Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

67 viewsUltra High Speed Camera Investigations of Laser Beam Welding

Ultra High Speed Camera Investigations of Laser Beam Welding

Uploaded by

mikoHigh-speed cameras were used to observe laser beam welding processes at frame rates up to 180,000 fps. This provided new insights into two cases:

1) Pulsed welding - High-speed imaging showed melt pool oscillations during solidification cause surface ripples. Adjusting the laser pulse shape to extend the molten period allowed ripples to dissipate before freezing.

2) Edge welding zinc-coated steel - High-speed videos revealed blowouts sometimes formed in the melt pool behind the keyhole, leading to a model of this phenomenon. Direct observation improved understanding of laser-material interactions during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- FP4M Part 0 To 3 PDFDocument76 pagesFP4M Part 0 To 3 PDFmiko67% (3)

- 100 Next-Level Sound Design Tips & Tricks - EDMProd PDFDocument46 pages100 Next-Level Sound Design Tips & Tricks - EDMProd PDFPalanisamy Balasubramani100% (1)

- A Study Into The Effects of Residual Stresses and Hot Dip GalvanizingDocument4 pagesA Study Into The Effects of Residual Stresses and Hot Dip GalvanizingSteve HornseyNo ratings yet

- Real-Time Nanofabrication With High-Speed Atomic Force MicrosDocument6 pagesReal-Time Nanofabrication With High-Speed Atomic Force MicrossahalbabuNo ratings yet

- Oiwa 2011Document8 pagesOiwa 2011Waqas MuneerNo ratings yet

- Residual Stress of Steels For Structure and Fillet Weld Zone After Laser PeeningDocument6 pagesResidual Stress of Steels For Structure and Fillet Weld Zone After Laser Peeningsanketpavi21No ratings yet

- Effect of Laser Pulse Duration On Damage To Metal Mirrors For Laser IFEDocument8 pagesEffect of Laser Pulse Duration On Damage To Metal Mirrors For Laser IFEKimberly PerezNo ratings yet

- بلور فوتونیDocument4 pagesبلور فوتونیMina MohammadiNo ratings yet

- Deep Drilling On A Silicon Plate With A Femtosecond Laser: Experiment and Model AnalysisDocument9 pagesDeep Drilling On A Silicon Plate With A Femtosecond Laser: Experiment and Model AnalysisFranklin DurandNo ratings yet

- A Deep Sub-Wavelength Process For TheDocument5 pagesA Deep Sub-Wavelength Process For TheAndrea JacassiNo ratings yet

- Micro-Hardness Measurement OF Photopolymer in StereolithographyDocument6 pagesMicro-Hardness Measurement OF Photopolymer in StereolithographyHPC 321No ratings yet

- Journal Homepage: - : Manuscript HistoryDocument6 pagesJournal Homepage: - : Manuscript HistoryIJAR JOURNALNo ratings yet

- H-14b MicroformingDocument9 pagesH-14b MicroformingVishwajeet GuptaNo ratings yet

- Laser Beam Machining LBMDocument33 pagesLaser Beam Machining LBMPPSwainNo ratings yet

- Atomic Force Microscopy: Team 1Document16 pagesAtomic Force Microscopy: Team 1Yash JainNo ratings yet

- Laser Beam MachiningDocument33 pagesLaser Beam MachiningVishalNo ratings yet

- Optical Generation of Surface Acoustic Waves Guided at The Linear Boundary BetweenDocument7 pagesOptical Generation of Surface Acoustic Waves Guided at The Linear Boundary BetweenSANTHAKUMAR SNo ratings yet

- Chapter 5 Lithography - I From WaterlooDocument22 pagesChapter 5 Lithography - I From WaterlooAdhi Cahyo WijayaNo ratings yet

- Mourou PFB 92Document11 pagesMourou PFB 92PedroNo ratings yet

- Laser Micro Processing of Carbide Tool PDFDocument9 pagesLaser Micro Processing of Carbide Tool PDFAnonymous AjEedIk81No ratings yet

- Cmos TechnogiesDocument6 pagesCmos TechnogiesARYA MURALI ECE-2020-24No ratings yet

- Chapter 5 Lithography: 1. Light Source and Photomask, AlignmentDocument28 pagesChapter 5 Lithography: 1. Light Source and Photomask, AlignmentKhánh NguyễnNo ratings yet

- S Himming A in T M Agic: The Shimming of High Resolution NMR MagnetsDocument38 pagesS Himming A in T M Agic: The Shimming of High Resolution NMR MagnetsorlandoNo ratings yet

- Manufacturing Processes (ME 361) Lecture-18: Instructor: Shantanu BhattacharyaDocument35 pagesManufacturing Processes (ME 361) Lecture-18: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- PHY-308 Date of Experimernt Experimnet No.5 13th February, 2024Document6 pagesPHY-308 Date of Experimernt Experimnet No.5 13th February, 2024upadhye21No ratings yet

- Laser PDFDocument13 pagesLaser PDFNIKITH ACHANTANo ratings yet

- High Level Compressive Residual Stresses Produced in Aluminum Alloys by Laser Shock ProcessingDocument5 pagesHigh Level Compressive Residual Stresses Produced in Aluminum Alloys by Laser Shock Processingdileep mNo ratings yet

- Lithography-Advanced MaterialsDocument15 pagesLithography-Advanced MaterialsJaya LohaniNo ratings yet

- 03 ICT EtchDocument37 pages03 ICT EtchCyrille MagdiNo ratings yet

- Optics and Lasers in Engineering: I. Eriksson, J. Powell, A.F.H. KaplanDocument6 pagesOptics and Lasers in Engineering: I. Eriksson, J. Powell, A.F.H. Kaplankamal touilebNo ratings yet

- Control of Laser Oscillators: Chapter SevenDocument20 pagesControl of Laser Oscillators: Chapter SevenShailendra SinghNo ratings yet

- Week 3 - High Aspect Ratio Photolithography For MEMS Applications PDFDocument10 pagesWeek 3 - High Aspect Ratio Photolithography For MEMS Applications PDFPreet Kamal SinghNo ratings yet

- HW3Document2 pagesHW3cx18717315873No ratings yet

- Lithographic ProcessesDocument4 pagesLithographic ProcessesyokeshNo ratings yet

- Atomic Force MicrosDocument30 pagesAtomic Force MicrosShreya GuptaNo ratings yet

- 20181127AA Lecture01 Supplemental-1Document42 pages20181127AA Lecture01 Supplemental-1Alonso GarciaNo ratings yet

- UNIT I and II - ESSAY AND SHORT QUESTIONS PDFDocument8 pagesUNIT I and II - ESSAY AND SHORT QUESTIONS PDFSãkëth RèddièNo ratings yet

- Figure 3.1 Metal Cutting of 5Document10 pagesFigure 3.1 Metal Cutting of 5joneth1g.1mostaceroNo ratings yet

- Restructuring The Physics 234 Course To Include Nanoscale InvestigationsDocument31 pagesRestructuring The Physics 234 Course To Include Nanoscale InvestigationsTufail AbdullahNo ratings yet

- Schoessow 1999 0158Document3 pagesSchoessow 1999 0158Particle Beam Physics LabNo ratings yet

- Lazer Beam MechiningDocument18 pagesLazer Beam MechiningBiresh RoyNo ratings yet

- ICLASS Presentation 2021Document9 pagesICLASS Presentation 2021raghav sikkaNo ratings yet

- Article FiberCollimatorsDocument4 pagesArticle FiberCollimatorsMohammad Abdullah BawtagNo ratings yet

- 2014 OE CR ZNS Graphene 41fsDocument8 pages2014 OE CR ZNS Graphene 41fsdemesh87No ratings yet

- Nanobeam ProcessDocument6 pagesNanobeam Processalessio.zicoschiNo ratings yet

- Laser Beam Machining LBMDocument33 pagesLaser Beam Machining LBMshivamNo ratings yet

- Module 5: Fabrication Methods Photolithography: Raja SellappanDocument24 pagesModule 5: Fabrication Methods Photolithography: Raja SellappanAbhiramNo ratings yet

- Pneumatically Switchable Graded Index Metamaterial LensDocument4 pagesPneumatically Switchable Graded Index Metamaterial LensNaga LakshmaiahNo ratings yet

- Effect of Current On Metal Transfer in SAW Part 1Document10 pagesEffect of Current On Metal Transfer in SAW Part 1Andrés Mauricio UribeNo ratings yet

- Direct Writing Three-Dimensional Crystalline Pattern in Glass With Ultrashort Pulse LaserDocument4 pagesDirect Writing Three-Dimensional Crystalline Pattern in Glass With Ultrashort Pulse LaserMustafa EL-BoghdadyNo ratings yet

- Finite Element Analysis of Resonant Frequencies in Surface Acoustic Wave DeviceDocument5 pagesFinite Element Analysis of Resonant Frequencies in Surface Acoustic Wave Devicebingwazzup100% (1)

- Nano Material CharacterisationDocument14 pagesNano Material CharacterisationRama SamyNo ratings yet

- Improving Weld Quality by Arc-Excited Ultrasonic Treatment: ZHANG O1unlei (WU Minsheng (DU Jinglei (Document4 pagesImproving Weld Quality by Arc-Excited Ultrasonic Treatment: ZHANG O1unlei (WU Minsheng (DU Jinglei (Minh TranNo ratings yet

- Module 4 Mems PDFDocument51 pagesModule 4 Mems PDFamithaanumadhusoodhananNo ratings yet

- Zhang2010 PDFDocument5 pagesZhang2010 PDFDhirajNo ratings yet

- 2016 - Zhang Et Al. - Tip-Enhanced Raman Spectroscopy - Analytical ChemistryDocument36 pages2016 - Zhang Et Al. - Tip-Enhanced Raman Spectroscopy - Analytical ChemistryClaudio BiaginiNo ratings yet

- Shin 2007Document4 pagesShin 2007zidan ojaNo ratings yet

- Vibrational GalvanometerDocument32 pagesVibrational GalvanometerJay ParkheNo ratings yet

- Black SiliconDocument9 pagesBlack SiliconfelipeintheboxNo ratings yet

- Probing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsFrom EverandProbing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsRating: 2 out of 5 stars2/5 (1)

- Sutton Tools Industrial Catalogue - AUG 2020Document276 pagesSutton Tools Industrial Catalogue - AUG 2020mikoNo ratings yet

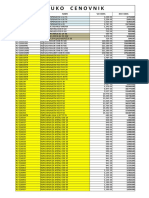

- Ruko Cenovnik 12.06.2017.Document13 pagesRuko Cenovnik 12.06.2017.mikoNo ratings yet

- Cylinder Bore Gage Manual: Operating Instructions and Parts Manual Model No: 52-646-100Document1 pageCylinder Bore Gage Manual: Operating Instructions and Parts Manual Model No: 52-646-100mikoNo ratings yet

- FT Kiray200 PDFDocument2 pagesFT Kiray200 PDFmikoNo ratings yet

- x86 StderrDocument2 pagesx86 StderrDiva DivaNo ratings yet

- The Ballad of The Drover - Henry LawsonDocument3 pagesThe Ballad of The Drover - Henry LawsonJason BenicNo ratings yet

- Grass Valley Encore Control SystemDocument354 pagesGrass Valley Encore Control SystemDenwegoNo ratings yet

- Quizler 2022-2023Document5 pagesQuizler 2022-2023İbrahim ÇetinkayaNo ratings yet

- English - TRBDocument6 pagesEnglish - TRBPonsethuNo ratings yet

- Advanced Open Firmware SecurityDocument15 pagesAdvanced Open Firmware Securitym_trNo ratings yet

- Icyizere No 37Document20 pagesIcyizere No 37Emmanuel HabumuremyiNo ratings yet

- Visharad Part II Instrumental NEWDocument53 pagesVisharad Part II Instrumental NEWGeethanjali Aberathna100% (1)

- Hoja de Práctica 1 - Past Tense A Song - Yellow Coldplay To CompletDocument1 pageHoja de Práctica 1 - Past Tense A Song - Yellow Coldplay To CompletRs JamesNo ratings yet

- Amazing Spider-Man Episode 1 (1-1)Document21 pagesAmazing Spider-Man Episode 1 (1-1)Ryan Taylor SpearmanNo ratings yet

- Biostar H81MDV3 SpecDocument8 pagesBiostar H81MDV3 SpecNugraha Dwi Ananta RNNo ratings yet

- Research Paper On Flying Car PDFDocument9 pagesResearch Paper On Flying Car PDFc9k7jjfk100% (1)

- 3 Revised Chapter 4 Pavement Design - RigidDocument38 pages3 Revised Chapter 4 Pavement Design - RigidUjjval SolankiNo ratings yet

- Soal Am Bahasa Inggris 2324Document10 pagesSoal Am Bahasa Inggris 2324gusti antungNo ratings yet

- Writing Academic Essays @ieltsieltsDocument23 pagesWriting Academic Essays @ieltsieltsJosue FishNo ratings yet

- 2 - PDFsam - Intel dz77sl 50k Manuel D UtilisationDocument1 page2 - PDFsam - Intel dz77sl 50k Manuel D UtilisationxuebiNo ratings yet

- Training Distance Runners: by Todd Thorson Ipswich SchoolDocument36 pagesTraining Distance Runners: by Todd Thorson Ipswich SchoolYared TegegneNo ratings yet

- Sample Movement AnalysisDocument15 pagesSample Movement Analysispanomo nasabyNo ratings yet

- Recorder RubricDocument1 pageRecorder Rubricapi-265032487No ratings yet

- (Borneo Lute) : Sarawak SapehDocument5 pages(Borneo Lute) : Sarawak SapehEjan FarizanNo ratings yet

- Egyptian Art ReportDocument44 pagesEgyptian Art ReportSam Sam100% (1)

- Midterm Test (Units 1-6) : Read, Look and Circle. Circle The Odd WordDocument2 pagesMidterm Test (Units 1-6) : Read, Look and Circle. Circle The Odd WordOutlaw StudioNo ratings yet

- Beauty and The Beast (Short)Document7 pagesBeauty and The Beast (Short)Alpaca parkaNo ratings yet

- CARDAMOMDocument16 pagesCARDAMOMAndre nicholsNo ratings yet

- 8 P's of AirtelDocument10 pages8 P's of Airtelrajat_singlaNo ratings yet

- How To Design and Provision A Production-Ready EKS Cluster: Image Credit: PixabayDocument11 pagesHow To Design and Provision A Production-Ready EKS Cluster: Image Credit: Pixabaycentinel29No ratings yet

- CỤM TỪ VÀ MỆNH ĐỀ CHỈ MỤC ĐÍCHDocument6 pagesCỤM TỪ VÀ MỆNH ĐỀ CHỈ MỤC ĐÍCHHàn HươngNo ratings yet

- Battle RealmsDocument3 pagesBattle RealmsantukaraNo ratings yet

- Dress The CakeDocument5 pagesDress The Cakenyimas genesiaNo ratings yet

Ultra High Speed Camera Investigations of Laser Beam Welding

Ultra High Speed Camera Investigations of Laser Beam Welding

Uploaded by

miko0 ratings0% found this document useful (0 votes)

67 views7 pagesHigh-speed cameras were used to observe laser beam welding processes at frame rates up to 180,000 fps. This provided new insights into two cases:

1) Pulsed welding - High-speed imaging showed melt pool oscillations during solidification cause surface ripples. Adjusting the laser pulse shape to extend the molten period allowed ripples to dissipate before freezing.

2) Edge welding zinc-coated steel - High-speed videos revealed blowouts sometimes formed in the melt pool behind the keyhole, leading to a model of this phenomenon. Direct observation improved understanding of laser-material interactions during welding.

Original Description:

Original Title

ULTRA_HIGH_SPEED_CAMERA_INVESTIGATIONS_OF_LASER_BEAM_WELDING.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHigh-speed cameras were used to observe laser beam welding processes at frame rates up to 180,000 fps. This provided new insights into two cases:

1) Pulsed welding - High-speed imaging showed melt pool oscillations during solidification cause surface ripples. Adjusting the laser pulse shape to extend the molten period allowed ripples to dissipate before freezing.

2) Edge welding zinc-coated steel - High-speed videos revealed blowouts sometimes formed in the melt pool behind the keyhole, leading to a model of this phenomenon. Direct observation improved understanding of laser-material interactions during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

67 views7 pagesUltra High Speed Camera Investigations of Laser Beam Welding

Ultra High Speed Camera Investigations of Laser Beam Welding

Uploaded by

mikoHigh-speed cameras were used to observe laser beam welding processes at frame rates up to 180,000 fps. This provided new insights into two cases:

1) Pulsed welding - High-speed imaging showed melt pool oscillations during solidification cause surface ripples. Adjusting the laser pulse shape to extend the molten period allowed ripples to dissipate before freezing.

2) Edge welding zinc-coated steel - High-speed videos revealed blowouts sometimes formed in the melt pool behind the keyhole, leading to a model of this phenomenon. Direct observation improved understanding of laser-material interactions during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

ULTRA HIGH SPEED CAMERA INVESTIGATIONS OF LASER BEAM WELDING

Paper (501)

Ingemar Eriksson, John Powell, Alexander F. H. Kaplan

Luleå University of Technology, 971 87 Luleå, Sweden

Abstract CCD and CMOS cameras dominate the high speed

photography market. The cameras used in this paper

With the help of high speed camera equipment, save the image to an internal random access memory

researchers can now directly observe melt flow capable of storing several thousand frames. This

phenomena which only could be imagined or simulated enables us to capture a long sequence of high speed

in the past. In this paper the motion of the molten photographs to isolate the events which cause defects.

metal inside the keyhole has been observed at frame By reducing the number of pixels saved in every frame

rates as high as 180000 fps to provide useful the frame rate can be increased. But the practical frame

information about the laser beam welding process. rate is limited to a few hundred thousand frames per

This paper describes two different cases where high second.

speed imaging has given new insights into the laser

beam welding process: A. In pulsed welding the melt The laser welding community has used the technology

pool oscillations can create ripples on the solidified of high speed photography for a long time and, as the

weld surface. With the help of a high speed camera this technology develops, phenomena can be observed in

phenomenon was analyzed, and the pulse shape was ever greater detail. To demonstrate the power of high

adjusted to reduce the ripple amplitude to a minimum. speed photography we present here two different cases

B. In Zn-coated steel edge welding it could be seen where the latest generation of digital cameras was used

that blowouts were sometimes created in the melt pool to provide interesting new information about the laser-

at some distance behind the keyhole. Direct slow- material interactions which take place during laser

motion observation has led to the formulation of a welding.

phenomenological model of this effect.

Ripples in spot welding

Introduction

The first example is an industrial case of laser spot

After the invention of photography, it wasn’t long welding of a titanium surgical implant. Surface ripples

before a scientist realized the power of high speed such as those shown in figure 1 were found on the

photography. The first known case is the famous finished weld. Ripples of this sort could be

galloping horse published in 1887 by Eadweard unacceptable because of their effect on the fatigue life

Muybridge. Muybridge proved that, at certain points or the visual appearance of the weld. In an

during a horse’s galloping cycle, all the hoofs were in experimental program which investigated the process

the air. These high speed images were created with one of the ripple formation with high speed cameras, a

camera for every frame. This reduced the number of strategy to minimize the effect was developed. The

frames to the number of cameras, but the frame rate phenomenology of ripple formation was examined by

was theoretically unlimited. A problem with multiple high speed photography under high intensity

cameras is that each camera will have a different point illumination and the strategy for ripple minimization

of view, and thus this technique is not suitable for involved suitable power modulation of the laser pulse.

micro photography. Ripples were found to originate from the oscillations

[1, 2] of the weld pool. As the weld pool solidifies

High speed photography was quickly developed to rapidly [3, 4] the oscillations are frozen to become

high frame rates. In the 1930’s a rate of 1000 frames ripples on the surface.

per second (fps) was reached, and by introducing the

rotating prism technique 40.000 fps were achieved

soon afterwards. By the conversion of photons to

electrons, images could be stored on a phosphorescent

screen. With electrical deflection to store the images

on a phosphorescent screen frame rates over

100.000.000 were reached in the 1960s. Today digital

completely solid surface was 3ms. This rapid

solidification froze the oscillations in the surface.

High speed photography of ripple formation.

Figure 3a-f presents a series of still photographs from

high speed filming of the creation of a single pulse

spot weld. A pulsed diode laser of 810nm wavelength

is utilized as illumination.

Figure 1. The rippled topography of typical pulsed

laser weld in titanium.

The experiment involved pulsed Nd:YAG welding of

titanium. The Laser used was a ROFIN-SINAR P500.

The laser pulse was ~1,5 ms long with a repetition rate

of 5Hz and 30% of the available pulse power. The

welded part was moved between pulses to produce a

weld seam of overlapping spot welds. The feed rate

was adjusted to give 50% overlap of the pulses

(~2mm/s). The shielding gas employed was Argon. To

observe the welding a Redlake X3 high speed camera

at 8000 frames per second was used with a Cavilux

illumination laser at a power of 500 Watts with 1µs

illumination time. Figure 2 is a magnified view of the

finished weld seam considered in this experimental

program, showing the overlap geometry and the

surface ripples on the individual spot welds.

Figure 2. The overlap geometry of the spot welds

investigated.

Examination of high speed filming shows that the melt

pool oscillated with a frequency of approximately

3kHz and the time from turning off the laser to

• The laser pulse ends and boiling ceases (Figure 3c).

Surface tension forces the melt to attempt to spring

back from a concave geometry to a convex one.

(Seen in figure 3d as a horizontal elongation of the

glare)

• The momentum of the melt in the direction

perpendicular to its surface makes the melt surface

overshoot its equilibrium position. The melt surface

then assumes damped simple harmonic motion

around its equilibrium position.

• The melt solidifies before this action has died down

and the ripples are frozen into the surface topology

of the weld (Figure 3e), and this generates surface

ripples. (Figure 3f)

Pulse shape modulation to suppress ripple formation.

A series of experiments was carried out to establish the

most effective pulse shape to minimize ripples in the

eventual weld topology. The overall strategy was to

extend the molten life of the melt so that the ripples

could die away before solidification took place.

Productivity was not affected by this technique

because the original pulse frequency of 5Hz was

maintained – the post weld heating was accommodated

in the gap between the pulses. The original 1.5ms

rectangular power profile of the weld pulse was

extended at a lower power level as shown in figure 4.

Successful welds with minimum surface rippling were

produced at an extended pulse lifetime of 4ms.

Figure 3 a-f. High speed photography sequence of a

single spot weld creating surface ripples.

From this series of photographs it can be inferred that

the progression of events which results in a set of

concentric ripples on a single pulse spot weld is as

follows;

• The laser pulse starts its interaction with the material

and begins to melt the surface. (Figure 3a)

• The weld pool grows in volume and diameter as the

laser continues to irradiate the surface. A depression

forms in the middle of the weld pool as a result of

localized boiling – which exerts a pressure on the Figure 4. One strategy of pulse shaping to minimizes

melt. And the melt is pushed laterally away from the the surface ripples

centre [5]. (Figure 3b)

Figure 5 demonstrates that the majority of the surface With the help of high speed photography it can clearly

ripple effect has been suppressed although there is be seen how the holes in the weld seam are created.

some evidence of minor rippling at the edge of the Different types of blowouts can be categorized, [10].

solidified melt where cooling and solidification rates Sometimes in the otherwise calm melt pool a blowout

are at their highest. can appear. In figure 6 one of these blowouts is caught

on film during the welding of a lap/edge joint in zinc

coated steel. (0.8mm, 2.5kW Nd:YAG, 100mm/s)

Melt pool Keyhole

Figure 5. spot weld with minimal surface ripples.

(Different crystal orientations of the titanium can be

seen on the smooth solidified surface.)

Conclusions - ripple case

In the latter stages of the laser-melt interaction during

pulsed laser spot welding, the central portion of the

weld is depressed as a result of localized boiling which

exerts a pressure on the melt. As the laser pulse ends,

the boiling ceases, and the pressure is removed. The

melt then begins to return to its equilibrium geometry

under the influence of surface tension, but the vertical

momentum of the melt carries it past this equilibrium

position. The surface then experiences damped simple

harmonic motion. Ripples on the surface of the solid Figure 6. Blowout in melt pool at 2500fps

welds are created by rapid solidification of a surface

which was undergoing damped simple harmonic These big blowouts are the results of the escape of

motion. By delaying the solidification until the pressurized zinc gas accumulated in the melt pool. In

harmonic motion is completely dampened, surface figure 7 the internal pores along the weld seam show

ripples can be avoided. that zinc vapor is constantly pushed into the melt pool.

Sometimes a pore reaches the surface and creates a

Zinc coated blow-out case small visible pore. But if the gas accumulates into

large pores, there is a risk of material blowout when

The welding of Zinc coated steel plates is an important the surface tension cannot hold the pressure.

part of automotive manufacturing. A common problem

during laser welding of zinc coated plates is that the

zinc is evaporated; the zinc vapor causes blowouts and

pores in the melt pool and produces holes in the weld

seam. Several different solutions to the problem have

been suggested and evaluated, but new methods are

still being developed [6-9] and more knowledge about Figure 7. Cut along weld seam showing pore content.

the process is needed.

One way of eliminating this problem is to introduce a 180 000 fps inside keyhole

small gap (0.1mm) in the joint, that enables the zinc Figure 8 shows a sequence of high speed images where

gas to be evacuated, and no gas pressure is built up in zero gap overlap welding provokes the entire melt pool

the melt. But to maintain a constant gap of 0.1 mm in

to be blown out of the weld zone. This event made it

an automated production line can be difficult. Some

possible for the second high speed camera we used to

researchers [11-12] have reported that pore-free zero-

catch a glimpse of the front side of the keyhole for a

gap welds are possible by pulsing the laser power. One

moment (as in Figure 9a). This second camera was a

theory is that, in this case, the zinc gas is evacuated Photron SA1 camera with a Micro-Nikkor 105mm

through the keyhole capillary. lens, running 180 000 frames per second with an

exposure time of 370ns. The image size was 128x128

pixels with 12 bit pixel depth. This back view camera

Keyhole was used without illumination so all the light collected

was from heat radiation (Figure 9b). With this camera

view it was possible to see a downward motion in the

molten metal, and how the pressurized zinc gas sprays

liquid metal away from the front wall of the keyhole.

Figure 9. a) simplified geometry b) camera image

Figure 8. Blow out of the keyhole region

In figure 10 a sequence of images (extracted from the Conclusions - zinc coated blow-out case

area indicated in figure 9b) shows the ejection of

droplets of molten metal. The gray scale level in these As the automotive industry has invested a lot in

images is an indication of temperature, the bright areas research about laser welding of zinc coated material,

are probably humps heated by the laser - having a much is already known or assumed to be known. With

higher temperature then the surroundings. A downward the help of new high speed camera equipment the

flow can be observed but as the surface changes over physical behaviour of the melt during the welding can

time a qualitative speed measurement is difficult. be observed directly, and theories about the welding

process can easily be confirmed or dismissed. As we

have show in this paper, the pressurized zinc gas can

create blow-outs in the melt pool, or create internal

pores that weaken the weld strength. We also show

that zinc gas can enter the keyhole capillary and exit

the weld this way, (but in our experimental case the

high speed of the zinc gas blows away the melt pool).

With the welding settings we used (2.5kW Nd:YAG,

Figure 10. Front wall of keyhole, 33µs long sequence.

100mm/s) there was a constant downward flow of

what looks to be humps on the front wall of the

To measure the speed a streak image technique can be

keyhole. Similar to that described by Matsunawa and

utilized. A thin, central strip, one pixel wide, can be

Semak in 1997 [13]. This type of flow happens

extracted from photographic images of the type shown

continuously, but is visible but only when the melt

in figure 9. A collection of these single pixel lines can

pool has been blown away and the entire front of the

then be placed side by side to present streak photo

keyhole is visible. The possibility to measure this flow

information mapping the movement of bright zones experimentally could help in calibrating simulation

along the centre line of the main image. Figure 11

models of this effect.

presents the data in this format, and shows the

variation in brightness along the capillary centre line General conclusions

over time.

Even though some laser researchers have been using

In figure 11 a total number of 540 frames have been high speed cameras for a long time, the recent

arranged in this way and it is clear that in the center of development of the equipment has enabled easier use.

the keyhole front there is a constant 7m/s motion The cameras can be used in industrial installations and

downwards of bright areas. The dark horizontal band help to develop our understanding of the process. (The

in figure 11 is the gap between the two welded plates ripple case was filmed in an industrial production line

where the zinc gas escapes. Molten metal from the on a commercial product.)

upper sheet flowing over the gap sometimes creates

spatter. The movement of this spatter can be observed The ability to view and measure the metal flow inside

as thin bright lines at the bottom of figure 11 and the keyhole will be of great help in explaining the

speeds vary from 5m/s to 15m/s. mechanisms of laser welding in the future. As the

number of research facilities with high speed cameras

is increasing, new methods of real time measurement

will be used to improve theoretical models.

Acknowledgements

This work was founded by VINNOVA as a part

of the DATLAS project. (no: 2005-02895)

The authors are also grateful at Rickard Olsson and

Ove Sundelin at Lasernova AB in Östersund for their

support in the experimental work.

Figure 11: Streak image of keyhole front

References International Conference on Lasers in Manufacturing,

pp 93–104

[1] Cho J, Farson D, Milewski J & Hollis K (2009)

Weld pool flows during initial stages of keyhole [13] Matsunawa A. and Semak V. (1997) The

formation in laser welding Journal of Physics D- simulation of front keyhole wall dynamics during laser

Applied Physics 42 175502 welding. Journal of Physics D-Applied Physics 30 798

[2] Klein T, Vicanek M & Simon G (1995) Forced

oscillations of the keyhole in penetration laser beam

welding Journal of Physics D-Applied Physics 29 322-

332

[3] He X, Elmer J W & DebRoy T (2005) Heat transfer

and fluid flow in laser microwelding Journal of applied

physics 97 84909

Meet the Authors

[4] He X, Fuerschbach P W & DebRoy T (2003) Heat

transfer and fluid flow during laser spot welding of 304 Ingemar Eriksson was born in Östersund, Sweden in

stainless steel Journal of Physics D-Applied Physics 36 1980. He studied Electrical Engineering at the Mid

1388-1398 Sweden University from 2001 to 2005. Since 2008 he

has been employed at Luleå University of Technology

[5] Semak V V, Knorovsky G A, MacCallum D O & as a PhD student in laser welding.

Allen Roach R (2006) Effect of surface tension on melt

pool dynamics during laser pulse interaction Journal of Dr. John Powell has been active in laser processing

Physics D-Applied Physics 39 590–5 research since the 1980's. He is the author of two

books on laser cutting and over 100 papers on laser

[6] Bley, H Weyand, L & Luft, A (2007) An processing. He is a visiting professor at Luleå

alternative approach for the cost-efficient laser welding University of Technology.

of zinc-coated sheet metal, Annals of the CIRP 56 pp.

17–20. Alexander Kaplan was born in Vienna, Austria in

1967 and employed as researcher at Vienna TU from

[7] Li X, Lawson S, Zhou Y, & Goodwin F. (2007) 1989 until 2000. He received a PhD in 1994 on

Novel technique for laser lap welding of zinc coated modeling of laser welding. After a post-doc year at

sheet steels. Journal of Laser Applications Osaka University, Japan, from 2002 on he has been

2007;19:259–64. appointed as professor and head of division on

manufacturing at Luleå University of Technology,

[8] Iqbal S, Gualini M & Rehman A, (2010) Dual Sweden. His research focus comprises laser materials

beam method for laser welding of galvanized steel: processing, in particular process modeling, laser

Experimentation and prospects, Optics & Laser welding and hybrid welding.

Technology 42 93-98,

[9] Chen W, Ackerson P & Molian P, (2009) CO2

laser welding of galvanized steel sheets using vent

holes, Materials & Design, 30 245-251

[10] Norman, P. Eriksson, I. & Kaplan, A. F. H.

(2009) Monitoring laser beam welding of zinc coated

sheet metal to analyse the defects occurring, in

Proceedings of the NOLAMP-conference,

Copenhagen, Denmark,

[11] Yih-fong T. (2006) Gap-free lap welding of zinc

coated steel using pulsed CO2 laser, Int. journal of

Advanced Manufacturing Technology 29 287-295.

[12] Heydon J, Nilsson K, Magnusson C (1989) Laser

welding of zinc coated steel. In: Proceedings of the 6th

You might also like

- FP4M Part 0 To 3 PDFDocument76 pagesFP4M Part 0 To 3 PDFmiko67% (3)

- 100 Next-Level Sound Design Tips & Tricks - EDMProd PDFDocument46 pages100 Next-Level Sound Design Tips & Tricks - EDMProd PDFPalanisamy Balasubramani100% (1)

- A Study Into The Effects of Residual Stresses and Hot Dip GalvanizingDocument4 pagesA Study Into The Effects of Residual Stresses and Hot Dip GalvanizingSteve HornseyNo ratings yet

- Real-Time Nanofabrication With High-Speed Atomic Force MicrosDocument6 pagesReal-Time Nanofabrication With High-Speed Atomic Force MicrossahalbabuNo ratings yet

- Oiwa 2011Document8 pagesOiwa 2011Waqas MuneerNo ratings yet

- Residual Stress of Steels For Structure and Fillet Weld Zone After Laser PeeningDocument6 pagesResidual Stress of Steels For Structure and Fillet Weld Zone After Laser Peeningsanketpavi21No ratings yet

- Effect of Laser Pulse Duration On Damage To Metal Mirrors For Laser IFEDocument8 pagesEffect of Laser Pulse Duration On Damage To Metal Mirrors For Laser IFEKimberly PerezNo ratings yet

- بلور فوتونیDocument4 pagesبلور فوتونیMina MohammadiNo ratings yet

- Deep Drilling On A Silicon Plate With A Femtosecond Laser: Experiment and Model AnalysisDocument9 pagesDeep Drilling On A Silicon Plate With A Femtosecond Laser: Experiment and Model AnalysisFranklin DurandNo ratings yet

- A Deep Sub-Wavelength Process For TheDocument5 pagesA Deep Sub-Wavelength Process For TheAndrea JacassiNo ratings yet

- Micro-Hardness Measurement OF Photopolymer in StereolithographyDocument6 pagesMicro-Hardness Measurement OF Photopolymer in StereolithographyHPC 321No ratings yet

- Journal Homepage: - : Manuscript HistoryDocument6 pagesJournal Homepage: - : Manuscript HistoryIJAR JOURNALNo ratings yet

- H-14b MicroformingDocument9 pagesH-14b MicroformingVishwajeet GuptaNo ratings yet

- Laser Beam Machining LBMDocument33 pagesLaser Beam Machining LBMPPSwainNo ratings yet

- Atomic Force Microscopy: Team 1Document16 pagesAtomic Force Microscopy: Team 1Yash JainNo ratings yet

- Laser Beam MachiningDocument33 pagesLaser Beam MachiningVishalNo ratings yet

- Optical Generation of Surface Acoustic Waves Guided at The Linear Boundary BetweenDocument7 pagesOptical Generation of Surface Acoustic Waves Guided at The Linear Boundary BetweenSANTHAKUMAR SNo ratings yet

- Chapter 5 Lithography - I From WaterlooDocument22 pagesChapter 5 Lithography - I From WaterlooAdhi Cahyo WijayaNo ratings yet

- Mourou PFB 92Document11 pagesMourou PFB 92PedroNo ratings yet

- Laser Micro Processing of Carbide Tool PDFDocument9 pagesLaser Micro Processing of Carbide Tool PDFAnonymous AjEedIk81No ratings yet

- Cmos TechnogiesDocument6 pagesCmos TechnogiesARYA MURALI ECE-2020-24No ratings yet

- Chapter 5 Lithography: 1. Light Source and Photomask, AlignmentDocument28 pagesChapter 5 Lithography: 1. Light Source and Photomask, AlignmentKhánh NguyễnNo ratings yet

- S Himming A in T M Agic: The Shimming of High Resolution NMR MagnetsDocument38 pagesS Himming A in T M Agic: The Shimming of High Resolution NMR MagnetsorlandoNo ratings yet

- Manufacturing Processes (ME 361) Lecture-18: Instructor: Shantanu BhattacharyaDocument35 pagesManufacturing Processes (ME 361) Lecture-18: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- PHY-308 Date of Experimernt Experimnet No.5 13th February, 2024Document6 pagesPHY-308 Date of Experimernt Experimnet No.5 13th February, 2024upadhye21No ratings yet

- Laser PDFDocument13 pagesLaser PDFNIKITH ACHANTANo ratings yet

- High Level Compressive Residual Stresses Produced in Aluminum Alloys by Laser Shock ProcessingDocument5 pagesHigh Level Compressive Residual Stresses Produced in Aluminum Alloys by Laser Shock Processingdileep mNo ratings yet

- Lithography-Advanced MaterialsDocument15 pagesLithography-Advanced MaterialsJaya LohaniNo ratings yet

- 03 ICT EtchDocument37 pages03 ICT EtchCyrille MagdiNo ratings yet

- Optics and Lasers in Engineering: I. Eriksson, J. Powell, A.F.H. KaplanDocument6 pagesOptics and Lasers in Engineering: I. Eriksson, J. Powell, A.F.H. Kaplankamal touilebNo ratings yet

- Control of Laser Oscillators: Chapter SevenDocument20 pagesControl of Laser Oscillators: Chapter SevenShailendra SinghNo ratings yet

- Week 3 - High Aspect Ratio Photolithography For MEMS Applications PDFDocument10 pagesWeek 3 - High Aspect Ratio Photolithography For MEMS Applications PDFPreet Kamal SinghNo ratings yet

- HW3Document2 pagesHW3cx18717315873No ratings yet

- Lithographic ProcessesDocument4 pagesLithographic ProcessesyokeshNo ratings yet

- Atomic Force MicrosDocument30 pagesAtomic Force MicrosShreya GuptaNo ratings yet

- 20181127AA Lecture01 Supplemental-1Document42 pages20181127AA Lecture01 Supplemental-1Alonso GarciaNo ratings yet

- UNIT I and II - ESSAY AND SHORT QUESTIONS PDFDocument8 pagesUNIT I and II - ESSAY AND SHORT QUESTIONS PDFSãkëth RèddièNo ratings yet

- Figure 3.1 Metal Cutting of 5Document10 pagesFigure 3.1 Metal Cutting of 5joneth1g.1mostaceroNo ratings yet

- Restructuring The Physics 234 Course To Include Nanoscale InvestigationsDocument31 pagesRestructuring The Physics 234 Course To Include Nanoscale InvestigationsTufail AbdullahNo ratings yet

- Schoessow 1999 0158Document3 pagesSchoessow 1999 0158Particle Beam Physics LabNo ratings yet

- Lazer Beam MechiningDocument18 pagesLazer Beam MechiningBiresh RoyNo ratings yet

- ICLASS Presentation 2021Document9 pagesICLASS Presentation 2021raghav sikkaNo ratings yet

- Article FiberCollimatorsDocument4 pagesArticle FiberCollimatorsMohammad Abdullah BawtagNo ratings yet

- 2014 OE CR ZNS Graphene 41fsDocument8 pages2014 OE CR ZNS Graphene 41fsdemesh87No ratings yet

- Nanobeam ProcessDocument6 pagesNanobeam Processalessio.zicoschiNo ratings yet

- Laser Beam Machining LBMDocument33 pagesLaser Beam Machining LBMshivamNo ratings yet

- Module 5: Fabrication Methods Photolithography: Raja SellappanDocument24 pagesModule 5: Fabrication Methods Photolithography: Raja SellappanAbhiramNo ratings yet

- Pneumatically Switchable Graded Index Metamaterial LensDocument4 pagesPneumatically Switchable Graded Index Metamaterial LensNaga LakshmaiahNo ratings yet

- Effect of Current On Metal Transfer in SAW Part 1Document10 pagesEffect of Current On Metal Transfer in SAW Part 1Andrés Mauricio UribeNo ratings yet

- Direct Writing Three-Dimensional Crystalline Pattern in Glass With Ultrashort Pulse LaserDocument4 pagesDirect Writing Three-Dimensional Crystalline Pattern in Glass With Ultrashort Pulse LaserMustafa EL-BoghdadyNo ratings yet

- Finite Element Analysis of Resonant Frequencies in Surface Acoustic Wave DeviceDocument5 pagesFinite Element Analysis of Resonant Frequencies in Surface Acoustic Wave Devicebingwazzup100% (1)

- Nano Material CharacterisationDocument14 pagesNano Material CharacterisationRama SamyNo ratings yet

- Improving Weld Quality by Arc-Excited Ultrasonic Treatment: ZHANG O1unlei (WU Minsheng (DU Jinglei (Document4 pagesImproving Weld Quality by Arc-Excited Ultrasonic Treatment: ZHANG O1unlei (WU Minsheng (DU Jinglei (Minh TranNo ratings yet

- Module 4 Mems PDFDocument51 pagesModule 4 Mems PDFamithaanumadhusoodhananNo ratings yet

- Zhang2010 PDFDocument5 pagesZhang2010 PDFDhirajNo ratings yet

- 2016 - Zhang Et Al. - Tip-Enhanced Raman Spectroscopy - Analytical ChemistryDocument36 pages2016 - Zhang Et Al. - Tip-Enhanced Raman Spectroscopy - Analytical ChemistryClaudio BiaginiNo ratings yet

- Shin 2007Document4 pagesShin 2007zidan ojaNo ratings yet

- Vibrational GalvanometerDocument32 pagesVibrational GalvanometerJay ParkheNo ratings yet

- Black SiliconDocument9 pagesBlack SiliconfelipeintheboxNo ratings yet

- Probing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsFrom EverandProbing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsRating: 2 out of 5 stars2/5 (1)

- Sutton Tools Industrial Catalogue - AUG 2020Document276 pagesSutton Tools Industrial Catalogue - AUG 2020mikoNo ratings yet

- Ruko Cenovnik 12.06.2017.Document13 pagesRuko Cenovnik 12.06.2017.mikoNo ratings yet

- Cylinder Bore Gage Manual: Operating Instructions and Parts Manual Model No: 52-646-100Document1 pageCylinder Bore Gage Manual: Operating Instructions and Parts Manual Model No: 52-646-100mikoNo ratings yet

- FT Kiray200 PDFDocument2 pagesFT Kiray200 PDFmikoNo ratings yet

- x86 StderrDocument2 pagesx86 StderrDiva DivaNo ratings yet

- The Ballad of The Drover - Henry LawsonDocument3 pagesThe Ballad of The Drover - Henry LawsonJason BenicNo ratings yet

- Grass Valley Encore Control SystemDocument354 pagesGrass Valley Encore Control SystemDenwegoNo ratings yet

- Quizler 2022-2023Document5 pagesQuizler 2022-2023İbrahim ÇetinkayaNo ratings yet

- English - TRBDocument6 pagesEnglish - TRBPonsethuNo ratings yet

- Advanced Open Firmware SecurityDocument15 pagesAdvanced Open Firmware Securitym_trNo ratings yet

- Icyizere No 37Document20 pagesIcyizere No 37Emmanuel HabumuremyiNo ratings yet

- Visharad Part II Instrumental NEWDocument53 pagesVisharad Part II Instrumental NEWGeethanjali Aberathna100% (1)

- Hoja de Práctica 1 - Past Tense A Song - Yellow Coldplay To CompletDocument1 pageHoja de Práctica 1 - Past Tense A Song - Yellow Coldplay To CompletRs JamesNo ratings yet

- Amazing Spider-Man Episode 1 (1-1)Document21 pagesAmazing Spider-Man Episode 1 (1-1)Ryan Taylor SpearmanNo ratings yet

- Biostar H81MDV3 SpecDocument8 pagesBiostar H81MDV3 SpecNugraha Dwi Ananta RNNo ratings yet

- Research Paper On Flying Car PDFDocument9 pagesResearch Paper On Flying Car PDFc9k7jjfk100% (1)

- 3 Revised Chapter 4 Pavement Design - RigidDocument38 pages3 Revised Chapter 4 Pavement Design - RigidUjjval SolankiNo ratings yet

- Soal Am Bahasa Inggris 2324Document10 pagesSoal Am Bahasa Inggris 2324gusti antungNo ratings yet

- Writing Academic Essays @ieltsieltsDocument23 pagesWriting Academic Essays @ieltsieltsJosue FishNo ratings yet

- 2 - PDFsam - Intel dz77sl 50k Manuel D UtilisationDocument1 page2 - PDFsam - Intel dz77sl 50k Manuel D UtilisationxuebiNo ratings yet

- Training Distance Runners: by Todd Thorson Ipswich SchoolDocument36 pagesTraining Distance Runners: by Todd Thorson Ipswich SchoolYared TegegneNo ratings yet

- Sample Movement AnalysisDocument15 pagesSample Movement Analysispanomo nasabyNo ratings yet

- Recorder RubricDocument1 pageRecorder Rubricapi-265032487No ratings yet

- (Borneo Lute) : Sarawak SapehDocument5 pages(Borneo Lute) : Sarawak SapehEjan FarizanNo ratings yet

- Egyptian Art ReportDocument44 pagesEgyptian Art ReportSam Sam100% (1)

- Midterm Test (Units 1-6) : Read, Look and Circle. Circle The Odd WordDocument2 pagesMidterm Test (Units 1-6) : Read, Look and Circle. Circle The Odd WordOutlaw StudioNo ratings yet

- Beauty and The Beast (Short)Document7 pagesBeauty and The Beast (Short)Alpaca parkaNo ratings yet

- CARDAMOMDocument16 pagesCARDAMOMAndre nicholsNo ratings yet

- 8 P's of AirtelDocument10 pages8 P's of Airtelrajat_singlaNo ratings yet

- How To Design and Provision A Production-Ready EKS Cluster: Image Credit: PixabayDocument11 pagesHow To Design and Provision A Production-Ready EKS Cluster: Image Credit: Pixabaycentinel29No ratings yet

- CỤM TỪ VÀ MỆNH ĐỀ CHỈ MỤC ĐÍCHDocument6 pagesCỤM TỪ VÀ MỆNH ĐỀ CHỈ MỤC ĐÍCHHàn HươngNo ratings yet

- Battle RealmsDocument3 pagesBattle RealmsantukaraNo ratings yet

- Dress The CakeDocument5 pagesDress The Cakenyimas genesiaNo ratings yet