Professional Documents

Culture Documents

HP and LP Dosing Manual - Metapow

HP and LP Dosing Manual - Metapow

Uploaded by

Saibabu Sai0 ratings0% found this document useful (0 votes)

145 views3 pagesHp and lp dosing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHp and lp dosing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

145 views3 pagesHP and LP Dosing Manual - Metapow

HP and LP Dosing Manual - Metapow

Uploaded by

Saibabu SaiHp and lp dosing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

MANUFACTURER OF :- METAPOW

SUGAR MACHINERY INDUSTRIES

PROCESS EQUIPMENTS:

BOILER ACCESSORIES, SUC HAS

DEAERATORS, OPHUNITS,

DOSING SYSTEMS,

W-1G3, ‘S" BLOCK MLLD.C. BHOSARI, PUNE-411 026. PH. & FAX 7120388, Email. —

metapowind @vsnl.net

CONTENTS

1) TECHNICAL SPECIFICATION

2) INSTALATION AND COMMISSIONING

3) PREVENTIVE MAINTENANCE

@)

METAPOW

MANUFACTURER OF

SUGAR MACHINERY INDUSTRIES

PROCESS EQUIPMENTS.

BOILER ACCESSORIES, SUC HAS

DEAERATORS, OPHUNITS,

DOSING SYSTEMS,

W-i43, ‘ BLOCK M.LD.C. BHOSARI, PUNE-411 026. PH. & FAX 7120388, Email.

metapowind @vsnl.net

INSTRUCTION MANUAL

CHEMICAL DOSING SYSTEM

CHEMICAL DOSING SYSTEM CONSIST OF CHEMICAL DOSING TANK WITH OR

\WITHOUTMOTORISED AGITATOR. TWO NUMBER METERING PUMP WITH ELECTRIC

MOTOR (ONE. STANDBY )

ALL PIPING ARE IN SS'304/SA 106 GRB WITH BALL VALVE, COMPLETE UNIT IS.

MOUNTED ON BASE FRAME.

CHEMICAL DOSING SYSTEM ARE REQUIRED TO MAINTAIN WATER QUALITY

[AT DESIVABLE DEGREE.

1) H. P, DOSING SYSTEM

‘TRIDOSIUM PHOSPHATE IS TO BE IN BOLIER DRUM TO MINIMISE

DEPOSITION OF HARD SCALE, NOT TO AFFECT THE HEAT TRANSFER

2) L. P. DOSING SYSTEM

‘SODIUM SULPHITE OR HYDRAZINE IS USED FOR TRACED OXYGEN

REMOVEL FROM BOILER FEED WATER IN DEAERATOR

INSTRUCTION BEFORE PUT INTO OPERATION :

1) CHECK OIL QUANTITY IN PUMPS FILL THE PUMPS UPTO THE MARKING OIL TO BE USED.

‘8) INDIAN O1L 'SERAMECH 460

B) HINDUSTAN PETROLIUM- ~ ENKLO 460

© BHARATPETROLIUM. ~ HYDROL 480

= BHARAT CABLE 460

2) SET THE STROKE ADJUSTMENT AT THE MINIUM SETTING.

3) SOLUTION OUTLET VALVE & PUMP INLET VALVES SHOULD BE IN OPEN POSITION.

4) ELECTRIC MOTOR CONNECTION ARE TO BE MADE.

5) PUMP ROTATED IN DIRECTION INDICATED ON PUMP.

6} START THE PUMP, RUN FOR SINUTE OBSERVE RUNNING PROPERLY, WITHOUT ANY.

NOISE, RUN FOR 10-20 MINUTES SET THE STROKE FOR $0% RUN FOR 10-20 MINUTES.

OBSERVE PRESSURE GAUGE SETTING AND PRV SETTING.

1) AGITATOR =

START THE AGITATOR BEFORE PUMP STARTS, SEE THE ROTATION OF AGITATOR,

DIRECTION MARKED ON AGITATOR BODY. OBSERVE SOME PERIOD & PUT COMPLETE,

UNIT ON OPERATION. DO.NOT RUN AGITATOR DRY, SOLUTION IN TANK SHOULD BE

MINIUM 3/4 NORMAL WATER LEVEL

MANUFACTURER OF METAPOW

SUGAR MACHINERY INDUSTRIES

PROCESS EQUIPMENTS

BOILER ACCESSORIES, SUC HAS

DEAERATORS, OPHUNITS,

DOSING SYSTEMS,

ment’ 'S' BLOCK M.LD.C. BITOSART, PUNE-AII 026, FL FAX 7120388, Email.

metapowind @vsni.net

COMISSIONING

A) CHECK LIST BEFORE COMMISSIONING.

2) OILIN PUMP - LEVEL OF OWL SHOULD BE UP TO-THE MARK

2) COUPLING - GRUB scREW TIGHTENED

3) GREASING FoR AGITATOR BEARING

4) ALLBOILTS ARE TIGHTENED

8) ELECTRICAL CONNECTIONS To BE CHECKED FoR MOTORS

OPEN THE WATER INLET VALVE. PUT WATER INTHE TANK WITH CHEMICALS

(© START THE PUMP WICH ISTO BE PLT INTO OPERRATIONS Ste THE DIRECTION

OF PUMP 1S CORRECT AS PER MARKING.

P) START THE AGITATOR, SEE THE DIRECTION OF ROTATION AS PER MARKING.

DO NOT REN THE AGITATOR DRY.

MAINTENCE :-

FOR PUMPS AND AGITATOR REFER INSTRUCTION MANUALS ENCLOSED,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Parada Saibabu: LTD.), Vizianagaram, Andhrapradesh. Job Role-As A Desk Engineer For IR-CFBC BoilerDocument2 pagesParada Saibabu: LTD.), Vizianagaram, Andhrapradesh. Job Role-As A Desk Engineer For IR-CFBC BoilerSaibabu SaiNo ratings yet

- Cause and Prevention For Steam Turbine Blade Scaling & FoulingDocument10 pagesCause and Prevention For Steam Turbine Blade Scaling & FoulingSaibabu SaiNo ratings yet

- Parada Saibabu: Career Objective Professional ExperienceDocument2 pagesParada Saibabu: Career Objective Professional ExperienceSaibabu SaiNo ratings yet

- FORGED - Gate, Globe & Check Valve Manual - Xomox SanmarDocument20 pagesFORGED - Gate, Globe & Check Valve Manual - Xomox SanmarSaibabu SaiNo ratings yet

- Burner ManualDocument23 pagesBurner ManualSaibabu Sai100% (1)

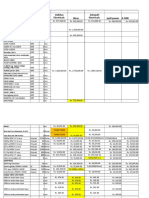

- Content Make Qty Unit Ideas Jyoti Power A-ONE Vaibhav Electricals Sahyadri ElectricalsDocument18 pagesContent Make Qty Unit Ideas Jyoti Power A-ONE Vaibhav Electricals Sahyadri ElectricalsSaibabu SaiNo ratings yet