Professional Documents

Culture Documents

Conventional Milling vs. Climb Milling

Conventional Milling vs. Climb Milling

Uploaded by

Nisar HussainCopyright:

Available Formats

You might also like

- Drilling ProcessDocument15 pagesDrilling ProcessAl Fredo95% (21)

- Getting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsFrom EverandGetting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsRating: 1 out of 5 stars1/5 (1)

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerFrom EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerRating: 4 out of 5 stars4/5 (1)

- Conventional Milling vs. Climb Milling: Technical ResourcesDocument1 pageConventional Milling vs. Climb Milling: Technical ResourcesAnonymous rweAHdNytyNo ratings yet

- Climb Milling vs. Conventional MillingDocument3 pagesClimb Milling vs. Conventional MillingM Aldityawan SyahputraNo ratings yet

- Advanced Cadcam Exam1 ReviewDocument7 pagesAdvanced Cadcam Exam1 Reviewapi-236166548No ratings yet

- Report NewDocument35 pagesReport NewSam DenishNo ratings yet

- Machining Methods PDFDocument13 pagesMachining Methods PDFMostarchinaNo ratings yet

- CNC MachiningDocument4 pagesCNC MachiningAdrianNo ratings yet

- 072 DEW Werkstoffauswahl Kaltarbeit GBDocument40 pages072 DEW Werkstoffauswahl Kaltarbeit GBFebrian JhaNo ratings yet

- Rake Angles: Negative-PositiveDocument5 pagesRake Angles: Negative-PositivekhareprafullNo ratings yet

- TDD-Metal Cutting & Special ToolsDocument27 pagesTDD-Metal Cutting & Special ToolsGS RathoreNo ratings yet

- Tech ClimbVsConventionalMillingDocument1 pageTech ClimbVsConventionalMillinglambrosNo ratings yet

- Up and Down MillingDocument5 pagesUp and Down MillingranerxNo ratings yet

- ITS Techpage-Conventional V Climb MillingDocument2 pagesITS Techpage-Conventional V Climb MillingAnkitPatel90No ratings yet

- Ch3 - Metal CuttingDocument30 pagesCh3 - Metal Cutting03 ABHISHEKNo ratings yet

- BMM3643 Milling Machining-1Document26 pagesBMM3643 Milling Machining-1Sarah AqirahNo ratings yet

- Manufacturing of An Indexing Jig Operated by Lever MechanismDocument7 pagesManufacturing of An Indexing Jig Operated by Lever MechanismInternational Journal of Engineering and TechniquesNo ratings yet

- L9 - Types of ChipsDocument36 pagesL9 - Types of Chipsudyadav3490No ratings yet

- Sheet Production TechnologyDocument23 pagesSheet Production TechnologyOmar AlyNo ratings yet

- Lecture2-Metalcutting 2Document40 pagesLecture2-Metalcutting 2girma workuNo ratings yet

- L11 - Types of ChipsDocument36 pagesL11 - Types of ChipsAditya AdityaNo ratings yet

- Upmilling Vs DownmillingDocument4 pagesUpmilling Vs DownmillingSaurabh BiswasNo ratings yet

- Problems of Clamping Rotary Tools: Jaroslav Kunstfeld, Josef BrychtaDocument4 pagesProblems of Clamping Rotary Tools: Jaroslav Kunstfeld, Josef BrychtaMaid GanjgoNo ratings yet

- Broaching - Sawing ProcessesDocument33 pagesBroaching - Sawing ProcessesashutoshNo ratings yet

- CHAPTER 3 - Lathe MachineDocument26 pagesCHAPTER 3 - Lathe MachineHarish Nagoor NahooranNo ratings yet

- Chip Formation: Manufacturing Technology-IiDocument20 pagesChip Formation: Manufacturing Technology-IiSachin BharadwajNo ratings yet

- Grinding Operations and Finishing Micro Milling: Competitive Manufacturing Processes (MCEN 3003)Document48 pagesGrinding Operations and Finishing Micro Milling: Competitive Manufacturing Processes (MCEN 3003)AntonyNo ratings yet

- Krishna Engineering College Department of Mechanical EngineeringDocument4 pagesKrishna Engineering College Department of Mechanical EngineeringVivek BajpaiNo ratings yet

- T&D - Core 4 Tool & DieDocument44 pagesT&D - Core 4 Tool & Dietisha revillaNo ratings yet

- Class Notes ManufacturingDocument13 pagesClass Notes ManufacturingRajangam VeeruchinnanNo ratings yet

- 3 Types of ChipsDocument35 pages3 Types of ChipsDhananjay SharmaNo ratings yet

- Difference Between Up Milling and Down MillingDocument4 pagesDifference Between Up Milling and Down MillingT. VeerabhadraiahNo ratings yet

- 4 Types of Chips-1Document35 pages4 Types of Chips-1Kishan KashyapNo ratings yet

- Hard Coating of Tool-Report PDFDocument43 pagesHard Coating of Tool-Report PDFRam TejaNo ratings yet

- FIA - Forging Facts - How Ar..Document6 pagesFIA - Forging Facts - How Ar..George CharitouNo ratings yet

- Sheet Metal OperationsDocument33 pagesSheet Metal Operationsziad almnaseerNo ratings yet

- Dawit SolomonDocument24 pagesDawit Solomondawit solomonNo ratings yet

- Cutting Force NoteDocument6 pagesCutting Force NotemtdestaNo ratings yet

- MCTDDocument28 pagesMCTDDHRUV SINGHALNo ratings yet

- 4 Types of ChipsDocument33 pages4 Types of Chipskagarwal3be23No ratings yet

- Built Up Edge (BUE) in Turning Applications Causes & EffectsDocument4 pagesBuilt Up Edge (BUE) in Turning Applications Causes & EffectsJo MarbeNo ratings yet

- Unit One Material and Geometry of Cutting Tools 2015Document46 pagesUnit One Material and Geometry of Cutting Tools 2015elnat feyisa100% (1)

- Manufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Document37 pagesManufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Sid SharmaNo ratings yet

- DJJ10033-chapter 4.2Document54 pagesDJJ10033-chapter 4.2Abbas SeuNo ratings yet

- MillingDocument33 pagesMillingRavichandran G0% (1)

- PTD Module 1.4Document21 pagesPTD Module 1.4Deepak DevasagayamNo ratings yet

- Machining by CuttingDocument4 pagesMachining by CuttingSiddhi JainNo ratings yet

- Tooling by Design - Pressuer Strippers Part 1Document2 pagesTooling by Design - Pressuer Strippers Part 1SIMONENo ratings yet

- Built Up Edge - Metal Cutting PhysicsDocument3 pagesBuilt Up Edge - Metal Cutting PhysicsJo MarbeNo ratings yet

- ch#21 Kal JaanDocument5 pagesch#21 Kal Jaansahb78428No ratings yet

- Parts Produced by Planning, Shaping and Slotting: Process DescriptionDocument7 pagesParts Produced by Planning, Shaping and Slotting: Process DescriptionsansagithNo ratings yet

- Cutting Tool DesignDocument67 pagesCutting Tool DesignBagus Bramantya bagusbramantya.2019No ratings yet

- Manufacturing Prcess PPT - Sheet Metal-1Document26 pagesManufacturing Prcess PPT - Sheet Metal-1Pranjali SinhaNo ratings yet

- Turning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelFrom EverandTurning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelRating: 4.5 out of 5 stars4.5/5 (3)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Important Dates PDFDocument1 pageImportant Dates PDFNisar HussainNo ratings yet

- 11072019Document1 page11072019Nisar HussainNo ratings yet

- Westbengal Notification 22.01.16 PDFDocument18 pagesWestbengal Notification 22.01.16 PDFNisar HussainNo ratings yet

- Syllabus of Inspector of Legal Metrology - 13052016 PDFDocument1 pageSyllabus of Inspector of Legal Metrology - 13052016 PDFNisar HussainNo ratings yet

- Acad 2D FCPDocument17 pagesAcad 2D FCPNisar HussainNo ratings yet

- TRG Cal All Institues 2016 17 v1 2 PDFDocument10 pagesTRG Cal All Institues 2016 17 v1 2 PDFNisar HussainNo ratings yet

- WBPDCL INDIA 2016 Advertisement PDFDocument10 pagesWBPDCL INDIA 2016 Advertisement PDFNisar HussainNo ratings yet

- West Bengal Staff Selection Commission: Transport/ Computer Supervisor RecruitmentDocument8 pagesWest Bengal Staff Selection Commission: Transport/ Computer Supervisor RecruitmentNisar HussainNo ratings yet

- Wk1 - Introduction To CNCDocument34 pagesWk1 - Introduction To CNCNisar HussainNo ratings yet

- OngcDocument1 pageOngcNisar HussainNo ratings yet

- HS 2018 History SuggestionDocument3 pagesHS 2018 History SuggestionNisar HussainNo ratings yet

- Ibm Infosphere Datastage Performance Tuning: MenuDocument9 pagesIbm Infosphere Datastage Performance Tuning: MenuNisar HussainNo ratings yet

- A Comparison of Thixocasting and Rheocasting: Previous Paper Next PaperDocument10 pagesA Comparison of Thixocasting and Rheocasting: Previous Paper Next PaperNisar HussainNo ratings yet

- Announcement of Inspector of Legal Metrology - 13052016Document1 pageAnnouncement of Inspector of Legal Metrology - 13052016Nisar HussainNo ratings yet

- PaintsDocument5 pagesPaintsTawfiq ZidanNo ratings yet

- Forging and Press 1Document18 pagesForging and Press 1Sumedh sonawane100% (1)

- Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4Document1 pagePessing Libya INC: As Per P No.3,4 To As Per P No.3,4Mahmoud HaggagNo ratings yet

- Daftar Pustaka KilnDocument2 pagesDaftar Pustaka Kilnazzahra ghina fadillahNo ratings yet

- Grades Gray Ductile SG Nodular GrapDocument2 pagesGrades Gray Ductile SG Nodular Grapjose.figueroa@foseco.comNo ratings yet

- Heat Treatment of Steel PDFDocument8 pagesHeat Treatment of Steel PDFkaviatchennai100% (2)

- Metalworking: Reporters: Casselle Madel Pable Ronie DagaleaDocument15 pagesMetalworking: Reporters: Casselle Madel Pable Ronie DagaleaRonie DagaleaNo ratings yet

- Catalogue-Tungaloy - 12 - Grades andDocument49 pagesCatalogue-Tungaloy - 12 - Grades andJose' TNo ratings yet

- Laboratory Manual Iitk Ta201 2017Document22 pagesLaboratory Manual Iitk Ta201 2017nithishNo ratings yet

- Carry Out Heat TreatmentDocument44 pagesCarry Out Heat TreatmentMelku AbebeNo ratings yet

- CRA Methods0117Document4 pagesCRA Methods0117JordanNo ratings yet

- Pettit Paints Pettit ThinnersDocument1 pagePettit Paints Pettit ThinnersRoddy GonzalezNo ratings yet

- Soldering, Brazing & Welding-A Manual of Techniques - D. PritchardDocument150 pagesSoldering, Brazing & Welding-A Manual of Techniques - D. PritchardDavid BogdanNo ratings yet

- Repair GI CoatingDocument2 pagesRepair GI CoatingcashloverNo ratings yet

- Manufacturing Processes (Abrasive Machining Processes) (BENG) HandoutDocument74 pagesManufacturing Processes (Abrasive Machining Processes) (BENG) HandoutbananaNo ratings yet

- Preparation and Tack UpDocument5 pagesPreparation and Tack UpCarmelo AlejandrinoNo ratings yet

- Paper Manufacturers in PakistanDocument7 pagesPaper Manufacturers in PakistanMuhammad UmairNo ratings yet

- Fitting Shop Operations:: 1. Measuring OperationDocument7 pagesFitting Shop Operations:: 1. Measuring OperationAliNo ratings yet

- Synthesis Decomposition: Teacher InstructionsDocument5 pagesSynthesis Decomposition: Teacher InstructionsMonette CabugayanNo ratings yet

- 1.2344 en PDFDocument2 pages1.2344 en PDFMarín HernándezNo ratings yet

- Paper Machine 2010 FinalDocument116 pagesPaper Machine 2010 FinalRedGlassesed Barney Liu75% (4)

- AstmDocument7 pagesAstmIlyas AhmedNo ratings yet

- Grinding Wheel Specifications: Name Roll NoDocument15 pagesGrinding Wheel Specifications: Name Roll NoShriyash GundawarNo ratings yet

- WTE Client List - Steel IndustryDocument2 pagesWTE Client List - Steel IndustryPooja MasalNo ratings yet

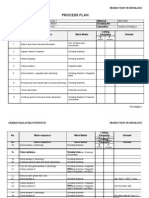

- Process Plan: Exercise 1 Mild Steel Vee Block 46.5 Hrs Surface Grinding 1Document6 pagesProcess Plan: Exercise 1 Mild Steel Vee Block 46.5 Hrs Surface Grinding 1mahazirismailNo ratings yet

- Aisi 4340 Alloy Steel (Uns g43400)Document4 pagesAisi 4340 Alloy Steel (Uns g43400)JourdyPradityaNo ratings yet

- S.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsDocument5 pagesS.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsRavi BabaladiNo ratings yet

- Astm A961Document8 pagesAstm A961Baskaran SubramaniyanNo ratings yet

- BSF Grinding Aid TestDocument16 pagesBSF Grinding Aid TestirfanNo ratings yet

- High Hardness & Toughness New General-Purpose Cold Die SteelDocument2 pagesHigh Hardness & Toughness New General-Purpose Cold Die SteelSinan YıldızNo ratings yet

Conventional Milling vs. Climb Milling

Conventional Milling vs. Climb Milling

Uploaded by

Nisar HussainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conventional Milling vs. Climb Milling

Conventional Milling vs. Climb Milling

Uploaded by

Nisar HussainCopyright:

Available Formats

TECHNICAL RESOURCES

CONVENTIONAL MILLING VS. CLIMB MILLING

There are two distinct ways to cut materials when milling, conventional (up) Figure 1: Backlash

milling and climb (down) milling. The difference between these two techniques

is the relationship of the rotation of the cutter to the direction of feed. In

conventional milling, the cutter rotates against the direction of the feed while PLAY

(BACKLASH)

during climb milling, the cutter rotates with the feed. Conventional milling is the

traditional approach when cutting because the backlash (Figure 1), the play

between the lead screw and the nut in the machine table, is eliminated.

Recently, climb milling has been recognized as the preferred way to approach a

workpiece due to the fact that more and more machines compensate for backlash

or have a backlash eliminator. Below are some key properties for both conventional

and climb milling. NUT

LEAD SCREW

Conventional Milling (Figure 2)

• Chip width starts from zero and increases which causes more heat to diffuse into

the workpiece and produces work hardening Figure 2: Conventional Milling

• Tool rubs more at the beginning of the cut causing faster tool wear and

decreases tool life

• Chips are carried upward by the tooth and fall in front of cutter creating a

marred finish and re-cutting of chips

• Upwards forces created in horizontal milling tend to lift the workpiece, more

intricate and expansive work holdings are needed to lessen the lift created

FEED

Climb Milling (Figure 3)

• Chip width starts from maximum and decreases so heat generated will more

likely transfer to the chip ROTATION

• Creates cleaner shear plane which causes the tool to rub less and increases

tool life

• Chips are removed behind the cutter which reduces the chance of re-cutting CHIP THICKNESS

• Downwards forces in horizontal milling is created that helps hold the BEGINS AT ZERO

AND INCREASES

workpiece down, less complex work holdings are need when coupled with

these forces

When to Choose Conventional or Climb Milling Figure 3: Climb Milling

Climb milling is generally the best way to machine parts today since it reduces the

ROTATION

load from the cutting edge, leaves a better surface finish, and improves tool life.

During conventional milling, the cutter tends to dig into the workpiece and may

cause the part to be cut out of tolerance.

Even though climb milling is the preferred way to machine parts, there are

times when conventional milling is the recommended choice. Backlash, which is

FEED

typically found in older and manual machines, is a huge concern with climb milling.

If the machine does not counteract backlash, conventional milling should be

implemented. Conventional milling is also suggested for use on casting or forgings

or when the part is case hardened since the cut begins under the surface of the

material.

CHIP THICKNESS

BEGINS AT MAX

AND DECREASES

Pg. 1 of 1 | Technical Resources | www.harveytool.com/technical | © 2017 Harvey Tool Company, LLC

You might also like

- Drilling ProcessDocument15 pagesDrilling ProcessAl Fredo95% (21)

- Getting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsFrom EverandGetting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsRating: 1 out of 5 stars1/5 (1)

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerFrom EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerRating: 4 out of 5 stars4/5 (1)

- Conventional Milling vs. Climb Milling: Technical ResourcesDocument1 pageConventional Milling vs. Climb Milling: Technical ResourcesAnonymous rweAHdNytyNo ratings yet

- Climb Milling vs. Conventional MillingDocument3 pagesClimb Milling vs. Conventional MillingM Aldityawan SyahputraNo ratings yet

- Advanced Cadcam Exam1 ReviewDocument7 pagesAdvanced Cadcam Exam1 Reviewapi-236166548No ratings yet

- Report NewDocument35 pagesReport NewSam DenishNo ratings yet

- Machining Methods PDFDocument13 pagesMachining Methods PDFMostarchinaNo ratings yet

- CNC MachiningDocument4 pagesCNC MachiningAdrianNo ratings yet

- 072 DEW Werkstoffauswahl Kaltarbeit GBDocument40 pages072 DEW Werkstoffauswahl Kaltarbeit GBFebrian JhaNo ratings yet

- Rake Angles: Negative-PositiveDocument5 pagesRake Angles: Negative-PositivekhareprafullNo ratings yet

- TDD-Metal Cutting & Special ToolsDocument27 pagesTDD-Metal Cutting & Special ToolsGS RathoreNo ratings yet

- Tech ClimbVsConventionalMillingDocument1 pageTech ClimbVsConventionalMillinglambrosNo ratings yet

- Up and Down MillingDocument5 pagesUp and Down MillingranerxNo ratings yet

- ITS Techpage-Conventional V Climb MillingDocument2 pagesITS Techpage-Conventional V Climb MillingAnkitPatel90No ratings yet

- Ch3 - Metal CuttingDocument30 pagesCh3 - Metal Cutting03 ABHISHEKNo ratings yet

- BMM3643 Milling Machining-1Document26 pagesBMM3643 Milling Machining-1Sarah AqirahNo ratings yet

- Manufacturing of An Indexing Jig Operated by Lever MechanismDocument7 pagesManufacturing of An Indexing Jig Operated by Lever MechanismInternational Journal of Engineering and TechniquesNo ratings yet

- L9 - Types of ChipsDocument36 pagesL9 - Types of Chipsudyadav3490No ratings yet

- Sheet Production TechnologyDocument23 pagesSheet Production TechnologyOmar AlyNo ratings yet

- Lecture2-Metalcutting 2Document40 pagesLecture2-Metalcutting 2girma workuNo ratings yet

- L11 - Types of ChipsDocument36 pagesL11 - Types of ChipsAditya AdityaNo ratings yet

- Upmilling Vs DownmillingDocument4 pagesUpmilling Vs DownmillingSaurabh BiswasNo ratings yet

- Problems of Clamping Rotary Tools: Jaroslav Kunstfeld, Josef BrychtaDocument4 pagesProblems of Clamping Rotary Tools: Jaroslav Kunstfeld, Josef BrychtaMaid GanjgoNo ratings yet

- Broaching - Sawing ProcessesDocument33 pagesBroaching - Sawing ProcessesashutoshNo ratings yet

- CHAPTER 3 - Lathe MachineDocument26 pagesCHAPTER 3 - Lathe MachineHarish Nagoor NahooranNo ratings yet

- Chip Formation: Manufacturing Technology-IiDocument20 pagesChip Formation: Manufacturing Technology-IiSachin BharadwajNo ratings yet

- Grinding Operations and Finishing Micro Milling: Competitive Manufacturing Processes (MCEN 3003)Document48 pagesGrinding Operations and Finishing Micro Milling: Competitive Manufacturing Processes (MCEN 3003)AntonyNo ratings yet

- Krishna Engineering College Department of Mechanical EngineeringDocument4 pagesKrishna Engineering College Department of Mechanical EngineeringVivek BajpaiNo ratings yet

- T&D - Core 4 Tool & DieDocument44 pagesT&D - Core 4 Tool & Dietisha revillaNo ratings yet

- Class Notes ManufacturingDocument13 pagesClass Notes ManufacturingRajangam VeeruchinnanNo ratings yet

- 3 Types of ChipsDocument35 pages3 Types of ChipsDhananjay SharmaNo ratings yet

- Difference Between Up Milling and Down MillingDocument4 pagesDifference Between Up Milling and Down MillingT. VeerabhadraiahNo ratings yet

- 4 Types of Chips-1Document35 pages4 Types of Chips-1Kishan KashyapNo ratings yet

- Hard Coating of Tool-Report PDFDocument43 pagesHard Coating of Tool-Report PDFRam TejaNo ratings yet

- FIA - Forging Facts - How Ar..Document6 pagesFIA - Forging Facts - How Ar..George CharitouNo ratings yet

- Sheet Metal OperationsDocument33 pagesSheet Metal Operationsziad almnaseerNo ratings yet

- Dawit SolomonDocument24 pagesDawit Solomondawit solomonNo ratings yet

- Cutting Force NoteDocument6 pagesCutting Force NotemtdestaNo ratings yet

- MCTDDocument28 pagesMCTDDHRUV SINGHALNo ratings yet

- 4 Types of ChipsDocument33 pages4 Types of Chipskagarwal3be23No ratings yet

- Built Up Edge (BUE) in Turning Applications Causes & EffectsDocument4 pagesBuilt Up Edge (BUE) in Turning Applications Causes & EffectsJo MarbeNo ratings yet

- Unit One Material and Geometry of Cutting Tools 2015Document46 pagesUnit One Material and Geometry of Cutting Tools 2015elnat feyisa100% (1)

- Manufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Document37 pagesManufacturing Processes (2), Ie-352 Ahmed M El-Sherbeeny, PHD Spring 2018Sid SharmaNo ratings yet

- DJJ10033-chapter 4.2Document54 pagesDJJ10033-chapter 4.2Abbas SeuNo ratings yet

- MillingDocument33 pagesMillingRavichandran G0% (1)

- PTD Module 1.4Document21 pagesPTD Module 1.4Deepak DevasagayamNo ratings yet

- Machining by CuttingDocument4 pagesMachining by CuttingSiddhi JainNo ratings yet

- Tooling by Design - Pressuer Strippers Part 1Document2 pagesTooling by Design - Pressuer Strippers Part 1SIMONENo ratings yet

- Built Up Edge - Metal Cutting PhysicsDocument3 pagesBuilt Up Edge - Metal Cutting PhysicsJo MarbeNo ratings yet

- ch#21 Kal JaanDocument5 pagesch#21 Kal Jaansahb78428No ratings yet

- Parts Produced by Planning, Shaping and Slotting: Process DescriptionDocument7 pagesParts Produced by Planning, Shaping and Slotting: Process DescriptionsansagithNo ratings yet

- Cutting Tool DesignDocument67 pagesCutting Tool DesignBagus Bramantya bagusbramantya.2019No ratings yet

- Manufacturing Prcess PPT - Sheet Metal-1Document26 pagesManufacturing Prcess PPT - Sheet Metal-1Pranjali SinhaNo ratings yet

- Turning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelFrom EverandTurning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelRating: 4.5 out of 5 stars4.5/5 (3)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Important Dates PDFDocument1 pageImportant Dates PDFNisar HussainNo ratings yet

- 11072019Document1 page11072019Nisar HussainNo ratings yet

- Westbengal Notification 22.01.16 PDFDocument18 pagesWestbengal Notification 22.01.16 PDFNisar HussainNo ratings yet

- Syllabus of Inspector of Legal Metrology - 13052016 PDFDocument1 pageSyllabus of Inspector of Legal Metrology - 13052016 PDFNisar HussainNo ratings yet

- Acad 2D FCPDocument17 pagesAcad 2D FCPNisar HussainNo ratings yet

- TRG Cal All Institues 2016 17 v1 2 PDFDocument10 pagesTRG Cal All Institues 2016 17 v1 2 PDFNisar HussainNo ratings yet

- WBPDCL INDIA 2016 Advertisement PDFDocument10 pagesWBPDCL INDIA 2016 Advertisement PDFNisar HussainNo ratings yet

- West Bengal Staff Selection Commission: Transport/ Computer Supervisor RecruitmentDocument8 pagesWest Bengal Staff Selection Commission: Transport/ Computer Supervisor RecruitmentNisar HussainNo ratings yet

- Wk1 - Introduction To CNCDocument34 pagesWk1 - Introduction To CNCNisar HussainNo ratings yet

- OngcDocument1 pageOngcNisar HussainNo ratings yet

- HS 2018 History SuggestionDocument3 pagesHS 2018 History SuggestionNisar HussainNo ratings yet

- Ibm Infosphere Datastage Performance Tuning: MenuDocument9 pagesIbm Infosphere Datastage Performance Tuning: MenuNisar HussainNo ratings yet

- A Comparison of Thixocasting and Rheocasting: Previous Paper Next PaperDocument10 pagesA Comparison of Thixocasting and Rheocasting: Previous Paper Next PaperNisar HussainNo ratings yet

- Announcement of Inspector of Legal Metrology - 13052016Document1 pageAnnouncement of Inspector of Legal Metrology - 13052016Nisar HussainNo ratings yet

- PaintsDocument5 pagesPaintsTawfiq ZidanNo ratings yet

- Forging and Press 1Document18 pagesForging and Press 1Sumedh sonawane100% (1)

- Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4Document1 pagePessing Libya INC: As Per P No.3,4 To As Per P No.3,4Mahmoud HaggagNo ratings yet

- Daftar Pustaka KilnDocument2 pagesDaftar Pustaka Kilnazzahra ghina fadillahNo ratings yet

- Grades Gray Ductile SG Nodular GrapDocument2 pagesGrades Gray Ductile SG Nodular Grapjose.figueroa@foseco.comNo ratings yet

- Heat Treatment of Steel PDFDocument8 pagesHeat Treatment of Steel PDFkaviatchennai100% (2)

- Metalworking: Reporters: Casselle Madel Pable Ronie DagaleaDocument15 pagesMetalworking: Reporters: Casselle Madel Pable Ronie DagaleaRonie DagaleaNo ratings yet

- Catalogue-Tungaloy - 12 - Grades andDocument49 pagesCatalogue-Tungaloy - 12 - Grades andJose' TNo ratings yet

- Laboratory Manual Iitk Ta201 2017Document22 pagesLaboratory Manual Iitk Ta201 2017nithishNo ratings yet

- Carry Out Heat TreatmentDocument44 pagesCarry Out Heat TreatmentMelku AbebeNo ratings yet

- CRA Methods0117Document4 pagesCRA Methods0117JordanNo ratings yet

- Pettit Paints Pettit ThinnersDocument1 pagePettit Paints Pettit ThinnersRoddy GonzalezNo ratings yet

- Soldering, Brazing & Welding-A Manual of Techniques - D. PritchardDocument150 pagesSoldering, Brazing & Welding-A Manual of Techniques - D. PritchardDavid BogdanNo ratings yet

- Repair GI CoatingDocument2 pagesRepair GI CoatingcashloverNo ratings yet

- Manufacturing Processes (Abrasive Machining Processes) (BENG) HandoutDocument74 pagesManufacturing Processes (Abrasive Machining Processes) (BENG) HandoutbananaNo ratings yet

- Preparation and Tack UpDocument5 pagesPreparation and Tack UpCarmelo AlejandrinoNo ratings yet

- Paper Manufacturers in PakistanDocument7 pagesPaper Manufacturers in PakistanMuhammad UmairNo ratings yet

- Fitting Shop Operations:: 1. Measuring OperationDocument7 pagesFitting Shop Operations:: 1. Measuring OperationAliNo ratings yet

- Synthesis Decomposition: Teacher InstructionsDocument5 pagesSynthesis Decomposition: Teacher InstructionsMonette CabugayanNo ratings yet

- 1.2344 en PDFDocument2 pages1.2344 en PDFMarín HernándezNo ratings yet

- Paper Machine 2010 FinalDocument116 pagesPaper Machine 2010 FinalRedGlassesed Barney Liu75% (4)

- AstmDocument7 pagesAstmIlyas AhmedNo ratings yet

- Grinding Wheel Specifications: Name Roll NoDocument15 pagesGrinding Wheel Specifications: Name Roll NoShriyash GundawarNo ratings yet

- WTE Client List - Steel IndustryDocument2 pagesWTE Client List - Steel IndustryPooja MasalNo ratings yet

- Process Plan: Exercise 1 Mild Steel Vee Block 46.5 Hrs Surface Grinding 1Document6 pagesProcess Plan: Exercise 1 Mild Steel Vee Block 46.5 Hrs Surface Grinding 1mahazirismailNo ratings yet

- Aisi 4340 Alloy Steel (Uns g43400)Document4 pagesAisi 4340 Alloy Steel (Uns g43400)JourdyPradityaNo ratings yet

- S.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsDocument5 pagesS.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsRavi BabaladiNo ratings yet

- Astm A961Document8 pagesAstm A961Baskaran SubramaniyanNo ratings yet

- BSF Grinding Aid TestDocument16 pagesBSF Grinding Aid TestirfanNo ratings yet

- High Hardness & Toughness New General-Purpose Cold Die SteelDocument2 pagesHigh Hardness & Toughness New General-Purpose Cold Die SteelSinan YıldızNo ratings yet