Professional Documents

Culture Documents

Floor Decking

Floor Decking

Uploaded by

xbitmanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Floor Decking

Floor Decking

Uploaded by

xbitmanCopyright:

Available Formats

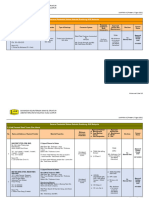

FLOOR DECKING

Our floor decking boasts of an interlocking feature, which makes it an efficient and cost effective

option in multi-storey buildings whenever a high strength concrete floor is required.

The decking is normally fastened to the supporting beam by arc spot welding or by shooting steel

pins with washers.

Standard concrete is poured into the decking with wire mesh and reinforcing bars used as optional

requirements to minimise surface cracking due to shrinkage. After the concrete attains the proper

strength, the full live load is shared by the steel and concrete in a highly efficient manner.

Compared to other floor decking systems, CSM’s system saves on time and eliminates the need for

sealing of the floor’s underside.

CSM’s decking is zinc coated, which affords a high level of corrosion resistance and conforms to

ASTM specifications.

PROFILES

ROOFING

BSI

ACCREDITED

ANSI RAB

QMS

ED

RE

GI

CARIBBEAN STEEL MILLS LTD. STER

Race Course Road, Arima, Trinidad, West Indies FM 37040

1SO 9001

Tel:(868) 642-0672/0872/2340/0771/7833/646-0889 Fax: (868) 642-5333 Sales: (868) 642-1780 email:csmsteel@tstt.net.tt

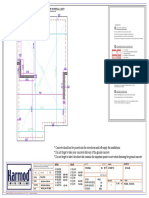

FLOOR DECKING FLOOR DECKING

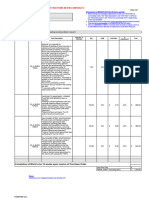

PROPERTIES

Nominal thickness of Nominal Nominal mass per unit Largest span without

material width length support

mm mm (inch) kg/m

0.96 625 24.6 6.47 See load table below

NOTES: 1. The standard length of all decking is 6.096m (20 feet) nominal. Tolerance : + 10mm, -5mm

2. The thickness of the material is the total of the steel and the zinc coating.

3. Special cuts can be provided.

4.8 1.8 4.8

7.8

4.8 1.8 4.8

LOAD TABLE (Kg/m2) calculated according to BS 5950: Part 4:1994 and Part 6:1995 for uniform

loading of single span; concrete cube strength 20 Mpa; concrete density 2400 kg/m3 (wet), 2.3

4.8 1.8 4.8

2350 kg/m3 (dry) 1.6 5.4 18.7 12.6 18.7 5.4

Span Thickness of concrete above metal ribs

m 50.8 mm (2") 63.5 mm (2.5") 76.2 mm (3") 88.9 mm (3.5")

Industrial Floor Decking

1.8 1321 (2677)* 1549 (3200) 1776 (3724) 2004 (4247)

2.0 1022 (2113) 1203 (2532) 1383 (2951) 1564 (3369)

2.2 802 (1697) 948 (2039) 1094 (2380) 1239 (2722)

2.4 636 (1382) 755 (1665) 874 (1948) 993 (2231)

2.6 507 (1138) 605 (1375) 703 (1612) 802 (1850)

2.8 405 (945) 487 (1146) 568 (1347) 650 (1548)

3.0 323 (790) 392 (962) 460 (1134) 528 (1305)

3.2 248 (656) 306 (803) 363 (951) 420 (1099)

Key

italics: excess sag when wet

*no parentheses: without shear studs parentheses: with full shear connection

Note ; values below line results in excess sag when wet

RAW MATERIAL : Hot-Dipped Zinc- Coated (Galvanised) Cold Rolled Steel Sheets -

ASTM A 924 M –99 ; ASTM A 653 M - 99

STEEL MECHANICAL PROPERTIES

Min. yield Min. tensile Min. elongation Bend test

strength strength in 50 mm ratio of inside bend diameter to thickness

M Pa M Pa %

255 360 18 2

Zinc coating mass: 275 g/m2 Triple Spot total of both sides

You might also like

- Installation and Operating Instructions Weishaupt Gas Burners Sizes 1 To 11Document46 pagesInstallation and Operating Instructions Weishaupt Gas Burners Sizes 1 To 11abuMalak75% (4)

- Case Study of La Posta Mexican RestaurantsDocument1 pageCase Study of La Posta Mexican RestaurantsFatima Atiq80% (5)

- Fiat Group Automobiles Normazione: Various Metallic Part PaintingDocument26 pagesFiat Group Automobiles Normazione: Various Metallic Part Paintingclaudio5475100% (3)

- Ufc 1 200 01 PDFDocument28 pagesUfc 1 200 01 PDFadangkoswaraNo ratings yet

- Group 1 - Structural Flooring and Floor FinishesDocument36 pagesGroup 1 - Structural Flooring and Floor FinishesIMRAN KHANNo ratings yet

- Pile Foundation DrawingDocument1 pagePile Foundation DrawingkiransimsNo ratings yet

- WJK & WJL SystemDocument1 pageWJK & WJL SystemJOSEPH PARINONo ratings yet

- WJK WJL SystemDocument1 pageWJK WJL SystemJOSEPH PARINONo ratings yet

- Pump Foundation Design PDFDocument18 pagesPump Foundation Design PDFArchana ArchuNo ratings yet

- Oups - Part - 36 S0.2Document1 pageOups - Part - 36 S0.2Muhammad Zeeshan MunirNo ratings yet

- Specification Typical Floor Plan: Now, Step Out of Your Imagination. Step Into Seven 9 SKYDocument1 pageSpecification Typical Floor Plan: Now, Step Out of Your Imagination. Step Into Seven 9 SKYThakor MistryNo ratings yet

- Deckspantm: Only Tested TrueDocument4 pagesDeckspantm: Only Tested True52891No ratings yet

- Online Course ETABS V17Document12 pagesOnline Course ETABS V17Lutfia Nurul AiniNo ratings yet

- Tarmac Pre Stressed BeamsDocument12 pagesTarmac Pre Stressed BeamsJesus LertNo ratings yet

- WATER KIOSK LAYOUT 2Document1 pageWATER KIOSK LAYOUT 2satejaNo ratings yet

- GN 01Document9 pagesGN 01Sohag114No ratings yet

- Sheet 7. Elevations 1&2Document1 pageSheet 7. Elevations 1&2caleb nyamoraNo ratings yet

- 2c Tender 4 Churches Chitar - DesignDocument16 pages2c Tender 4 Churches Chitar - DesignJoão LopesNo ratings yet

- Public Works Roads Department: Govt. of AssamDocument4 pagesPublic Works Roads Department: Govt. of AssamAnonymous fLgaidVBhzNo ratings yet

- To Rectify Spalling Concrete at Block 4 Level 6Document2 pagesTo Rectify Spalling Concrete at Block 4 Level 6atienzajury24No ratings yet

- 1.1 IEM Structural Engineering Design Course BS 8110, BS8007 CF EC2 Changes in RC CodesDocument18 pages1.1 IEM Structural Engineering Design Course BS 8110, BS8007 CF EC2 Changes in RC Codeswilliam6703No ratings yet

- BS S 524 (1969)Document8 pagesBS S 524 (1969)mrzap5007No ratings yet

- MB 3Document1 pageMB 3MAXWELL ERIPONNo ratings yet

- MB 2Document1 pageMB 2MAXWELL ERIPONNo ratings yet

- Standar Box Girder AashtoDocument21 pagesStandar Box Girder AashtoAbdul RahmanNo ratings yet

- Autodesk Revit Best Practices #2:: Shawn Zirbes, Cad Technology Center (CTC), Minneapolis, MNDocument24 pagesAutodesk Revit Best Practices #2:: Shawn Zirbes, Cad Technology Center (CTC), Minneapolis, MNtishebraNo ratings yet

- 1-Genset Floor PlanDocument1 page1-Genset Floor PlandnoorzyafiqiNo ratings yet

- 1ST FLOOR Altar-Layout1Document1 page1ST FLOOR Altar-Layout1Sean ChanNo ratings yet

- Cantilever Beam DrawingDocument1 pageCantilever Beam DrawingROHIT PANDEYNo ratings yet

- 6 Phase 1: Front ViewDocument1 page6 Phase 1: Front ViewMAXWELL ERIPONNo ratings yet

- Delaware Training Academy: Precast Box Culvert Installation ProceduresDocument13 pagesDelaware Training Academy: Precast Box Culvert Installation ProceduresPriyadarshi GautamNo ratings yet

- GATE CANOPY SectionDocument1 pageGATE CANOPY SectionMwesigwa DaniNo ratings yet

- 52 - ApprovedTrussSystem List Ogos 2022Document18 pages52 - ApprovedTrussSystem List Ogos 2022siti nabilahNo ratings yet

- Dextra TieTec Precast Tie Brochure 2022 enDocument4 pagesDextra TieTec Precast Tie Brochure 2022 enSanjoy SanyalNo ratings yet

- Brosur Produk PT Beton Prima Indonesia 04Document3 pagesBrosur Produk PT Beton Prima Indonesia 04Kartika SaktiNo ratings yet

- Balcasmart Aluminium Igno 10Document7 pagesBalcasmart Aluminium Igno 10stephane.kNo ratings yet

- Material Compliance-New DesignDocument6 pagesMaterial Compliance-New DesignvtalexNo ratings yet

- North West View 1 North East View 2: ClientDocument1 pageNorth West View 1 North East View 2: ClientCSEC Uganda Ltd.No ratings yet

- 01 StructuralDocument39 pages01 StructuralSaifullahNo ratings yet

- Smartdek 51Document12 pagesSmartdek 51Fairly InsurgentNo ratings yet

- Al-Arifi Villas: Structural Drawings List (VILLA 1 & 2)Document26 pagesAl-Arifi Villas: Structural Drawings List (VILLA 1 & 2)LeMasters ArabiaNo ratings yet

- 73mp PlanDocument1 page73mp PlanGârjelea AdrianNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- Armowel 1Document2 pagesArmowel 1Mahesh DeshmukhNo ratings yet

- 5 Metfloor Installation GuideDocument9 pages5 Metfloor Installation GuideTùng Hì100% (1)

- BG-DWG-2017-0171-R0 AL TATWEER CONTRACTING 30-OCT-2017-Layout1Document1 pageBG-DWG-2017-0171-R0 AL TATWEER CONTRACTING 30-OCT-2017-Layout1DanielNo ratings yet

- AASHTO Standard Details - Folded Steel Plate Girder System - 2014Document20 pagesAASHTO Standard Details - Folded Steel Plate Girder System - 2014houstonhimselfNo ratings yet

- KSN Anchors Nov 2013 v2 NZ 1113Document24 pagesKSN Anchors Nov 2013 v2 NZ 1113200365530No ratings yet

- LYT0003 - 2022-05-27 - L1P0W0 - User Guide - BONDEKDocument12 pagesLYT0003 - 2022-05-27 - L1P0W0 - User Guide - BONDEKMohammed HussainNo ratings yet

- ME463 Plate4 CapulDocument10 pagesME463 Plate4 CapulJuvy Lyka CapulNo ratings yet

- Structural DesignDocument7 pagesStructural DesignMajed NabeelNo ratings yet

- Metalfab PresentationDocument9 pagesMetalfab PresentationAbid KayaniNo ratings yet

- 2 Simply Supported Laterally Restrained Beam: 2.1 ScopeDocument11 pages2 Simply Supported Laterally Restrained Beam: 2.1 ScopePatrik AlfredssonNo ratings yet

- LYT0003 - 2019-11-18 - L1P0W0 - User Guide - BONDEKDocument12 pagesLYT0003 - 2019-11-18 - L1P0W0 - User Guide - BONDEKKAI CHUAN CHUNo ratings yet

- Reinforced Concrete Pitched Roof Apex Slab Reinforcement DetailDocument5 pagesReinforced Concrete Pitched Roof Apex Slab Reinforcement DetailDauji SahaNo ratings yet

- Sealbond 218 P Pressure Injection EpoxyDocument2 pagesSealbond 218 P Pressure Injection Epoxypauwee.arroNo ratings yet

- Final Boq - Ali HussainDocument3 pagesFinal Boq - Ali Hussainesramergani2No ratings yet

- 1613.8 ASCE 7-10, Table 12.2-1 SesmicDocument4 pages1613.8 ASCE 7-10, Table 12.2-1 Sesmiclaila. areebNo ratings yet

- Sesse: Multistory Buildings Concrete Joist ofDocument1 pageSesse: Multistory Buildings Concrete Joist ofjosNo ratings yet

- From ASCE - Recommendations For Seismic Design of Hybrid Coupled Wall SystemsDocument3 pagesFrom ASCE - Recommendations For Seismic Design of Hybrid Coupled Wall SystemsNemanja RandelovicNo ratings yet

- Safe Fast Efficient: SteelDocument2 pagesSafe Fast Efficient: SteelJesus Villaflor Jr.No ratings yet

- 3 KSN AnchorsDocument24 pages3 KSN AnchorsAhmedMahmoudNo ratings yet

- G1 Draft Road Construction EMP R61Document31 pagesG1 Draft Road Construction EMP R61xbitmanNo ratings yet

- Quick R Wall 20 Users GuideDocument51 pagesQuick R Wall 20 Users GuidexbitmanNo ratings yet

- Anil Bridgelal 2008 2011 CANADADocument4 pagesAnil Bridgelal 2008 2011 CANADAxbitmanNo ratings yet

- Soil Sub-Grade ModulusDocument2 pagesSoil Sub-Grade ModulusxbitmanNo ratings yet

- Summary 6ugfg4xf 54jdkatjDocument16 pagesSummary 6ugfg4xf 54jdkatjsaritabasnet916No ratings yet

- Improving Confidence in Cement Evaluation: Pablo EstradaDocument17 pagesImproving Confidence in Cement Evaluation: Pablo EstradaHassaanAhmed100% (1)

- Fructin PDFDocument1 pageFructin PDFSaifur Rahman SuzonNo ratings yet

- Automation of Nestle ProductsDocument41 pagesAutomation of Nestle ProductsRamesh KumarNo ratings yet

- Suraj Estate Developers Limited RHPDocument532 pagesSuraj Estate Developers Limited RHPJerry SinghNo ratings yet

- Score:: 1 Out of 1.00 PointDocument12 pagesScore:: 1 Out of 1.00 PointDiscord YtNo ratings yet

- Case Study Emirates AirlinesDocument4 pagesCase Study Emirates Airlinesuzzmapk33% (9)

- Contribution of Medieval MuslimDocument16 pagesContribution of Medieval Muslimannur osmanNo ratings yet

- Pre Project ActivitiesDocument20 pagesPre Project ActivitiesAlexcorbinNo ratings yet

- Standard CVDocument3 pagesStandard CVSurzo Chandra DasNo ratings yet

- Comparative Study of Soil Structure Interaction Analysis of Building On Clayey and Sandy Soil-IJRASETDocument11 pagesComparative Study of Soil Structure Interaction Analysis of Building On Clayey and Sandy Soil-IJRASETIJRASETPublicationsNo ratings yet

- NMKV - WikipediaDocument17 pagesNMKV - WikipediaNUTHI SIVA SANTHANNo ratings yet

- Haunted: MuseumDocument36 pagesHaunted: MuseumNgoc PhanNo ratings yet

- Sample Pages: Pearson AustraliaDocument5 pagesSample Pages: Pearson AustraliaMin ZekNo ratings yet

- WH2009 WaterHorseCatalogDocument132 pagesWH2009 WaterHorseCatalogAiko FeroNo ratings yet

- Diy Direct Drive WheelDocument10 pagesDiy Direct Drive WheelBrad PortelliNo ratings yet

- Sucker Rod Elevators (25-Ton)Document1 pageSucker Rod Elevators (25-Ton)CESAR SEGURANo ratings yet

- 0RBIAR0B4E1ADocument321 pages0RBIAR0B4E1AAnkur VermaNo ratings yet

- Railway Recruitment Board SiliguriDocument9 pagesRailway Recruitment Board SiliguripranavsircarNo ratings yet

- PoonamDocument54 pagesPoonamCH Rajan GujjarNo ratings yet

- Building A Trading PlanDocument38 pagesBuilding A Trading Planamy100% (1)

- Marcopolo Is A Leading Brazilian Bus Body ManufacturerDocument4 pagesMarcopolo Is A Leading Brazilian Bus Body ManufacturerCH NAIRNo ratings yet

- शरीर में सन्निहित शक्ति-केंद्र या चक्र Inner Powers Center or Chakra in BodyDocument33 pagesशरीर में सन्निहित शक्ति-केंद्र या चक्र Inner Powers Center or Chakra in BodygujjuNo ratings yet

- W6400 PC PDFDocument34 pagesW6400 PC PDFHùng TàiNo ratings yet

- The Psychological Aspects of Cinematography and Its ImpactDocument21 pagesThe Psychological Aspects of Cinematography and Its Impactanastasiapiven7No ratings yet

- Manual FSP150 GE114PRO FAM PDFDocument80 pagesManual FSP150 GE114PRO FAM PDFJanet Sabado CelzoNo ratings yet

- CiabattaDocument4 pagesCiabattaTarak ZayaniNo ratings yet