Professional Documents

Culture Documents

Crystallization Behaviour of Random Block Copolymers of Poly (Butylene Terephthalate) and Poly (Tetramethylene Ether Glycol)

Crystallization Behaviour of Random Block Copolymers of Poly (Butylene Terephthalate) and Poly (Tetramethylene Ether Glycol)

Uploaded by

Lucas Del PretteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crystallization Behaviour of Random Block Copolymers of Poly (Butylene Terephthalate) and Poly (Tetramethylene Ether Glycol)

Crystallization Behaviour of Random Block Copolymers of Poly (Butylene Terephthalate) and Poly (Tetramethylene Ether Glycol)

Uploaded by

Lucas Del PretteCopyright:

Available Formats

Crystallization behaviour of random block

copolymers of poly(butylene terephthalate)

and poly(tetramethylene ether glycol)

R. M . B r i b e r * a n d E. L. T h o m a s

Polymer Science and Engineering Department, University of Massachusetts, Amherst, MA

01003, USA

(Received 19 January 1984; revised 5 April 1984)

The morphology and crystallization behaviour of random block copolymers of poly(butylene tereph-

thalate) and poly(tetramethylene ether glycol) have been investigated. Single crystals have been grown

in thin films crystallized from the melt. Well defined lamellae, exhibiting (hkO) single crystal electron

diffraction patterns have been observed in copolymers containing down to 49 wt% (0.83 mole fraction)

poly(butylene terephthalate). WAXS and electron diffraction support a model of a relatively pure

poly(butylene terephthalate) crystal core with the poly(tetramethylene ether glycol) (soft segment)

sequences and short hard segments being rejected to the lamellar surface and the soft segment rich

matrix. The lateral dimensions of the lamellae are determined by the number of hard segment sequences

long enough to traverse the stable crystal size at the crystallization temperature. This leads to an initial

population of crystals formed at Tc and a second set of smaller crystals that grow from the short hard

segment sequences upon cooling to room temperature. The result is fractionation by sequence length

due to a coupling of the sequence distribution with the stable crystal size at the crystallization

temperature.

(Keywords: copolymer; morphology; poly(butylane terephthalate); single crystals; electron micro-

scopy; polyether-polyester)

INTRODUCTION being drawn from such indirect experiments as dynamical

mechanical testing and differential scanning calorimetry.

The polyether-polyesters examined in this study are It is generally accepted that the soft segment phase in

random block copolymers containing crystallizable hard these polyether-polyesters is a mixture of the soft segment

segments and elastomeric, amorphous soft segments. By material with short uncrystallized hard segments 1-3.

random block copolymer it is meant that polyether- Only a single glass transition temperature is observed

polyesters are multiblock copolymers of the ~AB-}, type which depends strongly on composition and sample

with A and B each representing a length of chain of a history (which determine the amount of dissolved hard

different polymer. Random block copolymers are distin- segment in the amorphous phase) 1-3. The melting of the

guished from random copolymers because one of the hard segment domains is observed, near that of the hard

starting components (the soft segment) used in the segment homopolymer, but depressed somewhat due to

copolymerization reaction is not a single repeat unit but small crystal size and defects in the crystals.

starts as an oligomer, usually of 1000-4000 molecular The early fundamental structure-property work on

weight. The lengths of the sequences of A and B units polyether-polyesters was done by Celia and has been

follow a geometrical distribution, hence the block length summarized in a number of articles ~'4'5. The morphologi-

varies considerably, with the average being determined by cal model presented by Celia consists of interpenetrating

the molar composition of the sample. One of the blocks is crystalline domains. The crystalline domains are lamellar

termed the hard segment because it is a rigid, high in nature and consist of long polyester (4GT) sequences

modulus plastic at the desired use temperature. The other with the polyether and short 4GT segments rejected to the

block is called the soft segment and is an elastomer at the amorphous phase. Chain folding was postulated for the

use temperature. Microphase separation occurs with the 4GT crystals by Cella4. A short but intriguing paper on

formation of hard and soft segment rich domains. The the subject of polyether-polyester morphology was pub-

hard segment domains or crystallites act as physical lished by Seymour et al. 6. The experiments included

crosslinks for the soft segment material at low hard chemical etching and g.p.c., small-angle light scattering

segment content giving the polyether-polyesters proper- (SALS) and dynamic mechanical experiments. The poly-

ties similar to a classical crosslinked rubber without the mers all exhibited small-angle light scattering patterns

use of covalent crosslinks. At high hard segment content characteristic of a spherulitic superstructure. The chemi-

the soft segment acts as a toughening agent for the hard cal etching and subsequent g.p.c, revealed a low molecular

segment material. The morphology of polyether- weight peak that corresponded to a lamellar thickness of 7

polyesters, indeed of all random block copolymers, is not to 8 monomer units. Evidence of chain folding was given

well understood with most of the morphological insight by a high molecular weight shoulder occurring at twice

* Present address: National Bureau of Standards,Gaithersburg,MD the molecular weight of the primary peak. This cor-

20899, USA. responds to chains that traverse the crystal, fold and re-

0032-3861/85/010008-O9503.00

© 1985 Butterworth& Co. (Publishers)Ltd.

8 POLYMER, 1985, Vol 26, January

Crystallization behaviour of random block copolymers: R. M. Briber and E. L. Thomas

enter the crystal. This high molecular weight peak There are a considerable number of papers in the

gradually disappears with longer etching time as the fold literature dealing with polyether-polyester morphology

surface is slowly degraded. More recent morphological either directly or indirectly and a number of differing

studies on polyether-polyesters were performed by viewpoints have been proposed concerning its nature. It is

Wegner's group at the University of Freiburg z'v's. In their the aim of this work to use electron microscopy and

view the morphology consists of spherulitic aggregations diffraction in an attempt to understand the basic struc-

of hard segment lamellae. They postulate that both short tural features of polyether-polyesters. In this study the

and long hard segment sequences are excluded from the morphology of melt crystallized thin films of polyether-

crystals with the lamellae being composed almost polyesters has been examined. These films exhibit a

exclusively of sequences equal to the average length of the unique morphology which is discussed and some new

hard segment. The long sequences were thought to be ideas regarding the crystallization behaviour of

excluded because the degree of crystallinity was less than polyether-polyesters and random block copolymers are

what would be expected if all the sequences greater than presented.

or equal to the average length were to crystallize. It is

difficult from a physical point of view to understand why EXPERIMENTAL

all the long hard segment sequences would be excluded

from the crystal when some could cooperate in Materials

crystallization by folding. The polyether-polyesters examined in this work were

Small-angle X-ray scattering studies have been done, based on poly(tetramethylene ether glycol) ( M n --- 1000) as

primarily by Bandara and Droscher 9 and Wegner et al. z. the soft segment (PTMEG) and poly(butylene tereph-

Generally the SAXS results indicate that the copolymers thalate) as the hard segment (4GT). The polymers were an

behave similar to homopolymers, with the long period experimental batch of the polyether-polyesters marketed

increasing with higher annealing temperatures. In ad- under the trade name Hytrel by the duPont Company.

dition to following the long period as a function of The samples were supplied by Dr W. H. Buck of the

crystallization conditions, Bandara and Droscher calcu- duPont Company. Sample compositions (weight per cent

lated one dimensional correlation functions, specific inner 4GT), mole fraction 4GT and average hard segment

surface areas, average chord lengths, lamellar thickness, length (calculated assuming a most probable distribution)

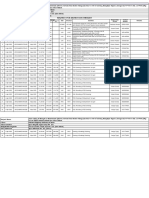

transition zone thickness and the mean squared electron are given in Table 1. The 4GT homopolymer studies was

density fluctuation as a function of undercooling and Valox 315, supplied by the General Electric Company.

composition. In general the data are consistent as a Chemical formulas are given in Figure 1.

function of undercooling with the samples crystallized at The samples were prepared by a melt condensation

high temperatures (low undercooling) exhibiting thicker reaction between PTMEG, the methyl ester of tereph-

crystals, lower internal surface area and better phase thalic acid and 1,4 butanediol. Details of the synthesis are

separation. Bandara and Droscher measured the interface reviewed in the papers by Celia TM and Wistsiepe 12. The

width between the two phases and found it to be 0.6 nm polyether-polyesters used in this study were chosen

for a sigmoidal interface profile model, independent of because the hard and soft segment sequence distributions

sample composition and undercooling. The absolute and the molecular weight distribution are believed to be

value of interface widths measured by SAXS is dependent

on the model chosen. Yet, measurements on polystyrene-

polyisoprene block copolymers, known to be incom- Table 1 Polyether--polyester compositions

patible and thought to possess sharp interfaces give a Composition Mole fraction Averagehard segment

sigmoidal boundary thickness of about 0.4-0.8 nm 1°'~'. (wt% 4GT) 4GT length N

Therefore the absolute value of 0.6 nm for a system that

should have inherently diffuse boundaries appears to be 81 0.96 23

too low. 73 0.93 15

An interesting crystallization feature observed by Zhu 59 0.88 8

49 0.83 6

and Wegner 7'8 in isothermally crystallized polyether- 43 0.79 5

polyesters was that at small undercoolings birefringent 36 0.74 4

aggregates can be observed growing scattered throughout

the melt. They do not exhibit the usual spherulitic maltese

cross extinction pattern in polarized light because they

contain only a few relatively large lamellae and therefore Hard segmenti Poly (butylene terephtholote)

do not have a fine enough texture and broad enough o

range of orientations to exhibit the maltese cross. As a rule

CI ~ / ')~CO-(-CH2-)~.O PBT or 4-GT

these birefringent aggregates stop growing long before

they impinge. The matrix surrounding the aggregates

never appears to crystallize at T~ even after long times.

Yet if the sample is quenched and then annealed at a Soft segment:Poly(tetromethylene ether) glycol

temperature below the original crystallization tempera-

ture new crystals form at the edges of the previous °

aggregates, indicating there was hard segment material c P,.EG

present in the matrix that was unable to crystallize at the -~ ~m Mn~llO0

original T~. At the new lower annealing temperature this

material crystallizes using the aggregates formed earlier as Figure I Chemical structures of the polyether-polyester system

nucleation sites. studied in this work

POLYMER, 1985, Vol 26, January 9

Crystallization behaviour of random block copolymers: R. M. Briber and E. L. Thomas

ideal and follow a most probable distribution. The Electron microscopy

polymerization is carried out in the melt which is one Transmission electron microscopy was performed

phase for this molecular weight soft segment. In a recent using a JEOL 100 CX transmission electron microscope

study by Shih and McKenna the effect of the soft segment equipped with a scanning transmission attachment. Since

molecular weight was studied by dynamic mechanical the main limitation in high resolution microscopy of

analysis (d.m.a.) and d.s.c.13. For PTMEG molecular polymers is radiation damage every attempt was made to

weights of 2000 and larger the melt was observed to be keep this to a minimum. For bright field (BF) microscopy

opaque during polymerization while for molecular wei- this entailed focusing in one area and translating to an

ghts of 1000 and below the melt was clear. This obser- adjacent area for exposure. To minimize radiation dam-

vation has also been made by Wolfe 14. The opacity was age during dark field (DF) microscopy the sample was

taken as evidence of phase separation during polymeri- either translated to an adjacent area for exposure or

zation and non-ideal reaction conditions. Non-ideal alternatively, with the beam off, the second condenser lens

reaction conditions will lead to sequence distributions would be excited to bring the beam to crossover. The

that are far from random with one phase rich in hard beam would then be turned on and the image focused and

segment and the other phase rich in soft segment. For soft the beam shut off again. Next the condenser lens current

segment molecular weights less than 2000 the reaction would be decreased to a predetermined value to spread

medium is homogeneous leading to a most probable hard the beam for even illumination and a reasonable ex-

segment sequence distribution. Further evidence for ran- posure. The beam would be turned on and the micrograph

dom sequence distribution has been presented by Shih 15. taken. Only the small central region illuminiated for

A sample containing 59 wt~ hard segment (PTMEG focusing would be damaged. In all cases exposures were

MW, 1000) was blended in the melt with pure 4GT checked to be 0.64).8 z, where z is the radiation lifetime of

homopolymer using a Brabender mixer. At all com- the crystal. Dark field microscopy was performed using

positions ranging from 10-90~o 4GT two melting points the tilted beam technique.

and glass transition temperatures were observed cor- Selected area diffraction patterns were obtained by

responding to the individual components in the blends. decreasing the strength of the intermediate lens to image

The melt was also found to be two-phase with the the black focal plane of the objective lens. Either a 4 or

polyether-polyester and 4GT homopolymer each for- 8 #m diameter SAD aperture was used.

ming discrete phases as observed by optical microscopy. Microdiffraction patterns were obtained using the

Although the melt was two phase initially one might STEM attachment and free lens control. In the STEM

expect that at long times the 4GT and polyether-polyester imaging mode the pre-field of the objective lens is excited

would become one phase as transesterification occurred. allowing the electron beam to be focused into a small

If the polyether-polyester copolymer contained large probe. The size of the probe determines the resolution

amounts of high hard segment content material, as would attainable and is controlled by the condenser lenses and

be present if the polymerization conditions were non- second condenser lens aperture. A very small probe size

homogeneous, then two melting points would be expected (~ 5 nm) results in a highly convergent beam which gives

in the copolymer as seen in the blends. This is not a convergent beam microdiffraction pattern. This large

observed. Based on this evidence the conclusion that spread of incident angles in the beam does not affect the

polyether-polyesters based on PTMEG of 1000 mole- image quality in STEM but it results in the microdiffrac-

cular weight (and less) and 4GT have truly random tion spots being very broad with overlap of adjacent

sequence distributions of both hard and soft segments is reflections. Consequently microdiffraction patterns using

justified. more coherent illumination were taken using a beam

diameter about 0.5/~m. The main advantage of microdif-

fraction over selected area diffraction in this application

Sample preparation was the ability to take adjacent diffraction patterns

Thin films for melt crystallization experiments were without damaging the surrounding area. The 0.5 #m

prepared by casting the polyether-polyesters from dilute probe size was not a limitation because the features of

solution. A 0.075 wt~o solution of the polymer was made interest were greater than 1 ktm in size. Scanning trans-

in hexaflouroisopropanol (HFIP). A freshly cleaved mica mission electron microscopy as applied to polymers has

sheet was then lightly coated with carbon (-,~5-10 nm been discussed in the literature by Low et al. 16 and by

thickness). This prevented the polymer from adhering to Thomas et al. 1 7 - 1 9

the mica in the subsequent crystallization step. The mica

was dipped into the polymer solution and the excess Differential scanning calorimetry

solution wiped off the bottom of the mica with filter paper. Differential scanning calorimetry (d.s.c.) was performed

The solvent was then quickly evaporated by placing the with a computer controlled Perkin Elmer DSC-2. Tem-

mica on a warm hot plate in a hood. If the solvent was not perature scale and thermal input were calibrated using an

evaporated rapidly the film produced was not homo- indium standard. All d.s.c, scans were carried out at a scan

geneous and contained holes and thickness variations. rate of 20°C min-l. Sample size was ~ 10 mg. The d.s.c.

The mica sheet was placed in a hot stage which was either scans presented are all normalized to 1 mg sample size.

under N 2 purge or inside a N2-filled glove bag. The

polymer film was melted and held at 250°C for 5 min and Wide-angle X-ray scattering

then quenched to the desired crystallization temperature Wide-angle X-ray scattering samples were prepared by

(T,). The polymer was kept at T~for 4 h and subsequently melt pressing 1.0ram thick samples and subsequently

quenched to room temperature. The film was floated off crystallizing them at the desired temperature. Diffractom-

the mica onto distilled water and picked up on electron etry was done on a Siemens D-500 diffractometer. In-

microscopic grids. cident slits defining an angle of 0.3 ° were generally used.

10 POLYMER, 1985, Vol 26, January

Crystallization behaviour of random block copolymers: R. M Briber and E. L. Thomas

presented in this work). Many relatively large (25 #m

long) single lamellae can be observed growing in the plane

of the film. The lamellae appear to be uniform in thickness

except for an occasional small overgrowth near the centre.

Figure 3 is slightly higher magnification micrograph of a

single lamella and associated microdiffraction patterns

from the lamella and the surrounding matrix. The lam-

mella gives a strong single crystal diffraction pattern while

the matrix shows only diffuse amorphous scattering.

Figure 4 is an indexed electron diffraction pattern from a

single lamella in a 73~o hard segment content film. The

pattern indexes to the alpha unit cell of4GT 2a -27. Similar

pattems were also obtained from films of the 4GT

homopolymer and the 49~o hard segment polymer. The d-

spacings measured were found to be independent of soft

segment concentration. The beta polymorph is reported,

to only appear under stress in the homopolymer 23-27 and

would not be expected in quiescently crystallized films.

Figure 2 Low magnification BF TEM micrograph of a melt The fact that the crystals give rise to (hkO)type reflections

crystallized 73% by weight hard segment polyether-polyester film indicates that the lamellar surface coincides with the a*-

b* plane of the unit cell. The g axis, and hence the chain

direction, is perpendicular to the a*-b* plane and the

lamellar surface. Since the unit cell is triclinic the direc-

tions of a, b, ~ do not coincide with a*, b*, ~* and the a axis

is not in the plane of the film. The crystal habit of 4GT has

been clearly observed as a result of these morphological

investigations on polyether-polyesters. For a complete

discussion see Ref. 28. Figure 5 is a low magnification BF

micrograph of a 49~ hard segment film crystallized at

190°C (AT -~ 15°C, Tm~- 205°C 21,22. Small lamellae can be

observed throughout the film. The largest lamellae are

only about l0 pm in length, in contrast to the much larger

crystals in the 739/0hard segment film. Another interesting

Figure 3 BF TEM micrograph and associated microdiffraction

patterns from 73% by weight hard segment polyether-polyester

film. (a) Microdiffraction pattern from matrix; (b) microdiffraction

patterns from lamella

Receiving slits were 0.3 ° and 0.05 °. The 20 scan rate was

1° min -1. Samples were run in reflection.

RESULTS AND DISCUSSION

Electron microscopy

Three different polymers were studied by melt crystal-

lizing thin films and subsequently examining them in the

electron microscope: pure 4GT homopolymer (Valox

315), 739/0 hard segment polyether-polyester, and a 49~o

hard segment polyether-polyester. The 73~ content

sample was studied most thoroughly and will be discussed

in the most detail.

Films crystallized at low undercoolings (AT~10 °-

15°C) were found to have single crystal lamellae growing

in them. Isolated single crystals grown in thin films from

the melt have been previously reported for homopo-

lymers, without much discussion 2°. Figure 2 is a low

magnification bright field electron micrograph of a 73~o

Figure 4 Indexed electron diffraction pattern from a lamellae in

hard segment content film crystallized at 200°C a 73% by weight polyether-polyester film. Pattern indexes with

(AT_~15°C, T,.~215°C 21'22, see also the d.s.c, data the = form of 4GT

POLYMER, 1985, Vol 26, January 11

Crystallization behaviour of random block copolymers: R. M Briber and E. L. Thomas

the (010) planes. While (010) folding is indicated by the

sides of the crystals being (010) planes, the (100) and (1 ]0)

facets present at the ends of the crystals implies folding

parallel to the (100) and (l]0) planes in the regions

(sectors) defined by these facets. As previously mentioned,

evidence for chain folding exists from the g.p.c, work done

by Seymour et al. 6. It is interesting to note that the cracks

are not observed in the smaller crystals grown in the 49~

hard segment content films.

Another explanation for the strip boundaries observed

in the dark field micrographs of the 73~ hard segment

crystals is that they correspond to boundaries between

fold domains. This explanation does not hold up to closer

scrutiny because the diffraction contrast features as-

sociated with fold domain boundaries would be expected

to disappear with radiation damage 29'3°. These 'boun-

daries' remain after the crystal has been completely

damaged. In addition the contrast features associated

Figure 5 Low magnification BF TEM micrograph at a melt with the strip boundaries do not shift with defocus of the

crystallized 49% by weight hard segment polyether-polyester electron microscope objective lens while for fold sector

film. Arrows indicate mono-, bi- and tri-layer crystals boundaries they would be expected to shift 29'3°.

No clear evidence of sectorization or sector boundaries

feature in the 49~ film is that not all the lamellae are the was observed by bright or dark field electron microscopy.

same thickness. Definite step changes in contrast cor- As mentioned previously the cracks observed often run

responding to integral layers of lamellae can be observed.

Indicated by the arrows and numbers in Figure 5 are

mono-, bi- and tri-layers. Virtually all of the large crystals

are either bilayers or thicker with the different layers

following the same growth front. This is not seen in the

73~o content films where the crystals appear mostly as

single monolayers. Once a chain exits the hard segment

crystal in the 49~ hard segment sample it appears to be

just as likely to re-enter the original lamellae as it is to

enter one directly adjacent. In the 73~o hard segment

sample the smaller amount of soft segment causes it to be

more favourable for the chain to re-enter the same crystal.

An attempt was made to grow single lamellae in films of

4GT homopolymer but the nucleation density was too

high to allow the identification of isolated crystals. Single

crystal diffraction patterns were obtained but the growth

fronts and overall shape of the crystals were not

discernible.

Figure 6 is a pair of dark field micrographs of the same

crystal using the (100) and (010) reflections to form the

images, respectively, in a 73~ hard segment film

(T~= 200°C). The most striking aspect of the crystal is that

it appears to be divided into strips parallel to (010) planes.

The strips are generally about 0.25-1.0 #m in width and

often run the entire length of the crystal. Figure 7 is a

bright field--(100) dark field pair of micrographs of the

same area of a 73~ hard segment crystal. The strip

boundaries observed in dark field appear to be cracks in

the crystal in the bright field micrograph. A possible

explanation for the cracks is that the crystal grows as a

single unit at the high (200°C) crystallization temperature

but breaks up on cooling to room temperature due to the

larger thermal contraction of the amorphous matrix

surrounding the crystal. This would indicate that the

mechanical strength is poor between the (010) planes and

the crystal cracks easily parallel to these planes. The (010)

plane has the largest d-spacing in the (hkO) unit cell

projection and might be expected to be an easy cleavage

Figure 6 Pair of dark field micrographs of the same crystal in a

plane. Another possible explanation is that any chain 73% polyether-polyester hard segment film. (a) Image formed

folding that might be present occurs along the (010) planes using the (100) reflection; (b) image formed using the (010)

which would lead to easy crack propagation parallel to reflection

12 POLYMER, 1985, Vol 26, Januarv

Crystallization behaviour of random block copolymers: R. M. Briber and E. L. Thomas

re-examined. It was found that the matrix had partially

crystallized. Figure 8 is a pair of electron diffraction

patterns from the matrix material of a 73~o hard segment

film, taken with a few hours after quenching from T~and

after about 3 months at room temperature. The polycrys-

talline pattern in Figure 8b corresponds to the alpha form

of 4GT indicating that there was a significant amount of

hard segment material present in the matrix that was

unable to crystallize at T~. Figure 9 is a dark field

micrograph of the matrix material taken using the

polycrystalline rings to form the dark field image. The

edge of a large lamella is seen in the left hand portion of

the micrograph. Small 50-20 nm clusters of crystals are

visible in the matrix. This observation correlates well with

the work of Zhu and Wegner who followed the crystalli-

zation of a series of PTMEG (1000)/4GT polyether-

polyesters by monitoring the growth of lamellar ag-

gregates (hedrites) by optical microscopy as a function of

time at a given T~7,8. They observed that the hedrites

stopped growing at a given T~ long before impingement.

Upon cooling to a lower T¢the hedrites would commence

growing again at the edges of the original aggregates. This

is analogous to our thin film crystallization where the

lamellae stop growing before the film is completely

transformed. After cooling to room temperature short

hard segment sequences remaining in the matrix crystall-

ize with time. At the initial high crystallization tempera-

ture the stable crystal thickness is large and only relatively

long hard segment sequences are able to crystallize.

Shorter sequences that are unable to traverse the crystal

cannot participate in crystallization. When the sample is

Figure 7 Bright field-dark field pair of micrographs of a 73%

hard segment polyether-polyester lamella. (a) Bright field

micrograph, note the presence of cracks running parallel to the

(010) planes; (b) dark field micrograph, note the discontinuity in

the diffracting regions at the crack boundaries

Figure 8 Electron diffraction patterns from the matrix material

in a 73% polyether-polyester and hard segment film. (a)

Immediately after crystallization; (b) after storage for 3 months at

room temperature. Note the presence of polycrystalline rings in

(b)

the entire length of the crystals whereas a change in the

crack propagation behaviour is usually expected upon

traversing from one fold sector to another. Similar crystal

faceting behaviour with only poorly defined sectorization

has been observed in solution grown nylon-6,6 crystals 31.

When the films were initially examined, the matrix Figure 9 Dark-field micrograph of the matrix in a 73%

polyether-polyester hard segment film after storage for 3 months

surrounding the crystals was amorphous as indicated by at room temperature. Small aggregations of diffracting crystals are

the microdiffraction pattern in Ficmre 3. The films were arrowed. Edge of a large lamella is visible in the left hand portion

then stored at room temperature c about 3 months and of the micrograph

POLYMER, 1985, Vol 26, January 13

Crystallization behaviour of random block copolymers." R. M. Briber and E. L. Thomas

AH ° = 33.5 cal g - 1.32 If one assumes that all sequences of

a minimum length and longer participate in crystalli-

zation one can calculate the hard segment length for

which 40~o of the sequences are equal to or larger from

=T I0.0 h

equation (1)

N; = XHsK -1 (])

4.5h

where N~ is the number fraction of hard segment blocks K

and longer, XHS is the hard segment mole fraction and K is

uJ l.Oh the block length. Setting N~ equal to 0.40 and Xns equal

0.5 h

to 0.93 yields a value o f K = 14. For the 73% hard segment

(0.93 mole fraction) content sample the average sequence

0.25 h length is 15. So it appears that most sequences of about the

I

190 200 210 220 250 average length and greater participate in crystallization at

Temperature (°C) T~= 200°C. This differs from conclusions drawn by other

Figure 10 D.s.c. scans of a 73% hard segment polyether- authors who asserted that only sequences of the average

polyester film crystallized at 200°C for various lengths of time length crystallize with shorter and longer sequences being

excluded from the crystal 2'7'a.

Wide-angle X-ray scattering

subsequently cooled the stable crystal thickness is less and

shorter sequences can then diffuse and crystallize forming WAXS diffractometer scans were run on the series of

the new growth observed at the edges of the hedrites polyether-polyesters and the 4GT homopolymer. Figure

observed by Zhu et al. or the small crystals scattered 11 shows the WAXS scans as a function of hard segment

through the matrix seen in this work. This implies that content. For samples of 49~o hard segment content and

fractionation of the hard segment sequences can occur higher the (0i 1), (010) and (100) d-spacings were measu red

according to length but not because of incompatibility of and are given in Table 2. The spacings were measured

different lengths, rather due to coupling of the sequence without peak separation or K=2 stripping. All the re-

distribution with the stable crystal size at a given To. flections observed agreed with the alpha form of 4GT. No

variation of the unit cell with decreasing hard segment

Differential scanning calorimetry content, within experimental error, was observed. This

D.s.c. scans were run on a 73~o hard segment sample agrees with the electron diffraction data presented earlier.

crystallized at 200°C for various lengths of time. The There does not appear to be any systematic expansion or

samples were melted in the d.s.c, pans in a Mettler hot contraction of the unit cell with decreasing hard segment

stage at 250°C for 5 min and then the temperature content as would be expected if appreciable amounts of

dropped to 200°C for different times and subsequently the soft segment were incorporated into the crystal as

quenched to room temperature. Pans were then transfer- defects.

red to the d.s.c, for the measurements. Figure 10 is a series All the data presented so far support a lamellar model

of scans of samples crystallized for 0.25, 0.5, 1.0, 4.5 and of a relatively pure 4GT crystalline core with the P T M E G

10 h. At short crystallization times two peaks at about soft segments rejected to the fold surfaces of the crystal.

215 ° and 207°C are observed. The higher temperature The striking (hkO) electron diffraction patterns obtained

peak arises from the melting of the large lamellae that form from the lamellae indicate that the chain axis is normal to

at 200°C. The low temperature peak is due to material the surface of the crystal and the chain must exit the top

that crystallizes during the scan and during the quench to surface of the crystal, fold and re-enter. The exact nature

room temperature from T~ before the scan. As the

crystallization time increases the low temperature peak

shrinks while the high temperature peak grows. This is (100)

consistent with increased lamellar growth as the crystalli- Alil)

zation time increases with the consequence of there being

fewer long hard segments to crystallize as the small, low

melting temperature crystals upon quenching. At 4.5 h at

T~ there is only a small shoulder indicative of low

temperature crystals and by 10 h only the high melting

point material is present. The crystallization of short hard

segment sequences in the matrix observed by electron

.~ ~ 59 %

microscopy for thin films indicates that even in the sample

crystallized for 10h there are hard segment sequences

present that are not able to crystallize because they are too

short to add to the crystals. At room temperature these

sequences take weeks to aggregate and crystallize.

The total heat of fusion for both peaks remains

relatively constant during crystallization as a function of 5 IO 15 20 25 :50 35

crystallization time. AH• varies from about 8.5 to 2e, Degrees

10 cal g-1. This corresponds to the hard segment being Figure 11 WAXS scans of the series of polyether-polyesters of

about 4 0 ~ o crystalline, using a value of various compositions

14 POLYMER, 1985, Vol 26, January

Crystallization behaviour of random block copolymers." R. 114. Briber and E. L. Thomas

T a b l e 2 (100)I(010) and (011) unit cell spacings of polyether-polyesters as a function of hard segment content as measured by WAXS

(nanometers)

Wt % 4GT dlo0 dolo d0i I Tc o C

100% 0.382 0.517 0.557 220

81% 0.383 0.517 0.556 210

73% 0.383 0.516 0.555 200

59% 0.383 0.517 0.559 195

49% 0.383 0.516 0.558 190

Calculated* 0.382 0.514 0.550

* Based on the unit cell presented by Oesborough and Hall 27

of the type of folding, i.e. adjacent re-entry versus random It is striking that single crystals of a random block

switchboard, cannot be determined. Indeed, the specifics copolymer can be grown from the melt. Lotz et al. have

of chain folding are still debated for homopolymers 33. reported, similar to this work, that it is actually easier to

Nevertheless, some pertinent comments can be made. grow single crystals of a diblock copolymer of po-

Small-angle X-ray studies in the literature indicate that lyethylene oxide (PEO) with polystyrene (PS) than from

PTMEG/4GT polyether-polyesters exhibit the classical PEO homopolymer 35, The PEO/PS crystals were essen-

dependence of the long period on crystallization tempera- tially identical to hompolymer PEO crystals with the PS

ture 2. At high crystallization temperatures thicker lamel- being confined to the fold surface. Single crystals of short

lae are formed. The aspect different from homopolymer branched polyethylene36 and of copolymers of tetra-

behaviour is that the crystal growth in these copolymers is methyl-p-silphenylene siloxane/dimethylsiloxane 37,38

limited by the number of hard segment sequences avail- have also been reported. In contrast, in both of these latter

able that are long enough to traverse the stable crystal cases the copolymers did not form individual single

thickness at a given T~which, in turn, is determined by the crystals as readily as the homopolymers.

sequence distribution. This implies that most of the hard

segment sequences participating in the crystal core must

terminate with a soft segment sequence near the surface of

the lamella. Only the longest hard segment sequences in CONCLUSIONS

the distribution would be of sufficient length to undergo

tight folding and traverse the crystal twice. The evidence Single crystals of 4GT have been grown in thin films from

presented by Seymour et al. on etching of the fold surfaces the melt of random block copolymers based on

and subsequent g.p.c, experiments indicated that there PTMEG/4GT. Well defined lamellae have been observed

was a fraction of stems twice the crystal thickness in films down to 49 wt% (0.83 mole fraction) 4GT

demonstrating that some of the longest sequences may component. Electron diffraction and WAXS support a

indeed fold tightly. The fold surface must consist of mainly model of a relatively pure 4GT crystal core in the ~ form

soft segment molecules and short hard segment se- with the PTMEG sequences and short hard segments

quences. The thickness of the amorphous layer (fold rejected to the crystal fold surface and soft segment rich

surface) should be directly proportional to the soft matrix. This is good agreement with the models presented

segment content of the sample. The disparity in length of previously by Celia 1'4'5 and Seymour et al. 6 with ad-

the sequences participating in crystallization naturally ditional insight into the fine details of the morphology.

leads one to expect relatively diffuse crystal boundaries. The strong (hkO) diffraction pattern exhibited by the

Yet, as mentioned earlier, SAXS studies of the interface lamellae indicates the ~ axis is normal to lamellar surface

have indicated relatively sharp boundaries 9. and the polymer chains must undergo some type of chain

Strobl et al. have presented a model for the crystalli- folding.

zation of low density polyethylene where crystal growth is The crystallization behaviour indicates that the lateral

not directly controlled by the sequence distribution of dimensions of the crystal growing at a given temperature

chain lengths between branch points but by the amor- are controlled by the number of 4 G T sequences long

phous layer between growing lamellae 34. In low density enough to traverse the crystal which is determined by the

polyethylene the long branches are excluded from the sequence distribution. This leads to an initial population

crystals to the fold surfaces and interlamellar regions. of crystals formed at T~and a second set of small crystals

The model was postulated to explain the strong (re- that grow upon cooling to room temperature. The result is

versible) temperature dependence of the long period while fractionation by sequence length due to coupling of the

accounting for a relatively constant crystal core thickness. sequence distribution with the stable crystal size at T~.

It appears unlikely that the polyether-polyesters studied

in this work follow this model. The fact that the lamellae

observed in this study and the hedrites examined by Zhu

et al. stop growing many microns apart suggests that ACKNOWLEDGEMENT

depletion of the long hard segment sequences controls the The authors would like to acknowledge the National

crystallization. It is not known whether polyether~ Science Foundation for financial support (grant CPE-

polyesters exhibit a temperature dependent long period or 8118232) and the Materials Research Laboratory at the

crystal thickness, although it is reasonable to predict that University of Massachusetts for the use of the experimen-

it would be observed. tal facilities.

POLYMER, 1985, Vol 26, January 15

Crystallization behaviour of random block copolymers." R. M. Briber and E. L. Thomas

REFERENCES 19 Chacko, V. P., Adams, W. W. and Thomas, E. L. J. Mater. Sci.

1983, 18, 1999

20 Wunderlich, B. 'Macromolecular Physics', Vol. 1, Academic

Press, N.Y., 1973, p. 217

1 Celia, R. J. J. Polym. Sci., Syrup. 1973, 42, 737 21 Shih, C. K., DuPont Co., unpublished data

2 Wegner, G., Fujii, T., Meyer, W. and Lieser, G. Die Angew. 22 Briber, R. M. PhD Dissertation, Polymer Science and Engineer-

Makromol. Chem. 1978, 74, 295 ing, University of Massachusetts, 1984

3 Lilaonitkal, A. and Cooper, S. L. Rubber Chem. Technol. 1977, 50, 23 Jakeways, R., Ward, I. M., Wilding, M. A., Hall, I. H., De-

1 sborough, I. J. and Pass, M. R. J. Polym. Sci., Polym. Phys. Edn.

4 Celia, R. J. 'Encyclopedia of Polymer Science and Technology', 1975, 13, 799

Supplement Vol. 2, Wiley and Sons, 1977, p. 485 24 Mencik, Z. J. Polym. Sci., Polym. Phys. Edn. 1975, 13, 2173

5 Buck, W. H., Cella, R. J., Gladding, E. K. and Wolfe, J. R. J. 25 Yokouchi, M., Sakakibara, Y., Chatani, Y., Tadokoro, H.,

Polym. Sci. Symposium 1974, No. 48, 47 Tanaka, T. and Yoda, K. Macromolecules 1976, 9, 266

6 Seymour, R. W., Overton, J. R. and Corley, L. S. Macromolecules 26 Hall, I. H. and Pass, M. G. Polymer 1976, 17, 807

1975, 8, 331 27 Desborough, I. J. and Hall, I. H. Polymer 1977, 18, 825

7 Zhu, L.-L. and Wegner, G. Makromol. Chem. 1981, 182, 3625 28 Briber, R. M. and Thomas, E. L., submitted to Polymer

8 Zhu, L.-L., Wegner, G. and Bandara, U. Makromol. Chem. 1981, 29 Thomas, E. L. J. Mater. Sci. 1977, 12, 234

182, 3639 30 Boudet, A. and Kubin, L. D. J. Microsc. Spectrosc. Electron. 1980,

9 Bandara, U. and Droscher, M. Colloid Polym. Sci. 1983, 261, 26 5, 187

10 Siemann, U. and Ruland, W. Colloid Polym. Sci. 1982, 269, 999 31 Khoury, F. A., private communication

11 Hashimoto, T., Todo, A., Itoi, H. and Kawai, H. Macromolecules 32 Illers, K. H. Colloid. Z. Z. 1980, 258, 117

1977, 10(2), 377 33 Faraday Discussions of the Royal Society, Organization of

12 Wistsiepe, W. K. and Hoeschele, G. K. Angew. Makromol. Chem. Macromolecules in the Condensed Phase, 1979, 68

1973, 29-30, 267 34 Strobl, G. R., Schneider, M. J. and Voight-Martin, I. G. J. Polym.

13 Shih, C. K. and McKenna, J. M., submitted to Rubber Chem. Sci., Polym. Phys. Edn. 1980, 18, 1361

Technol. 35 Lotz, B., Kovacs, A. J., Bassett, G. A. and Keller, A. Kolloid Z. Z.

14 Wolfe, Jr., J. R. Rubber Chem. Technol. 1977, 50(4), 688 Polym. 1966, 209, 115

15 Shih, C. K., to be submitted to Rubber Chem. Technol. 36 Geil, P. H. 'Polymer Single Crystals', Krieger Publishing Co.,

16 Low, A., Vesley, D.,Allen,P.and Bevis, M.J.Mater.Sci. 1979,14, N.Y., 1973, p. 100

1109 37 Li, H. M. and Magill, J. H. J. Polym. Sci., Polym. Phys. Edn. 1978,

17 Sherman, E. S. and Thomas, E. L. J. Mater. Sci. 1979, 14,1109 16, 1059

18 Sherman, E. S., Adams, W. W. and Thomas, E. L. J. Mater. Sci. 38 Kojima, M. and Magill, J. H. J. Macromol. Sci.-Phys. 1974,

1981, 16, 1 BI0(3), 419

16 POLYMER, 1985, Vol 26, January

You might also like

- Basic Maintenance KPI MetricsDocument20 pagesBasic Maintenance KPI MetricsKrishna Jasha100% (5)

- MW Vs Melting TempDocument12 pagesMW Vs Melting Temptripti060586No ratings yet

- ch3 Structure and Property PDFDocument29 pagesch3 Structure and Property PDF임성민No ratings yet

- Analysis of the α, β, And γ Relaxations in PolychlorotrifluoroethyleneDocument63 pagesAnalysis of the α, β, And γ Relaxations in PolychlorotrifluoroethylenezakariiNo ratings yet

- Conformation and Crystal Structure:, in Either AmorDocument34 pagesConformation and Crystal Structure:, in Either AmorUsama AwadNo ratings yet

- Effect of Polymer Morphology On Photodegradation Kinetics 411Document13 pagesEffect of Polymer Morphology On Photodegradation Kinetics 411Marister OliveiraNo ratings yet

- Does The Length of The Short Chain Branch Affect The Mechanical Properties of Linear Low Density PolyethylenesDocument19 pagesDoes The Length of The Short Chain Branch Affect The Mechanical Properties of Linear Low Density PolyethylenesAndrés Felipe PerezNo ratings yet

- Polymer: Junchai Zhao, Jianmin Zhang, Xiaoli Duan, Zheng Peng, Shaohui WangDocument9 pagesPolymer: Junchai Zhao, Jianmin Zhang, Xiaoli Duan, Zheng Peng, Shaohui WangMarióxido de SodioNo ratings yet

- Polymer Semiconductor Crystals: Abriseno@mail - Pse.umass - EduDocument11 pagesPolymer Semiconductor Crystals: Abriseno@mail - Pse.umass - Eduehagar60No ratings yet

- Valeur Temps RelaxDocument14 pagesValeur Temps RelaxRomain LefèbvreNo ratings yet

- Polymer Constitution and Fiber PropertiesDocument22 pagesPolymer Constitution and Fiber PropertiesMiriam GarciaNo ratings yet

- Crystallization and Morphology of Metallocene Polyethylenes With Well-Controlled Molecular Weight and BranchiDocument8 pagesCrystallization and Morphology of Metallocene Polyethylenes With Well-Controlled Molecular Weight and BranchifaezehNo ratings yet

- Crystallinity of PolymersDocument24 pagesCrystallinity of Polymersakived100% (2)

- Da Leggere 3Document10 pagesDa Leggere 3fottekupaugra-8350No ratings yet

- Mechanical Properties of Polymers 3Document16 pagesMechanical Properties of Polymers 3Christhy Vanessa Ruiz MadroñeroNo ratings yet

- WATKINS 1995 Polymerization of Styrene in Supercritical CO2 Swollen Poly (Chlorotrifluoroethylene)Document8 pagesWATKINS 1995 Polymerization of Styrene in Supercritical CO2 Swollen Poly (Chlorotrifluoroethylene)pstedile1234No ratings yet

- Buckling Instability in Liquid Crystalline Physical GelsDocument4 pagesBuckling Instability in Liquid Crystalline Physical Gelsjtw08No ratings yet

- Introduction To Polymer SpectrosDocument5 pagesIntroduction To Polymer SpectrossaurabhNo ratings yet

- Oxygen Barrier Properties of Crystallized and Talc-FilledDocument11 pagesOxygen Barrier Properties of Crystallized and Talc-FilledW00WNo ratings yet

- E Ffect of Chain Dynamics, Crystallinity, and Free Volume On The Barrier Properties of Poly (Ethylene Terephthalate) Biaxially Oriented FilmsDocument11 pagesE Ffect of Chain Dynamics, Crystallinity, and Free Volume On The Barrier Properties of Poly (Ethylene Terephthalate) Biaxially Oriented Filmslong tran hoangNo ratings yet

- Introduction To Polymer CrystallizationDocument12 pagesIntroduction To Polymer Crystallizationalina.tlekkabylova270202No ratings yet

- Air Separation Properties of Flat Sheet Homogeneous Pyrolytic Carbon MembranesDocument12 pagesAir Separation Properties of Flat Sheet Homogeneous Pyrolytic Carbon Membranesfilesfriendly93No ratings yet

- Publication 4 12613 5018Document17 pagesPublication 4 12613 5018a12b67scicbNo ratings yet

- Synthesis of A New Side-Chain Type Liquid Crystal Polymer Poly (Dicyclohexyl Vinylterephthalate)Document3 pagesSynthesis of A New Side-Chain Type Liquid Crystal Polymer Poly (Dicyclohexyl Vinylterephthalate)FiyanNo ratings yet

- Discussion 5.3 Stress-StrainDocument4 pagesDiscussion 5.3 Stress-StrainYow Sheng TanNo ratings yet

- Polymer ProDocument25 pagesPolymer ProJeerisuda KingklangNo ratings yet

- Polymer: Gung-Pei Chang, Ching-Nan Chuang, Jong-Yih Lee, Yung-Shen Chang, Man-Kit Leung, Kuo-Huang HsiehDocument8 pagesPolymer: Gung-Pei Chang, Ching-Nan Chuang, Jong-Yih Lee, Yung-Shen Chang, Man-Kit Leung, Kuo-Huang Hsieh張大帥No ratings yet

- STruture and Properties of PolymersDocument35 pagesSTruture and Properties of PolymersWasif Razzaq100% (1)

- J of Applied Polymer Sci - 2002 - Li - Complicated Resistivity Temperature Behavior in Polymer CompositesDocument5 pagesJ of Applied Polymer Sci - 2002 - Li - Complicated Resistivity Temperature Behavior in Polymer Composites白小宇No ratings yet

- Fiber Physics NoteDocument32 pagesFiber Physics Notezinabu abrhaNo ratings yet

- High-Temperature Viscoelasticity and Heat-Setting of Poly (Ethylene Terephthalate)Document17 pagesHigh-Temperature Viscoelasticity and Heat-Setting of Poly (Ethylene Terephthalate)api-3733260No ratings yet

- Influence of Long-Chain Branches in Polyethylenes On Linear Viscoelastic Flow Properties in Shear PDFDocument13 pagesInfluence of Long-Chain Branches in Polyethylenes On Linear Viscoelastic Flow Properties in Shear PDFfaezehNo ratings yet

- Transverse Loading of Monofilament Reinforced Rnicrocornposites: A Novel Fragmentation Technique For Measuring The Fibre Compressive StrengthDocument6 pagesTransverse Loading of Monofilament Reinforced Rnicrocornposites: A Novel Fragmentation Technique For Measuring The Fibre Compressive StrengthRosane MouraNo ratings yet

- Evidence For A Partially Ordered Component in Polyethylene From Wide-Angle X-Ray DiffractionDocument14 pagesEvidence For A Partially Ordered Component in Polyethylene From Wide-Angle X-Ray DiffractionSamuel GideyNo ratings yet

- Characterization of PolymersDocument30 pagesCharacterization of Polymerssuranjana26No ratings yet

- 0612617Document9 pages0612617Achiaa Osei-DonkorNo ratings yet

- Polymer Structure-Properties RelationshipDocument18 pagesPolymer Structure-Properties RelationshipRobert ChucklesNo ratings yet

- Polymer Cha4Document57 pagesPolymer Cha4Galma DhugaaNo ratings yet

- Crystallization Behaviour of Poly (-Lactide) : Tadakazu Miyata and Toru MasukoDocument7 pagesCrystallization Behaviour of Poly (-Lactide) : Tadakazu Miyata and Toru MasukoJavier Vallejo MontesinosNo ratings yet

- 2006 Preparation and Application of Cross-Linked Core-Shell PBA PS and PBA PMMA NanoparticlesDocument6 pages2006 Preparation and Application of Cross-Linked Core-Shell PBA PS and PBA PMMA Nanoparticleschiyuan.chuNo ratings yet

- Thermoplastic ElastomeDocument160 pagesThermoplastic ElastomeManas MondalNo ratings yet

- ADAMDocument8 pagesADAMapi-3733260No ratings yet

- Annealing of Poly (Ethylene Terephthalate)Document8 pagesAnnealing of Poly (Ethylene Terephthalate)SSGKONSPECNo ratings yet

- (2007) Analysis of Microporous Membranes Obtained From PPDocument10 pages(2007) Analysis of Microporous Membranes Obtained From PPsateeshbondaNo ratings yet

- Hedesiu CristianDocument143 pagesHedesiu CristianTrung NguyenNo ratings yet

- Crystallinity and Transition Temperatures in PolymersDocument46 pagesCrystallinity and Transition Temperatures in PolymersghenisNo ratings yet

- 9210 Dynamic Mechanical Analysis of Banana Fiber Reinforced Polyester CompositesDocument11 pages9210 Dynamic Mechanical Analysis of Banana Fiber Reinforced Polyester CompositesAdlan Akram Mohamad MazukiNo ratings yet

- Jurnal Pendukung 2Document11 pagesJurnal Pendukung 2Rehan AshariNo ratings yet

- Hill 2004Document16 pagesHill 2004brouuorbNo ratings yet

- 10.1016@0379 67798090022 3Document8 pages10.1016@0379 67798090022 3Yeison NúñezNo ratings yet

- App 1985 070300510Document24 pagesApp 1985 070300510Thivagaran VeeraiyaNo ratings yet

- Chemorheology and Properties of Epoxy-Layered Silicate NanocompositesDocument8 pagesChemorheology and Properties of Epoxy-Layered Silicate NanocompositesrenebarreiroNo ratings yet

- The Effect of Molecular Weight and Crystallinity On The Mechanical Properties of Injection Moulded Poly (Aryl-Ether-Ether-Ketone) ResinDocument7 pagesThe Effect of Molecular Weight and Crystallinity On The Mechanical Properties of Injection Moulded Poly (Aryl-Ether-Ether-Ketone) ResinSakhaviTVNo ratings yet

- Fibre Epoxy Composites at Low Temperature HartwigDocument9 pagesFibre Epoxy Composites at Low Temperature HartwigodormicchiNo ratings yet

- Effect of MW Co Monomer Content On Monomer StructureDocument9 pagesEffect of MW Co Monomer Content On Monomer StructuredeveshdptNo ratings yet

- (2023) (Thoudam) Effect of Topology On The Collapse Transition and The Instantaneous Shape of A Model HeteropolymerDocument13 pages(2023) (Thoudam) Effect of Topology On The Collapse Transition and The Instantaneous Shape of A Model HeteropolymerIsabel CamusNo ratings yet

- Polymer TacticityDocument28 pagesPolymer Tacticityowegibrian479No ratings yet

- Degree of Branching of PolypropyleneDocument7 pagesDegree of Branching of PolypropylenefaezehNo ratings yet

- Exam 2 Study GuideDocument4 pagesExam 2 Study Guidelongxuan xuNo ratings yet

- Unit 5 Polymer TechDocument44 pagesUnit 5 Polymer TechShyam MarquezNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Conformational Structure of Poly (Ethylene Terephthalate) - Infra-Red, Raman and N.M.R. SpectraDocument8 pagesConformational Structure of Poly (Ethylene Terephthalate) - Infra-Red, Raman and N.M.R. SpectraLucas Del PretteNo ratings yet

- Condensed Matter Film Behaviour: Thin Sotid Films, 204 (1991) 203 216Document14 pagesCondensed Matter Film Behaviour: Thin Sotid Films, 204 (1991) 203 216Lucas Del PretteNo ratings yet

- Design For Recycling Guidelines-PET Trays 03-12-2018Document1 pageDesign For Recycling Guidelines-PET Trays 03-12-2018Lucas Del PretteNo ratings yet

- Plasma Pretreatment of Polymer Web To Increase The Quality of Commodity Grade Packaging Films: An Adhesion PerspectiveDocument32 pagesPlasma Pretreatment of Polymer Web To Increase The Quality of Commodity Grade Packaging Films: An Adhesion PerspectiveLucas Del PretteNo ratings yet

- A Novel Method For Determination of Polyester End-Groups by NMR SpectrosDocument7 pagesA Novel Method For Determination of Polyester End-Groups by NMR SpectrosLucas Del PretteNo ratings yet

- 17 2018FoodHydrocolloidsPETfilmDocument8 pages17 2018FoodHydrocolloidsPETfilmLucas Del PretteNo ratings yet

- Krepker 2017Document10 pagesKrepker 2017Lucas Del PretteNo ratings yet

- Interdisciplinary Detection Science: Volume 135 - Number 11 - November 2010 - Pages 2745-3012Document12 pagesInterdisciplinary Detection Science: Volume 135 - Number 11 - November 2010 - Pages 2745-3012Lucas Del PretteNo ratings yet

- Inks For Printing On Plastic FilmsDocument8 pagesInks For Printing On Plastic FilmsLucas Del PretteNo ratings yet

- 8756087914559863Document28 pages8756087914559863Lucas Del PretteNo ratings yet

- 1 s2.0 S0300944004001249 MainDocument12 pages1 s2.0 S0300944004001249 MainLucas Del PretteNo ratings yet

- 1 s2.0 0300944080800105 MainDocument29 pages1 s2.0 0300944080800105 MainLucas Del PretteNo ratings yet

- Surface Defects and Surface Flows in Coatings : Gordon P. BierwagenDocument10 pagesSurface Defects and Surface Flows in Coatings : Gordon P. BierwagenLucas Del PretteNo ratings yet

- XPS Study of Al/polyethylene Terephtalate InterfaceDocument7 pagesXPS Study of Al/polyethylene Terephtalate InterfaceLucas Del PretteNo ratings yet

- Letter: Interfacial Analysis of Aluminum and Copper Thin Films Evaporated On Polyethylene-TerephthalateDocument5 pagesLetter: Interfacial Analysis of Aluminum and Copper Thin Films Evaporated On Polyethylene-TerephthalateLucas Del PretteNo ratings yet

- Example Beam ProblemDocument2 pagesExample Beam ProblemxicaodocetNo ratings yet

- BOL1219 A Leaflet190109Document2 pagesBOL1219 A Leaflet190109servicibsNo ratings yet

- High Altitude Aeronautical Platform Systems (Presentation)Document30 pagesHigh Altitude Aeronautical Platform Systems (Presentation)Mahenoor SiddiquiNo ratings yet

- 568f Pec Ts GuideDocument72 pages568f Pec Ts GuideLuciano F LopesNo ratings yet

- Atmospheric Temperature, Pressure and Density As Function of The Height Above Sea LevelDocument53 pagesAtmospheric Temperature, Pressure and Density As Function of The Height Above Sea LevelMustafa TıraşNo ratings yet

- Overview of OFDM Modulation TechniqueDocument15 pagesOverview of OFDM Modulation TechniqueDishant KhoslaNo ratings yet

- Working Platform For Installing and Dismantling Aluminum Formwork PDFDocument9 pagesWorking Platform For Installing and Dismantling Aluminum Formwork PDFmohd zulhafizNo ratings yet

- Datasheet Viscosity Compensating Flow Meter Switch VKGDocument4 pagesDatasheet Viscosity Compensating Flow Meter Switch VKGJairo MoralesNo ratings yet

- Getting Started With IFIXDocument138 pagesGetting Started With IFIXchris75726No ratings yet

- H.T Samsung Split Ducto Heat Pump R410aDocument3 pagesH.T Samsung Split Ducto Heat Pump R410aJorge Renato Chirinos QuiñonezNo ratings yet

- Screw Conveyors PDFDocument121 pagesScrew Conveyors PDFzackii90No ratings yet

- Wine Celler: Service ManualDocument38 pagesWine Celler: Service ManualaderlochNo ratings yet

- 6FM100D XDocument2 pages6FM100D XLê Anh TuấnNo ratings yet

- What Every Sailor Needs To Know About Seacocks: The Four Main Types of Seacock: Pros and ConsDocument2 pagesWhat Every Sailor Needs To Know About Seacocks: The Four Main Types of Seacock: Pros and ConsRicky WrightNo ratings yet

- 31 Waves ReflectionDocument2 pages31 Waves Reflectioneltytan100% (1)

- 10 Science Chemical Reactions and Equations Test 01Document2 pages10 Science Chemical Reactions and Equations Test 01Himanshu SharmaNo ratings yet

- Neleo 50Document3 pagesNeleo 50Anjum ParkarNo ratings yet

- Mechanical Relay-Type PDFDocument17 pagesMechanical Relay-Type PDFSaleCvetkovicNo ratings yet

- 9 Dam Break PDFDocument13 pages9 Dam Break PDFBrandon ArmeroNo ratings yet

- Erc 500-1000 - GBDocument2 pagesErc 500-1000 - GBtram 11100% (1)

- Manual Book Mov Auma PDFDocument44 pagesManual Book Mov Auma PDFDidi Gunawan100% (1)

- 15EC42 MicroprocessorDocument10 pages15EC42 Microprocessora_b_h_iNo ratings yet

- Operating System AdministrationDocument6 pagesOperating System AdministrationRahulsrivasNo ratings yet

- Writing Task 1 ProcessDocument11 pagesWriting Task 1 ProcessLe NgocNo ratings yet

- Splandek EsdDocument3 pagesSplandek Esdkiranmisale7No ratings yet

- MSDS Colacor 600Document3 pagesMSDS Colacor 600mndmatt100% (2)

- Curriculum Vitae: S.Mullainathan MOB: 8524896757Document2 pagesCurriculum Vitae: S.Mullainathan MOB: 8524896757BaraneedharanNo ratings yet

- Finite State Machine Based Vending Machine Controller With Auto-Billing FeaturesDocument5 pagesFinite State Machine Based Vending Machine Controller With Auto-Billing FeaturesSubbuNaiduNo ratings yet

- Request For Inspection Summary: Project Name: ClientDocument2 pagesRequest For Inspection Summary: Project Name: ClientAmit MaityNo ratings yet