Professional Documents

Culture Documents

Nuclear Density - Method Statement-STD - Checked - PDF

Nuclear Density - Method Statement-STD - Checked - PDF

Uploaded by

Maan LeungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nuclear Density - Method Statement-STD - Checked - PDF

Nuclear Density - Method Statement-STD - Checked - PDF

Uploaded by

Maan LeungCopyright:

Available Formats

CPG Laboratories Pte Ltd

115 Eunos Avenue 3

Singapore 409839

Tel: (65) 6848 3058

Fax: (65) 6848 3066

Website: http://www.cpglabs.com.sg/

METHOD STATEMENT FOR:

NUCLEAR DENSITY TESTING

ASTM D6938 – 08a

In-Place Density and Water Content of Soil and Soil – Aggregate

By Nuclear Methods (Shallow Depths)

A. INTRODUCTION

These test methods cover the determination of the total or wet density of soil and soil-rock

mixtures by the attenuation of gamma radiation where the source and detector(s) remain

on the surface (Backscatter Method) or the source is placed at a known depth up to 300

mm (12 in.) while the detector(s) remains on the surface (Direct Transmission Method).

The density in mass per unit volume of the material under test is determined by comparing

the detected rate of gamma radiation with previously established calibration data.

B. SIGNIFICANCE AND USE

The test methods described are useful as rapid, non-destructive techniques for the

in-place determination of density and moisture content of soil and soil-aggregate. The test

methods are suitable for quality control and acceptance testing for construction and for

research and development applications. The non-destructive nature of the tests allows

repetitive measurement to be made at a single test location.

C. HAZARDS

This equipment utilizes radioactive materials that may be hazardous to the health of the

users unless proper precautions are taken. CPG Lab’s operators are familiar with

applicable safety procedures and government regulations and are fully certified.

CPG Laboratories Method Statement – Nuclear Density Testing 1

CPG Laboratories Pte Ltd

115 Eunos Avenue 3

Singapore 409839

Tel: (65) 6848 3058

Fax: (65) 6848 3066

Website: http://www.cpglabs.com.sg/

D. STANDARDIZATION AND REFERENCE CHECK

Nuclear gages are subject to long-term aging of the radioactive source, detectors, and

electronics systems, which may change the relationship between count rate and material

density. To offset this aging, the gage may be calibrated as the ratio of the measured

count rate to a count rate made on a reference standard. Using the reference standard

take at least four repetitive readings at the normal measurement period and determine the

mean. If the value obtained above is within the limits specified below, the gage is

considered to be in satisfactory condition, and the value may be used to determine the

count ratios for the day of use.

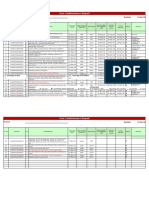

E. EQUIPMENTS

CPG Laboratories Method Statement – Nuclear Density Testing 2

CPG Laboratories Pte Ltd

115 Eunos Avenue 3

Singapore 409839

Tel: (65) 6848 3058

Fax: (65) 6848 3066

Website: http://www.cpglabs.com.sg/

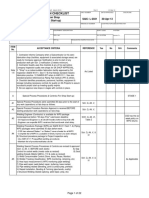

F. PROCEDURE FOR FIELD USE

1) Standardize the gage. (Refer to Section 4)

2) Select a test location. If the gage will be closer than 250 mm (10 in.) to any vertical

mass that might influence the result, such as in a trench or alongside a pipe, follow

the manufacturer’s correction procedure.

3) Remove all loose and disturbed material. Remove additional material as necessary

to reach the material that represents a valid sample of the zone or stratum to be

tested.

4) Plane or scrape a smooth horizontal surface so as to obtain maximum contact

between the gage and the material being tested. The optimum condition in all cases

is total contact between the bottom surface of the gauge and the surface of the

material being tested. To correct for surface irregularities, use of native fines or fine

sand as a filler may be necessary. The depth of the filler should not exceed

approximately 3 mm and the total area filled should not exceed 10% of the bottom

area of the instrument. The maximum depth of any void beneath the gage that can

be tolerated without filling shall not exceed approximately 3 mm.

5) Seat the gage firmly on the prepared test site.

6) Keep all other radioactive sources away from the gauge to avoid affecting the

measurement.

7) Secure and record one or more readings for the normal measurement period in the

backscatter position.

CPG Laboratories Method Statement – Nuclear Density Testing 3

You might also like

- ERSS - Method Statement of ConstructionDocument45 pagesERSS - Method Statement of ConstructionChoon Ewe LimNo ratings yet

- Ste Conchem Q3M4 CFGHSDocument26 pagesSte Conchem Q3M4 CFGHSJazmin Nicole Abanes100% (3)

- Method Statement For Construction of EmbankmentDocument6 pagesMethod Statement For Construction of EmbankmentRabnawaz Imam100% (1)

- Method Statement Fabrication of Girder - Rev4Document49 pagesMethod Statement Fabrication of Girder - Rev4John Rom Cabadongga100% (1)

- Method Statement For Soil Investigation WorkDocument14 pagesMethod Statement For Soil Investigation WorkNasir Nagoor Pitchai100% (1)

- Method Statement For Pile GroutingDocument2 pagesMethod Statement For Pile Groutingsaman2580No ratings yet

- Method Statement For Piling Works PDFDocument2 pagesMethod Statement For Piling Works PDFrozaidiabdulrahim100% (1)

- 3009 - Method Statement For Administration Building Construction PDFDocument38 pages3009 - Method Statement For Administration Building Construction PDFNjilou LagaticNo ratings yet

- MS For Wet TradeDocument11 pagesMS For Wet TradeGary LoNo ratings yet

- ME 2204 Fluid Mechanics and Machinery TEST (I Unit) KeyDocument12 pagesME 2204 Fluid Mechanics and Machinery TEST (I Unit) KeyVignesh Vicky80% (5)

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- Nuclear Density Test - Earthworks - Chapter - 12Document16 pagesNuclear Density Test - Earthworks - Chapter - 12Saud PathiranaNo ratings yet

- Sample Method Statement For Nuclear TestingDocument10 pagesSample Method Statement For Nuclear TestingdavethiyaguNo ratings yet

- Pile Head BreakingDocument4 pagesPile Head BreakingHakan Bnbsyz0% (1)

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Document19 pagesMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinNo ratings yet

- Contractor: Edward and ChristieDocument5 pagesContractor: Edward and ChristieSubasinghe DharmapalaparkNo ratings yet

- Method Statement Patch WorkDocument9 pagesMethod Statement Patch Worknoko100% (1)

- S86088-LKA-C07CE-MS-004 - Sub & Superstructure (Rev0)Document47 pagesS86088-LKA-C07CE-MS-004 - Sub & Superstructure (Rev0)Stephen David Gozun100% (1)

- Method Statement For Skim CoatDocument15 pagesMethod Statement For Skim Coatmohsin.meizaNo ratings yet

- 6 - Plate Load TestDocument6 pages6 - Plate Load Testmido medo100% (1)

- Method Statement For Plate Load Test (Final) - Ns37Document4 pagesMethod Statement For Plate Load Test (Final) - Ns37Debraj RoyNo ratings yet

- Method Statement of Plastering: Pembinaan Infra E&J SDN BHDDocument5 pagesMethod Statement of Plastering: Pembinaan Infra E&J SDN BHDChezy629No ratings yet

- Work Method Statement FOR Piling WorksDocument7 pagesWork Method Statement FOR Piling WorksLynn MailNo ratings yet

- Method Statement For Embankment FillingDocument9 pagesMethod Statement For Embankment Fillingdamith50% (2)

- Methodology of Kerb Construction: ScopeDocument2 pagesMethodology of Kerb Construction: ScopeAnish PanchalNo ratings yet

- Method Statement For Pile Load Test by Kentledge MDocument4 pagesMethod Statement For Pile Load Test by Kentledge MCza ManNo ratings yet

- Method Statement For Road Construction Over WetlandsDocument4 pagesMethod Statement For Road Construction Over WetlandsYibeltal ChaneNo ratings yet

- Method Statement Sheet Piling Works - 1628123140Document9 pagesMethod Statement Sheet Piling Works - 1628123140Christian HindangNo ratings yet

- Authorisation For Layig GSB and WMM-Rev-R2Document1 pageAuthorisation For Layig GSB and WMM-Rev-R2Guna SekaranNo ratings yet

- Testing of Concrete Cores For StrengthDocument3 pagesTesting of Concrete Cores For StrengthAshraf0% (1)

- Strut Method StatementDocument21 pagesStrut Method StatementhardywillimNo ratings yet

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedNo ratings yet

- Technical Note For LimestoneDocument15 pagesTechnical Note For LimestoneAmierul MukmienNo ratings yet

- SWP-07 Excavation WorksDocument7 pagesSWP-07 Excavation WorksMd Shahin100% (1)

- Form Work, Reinforcement & Concreting - MethodologyDocument10 pagesForm Work, Reinforcement & Concreting - MethodologyRabnawaz ImamNo ratings yet

- MS For BackfillingDocument3 pagesMS For BackfillingShan THALANo ratings yet

- Green Terramesh Method Statement ExampleDocument5 pagesGreen Terramesh Method Statement ExampleMe Kang He Kodos We Kang And KodosNo ratings yet

- Method Statement: Fabrication of Rebar Cages in CaissonDocument3 pagesMethod Statement: Fabrication of Rebar Cages in CaissonhanisahhamzahNo ratings yet

- Methodstm Leanconcrete 141120013214 Conversion Gate01Document7 pagesMethodstm Leanconcrete 141120013214 Conversion Gate01Zitheeq UmarNo ratings yet

- Probe & Grouting Ahead of Excavation MethodologyDocument4 pagesProbe & Grouting Ahead of Excavation Methodologykavi rajNo ratings yet

- MS For BoredDocument18 pagesMS For BoredsinlekmNo ratings yet

- RAMS For Concrete (Overt and Invert Lining) Repair WorksDocument16 pagesRAMS For Concrete (Overt and Invert Lining) Repair WorksDeep Sherawat100% (1)

- OD MS NJBP 03 Rev.0.Concrete WorkDocument13 pagesOD MS NJBP 03 Rev.0.Concrete WorkMuhammad zamanNo ratings yet

- Malaysia ReportDocument47 pagesMalaysia ReportAgim Derguti100% (1)

- PWA-RPD-CON-FM-1530 Asphalt Paving Inspection ChecklistDocument5 pagesPWA-RPD-CON-FM-1530 Asphalt Paving Inspection ChecklistUtpal MondalNo ratings yet

- Pavement RoadDocument6 pagesPavement Roadkartick adhikaryNo ratings yet

- Methodology For Subgrade Construction - Highway GuideDocument4 pagesMethodology For Subgrade Construction - Highway GuidesvsrnbNo ratings yet

- Concrete Placement (Spec)Document18 pagesConcrete Placement (Spec)Vetrivel MuruganNo ratings yet

- Plate Bearing TestDocument11 pagesPlate Bearing TestKelvin Lau100% (1)

- Comparison of Static and Dynamic Load Test of PileDocument11 pagesComparison of Static and Dynamic Load Test of PilehangNo ratings yet

- Method of Statement Bore Pile FoundationDocument11 pagesMethod of Statement Bore Pile FoundationRendi SeptriawanNo ratings yet

- MOS - Flexible Pavement RehabilitationDocument6 pagesMOS - Flexible Pavement RehabilitationcdipcinNo ratings yet

- Staircase Tower CuplockDocument1 pageStaircase Tower CuplockManu MohanNo ratings yet

- Method Statement For Taxiway Edge Lights & ManholesDocument7 pagesMethod Statement For Taxiway Edge Lights & ManholesRomeoAryan100% (1)

- BDSLT Method Statement - BT Maung PDFDocument39 pagesBDSLT Method Statement - BT Maung PDFSuhaidi Alias100% (3)

- Simple Drilling MethodsDocument4 pagesSimple Drilling MethodsGreen Action Sustainable Technology GroupNo ratings yet

- MOS of Shear Stud InstallationDocument3 pagesMOS of Shear Stud InstallationViisshnu SilvarajooNo ratings yet

- Road Pav LayerwDocument10 pagesRoad Pav LayerwAurelius GoraNo ratings yet

- Field Density Testing GuideDocument32 pagesField Density Testing Guidenikita6969No ratings yet

- D2922Document6 pagesD2922smanoj354No ratings yet

- ASTM D 2922-96 Standard Tests Methods For Density of Soil and Soil-Aggregate in Place by Nuclear Methods (Shallow Depth)Document5 pagesASTM D 2922-96 Standard Tests Methods For Density of Soil and Soil-Aggregate in Place by Nuclear Methods (Shallow Depth)Pablo Antonio Valcárcel Vargas100% (1)

- Determining The Density and Unit Weight of Soil in Place by Nuclear Methods (Shallow Depth)Document16 pagesDetermining The Density and Unit Weight of Soil in Place by Nuclear Methods (Shallow Depth)crycodNo ratings yet

- Instruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsFrom EverandInstruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsNo ratings yet

- Welcome: Ahsanullah University of Science & TechnologyDocument69 pagesWelcome: Ahsanullah University of Science & TechnologyWr ArNo ratings yet

- 6 July 2015 Sunlove Building ProjectDocument42 pages6 July 2015 Sunlove Building ProjectWr ArNo ratings yet

- IR Asphalt PremixDocument2 pagesIR Asphalt PremixWr ArNo ratings yet

- Drainworks ProgressDocument2 pagesDrainworks ProgressWr ArNo ratings yet

- @MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneDocument1 page@MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneWr ArNo ratings yet

- DAFLOU BATIS VpCI - 2Document6 pagesDAFLOU BATIS VpCI - 2Wr ArNo ratings yet

- Calculations of Unit Weight of Rebar PDFDocument1 pageCalculations of Unit Weight of Rebar PDFWr ArNo ratings yet

- BCM Anna University NotesDocument112 pagesBCM Anna University NotesaruchellamNo ratings yet

- Carpet Combing June 2013Document3 pagesCarpet Combing June 2013Wr ArNo ratings yet

- Rebar Arrangement in SlabDocument12 pagesRebar Arrangement in Slableovorig100% (2)

- Permit To Work On Public StreetsDocument27 pagesPermit To Work On Public StreetsWr ArNo ratings yet

- Calculations of Unit Weight of Rebar PDFDocument1 pageCalculations of Unit Weight of Rebar PDFWr ArNo ratings yet

- Cross Section Analysis and DesignDocument158 pagesCross Section Analysis and DesignWr ArNo ratings yet

- GeneralTechnicalInformation RebarSplicingDocument7 pagesGeneralTechnicalInformation RebarSplicingSarakikenpachiNo ratings yet

- Beam Rebar ArrangementDocument10 pagesBeam Rebar Arrangementme_decent28457100% (2)

- Seismic Rebar DetailingDocument11 pagesSeismic Rebar DetailingWr ArNo ratings yet

- Permit To Work On Public StreetsDocument27 pagesPermit To Work On Public StreetsWr ArNo ratings yet

- Concrete SlabsDocument15 pagesConcrete SlabsWr ArNo ratings yet

- Cross Section Analysis and Design - Worked ExamplesDocument148 pagesCross Section Analysis and Design - Worked ExamplesWr ArNo ratings yet

- Inform Guide - Structural CracksDocument8 pagesInform Guide - Structural Cracksgulilero_yoNo ratings yet

- Factories and Works Act 15:04 RGN 264: Building, Structural and Excavation WorkDocument19 pagesFactories and Works Act 15:04 RGN 264: Building, Structural and Excavation WorkCourageNo ratings yet

- 36IJELS 109202041 Pandemic PDFDocument4 pages36IJELS 109202041 Pandemic PDFIJELS Research JournalNo ratings yet

- Anant Kumar Antu: Profile SummeryDocument4 pagesAnant Kumar Antu: Profile SummerymkoelrealNo ratings yet

- IOW NHS Trust No Wrong Door MHLD Strategy - Embargoed Version PDFDocument34 pagesIOW NHS Trust No Wrong Door MHLD Strategy - Embargoed Version PDFOnTheWightNewsNo ratings yet

- Photoelectric Vs Ionization Smoke AlarmsDocument8 pagesPhotoelectric Vs Ionization Smoke AlarmssoufNo ratings yet

- Jealousy As Good: Bad Behavior and JealousyDocument2 pagesJealousy As Good: Bad Behavior and JealousyInesha FebrinaNo ratings yet

- US v. Dunlap Opinion and Order Granting Supervised ReleaseDocument12 pagesUS v. Dunlap Opinion and Order Granting Supervised ReleaseWashington Free BeaconNo ratings yet

- Health Condition1Document22 pagesHealth Condition1Barrack koderaNo ratings yet

- 428 Perioperative Management of Subarachnoid HemorrhageDocument27 pages428 Perioperative Management of Subarachnoid Hemorrhagemuthia yuniarta sinagaNo ratings yet

- Pre-Setting Manual Balancing Valves CIM 788: Technical InformationDocument7 pagesPre-Setting Manual Balancing Valves CIM 788: Technical InformationblindjaxxNo ratings yet

- Aircaft Avionics SystemDocument21 pagesAircaft Avionics SystemPavan KumarNo ratings yet

- PharmacyDocument20 pagesPharmacyRajJoshiNo ratings yet

- Neatecha 1Document20 pagesNeatecha 1cram retselNo ratings yet

- psc3 PDFDocument6 pagespsc3 PDFAnonymous mPbkM4vrFlNo ratings yet

- Lab Mud Solid Content DeterminationDocument10 pagesLab Mud Solid Content DeterminationIngenieur Khairuddin Ngah33% (3)

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- Decomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingsDocument9 pagesDecomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingskarthikkandaNo ratings yet

- Full Version Manual: Silva Marine Compass 100B/H MaintenanceDocument1 pageFull Version Manual: Silva Marine Compass 100B/H Maintenancesanginan100% (1)

- Issues and Unmet Needs in Advanced Prostate CancerDocument9 pagesIssues and Unmet Needs in Advanced Prostate CancerMuhammad MosliNo ratings yet

- Super Its 300h-3009964Document9 pagesSuper Its 300h-3009964Nguyễn SơnNo ratings yet

- Hydrometallurgy: Jochen PetersenDocument7 pagesHydrometallurgy: Jochen PetersenAlex Paolo Paz AldayNo ratings yet

- Ebp PosterDocument1 pageEbp Posterapi-340595961No ratings yet

- Bread and Pastry Production ReviewerDocument2 pagesBread and Pastry Production ReviewerKhrister TorresNo ratings yet

- Đề Cương Thi Giữa Kỳ i - Anh 11 (23-24)Document12 pagesĐề Cương Thi Giữa Kỳ i - Anh 11 (23-24)Nguyễn Phuong AnhNo ratings yet

- Paramyxovirus and RubellaDocument65 pagesParamyxovirus and RubellaishlionNo ratings yet

- A Comparison of Two Models of Experimental Periodontitis in RatsDocument8 pagesA Comparison of Two Models of Experimental Periodontitis in RatsRoza NafilahNo ratings yet