Professional Documents

Culture Documents

Burlington Resources Gas Plant: Case Study: Glycol Coolant Filtration March 2006

Burlington Resources Gas Plant: Case Study: Glycol Coolant Filtration March 2006

Uploaded by

jcdavid240 ratings0% found this document useful (0 votes)

35 views1 pageThe document describes a case study of a gas plant that was experiencing frequent failures of diaphragm pumps circulating glycol coolant due to fine ferrous metal contamination in the system. Installing a 1" magnetic Y-strainer on the pump suction side filtered the contamination to submicron levels, resulting in zero pump failures over 12 months and significantly reducing downtime and operational costs.

Original Description:

OEI-114 Burlington 5

Original Title

OEI-114 Burlington 5

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes a case study of a gas plant that was experiencing frequent failures of diaphragm pumps circulating glycol coolant due to fine ferrous metal contamination in the system. Installing a 1" magnetic Y-strainer on the pump suction side filtered the contamination to submicron levels, resulting in zero pump failures over 12 months and significantly reducing downtime and operational costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

35 views1 pageBurlington Resources Gas Plant: Case Study: Glycol Coolant Filtration March 2006

Burlington Resources Gas Plant: Case Study: Glycol Coolant Filtration March 2006

Uploaded by

jcdavid24The document describes a case study of a gas plant that was experiencing frequent failures of diaphragm pumps circulating glycol coolant due to fine ferrous metal contamination in the system. Installing a 1" magnetic Y-strainer on the pump suction side filtered the contamination to submicron levels, resulting in zero pump failures over 12 months and significantly reducing downtime and operational costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

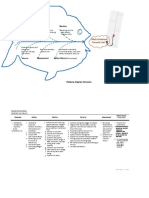

Case Study: Glycol Coolant Filtration Burlington Resources Gas

March 2006 Plant

Clairsholm, Alberta, Canada

APPLICATION: Glycol Coolant Pump

.

PROBLEM: Todd Torrene the

Maintenance Manager was frustrated with

excessive down time due to diaphragm

pump failures. These pumps circulate the

glycol coolant. Todd discovered the pumps

were failing because of excess fine ferrous

metal in the system and the filters

employed were not effective in removing

the metal. On many occasions the pumps

would fail in as little as three weeks after

Photo A

installation.

Photo B Photo C SOLUTION: Install a 1” Magnetic Y-

Strainer (5YB1TA) on the suction side of

the diaphragm pump.

RESULTS: The ferrous metal

contamination was filtered to submicron

levels and after 12 months in service,

Todd had recorded zero pump failures

thereby dramatically reducing pump

component failure and significantly

improving uptime and thus reducing

operational costs.

The contamination is easily removed and

analyzed for component wear identification

allowing predictive maintenance planning.

For further information contact our office or

visit www.OneEyeIndustries.com.

Canadian head office: 4344 – 12 Street SE Calgary, Alberta, T2G 3H9, Canada

Telephone (403) 242-4221 Fax: (403) 242-4249 Toll Free: 1-877-888-TRAP

info@OneEyeIndustries.com

You might also like

- Manual Cat 3606Document1,233 pagesManual Cat 3606jcdavid24100% (7)

- BSI Training Material V2Document61 pagesBSI Training Material V2Nitin AhlawatNo ratings yet

- Assignment 2 (Lighting)Document26 pagesAssignment 2 (Lighting)Hari HaranNo ratings yet

- SOW For Wire Rope Inspection and MaintenanceDocument12 pagesSOW For Wire Rope Inspection and MaintenanceParviz Nasirov100% (2)

- J Stead PaperDocument6 pagesJ Stead PaperixoteeNo ratings yet

- Prevention Solutions For Corrosion Issues in CO2 Removal SystemsDocument7 pagesPrevention Solutions For Corrosion Issues in CO2 Removal SystemsRameshKumarMauryaNo ratings yet

- TB47Kori Nuclear PlantDocument2 pagesTB47Kori Nuclear PlantarlunandaNo ratings yet

- Corrosion Solutions: For Chemical PumpsDocument23 pagesCorrosion Solutions: For Chemical PumpsAnonymous CMS3dL1TNo ratings yet

- Engineering Project in Varroc Chennai 2020-2021Document9 pagesEngineering Project in Varroc Chennai 2020-2021Manjeet Rana100% (1)

- HRSG Cleaning Options Presentation to TSM CustomerDocument61 pagesHRSG Cleaning Options Presentation to TSM CustomerAriel AguilozziNo ratings yet

- Pump Overhaul Prevents Downtime at Amine PlantDocument2 pagesPump Overhaul Prevents Downtime at Amine Plantadamnassir91No ratings yet

- Long Shutdown Management Dr. Pothala Kotewswara Rao ILAMDocument8 pagesLong Shutdown Management Dr. Pothala Kotewswara Rao ILAMP Koteswara RaoNo ratings yet

- Almona PP R Catalog Full PDFDocument29 pagesAlmona PP R Catalog Full PDFFirst LastNo ratings yet

- Port 5Document18 pagesPort 5gbsubbuNo ratings yet

- First PG FR TmdsDocument8 pagesFirst PG FR TmdsdhanarajNo ratings yet

- Failure of Suspension SystemDocument71 pagesFailure of Suspension Systemamit kumar jangdeNo ratings yet

- Feasibility Study - Rewinding of 4MVA Transformer - For SignatureDocument9 pagesFeasibility Study - Rewinding of 4MVA Transformer - For SignatureraudenNo ratings yet

- Audit Observation PDocument23 pagesAudit Observation Pmasthan6y100% (1)

- Philex Ojt Group Report Group 2Document31 pagesPhilex Ojt Group Report Group 2Krist Jan Jimenez SeparaNo ratings yet

- Oil Leakage From BushingDocument1 pageOil Leakage From BushingAshish BiswasNo ratings yet

- Improving Repair Qualitv of Turbine Nozzles Using SA650 Braze AlloyDocument8 pagesImproving Repair Qualitv of Turbine Nozzles Using SA650 Braze AlloywalkerbhoNo ratings yet

- Bad Actor Defect EliminationDocument28 pagesBad Actor Defect EliminationMunazar HussainNo ratings yet

- GE Quality Requirements For Heavy Wind Mill CastingsDocument9 pagesGE Quality Requirements For Heavy Wind Mill CastingsMy Dad My WorldNo ratings yet

- Water Reuse Strategies: Steel Industry Case StudiesDocument15 pagesWater Reuse Strategies: Steel Industry Case StudiesMashaelNo ratings yet

- Case Study Ninl Techno SmileDocument35 pagesCase Study Ninl Techno SmileBibhudutta mishra100% (1)

- Amine-Based Solutions Using A Solvent ResistantDocument8 pagesAmine-Based Solutions Using A Solvent ResistantCharlesNo ratings yet

- BHELDocument26 pagesBHELVishal ChoudharyNo ratings yet

- Maintenance Guide: 7. Filter in Cooling SystemDocument6 pagesMaintenance Guide: 7. Filter in Cooling SystemAnonymous Jw74aayApGNo ratings yet

- Lotte Chemical Titan TITANLENE LDF201FG Low Density PolyethyleneDocument2 pagesLotte Chemical Titan TITANLENE LDF201FG Low Density PolyethyleneMamdouhNo ratings yet

- Compressor Rotor Failure Due To FoulingDocument6 pagesCompressor Rotor Failure Due To FoulingAbdelkader TayebiNo ratings yet

- Frauscher Marcella - 2019 - Capillary GC-EI-MS and Low Energy Tandem MS of Base..Document9 pagesFrauscher Marcella - 2019 - Capillary GC-EI-MS and Low Energy Tandem MS of Base..Leila safiddineNo ratings yet

- PemasangDocument9 pagesPemasangNovy adi syaputra 93No ratings yet

- Case HistoryDocument1 pageCase HistoryJC MexguyNo ratings yet

- Henderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksDocument50 pagesHenderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksRm1262No ratings yet

- Plant Aging and Life Extension Program at Arun LNG Plant Lhokseumawe, North Aceh, IndonesiaDocument13 pagesPlant Aging and Life Extension Program at Arun LNG Plant Lhokseumawe, North Aceh, Indonesiamadhan_kumar2000No ratings yet

- Baldwin Fuel Dahl PDFDocument27 pagesBaldwin Fuel Dahl PDFjack sliverNo ratings yet

- Static Discharge On PTFE-lined Pipework On A Newly Built Plant - pp17-18Document2 pagesStatic Discharge On PTFE-lined Pipework On A Newly Built Plant - pp17-18Soeryanto SlametNo ratings yet

- Siemens PDFDocument10 pagesSiemens PDFejzuppelli8036No ratings yet

- RCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Document3 pagesRCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Vignesh PanchabakesanNo ratings yet

- Ex409 MmeDocument3 pagesEx409 MmeHERY HAKAT CHANELNo ratings yet

- Improving Wastewater Effluent Quality For RecyclingDocument5 pagesImproving Wastewater Effluent Quality For RecyclingInam KhanNo ratings yet

- Turn To Turn Insulation FaultDocument7 pagesTurn To Turn Insulation Faultzarchiwin05No ratings yet

- Fitness For Service Evaluations and Repair of Ammonia Storage Sphere After 25 Years of ServiceDocument9 pagesFitness For Service Evaluations and Repair of Ammonia Storage Sphere After 25 Years of Servicealimirpur100% (1)

- Getting The Best From Your Rover 75 / MGZT / Freelander Td4 (2L)Document2 pagesGetting The Best From Your Rover 75 / MGZT / Freelander Td4 (2L)davidNo ratings yet

- Supplier Technical Audit Report Example GMRDocument8 pagesSupplier Technical Audit Report Example GMRMohammad Faraz AkhterNo ratings yet

- Filtration Fact: Contamination BasicsDocument2 pagesFiltration Fact: Contamination BasicsApurv GoyalNo ratings yet

- Blackpowder PDFDocument2 pagesBlackpowder PDFDavood BarzegariNo ratings yet

- SPARKDocument49 pagesSPARKBibhudutta MishraNo ratings yet

- Breaker Maintenance and Common Failure Modes NWsu07 WhiteDocument8 pagesBreaker Maintenance and Common Failure Modes NWsu07 WhiteTruong HungNo ratings yet

- Success Story PresentationDocument18 pagesSuccess Story PresentationHARVENDRA9022 SINGHNo ratings yet

- Flow-Induced Fatigue Failure in Tubular Heat ExchangersDocument7 pagesFlow-Induced Fatigue Failure in Tubular Heat ExchangersVelpandian ManiNo ratings yet

- Admixture Technical Sheet - ATS 4 Accelerating AdmixturesDocument4 pagesAdmixture Technical Sheet - ATS 4 Accelerating Admixturesmehrdad_so1981No ratings yet

- 5.1 KATALOG Toray - TM800M - v1 - 202201Document2 pages5.1 KATALOG Toray - TM800M - v1 - 202201Diana SulardiNo ratings yet

- Aim m8 Solder Paste Rev 8Document4 pagesAim m8 Solder Paste Rev 8彭以和No ratings yet

- Toyota Prius C 2012 - 14 (Halogen & LED) Part Number: TPC-312 / TPC-812Document10 pagesToyota Prius C 2012 - 14 (Halogen & LED) Part Number: TPC-312 / TPC-812Bill ChinNo ratings yet

- Baldwin DahlDocument20 pagesBaldwin DahlBayu Silo TrenggonoNo ratings yet

- 6M - RCA Cond Vac DerationDocument2 pages6M - RCA Cond Vac DerationInja Victoria ManawataoNo ratings yet

- Intra PresentationDocument21 pagesIntra PresentationAin TieyNo ratings yet

- Licentiate Thesis Presentation - 3Document24 pagesLicentiate Thesis Presentation - 3Ramsey JadimNo ratings yet

- Project A Case Study SlideDocument16 pagesProject A Case Study SlideAkmal IsyrafNo ratings yet

- 11 PDFDocument236 pages11 PDFjuanmalegreNo ratings yet

- 02810-Irrigation SystemDocument13 pages02810-Irrigation SystemAhmed HussienNo ratings yet

- Electrochemical Surface Modification: Thin Films, Functionalization and CharacterizationFrom EverandElectrochemical Surface Modification: Thin Films, Functionalization and CharacterizationNo ratings yet

- TC1 4-Channel Digital Thermocouple Pyrometer Users Manual - 1Document15 pagesTC1 4-Channel Digital Thermocouple Pyrometer Users Manual - 1jcdavid24No ratings yet

- 2 - Transmisor de Temperatura FOXBORO RTT80 PDFDocument32 pages2 - Transmisor de Temperatura FOXBORO RTT80 PDFjcdavid24No ratings yet

- G 3600Document60 pagesG 3600DiyaNegiNo ratings yet

- 130P ITT Pressure SwitchsDocument2 pages130P ITT Pressure Switchsjcdavid24No ratings yet

- 130P ITT Pressure SwitchsDocument2 pages130P ITT Pressure Switchsjcdavid24No ratings yet

- SimulationDocument2 pagesSimulationAbhiraj RoyNo ratings yet

- Your Palletizing SolutionDocument8 pagesYour Palletizing SolutionKien Nguyen TrungNo ratings yet

- 2010 APhO Experimental Question 2 - SolutionDocument12 pages2010 APhO Experimental Question 2 - SolutionSiddharth AcharyaNo ratings yet

- Inventor Add-In Using C++ - CLR - Manufacturing DevBlogDocument3 pagesInventor Add-In Using C++ - CLR - Manufacturing DevBlogVitorHugoNo ratings yet

- CHAPTER 6 Bearings UpdatedDocument26 pagesCHAPTER 6 Bearings UpdatedMuhammad Azrul100% (1)

- BG 2000 SFDocument43 pagesBG 2000 SFdbricchiNo ratings yet

- 12 Pavement ManagementDocument20 pages12 Pavement ManagementFranklinNo ratings yet

- Root Mean SquareDocument3 pagesRoot Mean SquaresenthilanviewNo ratings yet

- INVERTER - AC Tonnage Calculator - All IndiaDocument37 pagesINVERTER - AC Tonnage Calculator - All Indiajkahamed0% (1)

- Multiband Multivendor U900 U2100 Layering Strategy v2Document17 pagesMultiband Multivendor U900 U2100 Layering Strategy v2Anonymous GNQg2TNo ratings yet

- Brooke CromptonDocument24 pagesBrooke Cromptond3xterNo ratings yet

- Base Plate Design (Fixed Base)Document3 pagesBase Plate Design (Fixed Base)Saravana NNo ratings yet

- Good Practice For Atmospheric Dispersion ModellingDocument152 pagesGood Practice For Atmospheric Dispersion ModellingMartin DelfinNo ratings yet

- UNO-2174 2178 Manual Ed4Document44 pagesUNO-2174 2178 Manual Ed4sonali_sadhukhan88No ratings yet

- Advert - Underground Rig Mechanic - 220507 - 190152Document2 pagesAdvert - Underground Rig Mechanic - 220507 - 190152ChelseaNo ratings yet

- Ta Nung Homestay Executive OfficeDocument11 pagesTa Nung Homestay Executive OfficeIrwan SugiartoNo ratings yet

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- LG Plasma TV Training & RepairDocument74 pagesLG Plasma TV Training & RepairErbmit100% (1)

- JFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisDocument1 pageJFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisIndra Nath MishraNo ratings yet

- MVAA11 CortecDocument652 pagesMVAA11 CortecBalaKamarajNo ratings yet

- Relativity QuestionsDocument4 pagesRelativity QuestionsChristoph KirchNo ratings yet

- Erco 35410 023 en Us SpecsDocument4 pagesErco 35410 023 en Us SpecslovetranceNo ratings yet

- Resume Gaurav NarulaDocument1 pageResume Gaurav Narulaapi-297740187No ratings yet

- Disclosure To Promote The Right To InformationDocument24 pagesDisclosure To Promote The Right To InformationIndira BanerjeeNo ratings yet

- Pico Hydro Power GenerationDocument6 pagesPico Hydro Power Generationdinesh sharmaNo ratings yet

- User Guide Gpec 2012 1Document27 pagesUser Guide Gpec 2012 1João GuilhermeNo ratings yet

- Experiment in Basics of Electronic TechnologyDocument13 pagesExperiment in Basics of Electronic TechnologyMehedi HasanNo ratings yet