of Job / Object :

Name of the person :

doing Hot work

I verify the above location has been examined, the precautions checked on the

required precautions checklist have been taken to prevent fire and permission is

authorized for work

Signed :

Permit Expiry date & :

Time

Note: Emergency Notification on back of form use as appropriate for your facility

THIS PERMIT IS GOOD FOR ONE DAY ONLY

Page 1

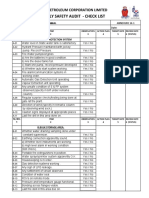

REQUIRED PRECAUTIONS CHECKLIST

Available sprinklers, hose streams, and extinguishers are in service / operable

Hot work equipment in good repair

Requirements within 35ft(10m) of work

Flammable liquids, dust, lint and oil deposits removed

Explosive atmosphere in area eliminated

Floors swept clean

Combustible floors wet down, covered with damp sand or fire resistant sheets.

Remove other combustibles where possible, otherwise protect with fire resistant

tarpaulins or metal sheets

All wall and floor openings covered

Fire resistant tarpaulins suspended beneath work.

Work on Walls or Ceilings/ enclosed equipment:

Construction is noncombustible and without combustible covering or insulation

Combustibles on other side of walls moved away

Danger exist by conduction of heat into another area.

Enclosed equipment cleaned of all combustibles

Containers purged of flammable liquids/ vapors

Fire Watch / Hot work area Monitoring:

Fire watch will be provided during and for 30 minutes after work including any coffee

and lunch breaks

Fire watch is supplied with suitable extinguishers

Fire watch is trained in use of this equipment and in sounding alarm

Fire watch may be required for adjoining areas, above and below.

Monitor hot work area for 30 minutes after job is completed.

Other Precautions Taken:

Confined space entry permit required

Is area protected with smoke or heat detection

Ample ventilation to remove smoke / vapor from work area.

Lockout / tagout required.

Page 2

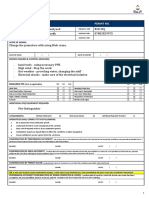

IMPORTANT POINTS FOR HOT WORK PERMIT

When Hot work is performed at an elevated level, it should be noted that the

sparks or slag can fall at a trajectory and land further than

35ft(11mtr)horizontally from a point directly under hot work operator.

It is advisable that the permit should b issued for a maximum period of 24 hrs

In some situations, It is advisable to inspect the area once per shift if

conditions warrant.

Situations where an additional fire watch(es) might be necessary include hot

work near open shafts , elevated heights or where sparks can travel through

openings and so on.

The Picture Given below demonstrates the Hot work 35 ft (11m) rule:

You might also like

- Fire Technology and Arson Investigation. Power Point PresentationDocument75 pagesFire Technology and Arson Investigation. Power Point PresentationPs Seven Neutron79% (14)

- TM 31-210 Improvised Munitions Handbook v3Document273 pagesTM 31-210 Improvised Munitions Handbook v3poisonknives100% (8)

- 14-03-00 Daily Pre-Task Plan (PTP)Document3 pages14-03-00 Daily Pre-Task Plan (PTP)JorgeNo ratings yet

- Hot Work Permit WordDocument3 pagesHot Work Permit Wordmush0025No ratings yet

- Safety Hot Work ProgramDocument10 pagesSafety Hot Work ProgramkevinNo ratings yet

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- Accident Investigation Form SampleDocument2 pagesAccident Investigation Form Sample811 - 813100% (2)

- Emergency Plan For Rescue From HeightsDocument9 pagesEmergency Plan For Rescue From HeightsMuhammad Shamaran AbdullahNo ratings yet

- Permit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedDocument3 pagesPermit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedJohn BusherNo ratings yet

- Hot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Document6 pagesHot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Wee Soon ChaiNo ratings yet

- EHS 2-F5 PTW Demolition Rev1Document2 pagesEHS 2-F5 PTW Demolition Rev1Lee Xiao YuNo ratings yet

- Jsa 2Document5 pagesJsa 2Muddassir Baig MirzaNo ratings yet

- Permit To Work EOH-SP-FORM 531.01Document2 pagesPermit To Work EOH-SP-FORM 531.01Brad EubankNo ratings yet

- Electrical Work Checklist: Saline Water Desalination Plant On The West CoastDocument1 pageElectrical Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- 18A - FO - Permit To Work LogDocument2 pages18A - FO - Permit To Work Lograjesh_rathNo ratings yet

- JHA - Plumbing WorksDocument1 pageJHA - Plumbing WorksBilly Joe BreakfastNo ratings yet

- Monthly Ladder Inspection ChecklistDocument1 pageMonthly Ladder Inspection ChecklistSalu BahiNo ratings yet

- Daily Safety ChecklistDocument4 pagesDaily Safety ChecklistKalyan ReddyNo ratings yet

- VR-ForM-F06.10 (Hot Work Permit Request Form)Document1 pageVR-ForM-F06.10 (Hot Work Permit Request Form)imtz2013No ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- 11.07.09 Working at Height (TD Repair)Document1 page11.07.09 Working at Height (TD Repair)Hamdi Rafiek100% (1)

- Noise MonitoringDocument7 pagesNoise Monitoringshahrul rollNo ratings yet

- HSE 09 Hotwork PermitDocument1 pageHSE 09 Hotwork PermitBa N Nhim100% (1)

- Task Risk AssesmentDocument6 pagesTask Risk Assesmentum erNo ratings yet

- Draft PTWDocument1 pageDraft PTWmohamad nur saufiNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- Excavaten Work PermitDocument1 pageExcavaten Work Permitasem sawalmehNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- Confined Space Entry PermitDocument2 pagesConfined Space Entry PermitradeepNo ratings yet

- Monthly Store Inspection ReportDocument1 pageMonthly Store Inspection ReportgkNo ratings yet

- Format - Task Based Hazard Identification & Risk AssessmentDocument2 pagesFormat - Task Based Hazard Identification & Risk AssessmentMohammad Asif100% (1)

- Loto Standard Operating Procedure Sop - Loto - : Lockout PointsDocument2 pagesLoto Standard Operating Procedure Sop - Loto - : Lockout PointsK3L ULP Tanjung RedebNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- MW-OPS-SP-3.6.13F1 Work Authorization Permit FormDocument3 pagesMW-OPS-SP-3.6.13F1 Work Authorization Permit FormGabriel Tan100% (1)

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Project EHS KPI - 24 Agustus 2013Document1 pageProject EHS KPI - 24 Agustus 2013Crystin Rotua Hasmi PanjaitanNo ratings yet

- Updated FMT05 MOM Safety Committee Jan-22Document3 pagesUpdated FMT05 MOM Safety Committee Jan-22anil kumarNo ratings yet

- 10-F20 Fuel Driven Equipment InspectionDocument3 pages10-F20 Fuel Driven Equipment InspectionSn AhsanNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Safety OfficerDocument16 pagesSafety OfficerAzad pravesh khanNo ratings yet

- HSE 13 Lifting Operation PermitDocument1 pageHSE 13 Lifting Operation PermitBa N Nhim100% (1)

- General Work Permit FormatDocument1 pageGeneral Work Permit FormatprabhuNo ratings yet

- 08n Safety Action PlanDocument103 pages08n Safety Action PlanMohammed MinhajNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- HIRA RCC Work (3) Approed by ClientDocument11 pagesHIRA RCC Work (3) Approed by ClientHARSHADNo ratings yet

- Heat-Stress-Management-Training-Program-Samir 11 R4Document28 pagesHeat-Stress-Management-Training-Program-Samir 11 R4Sheri DiĺlNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Ptw-Lifting Operation (Daily) : General Information OMC Permit NoDocument2 pagesPtw-Lifting Operation (Daily) : General Information OMC Permit NoPHP DEVELOPERNo ratings yet

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaNo ratings yet

- PLT - H&S - Project HIRA - (R 13) 191125Document115 pagesPLT - H&S - Project HIRA - (R 13) 191125soubhagyaNo ratings yet

- Jsa FormDocument5 pagesJsa FormRio HandokoNo ratings yet

- Permit To WorkDocument1 pagePermit To WorkMohammed KadhimNo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- JHA For Demolition of Hume PipeDocument2 pagesJHA For Demolition of Hume Pipeneecon techNo ratings yet

- 7-26 Scaffold Procedure (RV)Document7 pages7-26 Scaffold Procedure (RV)Lee JungNo ratings yet

- OHSE Project HIRA - Fencing Work - R 01Document8 pagesOHSE Project HIRA - Fencing Work - R 01Pankaj SinghNo ratings yet

- Confined Space Entry Risk AssessmentDocument9 pagesConfined Space Entry Risk Assessmentkoketso0% (1)

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Hot Work Permit ChecklistDocument1 pageHot Work Permit ChecklistDhanraj PatilNo ratings yet

- Chola MS Risk - Corporate ProfileDocument40 pagesChola MS Risk - Corporate ProfilejitheshsvNo ratings yet

- Mcete 104 Urban Transportation PlanningDocument2 pagesMcete 104 Urban Transportation PlanningjitheshsvNo ratings yet

- Buchholz RelayDocument2 pagesBuchholz RelayjitheshsvNo ratings yet

- JR East Railway MapDocument1 pageJR East Railway MapjitheshsvNo ratings yet

- Indonesia'S Export and Import Developments in February 2019Document6 pagesIndonesia'S Export and Import Developments in February 2019WennyKurniawatiNo ratings yet

- Rumaila ProjectDocument10 pagesRumaila ProjectJalal AlbadriNo ratings yet

- FSM (BPCL)Document15 pagesFSM (BPCL)Prabhat Kumar ChoubeyNo ratings yet

- 06-250 Old Farm EquipmentDocument191 pages06-250 Old Farm EquipmentJoseph Thomas Weber Jr.No ratings yet

- Riello Rls M MX Ts0064uk03 Rev1Document32 pagesRiello Rls M MX Ts0064uk03 Rev1weweqweqwNo ratings yet

- Advances in Chromatographic Analysis of Hydrocarbon Gases in Drilling Fluids - The Application of Semi-Permeable Membrane Technology To High Speed TCD Gas ChromatographyDocument9 pagesAdvances in Chromatographic Analysis of Hydrocarbon Gases in Drilling Fluids - The Application of Semi-Permeable Membrane Technology To High Speed TCD Gas ChromatographyNA NANo ratings yet

- ECOTRONS Turbo VZ21 Technical SpeclDocument16 pagesECOTRONS Turbo VZ21 Technical SpeclMauricio López AyalaNo ratings yet

- Action Plan Flame DetectorDocument2 pagesAction Plan Flame DetectorardipangulihiNo ratings yet

- JJMIE 41 09 Modified SOIDocument8 pagesJJMIE 41 09 Modified SOIED LiNo ratings yet

- Inventory Management ReportDocument24 pagesInventory Management Reportmahi5061100% (1)

- Fractional Distillation Is The Separation of A Mixture Into Its Component PartsDocument4 pagesFractional Distillation Is The Separation of A Mixture Into Its Component PartsMariana MarchenaNo ratings yet

- Brochure DUNGS Automatic Gas Burner ControlDocument4 pagesBrochure DUNGS Automatic Gas Burner ControlNestramiNo ratings yet

- Continued Success in A High Subsurface Risk Environment The Cendor StoryDocument1 pageContinued Success in A High Subsurface Risk Environment The Cendor StorymnoriegalNo ratings yet

- User Manual For Push Mower Model 02BDocument40 pagesUser Manual For Push Mower Model 02BshayetftNo ratings yet

- Sunval: Combined AssetsDocument9 pagesSunval: Combined AssetsWilliam MookNo ratings yet

- Countermeasure For SurgingDocument3 pagesCountermeasure For SurgingParthiban Nagarajan100% (1)

- Greenwald 1956Document5 pagesGreenwald 1956oreamigNo ratings yet

- Pinay Scientist Creates Lamp That Runs On SaltwaterDocument6 pagesPinay Scientist Creates Lamp That Runs On SaltwaterSamuel SeriñaNo ratings yet

- Fire Code Illustrated Commentary Salvage Shops &yardsDocument30 pagesFire Code Illustrated Commentary Salvage Shops &yardsMohammedNo ratings yet

- Tribolube 64Document2 pagesTribolube 64JasonNo ratings yet

- An Atmospheric Crude Tower RevampDocument6 pagesAn Atmospheric Crude Tower RevampMarlon Arteaga100% (1)

- All About SKV Welding: (A Complete Guide On AT Welding For P.Way Engineers / Officers)Document132 pagesAll About SKV Welding: (A Complete Guide On AT Welding For P.Way Engineers / Officers)radhakrishnangNo ratings yet

- VELVEX - AdditivesDocument11 pagesVELVEX - AdditivesVaradrajan jothi100% (1)

- Chapter 5 Rock MechanicsDocument59 pagesChapter 5 Rock MechanicsjcNo ratings yet

- Xp13000Eh Generator: User ManualDocument66 pagesXp13000Eh Generator: User ManualANGEL MALAVERNo ratings yet

- Perforation Job DesignDocument8 pagesPerforation Job DesignAfnan Mukhtar SyauqiNo ratings yet

- GEA31885 TM2500 Brochure PDFDocument8 pagesGEA31885 TM2500 Brochure PDFThanapaet RittirutNo ratings yet

- Contador de ParticulasDocument3 pagesContador de Particulascesar6huhNo ratings yet