Professional Documents

Culture Documents

Linh

Linh

Uploaded by

Kelvin NguyễnCopyright:

Available Formats

You might also like

- Business Plan On Plastic RecycleDocument25 pagesBusiness Plan On Plastic RecycleShailendra Joshi83% (6)

- Plastic Recycling SurveyDocument43 pagesPlastic Recycling SurveyMahmoud KamelNo ratings yet

- Business Plan On Plastic Recycling ManufacturingDocument13 pagesBusiness Plan On Plastic Recycling ManufacturingAmman Abedin100% (2)

- Due Care Petpreform-RILDocument40 pagesDue Care Petpreform-RILSyauqi AkmalaNo ratings yet

- Soy Based PlasticsDocument4 pagesSoy Based PlasticsA MahmoodNo ratings yet

- PET Bottle RecyclingDocument5 pagesPET Bottle Recyclingian jheferNo ratings yet

- Pet Bottles Flakes - RoughDocument19 pagesPet Bottles Flakes - RoughSivaraman P. S.100% (1)

- Polyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Document11 pagesPolyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Muhammad TanweerNo ratings yet

- Plastic Recycling AgainDocument5 pagesPlastic Recycling AgainzidaaanNo ratings yet

- Dimethyl TerephthalateDocument9 pagesDimethyl Terephthalatehung_metalNo ratings yet

- Choose The Right RollerDocument7 pagesChoose The Right Rollerkartik spectomsNo ratings yet

- Ethylene Polyethylene Polyethylene Terephthalate Polyvinyl Chloride PolystyreneDocument1 pageEthylene Polyethylene Polyethylene Terephthalate Polyvinyl Chloride PolystyreneRashail AshasNo ratings yet

- PolyesterDocument7 pagesPolyesterkgaviolaNo ratings yet

- Masterbatch - WikipediaDocument15 pagesMasterbatch - WikipediaSudhir PatilNo ratings yet

- Material FilamentDocument11 pagesMaterial Filamentalidina538No ratings yet

- Polyester Recycling Forum2006Document100 pagesPolyester Recycling Forum2006Atika Anan ToryNo ratings yet

- Worldwide Consumption of Thermoplastic Polyurethane ElastomersDocument5 pagesWorldwide Consumption of Thermoplastic Polyurethane ElastomersHerat TrivediNo ratings yet

- Project Profile Name of The ProductDocument11 pagesProject Profile Name of The ProductA.Allwin rajNo ratings yet

- Dow Hdpe ResinDocument7 pagesDow Hdpe ResinBudyawan SaputraNo ratings yet

- Fuel From Plastic WasteDocument56 pagesFuel From Plastic Wastesumit potdarNo ratings yet

- Plastic RecyclingDocument7 pagesPlastic RecyclingGeroldo 'Rollie' L. Querijero0% (1)

- Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesWaste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Overview of PET ProcessingDocument5 pagesOverview of PET ProcessingSwagat R Pyakurel50% (2)

- Production of PET Film and Sheets, Urethane Foams, Flexible Foams, Rigid Foams, Speciality Plastics. - 350919Document65 pagesProduction of PET Film and Sheets, Urethane Foams, Flexible Foams, Rigid Foams, Speciality Plastics. - 350919Beng-Tiek YapNo ratings yet

- Presentation On Recycling of PlasticDocument22 pagesPresentation On Recycling of PlasticTushar YadavNo ratings yet

- PET Foam White PaperDocument7 pagesPET Foam White PaperWilhelmina MurrayNo ratings yet

- Commen MaterialDocument2 pagesCommen MaterialFITIWINo ratings yet

- Guide To Plastic Recycling SymbolsDocument4 pagesGuide To Plastic Recycling Symbolssib62802No ratings yet

- Wepik Exploring The Versatility and Sustainability of Pet Plastic 20230915115616M3cfDocument8 pagesWepik Exploring The Versatility and Sustainability of Pet Plastic 20230915115616M3cfTronextyNo ratings yet

- Importance of Crude Oil Beyond EnergyDocument7 pagesImportance of Crude Oil Beyond EnergySamuel AcquahNo ratings yet

- Business Plan WorkDocument21 pagesBusiness Plan WorkumarNo ratings yet

- PET Fines From Recycled Bottles - A Valuable Raw MaterialDocument6 pagesPET Fines From Recycled Bottles - A Valuable Raw MaterialTomGaliciaNo ratings yet

- Types of PlasticsDocument13 pagesTypes of PlasticssasisNo ratings yet

- Plastic FilmsDocument30 pagesPlastic FilmsAbhineet ShrivastavaNo ratings yet

- Bottle Manufacturing UnitsDocument17 pagesBottle Manufacturing UnitsVIJAY PAREEKNo ratings yet

- Development of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberDocument8 pagesDevelopment of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Melting Point of HDPEDocument5 pagesThe Melting Point of HDPEPrabu NatarajanNo ratings yet

- Production of RubberDocument25 pagesProduction of RubberCarmel100% (2)

- Petrochemical Engineer DifnitionDocument7 pagesPetrochemical Engineer DifnitionYasser HashimNo ratings yet

- OGA - Chemical Series - Plastic Recycling Market Outlook 2019-2025Document23 pagesOGA - Chemical Series - Plastic Recycling Market Outlook 2019-2025ambarish ramNo ratings yet

- Plastic Recycling Business PlanDocument13 pagesPlastic Recycling Business PlanKennedy Njagi100% (1)

- BackgroundDocument9 pagesBackgroundJocelyn BasioNo ratings yet

- Corn Starch Blend Biodegradable PlasticDocument5 pagesCorn Starch Blend Biodegradable PlasticmitvkkNo ratings yet

- Plastics Recycler - Business Plan: Group 6Document27 pagesPlastics Recycler - Business Plan: Group 6Edgar DeanNo ratings yet

- Kebutuhan DMT AsiaDocument2 pagesKebutuhan DMT Asiafebry16pwjNo ratings yet

- DELTA Plastics Recycling: Industry Description and OutlookDocument19 pagesDELTA Plastics Recycling: Industry Description and OutlookprospereducationNo ratings yet

- Some Polymers Its ApplicationsDocument41 pagesSome Polymers Its ApplicationsManoranjan PandaNo ratings yet

- INJECTION AND BLOW 12 Dani 1Document12 pagesINJECTION AND BLOW 12 Dani 1abdulber kedirNo ratings yet

- 1.) Polyethylene Terephthalate (PET or PETE or Polyester)Document6 pages1.) Polyethylene Terephthalate (PET or PETE or Polyester)erioNo ratings yet

- ERP For Rubber and Plastic Manufacturing - Software Selection GuideDocument9 pagesERP For Rubber and Plastic Manufacturing - Software Selection Guidee2b teknologies100% (1)

- B.Fiber: Characteristics of Polyester FibersDocument2 pagesB.Fiber: Characteristics of Polyester FibersraphaelNo ratings yet

- Business Plan: Unique PlasticsDocument32 pagesBusiness Plan: Unique Plasticslaxman19100% (1)

- PlasticsDocument69 pagesPlasticsMyrna TabernillaNo ratings yet

- Business Plan RecycleDocument13 pagesBusiness Plan RecycleSanjay Wahal100% (1)

- Lecture 2production of PolyolefinsDocument12 pagesLecture 2production of Polyolefinsrk_gummaluri5334No ratings yet

- Environmental Footprints of Recycled PolyesterFrom EverandEnvironmental Footprints of Recycled PolyesterNo ratings yet

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- 2018 Monthly Us Holidays CalendarDocument11 pages2018 Monthly Us Holidays CalendarKelvin NguyễnNo ratings yet

- Vietnam National University Ho Chi Minh City University of Technology Chemical Engineering Faculty Process and Equiment DepartmentDocument15 pagesVietnam National University Ho Chi Minh City University of Technology Chemical Engineering Faculty Process and Equiment DepartmentKelvin NguyễnNo ratings yet

- Cover For ReportDocument1 pageCover For ReportKelvin NguyễnNo ratings yet

- Process and Equipment DepartmentDocument29 pagesProcess and Equipment DepartmentKelvin NguyễnNo ratings yet

Linh

Linh

Uploaded by

Kelvin NguyễnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Linh

Linh

Uploaded by

Kelvin NguyễnCopyright:

Available Formats

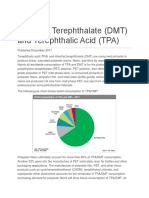

Applications of PET

PET resin (excluding textile grade PET resin) is predominantly used for making bottles. An

estimated 96-97% of PET resin goes into making bottles for various applications. There rest is

used for manufacturing sheets, straps, masterbatch, monofilament/injection molding.

PET bottles

Even in bottling applications, there are various sub-categories based on the end use. The table

below gives a break up of end uses (of PET bottles). Also given are estimated time it takes for a

PET bottle (after it is filled with liquids) to reach the waste stream—one could term this

‘Factory-to-Dustbin’ time or the time it takes for a typical PET bottle for a given application to

reach its consumer and for the consumer to discard the bottle into the waste stream.

Other applications of PET

Straps: PET straps are used in packaging, baling, and for various applications in industry. A

small percentage of PET produced goes into making these straps. PET straps are a convenient

alternative to metal wires and other such packaging aids.

Sheets: PET sheets are widely used in packaging a range of products such as consumer products,

pharmaceuticals, food & beverages, engineering items. If you have bought strawberries in

season, you must be familiar with the transparent packaging it come in—it is made of PET

sheets.

Masterbatch: A small percentage of PET is used in making masterbatches—where a high

concentration of pigments and other additives are incorporated into the PET resin, and typically

used to impart color into the raw polymer during the production/processing.

Monofilament: PET monofilament is mainly used for making mesh fabrics for screen-printing,

filter for oil and sand filtration, bracing wires for agricultural applications (greenhouses etc.),

woven/knitting belt, filter cloth, and other such industrial applications.

You might also like

- Business Plan On Plastic RecycleDocument25 pagesBusiness Plan On Plastic RecycleShailendra Joshi83% (6)

- Plastic Recycling SurveyDocument43 pagesPlastic Recycling SurveyMahmoud KamelNo ratings yet

- Business Plan On Plastic Recycling ManufacturingDocument13 pagesBusiness Plan On Plastic Recycling ManufacturingAmman Abedin100% (2)

- Due Care Petpreform-RILDocument40 pagesDue Care Petpreform-RILSyauqi AkmalaNo ratings yet

- Soy Based PlasticsDocument4 pagesSoy Based PlasticsA MahmoodNo ratings yet

- PET Bottle RecyclingDocument5 pagesPET Bottle Recyclingian jheferNo ratings yet

- Pet Bottles Flakes - RoughDocument19 pagesPet Bottles Flakes - RoughSivaraman P. S.100% (1)

- Polyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Document11 pagesPolyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Muhammad TanweerNo ratings yet

- Plastic Recycling AgainDocument5 pagesPlastic Recycling AgainzidaaanNo ratings yet

- Dimethyl TerephthalateDocument9 pagesDimethyl Terephthalatehung_metalNo ratings yet

- Choose The Right RollerDocument7 pagesChoose The Right Rollerkartik spectomsNo ratings yet

- Ethylene Polyethylene Polyethylene Terephthalate Polyvinyl Chloride PolystyreneDocument1 pageEthylene Polyethylene Polyethylene Terephthalate Polyvinyl Chloride PolystyreneRashail AshasNo ratings yet

- PolyesterDocument7 pagesPolyesterkgaviolaNo ratings yet

- Masterbatch - WikipediaDocument15 pagesMasterbatch - WikipediaSudhir PatilNo ratings yet

- Material FilamentDocument11 pagesMaterial Filamentalidina538No ratings yet

- Polyester Recycling Forum2006Document100 pagesPolyester Recycling Forum2006Atika Anan ToryNo ratings yet

- Worldwide Consumption of Thermoplastic Polyurethane ElastomersDocument5 pagesWorldwide Consumption of Thermoplastic Polyurethane ElastomersHerat TrivediNo ratings yet

- Project Profile Name of The ProductDocument11 pagesProject Profile Name of The ProductA.Allwin rajNo ratings yet

- Dow Hdpe ResinDocument7 pagesDow Hdpe ResinBudyawan SaputraNo ratings yet

- Fuel From Plastic WasteDocument56 pagesFuel From Plastic Wastesumit potdarNo ratings yet

- Plastic RecyclingDocument7 pagesPlastic RecyclingGeroldo 'Rollie' L. Querijero0% (1)

- Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesWaste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003No ratings yet

- Overview of PET ProcessingDocument5 pagesOverview of PET ProcessingSwagat R Pyakurel50% (2)

- Production of PET Film and Sheets, Urethane Foams, Flexible Foams, Rigid Foams, Speciality Plastics. - 350919Document65 pagesProduction of PET Film and Sheets, Urethane Foams, Flexible Foams, Rigid Foams, Speciality Plastics. - 350919Beng-Tiek YapNo ratings yet

- Presentation On Recycling of PlasticDocument22 pagesPresentation On Recycling of PlasticTushar YadavNo ratings yet

- PET Foam White PaperDocument7 pagesPET Foam White PaperWilhelmina MurrayNo ratings yet

- Commen MaterialDocument2 pagesCommen MaterialFITIWINo ratings yet

- Guide To Plastic Recycling SymbolsDocument4 pagesGuide To Plastic Recycling Symbolssib62802No ratings yet

- Wepik Exploring The Versatility and Sustainability of Pet Plastic 20230915115616M3cfDocument8 pagesWepik Exploring The Versatility and Sustainability of Pet Plastic 20230915115616M3cfTronextyNo ratings yet

- Importance of Crude Oil Beyond EnergyDocument7 pagesImportance of Crude Oil Beyond EnergySamuel AcquahNo ratings yet

- Business Plan WorkDocument21 pagesBusiness Plan WorkumarNo ratings yet

- PET Fines From Recycled Bottles - A Valuable Raw MaterialDocument6 pagesPET Fines From Recycled Bottles - A Valuable Raw MaterialTomGaliciaNo ratings yet

- Types of PlasticsDocument13 pagesTypes of PlasticssasisNo ratings yet

- Plastic FilmsDocument30 pagesPlastic FilmsAbhineet ShrivastavaNo ratings yet

- Bottle Manufacturing UnitsDocument17 pagesBottle Manufacturing UnitsVIJAY PAREEKNo ratings yet

- Development of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberDocument8 pagesDevelopment of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Melting Point of HDPEDocument5 pagesThe Melting Point of HDPEPrabu NatarajanNo ratings yet

- Production of RubberDocument25 pagesProduction of RubberCarmel100% (2)

- Petrochemical Engineer DifnitionDocument7 pagesPetrochemical Engineer DifnitionYasser HashimNo ratings yet

- OGA - Chemical Series - Plastic Recycling Market Outlook 2019-2025Document23 pagesOGA - Chemical Series - Plastic Recycling Market Outlook 2019-2025ambarish ramNo ratings yet

- Plastic Recycling Business PlanDocument13 pagesPlastic Recycling Business PlanKennedy Njagi100% (1)

- BackgroundDocument9 pagesBackgroundJocelyn BasioNo ratings yet

- Corn Starch Blend Biodegradable PlasticDocument5 pagesCorn Starch Blend Biodegradable PlasticmitvkkNo ratings yet

- Plastics Recycler - Business Plan: Group 6Document27 pagesPlastics Recycler - Business Plan: Group 6Edgar DeanNo ratings yet

- Kebutuhan DMT AsiaDocument2 pagesKebutuhan DMT Asiafebry16pwjNo ratings yet

- DELTA Plastics Recycling: Industry Description and OutlookDocument19 pagesDELTA Plastics Recycling: Industry Description and OutlookprospereducationNo ratings yet

- Some Polymers Its ApplicationsDocument41 pagesSome Polymers Its ApplicationsManoranjan PandaNo ratings yet

- INJECTION AND BLOW 12 Dani 1Document12 pagesINJECTION AND BLOW 12 Dani 1abdulber kedirNo ratings yet

- 1.) Polyethylene Terephthalate (PET or PETE or Polyester)Document6 pages1.) Polyethylene Terephthalate (PET or PETE or Polyester)erioNo ratings yet

- ERP For Rubber and Plastic Manufacturing - Software Selection GuideDocument9 pagesERP For Rubber and Plastic Manufacturing - Software Selection Guidee2b teknologies100% (1)

- B.Fiber: Characteristics of Polyester FibersDocument2 pagesB.Fiber: Characteristics of Polyester FibersraphaelNo ratings yet

- Business Plan: Unique PlasticsDocument32 pagesBusiness Plan: Unique Plasticslaxman19100% (1)

- PlasticsDocument69 pagesPlasticsMyrna TabernillaNo ratings yet

- Business Plan RecycleDocument13 pagesBusiness Plan RecycleSanjay Wahal100% (1)

- Lecture 2production of PolyolefinsDocument12 pagesLecture 2production of Polyolefinsrk_gummaluri5334No ratings yet

- Environmental Footprints of Recycled PolyesterFrom EverandEnvironmental Footprints of Recycled PolyesterNo ratings yet

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- 2018 Monthly Us Holidays CalendarDocument11 pages2018 Monthly Us Holidays CalendarKelvin NguyễnNo ratings yet

- Vietnam National University Ho Chi Minh City University of Technology Chemical Engineering Faculty Process and Equiment DepartmentDocument15 pagesVietnam National University Ho Chi Minh City University of Technology Chemical Engineering Faculty Process and Equiment DepartmentKelvin NguyễnNo ratings yet

- Cover For ReportDocument1 pageCover For ReportKelvin NguyễnNo ratings yet

- Process and Equipment DepartmentDocument29 pagesProcess and Equipment DepartmentKelvin NguyễnNo ratings yet