Professional Documents

Culture Documents

Mould Starndard Parts PDF

Mould Starndard Parts PDF

Uploaded by

lecongtruc87Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mould Starndard Parts PDF

Mould Starndard Parts PDF

Uploaded by

lecongtruc87Copyright:

Available Formats

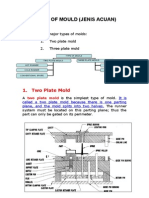

CAE DS –Mould Design

Mould and Die Standard Parts

Tampere University of technology - Tuula Höök

Mould standard parts can be divided into the following groups:

− Standard mould set with guide bars, guide sleeves and other guiding ele-

ments

− Ejector pins and special components for ejection

− Ejector set guiding elements

− Core pins

− Core moving elements

− Cold runner system components

− Hot runner system components

− Tempering device fixtures, insulating elements

− Fastening and closing elements, elements for lifting the mould

There are several mould standard part manufacturers, who have sales offices in

Europe. (See table.)

Table 1. Some of the mould and die standard part manufacturers

Standard mould part Electrode materials Hot runner systems

manufacturers

− Cumsa − Berkenhoff − Flygenring

− D-M-E − Carbone Lorraine − Gunther

− DMS Diemould − Poco − Heatlock

− Drei-S-Werk − SGL Carbon − Mastip

− Fodesco − Mold Masters

− Meusburger − Synventive

− Rabourdin − Thermoplay

− Schumag AG

− Strack Norma-

lien

− Superior Die Set

Quick clamping Core pulling cylinders Surface finishing

systems equipments

− EAS − AHP Merkle − Novapax

− Hilma − CyTec

Mould and Die Standard Parts - 1

CAE DS –Mould Design

Standard mould set with guide bars, guide sleeves and other guid-

ing elements

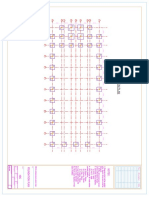

Standard mould set consists of two clamping plates, two cavity plates, an optional Standard mould and

back plate, risers and an ejector set (See image.). Core and cavity side are 3D-CAD die set

terms. Most of the cavity is typically placed into the fixed side and most of the core

into the moving side of the mould. This assures that the part is in the ejection side

cavity after the mould has been opened.

Image 1. Standard mould set basic structure.

Usually the standard mould part sales agents

have suitable sets for injection moulding

moulds except for the very biggest types.

High pressure die casting moulds are nor-

mally manufactured to a set of flame cut steel

plates, not to a pre-fabricated standard

mould set.

Ejector set consists of two plates: an ejector retaining plate and an ejector plate. Ejector set

These are fastened together with four bolts and the ejectors are placed between

them. Usually there are bumper plates between the ejector set and the clamping

plate. (See image.) Risers determine the longest possible ejection distance.

Image 2. Ejector set components.

Moving and fixed mould halves are guided towards each other with different Basic guiding

guiding elements. Basic guiding elements, which usually are a part of the standard elements

mould set, are guiding pillars, guiding sleeves and centering sleeves. If it is neces-

sary to locate the cavity halves with more accuracy, the mould is equipped with

cavity interlocks: straight side interlocks or tapered interlocks. (See images below

and next page.)

Image 3. Basic guiding elements: Guide

pillars, guide sleeves and centering sleeves.

Mould and Die Standard Parts - 2

CAE DS –Mould Design

Interlocks

Image 4. Tapered interlocks for accurate mould cavity halves positioning. These parts are

fastened with screws from back side of the cavity plate.

Image 5. Straight side interlocks. Easy maintenance. These parts can be replaced without

disassembling the mould.

Ejector pins and special components for ejection

Basic parts in the mould ejection system are ejectors and sprue pullers. There are

different types of ejectors. The main types are round ejector pins, flat ejector pins

and ejector sleeves. Sprue pullers are specially shaped or specially placed ejectors,

which stick to the sprue and pull it out from the sprue bushing. (See images.) Ejector pins

Image 6. Above left: Round ejector pins. Above right: Flat ejector pins. Below left: Ejector

sleeves. Below right: Ejected part.

Mould and Die Standard Parts - 3

CAE DS –Mould Design

Ejectors are attached between the ejector set plates with the collar in the end of the Fixed ejector position

ejector. If the mould cavity surface is shaped, it is common to grind a flat surface to

the collar. This flat surface sets the ejector to a fixed position. (See image below.)

Image 7. Ejectors in a fixed position.

Sprue pullers are either special components or specially shaped ejector pins. (See Sprue pullers

images below.)

Image 8. Above left: Two cavity mould with a sprue puller sleeve. Above right: Sprue puller

sleeve structure, a cross section image Part of the runner forms inside the sprue puller

sleeve. Below left: Ejected part with the cold runner system. Below right: Sprue puller sleeve

structure. Many standard part manufactures have this kind of constructions in their prod-

uct range.

Image 9. Another sprue puller type. This type is fabricated to the ejector pin. No other

components needed.

Mould and Die Standard Parts - 4

CAE DS –Mould Design

There are also some special ejector types like tilting ejectors and stripper plates.

Tilting ejectors are suitable for moulding small back draft details like snap fits and

small slots. Stripper plates are very useful in ejecting high cup shaped parts. (See

images.) Tilting ejectors

Image 10. Tilting ejector in a closed and an open position. The ejector bends along

the ejection movement. D-M-E.

Stripper plate

Image 11. Stripper plate. This type of ejection

mechanism is practical if the part is very high. Ejector

plate is not actually a standard part, but still a common

structure.

Ejector set guiding and returning elements

Injection moulding mould ejector set is fixed to the moulding machine with one

element in the centre of the mould. Without guides, the ejector pins are sole ele-

ments, which support these plates along with the fixture. Compared to the ejection

pins strength and stiffness, the ejector set produces a relatively high load. Even the

smallest imbalance will bend and in the worst case break the pins.

High pressure die casting die ejector set is fixed to the casting machine with four

ejection bars. Four bars give rather good support, but it is still possible that the

ejector set bends - for example if the part sticks to the die cavity from one side or

there is some other kind of imbalance in the ejection. Usually the high pressure die

casting machine ejector mechanism works with hydraulic cylinders. It returns the

die ejector set to the back position with a cylinder backward movement.

In some injection moulding machine types the ejector mechanism is returned with

the mechanism backward movement. In some machines the returning movement is

done with a spring in the fixture. High pressure die casting hydraulic cylinders

typically produce also the backward movement. In any of these cases it is recom-

mended to place four ejector set returning pins to mechanically return the ejection

system to the initial position.

The set of returning pins is also the lightest guiding construction. Returning pins

are thick ejector pins, which are placed outside the cavity and extended to the

mould parting surface. If the ejector set returning system does not work properly,

these pins secure the ejector set to the initial position. (See image next page.)

Mould and Die Standard Parts - 5

CAE DS –Mould Design

Returning pin

Image 12. Returning pins and ejector pins in back and front positions.

If it is necessary to guide the ejector set more reliable and accurately, there are Ejector guiding

different guiding elements. Guide pillars and sleeves are available with or without elements

bearings.

Image 13. Ejector set guiding elements.

Cavity supporting elements

Usually the ejection side mould cavity is supported with supporting pillars. The Support pillar

fixed cavity plate has enough support from the moulding and casting machine

base, but the ejection side cavity plate faces an open ejection box construction. The

supporting pillar is placed between the clamping plate and the cavity or back plate

under the cavity.

Image 14. Cavity support pillar.

Mould and Die Standard Parts - 6

CAE DS –Mould Design

Core pins

Core pins are similar to the ejector pins, but the material is different. The core pins

are placed to the mould cavity to shape deep and narrow holes in the part. (See

image.)

Image 15. Left: Core pin. Middle: Core pin in the mould cavity. Right:

The molded part.

Core moving elements

Core moving elements are different hydraulic or pneumatic cylinders, electric

equipment or slide mechanisms, which will move the moving core out of the mould

cavity to enable part ejection.

Slide mechanism is pure mechanical. It moves by the mould opening movement.

Main parts in the slide mechanism are angle pin, slide locking parts, slide guiding

and slide. Moving faces are typically covered with war plates. Some of the standard

part manufacturers sell complete slide sets with all necessary parts in them. Some

sell only angle pins and wear components. There is also a special standard mould

set for constructing sliding core moulds. (See images.)

Slide mechanism

with “self made” and

standard components

Image 16. Slide mechanism. The construction consists of standard parts and self

made components.

Mould and Die Standard Parts - 7

CAE DS –Mould Design

Compact ready made

slide mechanism

Image 17. Compact ready made slide mechanism,

CUMSA.

Sliding core mould

set

Image 18. Sliding core mould set. The slides move with a sideward movement while

mould opens.

If the moving core is relatively long, it is more practical to use core pulling cylin- Core pulling

ders. The slide opening movement is restricted by the angle pin length. In average cylinders

size moulds and dies, the typical core movement is less than 50 mm. Core pulling

cylinder stroke varies between 100 – 250 mm, even 300 mm if required.

Image 19. One core pulling cylinder type. Basically it is possible to use any bidirec-

tional guided hydraulic or pneumatic cylinders. The injection moulding or high pressure die

casting machine forces the cylinder opening and closing movements. Depending on the

machine control unit, it is possible to force single or multiple opening or closing instruc-

tions. It is common to use end position sensors to secure the mould opening.

Mould and Die Standard Parts - 8

CAE DS –Mould Design

Runner system components for injection moulding moulds

The purpose of the injection moulding mould runner system is to provide the Cold runner

melted plastic a route from the injection moulding machine nozzle to the mould

cavities. There are basically three runner types: cold runner, hot runner and com-

bined system. The plastic solidifies inside the cold runner system. For that reason

the cold runner system is removed from the mould cavity with the moulded part.

Hot runner system keeps the plastic in liquid form and only the part is ejected.

Cold runner system consists of a central gate (sprue bushing), runners, gates and Sprue bushings and

ingates. Runners, gates and ingates are mainly machined channels in the mould the centering ring

plates. The most common standard cold runner system parts are sprue bushings

and rings for centering the injection moulding machine nozzle to the sprue head.

Some standard part manufacturers produce also special tunnel gate components for

injecting the cavity below.

Image 20. Sprue bushings and a centering ring.

These bushings are flat on the top. Sprue bushings are available with different hemisphere

shapes on the top. The hemisphere radius is selected to fit the machine nozzle radius.

Image 21. The sprue bushing and the centering

ring assembled to a standard mould set.

Tunnel gate

Image 22. Component for tunnel gate struc-

ture. Left: Part outside. Right: Cross section image.

Fodesco.

Mould and Die Standard Parts - 9

CAE DS –Mould Design

Hot runner system consists of a sprue bushing, manifold, nozzles and gate bush- Hot runner

ings. There are basically three hot runner system types: externally heated system,

internally heated system and combined system. In the image below there are some

typical components of an externally heated system.

A manifold and a

heated nozzle

Image 23. Left: A heated manifold for an externally heated hot runner system. There

are manifolds in different shapes and sizes. Right: A heated nozzle to be attached to the

manifold. Manifold is similar to the runner system in an injection moulding mould cold

runner system.

A heated sprue

bushing and a gate

bushing

Image 24. Left: A heated sprue bushing

for the externally heated hot runner system.

Right: Gate bushing.

Image 25. Hot runner system assembly.

This structure is placed to the fixed mould half

inside and behind the cavity plate. Mould with

hot runners is reasonably high and complicated

compared to the cold runner mould.

Internally heated system is constructed with the similar components. The difference

is in heating the channels. Internally heated system has internally heated channels.

Externally heated system has externally heated channels.

Mould and Die Standard Parts - 10

CAE DS –Mould Design

Tempering channel fixtures and other components

Injection moulding mould tempering is typically done with straight and/or confor-

mal cooling channels. The cooling liquid is water. High pressure die casting die

tempering liquid is some heat transfer oil. The channels are similar, but due to a

higher strength demands, simpler.

Mould and die standard part manufac- Fixing components

turers have different small equipments

for building the tempering channels.

These equipments include fittings for

connecting the tempering machine to the

channels with pipes and also for con-

necting channels with each other. It is

common to extend the tempering chan-

nels externally with pipes.

Image 26. Fittings for connecting tempering devices and tempering / cool-

ing channels.

There are also equipments to cascade the tempering liquid with the aim to Cascading flow

strengthen the cooling effect. These equipments include cascading liquid junctions, components

cooling baffles and cooling cores. Typically these equipments are placed inside high

and relatively narrow cores.

Image 27. From left: A cooling core, a straight

baffle and a spiral baffle.

Image 28. Left: A spiral

baffle inside a high core. Right: A

cooling core inside a high core.

Mould and Die Standard Parts - 11

CAE DS –Mould Design

Fastening and closing elements, elements for lifting the mould

Injection moulding moulds and die casting dies are fastened to the machine platens Clamps

with similar components. The two most common components are clamps and

screws or only screws. High pressure die casting machine platens are typically

equipped with T-slots. Injection moulding machine platens with threaded holes.

The clamps and fastening screws are quite similar (See images).

Image 29. Left: Clamp for a high

pressure die casting die. Right: Plain

screw and bolts fastening set. The high

pressure die casting machine platens are

equipped with T-slots and the fastening

equipments with T-bolts.

Image 30. Left: Clamp for an

injection moulding mould. Right: Fasten-

ing screw for an injection moulding

mould.

Some manufacturers have also different quick-clamping systems. These systems Quick clamping

include magnetic and hydraulic clamping systems and different mechanical sys-

tems.

Eyebolt for lifting

Moulds and dies are quite often lifted to the machine with a

crane. To make short work of the lifting, the mould and dies

are equipped with at least two pairs of eyebolts. If it is neces-

sary to lift the mould or die halves separately, it is important

to place two eyebolt pairs to the moving half and one pair to

the fixed half. Otherwise the heavy moving half will not be

balanced.

Image 31. An eyebolt

for lifting the mould.

Mould and Die Standard Parts - 12

CAE DS –Mould Design

Injection moulding machines typically have several different ways of clamping the Ejector clamps

mould ejection plates to the machine ejection system. There is only one point of

attachment, but the equipments for attaching are numerous. The simplest clamping

system is one ejector rod. But there are also different couplings for pneumatic or

mechanical quick-clamping devices. (See images.) The point of attachment is in the

middle of the mould ejector plates.

Image 32. Ejector rod.

Image 33. Couplings for different ejector clamping systems.

High pressure die casting machines use different system. The machine ejection

system is hydraulic. There are four ejector bars, which are attached to the machine

ejection cylinders through holes in the machine moving platen.

Mould and Die Standard Parts - 13

You might also like

- Injection Molding: Part Cost EstimatorDocument3 pagesInjection Molding: Part Cost Estimatorpchakkrapani100% (1)

- QR-06-54 Injection Molding Process SheetDocument2 pagesQR-06-54 Injection Molding Process Sheetmuhamad yasserNo ratings yet

- 2 Manual Service Kymco MXU 50 Reverse Kymco MXU 50 Kymco Mxer 50 Part2Document123 pages2 Manual Service Kymco MXU 50 Reverse Kymco MXU 50 Kymco Mxer 50 Part2Justin Lowe100% (1)

- A100 - FOUNDATION PLAN Layout1Document1 pageA100 - FOUNDATION PLAN Layout1avdesh7777No ratings yet

- RHINO GRASSHOPPER. WWW - Woojsung.com TUTORIAL Woo Jae SungDocument12 pagesRHINO GRASSHOPPER. WWW - Woojsung.com TUTORIAL Woo Jae Sungapi-2601040950% (4)

- Hot Runner System: Training ManualDocument21 pagesHot Runner System: Training ManualHồng HoàngNo ratings yet

- Theory of Moulds - ContentsDocument9 pagesTheory of Moulds - Contentsnagesh_sprao19275% (4)

- Mould HPDC Runner PDFDocument18 pagesMould HPDC Runner PDFMohd Nazri SalimNo ratings yet

- Website & SEO Proposal To SampleDocument8 pagesWebsite & SEO Proposal To Samplemanoj digiNo ratings yet

- Final Op Amp Lab ReportDocument7 pagesFinal Op Amp Lab Reportmehrin12367% (3)

- 02injection Moulding MachineDocument31 pages02injection Moulding MachineS Karthick KeyanNo ratings yet

- CTM Mold Design Standards PDFDocument43 pagesCTM Mold Design Standards PDFDini ViruNo ratings yet

- Plastic Injection Molding Write UpDocument16 pagesPlastic Injection Molding Write UpVishal MahajanNo ratings yet

- Minsa Trial Report Molde SC194Document2 pagesMinsa Trial Report Molde SC194daniel ortiz fuentesNo ratings yet

- Mold Cost EstimationDocument5 pagesMold Cost EstimationPenjahit TedyNo ratings yet

- Basic Gating and Runner DesignDocument66 pagesBasic Gating and Runner DesignRockfort HarshaNo ratings yet

- Inj Mold CalculateDocument9 pagesInj Mold CalculateGiap NguyenNo ratings yet

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramNo ratings yet

- Tool Design - Chapter 3 (Part 3)Document48 pagesTool Design - Chapter 3 (Part 3)Fiq IFTNo ratings yet

- Mold Bases & Plates Catalog 2020 DECDocument292 pagesMold Bases & Plates Catalog 2020 DECShinichi SuzukiNo ratings yet

- Mould Maintenance A KumarDocument40 pagesMould Maintenance A KumarprashanthNo ratings yet

- HASCO-General Mould Components IndexDocument7 pagesHASCO-General Mould Components IndexНикола МедићNo ratings yet

- Sptech Tooling GuideDocument25 pagesSptech Tooling GuideKa Wing LeeNo ratings yet

- The Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SDocument6 pagesThe Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SSanjay KumarNo ratings yet

- Mold Design Fundamental Calculation BATTERY COVERDocument7 pagesMold Design Fundamental Calculation BATTERY COVERrgrao85No ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Mould Manufacturing Technology: Checklist For Mould AssemblyDocument8 pagesMould Manufacturing Technology: Checklist For Mould AssemblyThe Pure ConsciousnessNo ratings yet

- KSS713 - Die Casting Tool Standard - Rev.03Document17 pagesKSS713 - Die Casting Tool Standard - Rev.03Adrian Doru100% (2)

- Design of Family Mould Tool For Plastic BoxDocument4 pagesDesign of Family Mould Tool For Plastic BoxEditor IJTSRDNo ratings yet

- 塑模保養維修講義 mold maintenance handbook: By PimDocument33 pages塑模保養維修講義 mold maintenance handbook: By PimHồng Hoàng100% (1)

- Injection Mold Design DetailsDocument43 pagesInjection Mold Design DetailsKen100% (1)

- Injection Molding Cost CalculatorDocument111 pagesInjection Molding Cost CalculatorvenkithankamNo ratings yet

- Injection Molding LabDocument2 pagesInjection Molding LabZulhusni Abdul JamanNo ratings yet

- Injection Mold DesignDocument12 pagesInjection Mold DesignbobNo ratings yet

- Tooling Standards Manual: MouldsDocument36 pagesTooling Standards Manual: Mouldsandre boniniNo ratings yet

- Moulding Manual For Dupont M and Z Resins: Inlon YtelDocument43 pagesMoulding Manual For Dupont M and Z Resins: Inlon YtelSumeet ShindeNo ratings yet

- Tool Steel - Material Selection Guide: High Speed SteelsDocument1 pageTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNo ratings yet

- DME Slide Retainer - AllDocument5 pagesDME Slide Retainer - AllAmit RawatNo ratings yet

- Tool Design TerminologyDocument5 pagesTool Design Terminologyanmol6237No ratings yet

- Seminar On Split Cavity MouldDocument43 pagesSeminar On Split Cavity MouldasgrutuNo ratings yet

- Mold Flow Process ParametersDocument28 pagesMold Flow Process ParametersArun PrasadNo ratings yet

- Metals Stamping GlobalDocument40 pagesMetals Stamping GlobalMostafa Abd El AlemNo ratings yet

- Injection Moulding ProcessDocument3 pagesInjection Moulding ProcessSteven ChengNo ratings yet

- Plastic - Die - Engineering - TP IndiaDocument13 pagesPlastic - Die - Engineering - TP IndiaGiyanto NanitNo ratings yet

- Moulding Technology: by Balraj TanwarDocument37 pagesMoulding Technology: by Balraj TanwarVinod KumarNo ratings yet

- Shot Area: Must Be 50% From Injection PressureDocument7 pagesShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNo ratings yet

- Advance Injection Mould DesignDocument175 pagesAdvance Injection Mould DesignŠetkić Semir100% (1)

- 9 Ejection System PDFDocument10 pages9 Ejection System PDFBa BuNo ratings yet

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- PP - Injection Mould Component Cost EstimationDocument7 pagesPP - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Mould BaseDocument58 pagesMould BaseFurqan AlamNo ratings yet

- Design of The Injection MouldDocument19 pagesDesign of The Injection MouldSiddhant Prakash GoyalNo ratings yet

- Injctmld F03Document2 pagesInjctmld F03prasad_kcpNo ratings yet

- Mold Building Standards: Revised DateDocument13 pagesMold Building Standards: Revised Datelam nguyenNo ratings yet

- Marplex - Injection Moulding of ThermoplasticsDocument24 pagesMarplex - Injection Moulding of ThermoplasticsStarchyLittleOleMeNo ratings yet

- Dme Comp MoldesDocument186 pagesDme Comp MoldesNuno CamarinhoNo ratings yet

- Mold SpecificationDocument1 pageMold SpecificationVictor Villouta LunaNo ratings yet

- Microsoft Word - Molding Notes Rev 03Document43 pagesMicrosoft Word - Molding Notes Rev 03Panir Selvam Periannan100% (1)

- Process Parameter CalculationDocument2 pagesProcess Parameter CalculationmaheshNo ratings yet

- Plastic Design ConsiderationsDocument16 pagesPlastic Design ConsiderationsAlok MallickNo ratings yet

- Tool Design For Plastic Injection Molding.1Document14 pagesTool Design For Plastic Injection Molding.1Shreekant GurlakattiNo ratings yet

- Plastics Processing: ExtrusionDocument17 pagesPlastics Processing: ExtrusionAnand PatelNo ratings yet

- Ejector Pins and Sleeves: School of Technology and Management, Polytechnic Institute of LeiriaDocument18 pagesEjector Pins and Sleeves: School of Technology and Management, Polytechnic Institute of LeiriaAnshul GuptaNo ratings yet

- 2.describe Mould Parts and ConstructionDocument49 pages2.describe Mould Parts and ConstructionNazri100% (4)

- 05 Mould StructureDocument7 pages05 Mould StructureAlex Kiko VillalobosNo ratings yet

- Mould ElementsDocument72 pagesMould Elementsvinayak100% (4)

- Onexox Faq PDFDocument4 pagesOnexox Faq PDFMohd Nazri SalimNo ratings yet

- Faq Online Guard PlusDocument4 pagesFaq Online Guard PlusMohd Nazri SalimNo ratings yet

- Onexox Faq PDFDocument4 pagesOnexox Faq PDFMohd Nazri SalimNo ratings yet

- 3c3-TrigonometIntegrals Stu PDFDocument12 pages3c3-TrigonometIntegrals Stu PDFEnrique Matom GallegoNo ratings yet

- Xox Prepaid FaqDocument15 pagesXox Prepaid FaqMohd Nazri SalimNo ratings yet

- Welding Inventor TutorialDocument2 pagesWelding Inventor TutorialMohd Nazri SalimNo ratings yet

- Contoh Soalan Shear StressDocument2 pagesContoh Soalan Shear StressMohd Nazri SalimNo ratings yet

- Inventor 2011 Weldments Elise MossDocument18 pagesInventor 2011 Weldments Elise MossVICTORSJNo ratings yet

- Mould HPDC Alloys PDFDocument4 pagesMould HPDC Alloys PDFMohd Nazri SalimNo ratings yet

- JemputanKawin PDFDocument1 pageJemputanKawin PDFMohd Nazri SalimNo ratings yet

- Contoh SoalanDocument1 pageContoh SoalanMohd Nazri SalimNo ratings yet

- Cive1400 200304 PDFDocument17 pagesCive1400 200304 PDFMohd Nazri SalimNo ratings yet

- Control Chart ExerciseDocument2 pagesControl Chart ExerciseMohd Nazri SalimNo ratings yet

- Pressure PDFDocument25 pagesPressure PDFMohd Nazri SalimNo ratings yet

- Employee Scheduling Methods Using A CalculatorDocument6 pagesEmployee Scheduling Methods Using A CalculatorMohd Nazri SalimNo ratings yet

- Minitab Basic TutorialDocument32 pagesMinitab Basic TutorialMohd Nazri SalimNo ratings yet

- MS - Excel - Linear - & - Multiple - Regression Office 2007Document7 pagesMS - Excel - Linear - & - Multiple - Regression Office 2007Mohd Nazri SalimNo ratings yet

- Petronas Technical StandardsDocument20 pagesPetronas Technical StandardsMohd Nizamuddin Mohamad NoorNo ratings yet

- Pipe Jacking - Herren PDFDocument2 pagesPipe Jacking - Herren PDFnurNo ratings yet

- HLP IntroductionDocument14 pagesHLP IntroductionJorge RuizNo ratings yet

- TLV JA3 Air Drain TrapDocument2 pagesTLV JA3 Air Drain TrapMONANo ratings yet

- Manual Reloj PyleDocument69 pagesManual Reloj PyleBanfieldSMNo ratings yet

- Monitor Audio RX - BrochureDocument20 pagesMonitor Audio RX - BrochuresistocNo ratings yet

- Database - Entity, Attribute, IUDDocument24 pagesDatabase - Entity, Attribute, IUDNajm Jibril PulindaoNo ratings yet

- Project ReportDocument9 pagesProject Reportapi-307821649No ratings yet

- Physics Binder 1Document2,790 pagesPhysics Binder 1tbs0sisirakumaraNo ratings yet

- Analysis Authorization Using Variable ExitsDocument17 pagesAnalysis Authorization Using Variable ExitshshahrianNo ratings yet

- Q:-7 Explain The Concept of Encapsulation With The Help of An Diagram?. AnsDocument4 pagesQ:-7 Explain The Concept of Encapsulation With The Help of An Diagram?. AnsKaran GabaNo ratings yet

- Geodetic Eng Job DescriptionDocument11 pagesGeodetic Eng Job DescriptionMuhammad Zaky MudzakirNo ratings yet

- SCBA2Document12 pagesSCBA2deddy priambodoNo ratings yet

- Introduction To General Ethics and Ethical ValuesDocument21 pagesIntroduction To General Ethics and Ethical ValuesMakotoNo ratings yet

- FW1Document5 pagesFW1Mary Faye ReyesNo ratings yet

- Engineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyDocument26 pagesEngineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyRandøm TalkìêsNo ratings yet

- Maths in Chem Eng A 50 Year IntrospectionDocument17 pagesMaths in Chem Eng A 50 Year IntrospectioncerpegarNo ratings yet

- CFR 2011 Title49 Vol3 Part195 PDFDocument70 pagesCFR 2011 Title49 Vol3 Part195 PDFjorgepetroleoNo ratings yet

- Modern Power Electronics and AC Drives by Bimal K Bose PDFDocument738 pagesModern Power Electronics and AC Drives by Bimal K Bose PDFtkn5520No ratings yet

- Short CircuitDocument9 pagesShort CircuitMarck Anthony MagpantayNo ratings yet

- محاضرات بودر دزعراقيDocument5 pagesمحاضرات بودر دزعراقيMohammed GhisheerNo ratings yet

- Marathi Speech Synthesis A ReviewDocument4 pagesMarathi Speech Synthesis A ReviewEditor IJRITCCNo ratings yet

- Water Specialist WS2H and WS3 Control Valve Drawings and Service ManualDocument44 pagesWater Specialist WS2H and WS3 Control Valve Drawings and Service Manualanon_771758198No ratings yet

- MTR - HT# 52154Document1 pageMTR - HT# 52154ColinNo ratings yet

- Flexabrasion of HairDocument10 pagesFlexabrasion of Hairilu_007_in6535No ratings yet