Professional Documents

Culture Documents

7-Point Ocean Container Security Inspection Guide

7-Point Ocean Container Security Inspection Guide

Uploaded by

Geroldo 'Rollie' L. QuerijeroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7-Point Ocean Container Security Inspection Guide

7-Point Ocean Container Security Inspection Guide

Uploaded by

Geroldo 'Rollie' L. QuerijeroCopyright:

Available Formats

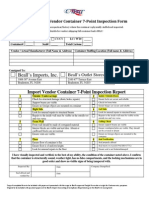

7-Point Ocean Container Security Inspection Guide

Conduct 7-point interior and exterior inspection of ISO

ocean container to verify the physical integrity prior to

loading. Document container results and keep with

shipping records. Reject containers that do not

pass the 7-Point Inspection criteria.

Reference back for additional

inspection criteria information.

Outside and Undercarriage

Before allowing the container to

enter the facility, inspect undercarriage

and outside of container. Use a mirror

to access hard-to-see areas.

Left and Right Sides

Inspect internal and external surfaces, including

structural beams. Use a tool to tap side walls –

listen and feel for hollow, metal sound. All walls,

ceiling, and doors should be metal.

Undercarriage support beams

should be visible; solid plates

should not cover the beams.

Doors – Outside and Inside

Any repairs on the inside must be also visible

Ensure locking mechanisms are secure and in

on the outside. Blocks and vents (9 holes)

good working order. There should be ribs on the inside container must be visible and

interior sides of each door; solid plates should not appropriately spaced (see above picture).

cover standard interior door cavities.

Front Wall

Inspect front wall, making sure vents and blocks

are visible and appropriately spaced. Measure

interior and exterior with a tape measure, range

finder or string. Container should be exact to

specifications.

Look for different color bonding material, loose

bolts, new and worn metals on same device.

Doors should seal completely when closed.

Look for different wall colors and blocks that are too

close to the vents. Use a tool to tap front wall – you

Ceiling & Roof should hear a hollow, metal sound.

Inspect external roof and internal ceiling, including

structural beams. Use tool to tap – you should hear a

metal, hollow sound. If unable to see roof of Interior Floor

container, use ladder or a mirror attached to a pole.

Inspect floor for unusual repairs. Floor should be flat

and one height. Measure floor to ceiling with a tape

measure, range finder or piece of wood. Container

should be exact to specifications.

false compartments

You should not need to

step up from edge of

container to get inside;

Any weld repairs on the inside must be also be visible there should be no steps

on the outside. Watch for unusual welding or repair on or raised platforms inside

support beams. False compartments are common in container.

ceilings, beams, floors, doors, and the front wall.

Ocean Container Defect Reference Guide

Every precaution should be taken to ensure proper inspections. Use your experience and judgment when inspecting

ocean containers (ISO standard) to determine whether or not they are suitable for shipments. Please note that

graffiti or inappropriate messaging on the interior of containers is not acceptable.

Minor to moderate blemishes and damage are acceptable and considered normal. Look for structural defects that

jeopardize the safety and security of people loading and unloading containers and those that compromise the

integrity of the products being transported (see example photographs below):

–Significantly bent / bowed posts, support beams or broken welds

–Door hardware in poor condition or working order that prevents seal and locking integrity

–Holes that allow light or external weather conditions into container

–Infestation, mold or residual cargo debris / dirt

–Condensation / standing water or wet floors

–Persistent odor or physical reaction such as watering eyes or coughing

–Defaced container markings or interior graffiti / inappropriate messaging

Please note that Illegal contraband can be stored in modified pallets, hidden within products or among boxes and

can also simply be added to a shipment in a box, bag or other receptacle.

hole in door

broken locking broken structural

bar guide beam weld

defaced markings

infestation

j-bar bent causing

seal and structural

support post integrity issues

bowed Interior graffiti /

inappropriate messaging

Cargo container doors should seal completely and securely when shut. The container should be light-tight, which

will also prevent entry of any external elements into the container while in transit. To ensure a satisfactory light-

tight seal, you can conduct a light test by observing the seal performance from inside a closed container. In

addition, all door locking hardware (hasps, hinges, handles, bars, bolts, etc.) must be tested and be in good

working order (see below diagram).

When contracting with third party trucking companies to transport cargo, you must ensure that those organizations

also inspect ocean containers and the vehicles (truck / tractor trailer) prior to delivering equipment to you. Please

access the below link to the U.S. Customs & Border Protection website for a complete list of inspection criteria for

truck / tractor trailers.

http://www.customs.gov/xp/cgov/import/commercial_enforcement/ctpat/security_criteria/hwy_carrier_criteria/hwy_carrier_criteria.xml

Source: International Chamber of Shipping and Institute of International Container Lessors, Ltd.

You might also like

- CTPAT 7-Point Container Seal Inspection ChecklistDocument3 pagesCTPAT 7-Point Container Seal Inspection ChecklistKartika Wulandari100% (4)

- Unified Container Inspection and Repair CriteriaDocument4 pagesUnified Container Inspection and Repair CriteriaPaulo Dias100% (3)

- ISO Container Inspection ChecklistDocument14 pagesISO Container Inspection Checklistioanrosky100% (2)

- Container ChecklistDocument1 pageContainer Checklistzahid_497100% (1)

- Usdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideDocument2 pagesUsdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideMohd Shahrul Irwan Mohd ZinNo ratings yet

- Container ChecklistDocument1 pageContainer ChecklistMuthu Kumar100% (1)

- Parl List TKDocument4 pagesParl List TKJosé Chancafe Angeles100% (1)

- Ctpat Container Inspection Procedures PDFDocument102 pagesCtpat Container Inspection Procedures PDFDavidNo ratings yet

- Wire Rope SpecificationDocument15 pagesWire Rope Specificationfarichtape channel100% (1)

- Category: Grading Rubric For Storyboard ProjectDocument1 pageCategory: Grading Rubric For Storyboard ProjectRyan EstonioNo ratings yet

- Mumbai CxoDocument9 pagesMumbai CxopoonamNo ratings yet

- Escaid High Performance Base Fluids LR PDFDocument4 pagesEscaid High Performance Base Fluids LR PDFLê CôngNo ratings yet

- CTPAT 7-Point Container Inspection ChecklistDocument14 pagesCTPAT 7-Point Container Inspection ChecklistAshley100% (1)

- Beall's Imports, Inc.: Beall's Import Vendor Container 7-Point Inspection FormDocument1 pageBeall's Imports, Inc.: Beall's Import Vendor Container 7-Point Inspection FormbgaldamezNo ratings yet

- ContainerDocument25 pagesContainersrushtimohapatra100% (2)

- Container Spare Part CatalogueDocument66 pagesContainer Spare Part CatalogueKrishna TiruvedulaNo ratings yet

- Dry Van ManualDocument129 pagesDry Van ManualDenis SilvaNo ratings yet

- 7 Point Container InspectionDocument1 page7 Point Container InspectionDang Minh Huong100% (1)

- Container Damage ReportDocument1 pageContainer Damage ReportTeremetskyNo ratings yet

- 2016 Container Information BulletinDocument14 pages2016 Container Information Bulletinacere18No ratings yet

- Guidelines On Certification of Containers - Rev 0 - April 2021Document60 pagesGuidelines On Certification of Containers - Rev 0 - April 2021Sagar PanditNo ratings yet

- Diptico Container SpreadersDocument4 pagesDiptico Container Spreadersmkfe2005No ratings yet

- 02 - Standard Container Inspection Criteria - 02-2019Document8 pages02 - Standard Container Inspection Criteria - 02-2019Beatrix KiddoxNo ratings yet

- BB-Shipping Container Manual (REV B) PDFDocument15 pagesBB-Shipping Container Manual (REV B) PDFAntonio Ruiz TroyanoNo ratings yet

- Cross MemberDocument4 pagesCross Memberbrenmcs2010No ratings yet

- 8 Point Container Inspection Checklist: Location of Container SecureDocument3 pages8 Point Container Inspection Checklist: Location of Container SecureCarlos Moreno100% (2)

- Sample Inspection ReportDocument3 pagesSample Inspection ReportUzair DanishNo ratings yet

- Brochure Container Specification enDocument4 pagesBrochure Container Specification enNidai IlkayNo ratings yet

- YM Cargo WorthyDocument109 pagesYM Cargo WorthyHoan Vu100% (1)

- Shipping Container Structural Components and TerminologyDocument5 pagesShipping Container Structural Components and TerminologyJohn Rheynor MayoNo ratings yet

- Brochure Sany Empty Container HandlerDocument14 pagesBrochure Sany Empty Container HandlerMuhammad IqbalNo ratings yet

- 07412.May2017.Exam PaperDocument13 pages07412.May2017.Exam PaperSasidharan RajendranNo ratings yet

- InspectionStandards Triton Inspection Standards WebDocument2 pagesInspectionStandards Triton Inspection Standards WebTo Ze100% (1)

- Maersk Line Container Equipment Guide PDFDocument4 pagesMaersk Line Container Equipment Guide PDFfahrie_manNo ratings yet

- BOWEN Storage CH1 PalletrackingDocument34 pagesBOWEN Storage CH1 PalletrackingMnttoMecNo ratings yet

- Safety Harness Inspection Checklist-1Document1 pageSafety Harness Inspection Checklist-1Martine OtienoNo ratings yet

- HLL Container Specification Engl PDFDocument54 pagesHLL Container Specification Engl PDFSzilárd SzabóNo ratings yet

- Trailer Stands & Jacks: Ez-Riser Trailer StandDocument2 pagesTrailer Stands & Jacks: Ez-Riser Trailer StandRyan100% (1)

- TB-002 EDIS February 2003Document51 pagesTB-002 EDIS February 2003JavoB85No ratings yet

- Intertek Turkiye Bitumen Tests 2022Document1 pageIntertek Turkiye Bitumen Tests 2022Mehmet özelNo ratings yet

- Shipping Container Structural Components and TerminologyDocument5 pagesShipping Container Structural Components and TerminologyEbay BoyNo ratings yet

- Container HandbookDocument49 pagesContainer HandbookdivyeshmodyNo ratings yet

- Safety and Storage Solutions LowResDocument188 pagesSafety and Storage Solutions LowResRafael Alejandro Vargas Giron100% (1)

- 6 - 21 APRIL 2019: Test Information BulletinDocument11 pages6 - 21 APRIL 2019: Test Information BulletinSasidharan RajendranNo ratings yet

- Shipping Container ReportDocument12 pagesShipping Container ReportThe London Free Press100% (1)

- Amendments Table Depot 5 A N Rev2Document13 pagesAmendments Table Depot 5 A N Rev2nndungNo ratings yet

- PackagingDocument9 pagesPackagingRag LakNo ratings yet

- IICL 6 Measurement Technique PDFDocument16 pagesIICL 6 Measurement Technique PDFJackNo ratings yet

- Co2dh20 - 22B - 204 - IsocontenedorDocument5 pagesCo2dh20 - 22B - 204 - IsocontenedorLuis CortezNo ratings yet

- 7 Point Container InspectionDocument1 page7 Point Container InspectionAkash PandyaNo ratings yet

- Skip Waste06Document6 pagesSkip Waste06Moath M. KassabNo ratings yet

- Cargo Container RegulationsDocument152 pagesCargo Container RegulationsMARKANTHONY1979100% (1)

- 2-Stage Mast: MaintenanceDocument80 pages2-Stage Mast: MaintenanceRex PereiraNo ratings yet

- Kelley Dock Planning StandardsDocument30 pagesKelley Dock Planning Standardsclamavi100% (1)

- TB 003 Finger CracksDocument2 pagesTB 003 Finger CracksLe Cuong Thinh100% (1)

- SafewayDocument70 pagesSafewayhampshireiiiNo ratings yet

- Dry Van Test SimulationDocument41 pagesDry Van Test Simulationsahil josephNo ratings yet

- CSC ACEP Inspection GuideDocument7 pagesCSC ACEP Inspection GuideJackNo ratings yet

- Hamburg Sud Reefer - GuideDocument48 pagesHamburg Sud Reefer - GuideJack100% (1)

- 7-Point Security Inspection Guide PDFDocument1 page7-Point Security Inspection Guide PDFLoan HuynhNo ratings yet

- 7-Point Ocean Container Security Inspection GuideDocument2 pages7-Point Ocean Container Security Inspection GuideEngr Malik100% (1)

- 7 Point Container Inspection ChecklistDocument1 page7 Point Container Inspection ChecklistAshraful Haider (Suman)No ratings yet

- CTPAT 7 - Point Container Seal Inspection ChecklistDocument3 pagesCTPAT 7 - Point Container Seal Inspection ChecklistFriska Devi Mella Nurita67% (3)

- Adc With No Adc PDFDocument10 pagesAdc With No Adc PDFGeroldo 'Rollie' L. QuerijeroNo ratings yet

- NSH 7 Element 2 Meter Beam AntennaDocument3 pagesNSH 7 Element 2 Meter Beam AntennaGeroldo 'Rollie' L. QuerijeroNo ratings yet

- 5 To 30 Minute Timer Descriptipn: Circuit DiagramDocument2 pages5 To 30 Minute Timer Descriptipn: Circuit DiagramGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Logic Level Mosfet v1 00Document13 pagesLogic Level Mosfet v1 00Geroldo 'Rollie' L. QuerijeroNo ratings yet

- RA 10173 With CommentsDocument7 pagesRA 10173 With CommentsGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Risk and OpportunityDocument2 pagesRisk and OpportunityGeroldo 'Rollie' L. QuerijeroNo ratings yet

- GuitarNuts 00Document13 pagesGuitarNuts 00Geroldo 'Rollie' L. QuerijeroNo ratings yet

- Siege of Baler-Fictional VersionDocument4 pagesSiege of Baler-Fictional VersionGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Fender Stratocaster - Shielding For Hum ReductionDocument6 pagesFender Stratocaster - Shielding For Hum ReductionGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Thermometer CalibrationDocument8 pagesThermometer CalibrationGeroldo 'Rollie' L. Querijero100% (1)

- Irrigation DENRDocument32 pagesIrrigation DENRGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Global Warming PotentialsDocument2 pagesGlobal Warming PotentialsGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Environmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Document50 pagesEnvironmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Geroldo 'Rollie' L. QuerijeroNo ratings yet

- Contemporary Music in The Philippines Usually Refers To Compositions That Have Adopted Ideas and Elements From Twentieth Century Art Music in The WestDocument4 pagesContemporary Music in The Philippines Usually Refers To Compositions That Have Adopted Ideas and Elements From Twentieth Century Art Music in The WestGeroldo 'Rollie' L. Querijero67% (3)

- United States Court of Appeals, Eleventh CircuitDocument52 pagesUnited States Court of Appeals, Eleventh CircuitScribd Government DocsNo ratings yet

- Labor UnionDocument16 pagesLabor UnionRZ RosalNo ratings yet

- TAX Calalang v. LorenzoDocument3 pagesTAX Calalang v. LorenzoAnathea CadagatNo ratings yet

- Ynatrwl Nonannexure2022augm25 5532078444 8661400943Document4 pagesYnatrwl Nonannexure2022augm25 5532078444 8661400943INSIGNIA LABS - DATANo ratings yet

- 1 s2.0 S0160738323001846 MainDocument4 pages1 s2.0 S0160738323001846 Mainussual humanNo ratings yet

- Annotated BibliographyDocument4 pagesAnnotated Bibliographyapi-302549909No ratings yet

- Goldfarb School of Nursing at Barnes-Jewish College Textbooks - Summer 2020Document6 pagesGoldfarb School of Nursing at Barnes-Jewish College Textbooks - Summer 2020brad0% (1)

- Copy Machine Study Ellen LangerDocument8 pagesCopy Machine Study Ellen Langerstu2001stu2001No ratings yet

- Adv Unit8 RevisionDocument3 pagesAdv Unit8 RevisionDivi DaviNo ratings yet

- 2014 SIM Annual Report Print FriendlyDocument73 pages2014 SIM Annual Report Print Friendlyzaid chaudry1No ratings yet

- Idoc - Pub Magic Sing Et25k Song List EnglishDocument30 pagesIdoc - Pub Magic Sing Et25k Song List EnglishFlorentino EsperaNo ratings yet

- A Review of Our Present Situation - Sirdar Kapur SinghDocument2 pagesA Review of Our Present Situation - Sirdar Kapur SinghSikhDigitalLibraryNo ratings yet

- University Day 2018Document16 pagesUniversity Day 2018jackbull321No ratings yet

- L'Altra Montessori School Inc.,: High School Department First Periodical Exam Technology and Livelihood Education 9Document4 pagesL'Altra Montessori School Inc.,: High School Department First Periodical Exam Technology and Livelihood Education 9Kristine HensonNo ratings yet

- CHN Transes Week 1Document5 pagesCHN Transes Week 1cheskalyka.asiloNo ratings yet

- Lesson Exemplar School Grade Level Teacher Learning Area Practical Research 2 Teaching Date Quarter Teaching Time No. of DaysDocument9 pagesLesson Exemplar School Grade Level Teacher Learning Area Practical Research 2 Teaching Date Quarter Teaching Time No. of DaysJovie Bitas DaeloNo ratings yet

- Biochemical Characterization of Blood Orange, Sweet OrangeDocument7 pagesBiochemical Characterization of Blood Orange, Sweet Orangehociner06No ratings yet

- Unit 10: Sitcom: Tonight, I'm CookingDocument3 pagesUnit 10: Sitcom: Tonight, I'm CookingDaissy FonsecaNo ratings yet

- MPLS Segment RoutingDocument60 pagesMPLS Segment RoutingDúber PérezNo ratings yet

- Lessonplans Self ProtectionDocument6 pagesLessonplans Self ProtectionteacherasyikinNo ratings yet

- Stolen by The Sinner Russian Torpedo Book 1 Hayley Faiman All ChapterDocument67 pagesStolen by The Sinner Russian Torpedo Book 1 Hayley Faiman All Chapterjoshua.sweat158100% (4)

- Sean Combs v. All Surface Entertainment, Inc., Cancellation No. 92051490 (T.T.A.B. 2012) (DIRTY MONEY)Document21 pagesSean Combs v. All Surface Entertainment, Inc., Cancellation No. 92051490 (T.T.A.B. 2012) (DIRTY MONEY)Charles E. ColmanNo ratings yet

- Saeed Elseddig 4110 XA Paper 4Document16 pagesSaeed Elseddig 4110 XA Paper 4ShiawaNo ratings yet

- The Ethical Implications of Genetic Engineering in Humans - Balancing Progress With ResponsibilityDocument4 pagesThe Ethical Implications of Genetic Engineering in Humans - Balancing Progress With Responsibilitymdabdulhannan018506No ratings yet

- E-Vehicle Article FinalDocument22 pagesE-Vehicle Article Finalvishnu varthanNo ratings yet

- CHEM 101 Chapter 2Document78 pagesCHEM 101 Chapter 2mikayla sirovatkaNo ratings yet

- Twelve Tips For The Effective Use of Videos in Medical EducationDocument6 pagesTwelve Tips For The Effective Use of Videos in Medical EducationRamón Ruesta Berdejo0% (1)