Professional Documents

Culture Documents

WD Turret PLC

WD Turret PLC

Uploaded by

AryCopyright:

Available Formats

You might also like

- P66 B1 M5 Lufthansa PDFDocument196 pagesP66 B1 M5 Lufthansa PDFDAVID FAJARDO PUERTO100% (1)

- Cost Planning For The Product Life CycleDocument23 pagesCost Planning For The Product Life CyclesugihartiniNo ratings yet

- Dodge 054153 CatalogDocument214 pagesDodge 054153 CatalogRicardo PerezNo ratings yet

- QY8-31SK-000: Revision 0Document37 pagesQY8-31SK-000: Revision 0Nebi aktaşNo ratings yet

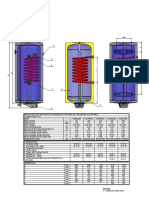

- Interacumulador Ac 80-200 T Vertikalni Za Stena enDocument1 pageInteracumulador Ac 80-200 T Vertikalni Za Stena ennachoxxiNo ratings yet

- List of QC Inspection Form For Mechanical: Tanjung Jati B, Boiler of BopDocument34 pagesList of QC Inspection Form For Mechanical: Tanjung Jati B, Boiler of BopAlif Rahmat FebriantoNo ratings yet

- M06-2053-101 (No Logo) - 231218 - 214518Document246 pagesM06-2053-101 (No Logo) - 231218 - 214518ehsanabedi686868No ratings yet

- NHD 14432WG Atfh VTDocument12 pagesNHD 14432WG Atfh VTcizetawwwNo ratings yet

- 320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 10) - Front GlassDocument2 pages320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 10) - Front GlassAbi ManyuNo ratings yet

- 1 CSP-E - I2r17p DE VUELO 369EDocument284 pages1 CSP-E - I2r17p DE VUELO 369Efredy SanchezNo ratings yet

- SRC - 130 KATALOGDocument3 pagesSRC - 130 KATALOGSomiar TradingNo ratings yet

- Substation - 2 ModelDocument26 pagesSubstation - 2 ModelSolanki SamarthNo ratings yet

- Electrical Turrets: Instruction For Use and MaintenanceDocument14 pagesElectrical Turrets: Instruction For Use and MaintenanceАлександр ЕвграфовNo ratings yet

- Im-R32 FCFV NCCKDocument48 pagesIm-R32 FCFV NCCKPierreNo ratings yet

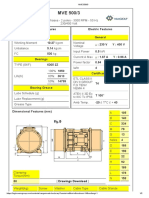

- Motovibrator OLI MVE 500/3E-40A0 - SpecsDocument2 pagesMotovibrator OLI MVE 500/3E-40A0 - SpecsfernandoalvesvnbNo ratings yet

- 843Document6 pages843cleberNo ratings yet

- DC 5 A/T Practice: Ssangyong Motor CompanyDocument32 pagesDC 5 A/T Practice: Ssangyong Motor CompanyMigue SalazarNo ratings yet

- 370Z CanDocument98 pages370Z CanMitch MintonNo ratings yet

- I210 Is Reference Design Schematic PDFDocument13 pagesI210 Is Reference Design Schematic PDFgledyson gueNo ratings yet

- "Fuel" Gauge: Curtis Instruments, IncDocument11 pages"Fuel" Gauge: Curtis Instruments, IncGonzalo D'AddarioNo ratings yet

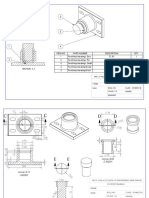

- Spare Parts Catalogue: Aluminium Slide ValveDocument6 pagesSpare Parts Catalogue: Aluminium Slide Valvegracy2288No ratings yet

- CVE 196 FInal ComputationDocument7 pagesCVE 196 FInal Computationjoshua ablinNo ratings yet

- CLT120 CMT260 CHT450 ManualDocument28 pagesCLT120 CMT260 CHT450 Manuallobogoncalves46No ratings yet

- Boss CE-5 (T)Document10 pagesBoss CE-5 (T)Dadson DadoNo ratings yet

- ETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignMuhammad AhsunNo ratings yet

- Accumulator CatalogueDocument4 pagesAccumulator CatalogueDomingos BarrosNo ratings yet

- Lica NotesDocument115 pagesLica NotesAshishNo ratings yet

- PAC-AH125, 140, 250, 500M-J: Air Handling Unit ControllerDocument16 pagesPAC-AH125, 140, 250, 500M-J: Air Handling Unit Controllernguyendinhphuc22008No ratings yet

- M30-1645 (Elec CKT DWG) PDFDocument198 pagesM30-1645 (Elec CKT DWG) PDFAdvance CNC TechnologiesNo ratings yet

- MFL69708212 01 Q 1670306 Uj75-TaDocument41 pagesMFL69708212 01 Q 1670306 Uj75-Tajeanpierreboeuf2No ratings yet

- E90-803-001-001-01 - X 500-2 Brushless - 24v DCDocument20 pagesE90-803-001-001-01 - X 500-2 Brushless - 24v DCAlexNo ratings yet

- 212 Si 01Document36 pages212 Si 01Hector BoliboNo ratings yet

- HCPM Tutorial 5 Project ManagementDocument4 pagesHCPM Tutorial 5 Project ManagementAjay MeenaNo ratings yet

- Lennox-VRF Submittals IDU VE8K009N STDDocument2 pagesLennox-VRF Submittals IDU VE8K009N STDDaniel Sullón López100% (1)

- Arme de La Bomba 330cDocument37 pagesArme de La Bomba 330cEckard GuendelNo ratings yet

- Pages From HydraLinksDocument3 pagesPages From HydraLinksAshishNo ratings yet

- Linde (BPV) Model Codes For B Series Closed Loop PumpsDocument2 pagesLinde (BPV) Model Codes For B Series Closed Loop Pumpsحري فوكو ني100% (2)

- SPR-V1 2000.00-A Plate Frame Upper AssemblyDocument1 pageSPR-V1 2000.00-A Plate Frame Upper AssemblyAlanNo ratings yet

- m655 BrochureDocument5 pagesm655 Brochurejosue jetavionicsNo ratings yet

- Airframe-Mounted Oil-Tank Probe - Removal/InstallationDocument8 pagesAirframe-Mounted Oil-Tank Probe - Removal/InstallationAdrian LauNo ratings yet

- 7-Footstep BearingDocument3 pages7-Footstep BearingMEA517MIHIR BORANo ratings yet

- F2 Manual Transmission/Manual Transaxle: To IndexDocument21 pagesF2 Manual Transmission/Manual Transaxle: To IndexKwun Hok ChongNo ratings yet

- Reglage Allumage 70 CV MercDocument5 pagesReglage Allumage 70 CV MercasursNo ratings yet

- 2N3478Document2 pages2N3478sas999333No ratings yet

- Nce - Euro STD Viewports (Kodial) - 03.17Document2 pagesNce - Euro STD Viewports (Kodial) - 03.17eb7dzpNo ratings yet

- MacGregor Crane Electrical Part 1Document50 pagesMacGregor Crane Electrical Part 1ruslan100% (3)

- AP35.00-B-3501E.fm Rear Axle: Changing Oil 27.11.00: Rear Axle HL 4, HH 4, HO 4, HL 5 1 Filler Plug 2 Drain PlugDocument5 pagesAP35.00-B-3501E.fm Rear Axle: Changing Oil 27.11.00: Rear Axle HL 4, HH 4, HO 4, HL 5 1 Filler Plug 2 Drain PlugLUKASNo ratings yet

- Axle HousingDocument16 pagesAxle HousingGégé di TPNo ratings yet

- YK Optiview (Rev K 03)Document24 pagesYK Optiview (Rev K 03)mk saravananNo ratings yet

- Nikon NRK-8000 Auto Ref-Keratometer Repair Parts ListDocument49 pagesNikon NRK-8000 Auto Ref-Keratometer Repair Parts ListARIF NAQSHBANDINo ratings yet

- All Dynamic Acera Hydraulic Motor (Swing & Travel)Document17 pagesAll Dynamic Acera Hydraulic Motor (Swing & Travel)julianNo ratings yet

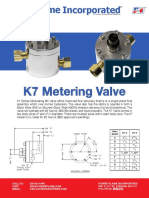

- PF - K7 Valve 2022Document2 pagesPF - K7 Valve 2022sahirprojectsNo ratings yet

- 3500 Exhaust Manifold InstallDocument10 pages3500 Exhaust Manifold Installguddy1No ratings yet

- Mc90 V500e Oper (New) EMPC9000Document50 pagesMc90 V500e Oper (New) EMPC9000Joshua CuevasNo ratings yet

- Group 2 Specifications: 1. General LocationsDocument8 pagesGroup 2 Specifications: 1. General LocationsAndré TarginoNo ratings yet

- 8100 ChangesDocument2 pages8100 ChangesHrishikesh NarasimhanNo ratings yet

- Ilive Service. Ilive PARTS IDENTIFICATION Issue 5 CONTENTSDocument22 pagesIlive Service. Ilive PARTS IDENTIFICATION Issue 5 CONTENTSpalprodNo ratings yet

- 800-Us-002 Abb Rev.hDocument13 pages800-Us-002 Abb Rev.hEL_AS_07No ratings yet

- Parker 690 - Product Code BreakdownDocument7 pagesParker 690 - Product Code BreakdownGabriel Leite Dos SantosNo ratings yet

- Exploring BeagleBone: Tools and Techniques for Building with Embedded LinuxFrom EverandExploring BeagleBone: Tools and Techniques for Building with Embedded LinuxRating: 4 out of 5 stars4/5 (2)

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- Investors Presentation 1Document26 pagesInvestors Presentation 1Positive ThinkerNo ratings yet

- Adult PSG Guidelines 2014Document49 pagesAdult PSG Guidelines 2014mohanNo ratings yet

- 6yc Multifunction Meter: Operation ManualDocument46 pages6yc Multifunction Meter: Operation ManualHamish JosephNo ratings yet

- 360 Degree Peer Evaluation FormDocument4 pages360 Degree Peer Evaluation FormAjisafe Jerry T-money100% (1)

- Nothing Can Keep Us Together: Cecily Von ZiegesarDocument16 pagesNothing Can Keep Us Together: Cecily Von ZiegesarPatricia NacuNo ratings yet

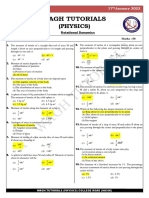

- Mock Test - 98 (17 Jan 2023) Rotational DynamicsDocument1 pageMock Test - 98 (17 Jan 2023) Rotational DynamicsparamNo ratings yet

- Road Safety FundamentalsDocument122 pagesRoad Safety Fundamentalssmanoj354100% (3)

- Results For Sri Lakshmi Chennakesava Tirupatham - Rajahmundry - Zonalinfo2Document2 pagesResults For Sri Lakshmi Chennakesava Tirupatham - Rajahmundry - Zonalinfo2SRINIVASARAO JONNALANo ratings yet

- Mint OilDocument4 pagesMint OilPreeti SinghNo ratings yet

- Mag Issue 1Document20 pagesMag Issue 1Anik AichNo ratings yet

- Second Order Runge-Kutta Method: ExampleDocument9 pagesSecond Order Runge-Kutta Method: ExampleAhmed MobarkiNo ratings yet

- Which of The Following Is An External Sorting?: Merge Sort Tree Sort Bubble Sort Insertion SortDocument3 pagesWhich of The Following Is An External Sorting?: Merge Sort Tree Sort Bubble Sort Insertion SortAjay BhoopalNo ratings yet

- Full Chapter Matlab For Engineers 6Th Edition Holly Moore PDFDocument53 pagesFull Chapter Matlab For Engineers 6Th Edition Holly Moore PDFpatricia.lovejoy850100% (6)

- Technical DescriptionDocument5 pagesTechnical DescriptionTimothy Roger Reyes0% (1)

- KPI FormulaDocument3 pagesKPI FormulaSrikant GuptaNo ratings yet

- BlazeVideo HDTV Player v6.0R User's Manual DTR8101Document16 pagesBlazeVideo HDTV Player v6.0R User's Manual DTR8101Oscar Dario NIño GonzalezNo ratings yet

- PowerDB Uninstall Guide PDFDocument4 pagesPowerDB Uninstall Guide PDFMarco C. PumaNo ratings yet

- Bed and Bathroom Linen - 29.12.2020Document2 pagesBed and Bathroom Linen - 29.12.2020Eden Led LightingNo ratings yet

- KaksbsjsusnsklsDocument244 pagesKaksbsjsusnsklskevin0% (1)

- Chapter 4 ProblemsDocument4 pagesChapter 4 ProblemsSteve DiazNo ratings yet

- Mistral: DehumidifierDocument16 pagesMistral: DehumidifierAntreprenor XNo ratings yet

- Revenue and Treasury Management Offices in The PhilippinesDocument73 pagesRevenue and Treasury Management Offices in The Philippinesmarj berting67% (3)

- Torque Spiral Wound GSKT TableDocument2 pagesTorque Spiral Wound GSKT TableCarlos Roberto Tamariz100% (1)

- Pattern, Price and Time - Using Gann TheoryDocument29 pagesPattern, Price and Time - Using Gann TheoryRohitOhri44% (9)

- Personal Style ScaleDocument3 pagesPersonal Style ScalesomaNo ratings yet

- 2.1.c.ii. Theory of Liming and UnhairingDocument5 pages2.1.c.ii. Theory of Liming and UnhairingAnanthNo ratings yet

- Persuasive WritingDocument34 pagesPersuasive WritingRoda RodaNo ratings yet

- Horizon Aviation Academy - HellasDocument2 pagesHorizon Aviation Academy - Hellas1n4r51ssNo ratings yet

WD Turret PLC

WD Turret PLC

Uploaded by

AryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WD Turret PLC

WD Turret PLC

Uploaded by

AryCopyright:

Available Formats

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 1 :

*********************************************************************

* TURRET DRIVE *

*********************************************************************

Segment 2 : POSITION DETECTION TURRET DRIVE

label Instruction

Operand Comment

U E 44.7

= M 65.0 ;WINDER B IN WINDING POSITION

U E 45.0 ;WINDER B IN TAKE-OUT POSITION

= M 65.4 ;WINDER A IN WINDING POSITION

***

E 44.7 E 44.7 =410-006 rewinder A: disassembly position

E 45.0 E 45.0 =420-006 rewinder B: disassembly position

M 65.0 F 65.0 position winder B: in winding position

M 65.4 F 65.4 position winder A: in winding position

Segment 3 : flag stop in position a or b

E 44.7 >=1

M 65.7

E 45.0 &

M 65.6 SR

M 65.7 # S

E 44.7 &

E 45.0 R Q

E 44.7 E 44.7 =410-006 rewinder A: disassembly position

E 45.0 E 45.0 =420-006 rewinder B: disassembly position

M 65.6 F 65.6

M 65.7 F 65.7

Segment 4 : stop in position at jogging

M 66.0

SR

M 65.6 S

E 68.5 &

A 1.2 R Q

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 1

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

E 68.5 E 68.5 =650-007 turret drive: turret index forward

A 1.2 A 1.2 =650-001 turret drive: on

M 65.6 F 65.6

M 66.0 F 66.0

Segment 5 : CALL AUTOM. COILCHANGE WINDER A

label Instruction

Operand Comment

SPA PB 177

***

PB 177 PB 177 -- PB 115 rewinder A: automatic coil change

Segment 6 : CALL AUTOM. COILCHANGE WINDER B

label Instruction

Operand Comment

SPA PB 178

***

PB 178 PB 178 -- PB 115 rewinder B: automatic coil change

Segment 7 : CALL DATABLOCK OF TEMP. FLAGS

label Instruction

Operand Comment

A DB 255

***

DB 255 DB 255 TEMPORARY DB to save and restore temporary flags

Segment 8 : RESTORE FLAG AREA (I)

label Instruction

Operand Comment

L DW 115

T MW 210

***

Segment 9 : RESTORE FLAG AREA (II)

label Instruction

Operand Comment

L DW 212

T MW 212

***

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 2

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 10 : ENABLE TURRET DRIVE

E 6.2 &

E 6.3 >=1

E 65.5 >=1

E 64.4 &

E 1.5

M 13.1

E 15.7

M 0.7

M 37.7

M 19.0 &

M 24.0 >=1

E 64.4

M 200.0

M 41.0

M 42.0 =

E 1.5 E 1.5 =650-001 turret drive: no fault

E 6.2 E 6.2 =700-022 turret drive: door of safety box closed

E 6.3 E 6.3 =700-022 turret drive: flap to retract closed

E 15.7 E 15.7 =800-057 carriage is outside of winding range

E 64.4 E 64.4 =310-006 Service

E 65.5 E 65.5 =310-005 winding carriage: scrap[1],manual[0]

M 0.7 F 0.7 machine emergency stop not

M 13.1 F 13.1 pneumatic: mains pressure ok

M 19.0 F 19.0 cones A: chucked and locked

M 24.0 F 24.0 cones B: chucked and locked

M 37.7 F 37.7 winding carriage in rear

M 41.0 F 41.0 material on winder A in unloading posit.

M 42.0 F 42.0 material on winder B in unloading posit.

Segment 11 : TURRET FORWARD JOG

E 68.5 &

E 68.6

M 200.1

M 9.1

M 200.0 =

E 68.5 E 68.5 =650-007 turret drive: turret index forward

E 68.6 E 68.6 =650-007 turret drive: turret index backward

M 9.1 F 9.1 turret drive: WS at manual

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 3

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 12 : TURRET BACKWARD JOG

M 9.1 >=1

M 9.2 &

E 68.5

M 200.2

E 68.6

M 200.0 =

E 68.5 E 68.5 =650-007 turret drive: turret index forward

E 68.6 E 68.6 =650-007 turret drive: turret index backward

M 9.1 F 9.1 turret drive: WS at manual

M 9.2 F 9.2 turret drive: WS at threading operation

Segment 13 : TURRET WINDING POS. TO WINDING P

M 210.0

SR

E 69.0 &

M 9.1 S

M 200.0 >=1

E 64.6

E 68.7

M 210.2 R Q

E 64.6 E 64.6 =650-005 turret drive: turret index stop

E 68.7 E 68.7 =650-007 turret drive: turret index stop

E 69.0 E 69.0 =650-007 turret drive: turret index start

M 9.1 F 9.1 turret drive: WS at manual

Segment 14 : WINDER LEAVE WINDING POS.

M 210.1

M 65.4 &

SR

M 65.0

M 210.0 S

M 200.0 >=1

E 64.6

E 68.7

M 210.2 R Q

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 4

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

E 64.6 E 64.6 =650-005 turret drive: turret index stop

E 68.7 E 68.7 =650-007 turret drive: turret index stop

M 65.0 F 65.0 position winder B: in winding position

M 65.4 F 65.4 position winder A: in winding position

Segment 15 : TURRET WINDING POS. REACHED

M 65.4 >=1

M 65.0 &

T 59

M 210.2 S_VIMP

M 210.1

M 200.0 # SV

KT 100.0 TW DUAL

DEZ

R Q

M 65.0 F 65.0 position winder B: in winding position

M 65.4 F 65.4 position winder A: in winding position

T 59 T 59 turret drive: pulse position reached

Segment 16 : TURRET FORWARD IN AUTOMATIC

M 50.2 &

M 50.3 >=1

M 52.2 &

M 52.3 &

M 200.4

M 9.0

M 200.0 =

M 9.0 F 9.0 turret drive: WS at automatic

M 50.2 F 50.2 WA to unload.pos: start turret

M 50.3 F 50.3 WA to unload.pos: turret drive off

M 52.2 F 52.2 WB to unload.pos: start turret

M 52.3 F 52.3 WB to unload.pos: turret drive off

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 5

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 17 : IL-TURRET AUTOMATIC

M 51.0 >=1

A 64.6

M 53.0

M 3.0 =

A 64.6 A 64.6 =310-008 coil change start

M 3.0 F 3.0 lamptest

M 51.0 F 51.0 WA to unload.pos: active

M 53.0 F 53.0 WB to unload.pos: active

Segment 18 : SWITCH OVER FAST->SLOW

M 64.6

SR

E 46.4 &

M 34.0 S

E 45.0 >=1

E 44.7 &

M 34.0 R Q

E 44.7 E 44.7 =410-006 rewinder A: disassembly position

E 45.0 E 45.0 =420-006 rewinder B: disassembly position

E 46.4 E 46.4 =650-008 turret drive: switchover fast[1]/slow[0]

M 34.0 F 34.0 turret drive: on to n=0

M 64.6 F 64.6

Segment 19 : FLAG TURRET ON

M 200.1 &

M 66.0 >=1

M 210.6

M 200.2

M 200.5 SR

M 200.4

M 210.0 # S

M 210.4

M 200.5 &

M 117.0 R Q S

M 66.0 F 66.0

M 117.0 F 117.0 <- Sim D turret drive: n=0 <- Sim D

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 6

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 20 : TURRET DEL.OFF AFTER BRAKE CLOSE

T 64

S_EVERZ

M 210.6 SE

KT 030.1 TW DUAL

DEZ

M 210.4

R Q R

T 64 T 64 turret drive: del. off after brake close

Segment 21 : TURRET DRIVE BRAKE OPEN

T 61

S_EVERZ

M 210.6 SE

KT 000.0 TW DUAL

DEZ

A 1.3

R Q =

A 1.3 A 1.3 =650-010 turret drive: brake open

T 61 T 61 turret drive: delay brake open after on

Segment 22 :

M 210.0 >=1

T 69

M 200.4 &

S_VIMP

M 210.6 SV

KT 005.1 TW DUAL

DEZ

R Q

T 69 T 69

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 7

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 23 : ENABLE N-REGULATOR

T 100

S_AVERZ

M 34.0 SA

KT 020.1 TW DUAL

DEZ

A 16.7

R Q =

A 16.7 A 16.7 =650-011 turret drive: enable n-regulator-> SIM-D

M 34.0 F 34.0 turret drive: on to n=0

T 100 T 100 turret drive: feedback mains contactor

Segment 24 : TURRET FORWARD

M 200.5 &

M 200.2

E 46.2

A 17.0

E 46.0

A 17.1 =

E 46.0 E 46.0 =602-003 turret disk: brake open operating side

E 46.2 E 46.2 =602-003 turret disk: brake open drive side

A 17.0 A 17.0 =650-011 turret drive: index forward -> SIM-D

A 17.1 A 17.1 =650-011 turret drive: index backward -> SIM-D

Segment 25 : TURRET BACKWARD

M 200.2 &

A 17.0

E 46.2

E 46.0 >=1

A 17.1

T 69 =

E 46.0 E 46.0 =602-003 turret disk: brake open operating side

E 46.2 E 46.2 =602-003 turret disk: brake open drive side

A 17.0 A 17.0 =650-011 turret drive: index forward -> SIM-D

A 17.1 A 17.1 =650-011 turret drive: index backward -> SIM-D

T 69 T 69

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 8

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 26 : TURRET FAST

M 200.5 &

M 200.1

M 200.2

A 17.2

M 64.6

A 17.1 =

A 17.1 A 17.1 =650-011 turret drive: index backward -> SIM-D

A 17.2 A 17.2 =650-011 turret drive: index fast -> SIM-D

M 64.6 F 64.6

Segment 27 : E-STOP-NOT -> SIMADYN-D

A 17.3

M 0.7 & =

A 17.3 A 17.3 =650-011 turret drive: e-stop not -> SIM-D

M 0.7 F 0.7 machine emergency stop not

Segment 28 : winding pos. ->sim.-d

T 62

S_IMPULS

M 65.0 >=1

M 65.4 SI

KT 010.1 TW DUAL

DEZ

M 135.5

R Q =

M 65.0 F 65.0 position winder B: in winding position

M 65.4 F 65.4 position winder A: in winding position

T 62 T 62

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 9

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 29 : TURRET DRIVE ON + IL-DRIVE ON

A 1.2

M 210.4 # >=1

M 3.0

M 3.1 &

M 200.0

A 66.1

M 9.1

E 64.6 =

E 64.6 E 64.6 =650-005 turret drive: turret index stop

A 1.2 A 1.2 =650-001 turret drive: on

A 66.1 A 66.1 =650-009 turret drive: on

M 3.0 F 3.0 lamptest

M 3.1 F 3.1 flash frequency 1

M 9.1 F 9.1 turret drive: WS at manual

Segment 30 : SIGNAL LAMP ON

A 0.6

A 1.2 & =

A 0.6 A 0.6 =650-010 turret drive: flashlamp warning indexing

A 1.2 A 1.2 =650-001 turret drive: on

Segment 31 : TURRET DISK BRAKE OPEN

T 63

S_EVERZ

M 210.6 SE

KT 004.1 TW DUAL

DEZ

A 45.4

R Q =

A 45.5

A 45.4 A 45.4 =602-008 turret disk: brake open drive side

A 45.5 A 45.5 =602-008 turret disk: brake open operating side

T 63 T 63 turret disk: brake open delayed

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 10

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 32 : TURRET DRIVE ON TO N=0

M 34.0

M 210.6 & =

M 34.0 F 34.0 turret drive: on to n=0

Segment 33 : ENABLE THREAD

M 35.7

M 65.0 >=1

M 65.4 =

M 35.7 F 35.7 turret drive: in threading position

M 65.0 F 65.0 position winder B: in winding position

M 65.4 F 65.4 position winder A: in winding position

Segment 34 : E-STOP TURRET DRIVE

M 34.7

M 0.7 &

E 1.5 =

E 1.5 E 1.5 =650-001 turret drive: no fault

M 0.7 F 0.7 machine emergency stop not

M 34.7 F 34.7 turret drive: machine e-stop

Segment 35 : STATUS BITS TO PC

label Instruction

Operand Comment

A DB 230

U E 1.5

UN D 27.1

= D 27.0 ;drive ready to start

U M 34.0

= D 27.1 ;drive on to V=0

UN M 0.7

UN E 1.5

= D 27.2 ;drive fault

***

E 1.5 E 1.5 =650-001 turret drive: no fault

M 0.7 F 0.7 machine emergency stop not

M 34.0 F 34.0 turret drive: on to n=0

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 11

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 36 : CALL DATABLOCK OF TEMP. FLAGS

label Instruction

Operand Comment

A DB 255

***

DB 255 DB 255 TEMPORARY DB to save and restore temporary flags

Segment 37 : SAVE FLAG AREA (I)

label Instruction

Operand Comment

L MW 210

T DW 115

***

Segment 38 : SAVE FLAG AREA (II)

label Instruction

Operand Comment

L MW 212

T DW 212

***

Segment 39 : INFORMATION TO MMI

label Instruction

Operand Comment

A DB 230 ;call DB PLC -> PC

U M 34.0

= D 16.2 ;turreting active

UN M 65.0

UN M 65.4

= D 15.4 ;no winder in winding position

***

M 34.0 F 34.0 turret drive: on to n=0

M 65.0 F 65.0 position winder B: in winding position

M 65.4 F 65.4 position winder A: in winding position

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 12

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Segment 40 : CALL FAULT/PROMPTING

*********************************************************************

* CALL FX-FAULT EVALUATION AND OPERATOR PROMPTING *

*********************************************************************

FX 209

PB115

FX 209 FX 209 -- PB 115 user guide and fault evaluation of PB115

Segment 41 :

File: 0301E0ST Prog:

- PB 115 - Checked:

Mod: 4/11/2017 9:5s Date: 4/11c Page: 13

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

E 0.1 =700-007 E 0.1 Supply monitor no trouble

E 0.2 =700-008 E 0.2 control voltage no trouble

E 0.4 =700-011 E 0.4 E-stop not

E 0.5 =700-011 E 0.5 Reset

E 0.6 =700-011 E 0.6 main contactor delayed off

E 0.7 =700-015 E 0.7 control voltage PLC-output

E 1.0 =700-016 E 1.0 KK 3 fan: no fault

E 1.1 =221-005 E 1.1 rewind.A/B: monitoring supply mains unit

E 1.2 =221-001 E 1.2 mains unit AC-servos: no fault

E 1.4 =650-001 E 1.4 turret drive: exess temperature

E 1.5 =650-001 E 1.5 turret drive: no fault

E 1.6 =650-001 E 1.6 turret drive: n=0

E 2.0 =221-002 E 2.0 tension measuring roll: excess temperat.

E 2.1 =221-002 E 2.1 tension measuring roll: no fault

E 2.2 =221-002 E 2.2 tension measuring roll: n=0

E 2.4 =310-001 E 2.4 contact roller: excess temperature

E 2.5 =310-001 E 2.5 contact roller: no fault

E 2.6 =310-001 E 2.6 contact roller: n=0

E 3.0 =600-001 E 3.0 winding carriage: excess temperature

E 3.1 =600-001 E 3.1 winding carriage: no fault

E 3.2 =600-001 E 3.2 winding carriage: n=0

E 3.4 =660-001 E 3.4 x-cut-knife: excess temperature

E 3.5 =660-001 E 3.5 x-cut-knife: no fault

E 3.6 =660-001 E 3.6 x-cut-knife: n=0

E 4.0 =410-002 E 4.0 rewinder A: n=0

E 4.1 =410-002 E 4.1 rewinder A: open brake

E 4.2 =410-002 E 4.2 rewinder A: winder is ready

E 4.3 =410-002 E 4.3 rewinder A: fault actuator

E 4.4 =410-004 E 4.4 rewinder A: monitoring synchronization

E 4.5 =410-004 E 4.5 rewinder A: fan monitoring

E 4.6 =410-004 E 4.6 rewinder A: load circuit on

E 4.7 =410-004 E 4.7 rewinder A: field on

E 5.0 =420-002 E 5.0 rewinder B: n=0

E 5.1 =420-002 E 5.1 rewinder B: open brake

E 5.2 =420-002 E 5.2 rewinder B: ready to start

E 5.3 =420-002 E 5.3 rewinder B: fault actuator

E 5.4 =420-004 E 5.4 rewinder B: monitoring synchronization

E 5.5 =420-004 E 5.5 rewinder B: fan monitoring

E 5.6 =420-004 E 5.6 rewinder B: load circuit on

E 5.7 =420-004 E 5.7 rewinder B: field on

E 6.0 =410-004 E 6.0 rewinder A fan on

E 6.1 =420-004 E 6.1 rewinder B fan on

E 6.2 =700-022 E 6.2 turret drive: door of safety box closed

E 6.3 =700-022 E 6.3 turret drive: flap to retract closed

E 6.4 =301-001 E 6.4 idler roller: exess temperature

E 6.5 =301-001 E 6.5 idler roller: ready to start

E 6.6 =301-001 E 6.6 idler roller: n=0

E 12.0 =700-015 E 12.0 control voltage Simadyn-D chassis

E 12.1 =700-018 E 12.1 KK 3 fan: no fault

E 12.7 =320-001 E 12.7 threading transport drive: motor protect

E 13.0 =611-003 E 13.0 rewinder A chucks ready to start

E 13.1 =611-005 E 13.1 rewinder B chucks ready to start

E 13.2 =624-003 E 13.2 guide roller A/B: no fault

E 13.4 =611-009 E 13.4 rewinder A: chuck is engaged <- SIM-D

E 13.5 =611-009 E 13.5 rewinder A: chuck is synchronize<- SIM-D

E 13.6 =611-009 E 13.6 rewinder A: chuck ds center adj.<- SIM-D

E 13.7 =611-009 E 13.7 rewinder A: chuck os center adj.<- SIM-D

E 14.0 =611-009 E 14.0 rewinder B: chuck is engaged <- SIM-D

E 14.1 =611-009 E 14.1 rewinder B: chuck is synchronize<- SIM-D

E 14.2 =611-009 E 14.2 rewinder B: chuck ds center adj.<- SIM-D

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 14

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

E 14.3 =611-009 E 14.3 rewinder B: chuck os center adj.<- SIM-D

E 14.4 =800-058 E 14.4 Simadyn-D is not ok <- SIM-D

E 14.5 =800-058 E 14.5 DUST 3 fault <- SIM-D

E 14.6 =950-001 E 14.6 Simadyn D is OK <- SIM-D

E 15.0 =800-056 E 15.0 e-stop not stretching line

E 15.1 =800-056 E 15.1 enable drive coil carriage

E 15.2 =800-056 E 15.2 take up -> winder: all drives start

E 15.3 =800-056 E 15.3 take up -> winder: all drives stop

E 15.4 =800-056 E 15.4 take up -> winder: web break

E 15.5 =800-057 E 15.5 carriage is in roll-take-up position

E 15.6 =800-057 E 15.6 carriage is in chucking pos.for new core

E 15.7 =800-057 E 15.7 carriage is outside of winding range

E 30.0 =410-008 E 30.0 rewinder A: os chuck moved out/opened

E 30.1 =410-008 E 30.1 rewinder A: os chuck moved in/engaged

E 30.2 =410-008 E 30.2 rewinder A: os monitoring chuck locking

E 30.3 =410-008 E 30.3 rewinder A: os chucking heads expand

E 30.4 =602-004 E 30.4 rewinder A: os limit oscilation

E 30.5 =611-008 E 30.5 rewinder A: os centring bolt moved in

E 30.6 =611-008 E 30.6 rewinder A: os centring bolt moved out

E 31.0 =420-008 E 31.0 rewinder B: os chuck moved out/opened

E 31.1 =420-008 E 31.1 rewinder B: os chuck moved in/engaged

E 31.2 =420-008 E 31.2 rewinder B: os monitoring chuck locking

E 31.3 =420-008 E 31.3 rewinder B: os chucking heads expand

E 31.4 =602-004 E 31.4 rewinder B: os limit oscilation

E 31.5 =611-008 E 31.5 rewinder B: os centring bolt moved in

E 31.6 =611-008 E 31.6 rewinder B: os centring bolt moved out

E 38.0 =410-007 E 38.0 rewinder A: ds chuck moved out/opened

E 38.1 =410-007 E 38.1 rewinder A: ds chuck moved in/engaged

E 38.2 =410-007 E 38.2 rewinder A: ds monitoring chuck locking

E 38.3 =410-007 E 38.3 rewinder A: ds chucking heads expand

E 38.4 =410-007 E 38.4 rewinder A: e-stop brake

E 38.5 =602-004 E 38.5 rewinder A: ds limit oscilation

E 38.6 =611-008 E 38.6 rewinder A: ds centring bolt moved in

E 38.7 =611-008 E 38.7 rewinder A: ds centring bolt moved out

E 39.0 =420-007 E 39.0 rewinder B: ds chuck moved out/opened

E 39.1 =420-007 E 39.1 rewinder B: ds chuck moved in/engaged

E 39.2 =420-007 E 39.2 rewinder B: ds monitoring chuck locking

E 39.3 =420-007 E 39.3 rewinder B: ds chucking heads expand

E 39.4 =420-007 E 39.4 rewinder B: e-stop brake

E 39.5 =602-004 E 39.5 rewinder B: ds limit oscilation

E 39.6 =611-008 E 39.6 rewinder B: ds centring bolt moved in

E 39.7 =611-008 E 39.7 rewinder B: ds centring bolt moved out

E 44.0 =310-007 E 44.0 winding carriage: contact roller in rear

E 44.1 =310-007 E 44.1 drive winding carriage overload

E 44.2 =320-003 E 44.2 thread-in material

E 44.3 =320-003 E 44.3 Machine jogging

E 44.4 =320-003 E 44.4 thread-in stop

E 44.6 =320-003 E 44.6 thread-in stop

E 44.7 =410-006 E 44.7 rewinder A: disassembly position

E 45.0 =420-006 E 45.0 rewinder B: disassembly position

E 45.1 =600-004 E 45.1 winding carriage in front

E 45.2 =600-004 E 45.2 winding carriage in rear

E 45.3 =602-002 E 45.3 spreader unit: drive side swung in

E 45.4 =602-002 E 45.4 spreader unit: drive side swung out

E 45.5 =602-002 E 45.5 spreader unit: operating side swung in

E 45.6 =602-002 E 45.6 spreader unit: operating side swung out

E 46.0 =602-003 E 46.0 turret disk: brake open operating side

E 46.1 =602-003 E 46.1 pneumatic: total pressure operating side

E 46.2 =602-003 E 46.2 turret disk: brake open drive side

E 46.3 =602-003 E 46.3 pneumatic: total pressure drive side

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 15

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

E 46.4 =650-008 E 46.4 turret drive: switchover fast[1]/slow[0]

E 46.5 =660-005 E 46.5 x-cut-knife: park position

E 46.6 =660-005 E 46.6 x-cut-knife: cut in end position

E 46.7 =660-005 E 46.7 x-cut device: park position

E 47.0 =660-005 E 47.0 x-cut device: slitting position

E 47.1 =660-005 E 47.1 x-cut device: start position

E 47.4 =700-018 E 47.4 KK 3 fan: no fault

E 64.0 =700-008 E 64.0 control voltage on

E 64.1 =310-006 E 64.1 key protect

E 64.2 =310-006 E 64.2 lamptest

E 64.3 =310-006 E 64.3 horn off

E 64.4 =310-006 E 64.4 Service

E 64.5 =700-016 E 64.5 desk fan no trouble

E 64.6 =650-005 E 64.6 turret drive: turret index stop

E 64.7 =650-005 E 64.7 turret drive: light barrier not actuated

E 65.0 =210-003 E 65.0 ionization control on

E 65.1 E 65.1

E 65.2 =310-005 E 65.2 coil change start

E 65.3 =310-005 E 65.3 coil change stop

E 65.4 =310-005 E 65.4 winding carriage: automatic[1],manual[0]

E 65.5 =310-005 E 65.5 winding carriage: scrap[1],manual[0]

E 65.6 =310-006 E 65.6 all drives start

E 65.7 =310-006 E 65.7 all drives stop

E 66.0 =310-004 E 66.0 gap winding

E 66.1 =310-004 E 66.1 contact winding open loop

E 66.2 =310-004 E 66.2 contact winding closed loop

E 66.3 =310-004 E 66.3 contact winding pneumatic

E 66.4 =410-005 E 66.4 rewinder A: off

E 66.5 =410-005 E 66.5 rewinder A: on

E 66.6 =420-005 E 66.6 rewinder B: off

E 66.7 =420-005 E 66.7 rewinder B: on

E 67.0 =600-003 E 67.0 winding carriage: forward

E 67.1 =600-003 E 67.1 winding carriage: backward

E 67.2 =602-001 E 67.2 spreader unit: swing out

E 67.3 =602-001 E 67.3 spreader unit: swing in

E 67.4 =611-007 E 67.4 chuck open

E 67.5 =611-007 E 67.5 chuck close

E 67.6 =611-007 E 67.6 chucks oscilation on

E 68.0 =624-004 E 68.0 guide roller A/B: manual[0],automatic[1]

E 68.1 =624-004 E 68.1 guide roller A: move off

E 68.2 =624-004 E 68.2 guide roller A: move on

E 68.3 =624-004 E 68.3 guide roller B: move off

E 68.4 =624-004 E 68.4 guide roller B: move on

E 68.5 =650-007 E 68.5 turret drive: turret index forward

E 68.6 =650-007 E 68.6 turret drive: turret index backward

E 68.7 =650-007 E 68.7 turret drive: turret index stop

E 69.0 =650-007 E 69.0 turret drive: turret index start

E 69.2 =660-004 E 69.2 slitting section move on

E 69.3 =660-004 E 69.3 slitting section move off

E 69.4 =660-004 E 69.4 x-cut-knife: cut

E 69.5 =310-006 E 69.5 winding carriage: pick-up strip on

E 69.6 =410-005 E 69.6 winder jog backwards

E 69.7 =410-005 E 69.7 winder jog forwards

A 0.0 =700-010 A 0.0 e-stop not PLC

A 0.1 =700-011 A 0.1 machine V=0

A 0.2 =700-023 A 0.2 horn general fault

A 0.4 =700-022 A 0.4 open safety doors

A 0.5 =700-022 A 0.5 open safety doors at insert material

A 0.6 =650-010 A 0.6 turret drive: flashlamp warning indexing

A 0.7 =650-010 A 0.7 turret drive: enable light barrier

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 16

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

A 1.0 =221-001 A 1.0 mains unit: fault acknowledge

A 1.1 =221-001 A 1.1 mains unit: enable

A 1.2 =650-001 A 1.2 turret drive: on

A 1.3 =650-010 A 1.3 turret drive: brake open

A 1.4 =221-002 A 1.4 tension measuring roll: on

A 1.6 =310-001 A 1.6 contact roller: on

A 2.0 =600-001 A 2.0 winding carriage: on

A 2.1 =600-005 A 2.1 winding carriage: brake open

A 2.2 =660-001 A 2.2 x-cut device: on

A 2.3 =660-007 A 2.3 x-cut device: brake open

A 2.4 =410-002 A 2.4 rewinder A: enable statics

A 2.5 =410-002 A 2.5 rewinder A: quick-stop initiated

A 2.6 =410-002 A 2.6 rewinder A: jog backward

A 2.7 =410-002 A 2.7 rewinder A: jog forward

A 3.0 =410-002 A 3.0 rewinder A: enable setpoint

A 3.1 =410-002 A 3.1 rewinder A: en*able

A 3.2 =410-002 A 3.2 rewinder A: on

A 3.3 =410-002 A 3.3 rewinder A: fault acknowledge

A 3.4 =410-003 A 3.4 rewinder A: field on

A 3.5 =410-003 A 3.5 rewinder A: fan on

A 3.6 =410-009 A 3.6 web break winder

A 3.7 =660-007 A 3.7 x-cut is done

A 4.0 =420-002 A 4.0 rewinder B: enable statics

A 4.1 =420-002 A 4.1 rewinder B: quick-stop initiated

A 4.2 =420-002 A 4.2 rewinder B: jog backward

A 4.3 =420-002 A 4.3 rewinder B: jog forward

A 4.4 =420-002 A 4.4 rewinder B: enable setpoint

A 4.5 =420-002 A 4.5 rewinder B: enable

A 4.6 =420-002 A 4.6 rewinder B: on

A 4.7 =420-002 A 4.7 rewinder B: fault acknowledge

A 5.0 =420-003 A 5.0 rewinder B: field on

A 5.1 =420-003 A 5.1 rewinder B: fan on

A 5.4 =301-001 A 5.4 idler roller drive on

A 12.0 =611-010 A 12.0 rewinder A: enable oscilation chucks

A 12.1 =611-010 A 12.1 rewinder B: enable oscilation chucks

A 12.2 =611-011 A 12.2 rewinder A: bypassing ls to open chucks

A 12.3 =611-011 A 12.3 rewinder B: bypassing ls to open chucks

A 12.4 =611-011 A 12.4 chucks on

A 12.5 =611-011 A 12.5 chucks opened

A 12.6 =611-012 A 12.6 rewinder A: drive side chuck brake open

A 12.7 =611-012 A 12.7 rewinder B: drive side chuck brake open

A 13.0 =611-012 A 13.0 rewinder A: oper. side chuck brake open

A 13.1 =611-012 A 13.1 rewinder B: oper. side chuck brake open

A 13.2 =210-002 A 13.2 x-cut device: ionization device on

A 13.3 =210-002 A 13.3 x-cut device: ionisation device on

A 13.4 =320-002 A 13.4 threading transport drive: on

A 14.0 =420-010 A 14.0 rewinder B: active -> SIM-D

A 14.1 =611-013 A 14.1 rewinder A: chuck left moved in -> SIM-D

A 14.2 =611-013 A 14.2 rewinder A: chuck left moved out-> SIM-D

A 14.3 =611-013 A 14.3 rewinder A: chuck right moved in-> SIM-D

A 14.4 =611-013 A 14.4 rewinder A:chuck right moved out-> SIM-D

A 14.5 =611-013 A 14.5 rewinder B: chuck left moved in -> SIM-D

A 14.6 =611-013 A 14.6 rewinder B: chuck left moved out-> SIM-D

A 14.7 =611-013 A 14.7 rewinder B: chuck right moved in-> SIM-D

A 15.0 =611-013 A 15.0 rewinder B:chuck right moved out-> SIM-D

A 15.1 =611-014 A 15.1 rewinder A: enble chuck left -> SIM-D

A 15.2 =611-014 A 15.2 rewinder A: chuck close -> SIM-D

A 15.3 =611-014 A 15.3 rewinder A: chuck open -> SIM-D

A 15.4 =611-014 A 15.4 rewinder A: chuck oscillation -> SIM-D

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 17

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

A 15.5 =611-014 A 15.5 rewinder A:chuck drive to center-> SIM-D

A 15.6 =611-014 A 15.6 rewinder A: chuck start synchr. -> SIM-D

A 15.7 =611-014 A 15.7 rewinder A: chucks engaged -> SIM-D

A 16.0 =611-015 A 16.0 rewinder B: enble chuck left -> SIM-D

A 16.1 =611-015 A 16.1 rewinder B: chuck close -> SIM-D

A 16.2 =611-015 A 16.2 rewinder B: chuck open -> SIM-D

A 16.3 =611-015 A 16.3 rewinder B: chuck oscillation -> SIM-D

A 16.4 =611-015 A 16.4 rewinder B:chuck drive to center-> SIM-D

A 16.5 =611-015 A 16.5 rewinder B: chuck start synchr. -> SIM-D

A 16.6 =611-015 A 16.6 rewinder B: chucks engaged -> SIM-D

A 16.7 =650-011 A 16.7 turret drive: enable n-regulator-> SIM-D

A 17.0 =650-011 A 17.0 turret drive: index forward -> SIM-D

A 17.1 =650-011 A 17.1 turret drive: index backward -> SIM-D

A 17.2 =650-011 A 17.2 turret drive: index fast -> SIM-D

A 17.3 =650-011 A 17.3 turret drive: e-stop not -> SIM-D

A 17.4 =800-061 A 17.4 e-stop not -> SIM-D

A 17.5 =800-061 A 17.5 e-stop not (software) -> SIM-D

A 17.6 =800-061 A 17.6 quick stop -> SIM-D

A 17.7 =800-061 A 17.7 strip pick-up -> SIM-D

A 18.0 =800-059 A 18.0 end of roll

A 18.1 =800-059 A 18.1 winder in thread-in position

A 18.2 =800-059 A 18.2 enable carriage into winding range

A 18.3 =800-060 A 18.3 open chucking heads to unload

A 18.4 =800-060 A 18.4 chucking heads are closed with new core

A 18.5 =624-006 A 18.5 guide roller A/B: on

A 18.6 =624-006 A 18.6 guide roller A: enable on

A 18.7 =624-006 A 18.7 guide roller B: enable on

A 19.0 =660-008 A 19.0 knife in idle position

A 19.1 =660-008 A 19.1 knife in end position

A 30.0 =602-010 A 30.0 rewinder A: oper. side e-stop brake open

A 30.1 =602-010 A 30.1 rewinder B: oper. side e-stop brake open

A 30.2 =602-010 A 30.2 rewinder A: oper. side core radial open

A 30.3 =602-010 A 30.3 rewinder B: oper. side core radial open

A 30.4 =602-010 A 30.4 rewinder A: oper. side core unlock

A 30.5 =602-010 A 30.5 rewinder A: oper. side core lock

A 30.6 =602-010 A 30.6 rewinder B: oper. side core unlock

A 30.7 =602-010 A 30.7 rewinder B: oper. side core lock

A 38.0 =602-009 A 38.0 rewinder A: drive side e-stop brake open

A 38.1 =602-009 A 38.1 rewinder B: drive side e-stop brake open

A 38.2 =602-009 A 38.2 rewinder A: drive side core radial open

A 38.3 =602-009 A 38.3 rewinder B: drive side core radial open

A 38.4 =602-009 A 38.4 rewinder A: drive side core unlock

A 38.5 =602-009 A 38.5 rewinder A: drive side core lock

A 38.6 =602-009 A 38.6 rewinder B: drive side core unlock

A 38.7 =602-009 A 38.7 rewinder B: drive side core lock

A 44.0 =602-005 A 44.0 spreader roller: drive side move off

A 44.1 =602-005 A 44.1 spreader roller: drive side move on

A 44.2 =602-005 A 44.2 spreader roller: operating side move off

A 44.3 =602-005 A 44.3 spreader roller: operating side move on

A 44.4 =602-006 A 44.4 x-cut device: move on

A 44.5 =602-006 A 44.5 x-cut device: move off

A 44.6 =602-006 A 44.6 x-cut device: move on

A 44.7 =602-006 A 44.7 x-cut device: move off

A 45.0 =602-007 A 45.0 guide roller A: move on

A 45.1 =602-007 A 45.1 guide roller A: move off

A 45.2 =602-007 A 45.2 guide roller B: move on

A 45.3 =602-007 A 45.3 guide roller B: move off

A 45.4 =602-008 A 45.4 turret disk: brake open drive side

A 45.5 =602-008 A 45.5 turret disk: brake open operating side

A 64.0 =700-010 A 64.0 general fault

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 18

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

A 64.2 =611-020 A 64.2 chucks opened

A 64.3 =611-020 A 64.3 cones closed

A 64.4 =611-020 A 64.4 cones in middle position

A 64.5 =310-008 A 64.5 all drives on

A 64.6 =310-008 A 64.6 coil change start

A 65.0 =410-009 A 65.0 rewinder A: on

A 65.2 =420-009 A 65.2 rewinder B: on

A 66.0 =650-009 A 66.0 turret drive: light barrier actuated

A 66.1 =650-009 A 66.1 turret drive: on

A 66.2 =650-009 A 66.2 turret drive: horn on, attention coil ch;

F 0.0 M 0.0

F 0.1 M 0.1

F 0.2 M 0.2

F 0.3 M 0.3

F 0.4 M 0.4

F 0.5 M 0.5 machine quick stop

F 0.6 M 0.6 machine emergency stop

F 0.7 M 0.7 machine emergency stop not

;

F 1.0 M 1.0 fault acknowledge

F 1.1 M 1.1

F 1.2 M 1.2 enable: machine on or jog

F 1.3 M 1.3 enable: machine on

F 1.4 M 1.4 machine jog

F 1.5 M 1.5 machine on

F 1.6 M 1.6 machine is ready to start

F 1.7 M 1.7 machine on up to V=0

;

F 2.0 M 2.0 machine jog to V=0

F 2.1 M 2.1 control voltage is on

F 2.2 M 2.2

F 2.3 M 2.3

F 2.4 M 2.4

F 2.5 M 2.5

F 2.6 M 2.6

F 2.7 M 2.7 enable operator prompting

;

F 3.0 M 3.0 lamptest

F 3.1 M 3.1 flash frequency 1

F 3.2 M 3.2 flash frequency 2

F 3.3 M 3.3 flash frequency 3

F 3.4 M 3.4 local flag

F 3.5 M 3.5 reset counter 1

F 3.6 M 3.6 reset counter 2

F 3.7 M 3.7 machine web break

;

F 4.0 M 4.0 all drives n=0

F 4.1 M 4.1 start turret cycle WB to unload position

F 4.2 M 4.2 start turret cycle WA to unload position

F 4.3 M 4.3 hf for web break counter

F 4.4 M 4.4 hf for web break counter

F 4.5 M 4.5 maintenance chucks A released

F 4.6 M 4.6 maintenance chucks B released

F 4.7 M 4.7 monitor. winder switch-over to automatic

;

F 5.0 M 5.0

F 5.1 M 5.1

F 5.2 M 5.2

F 5.3 M 5.3

F 5.4 M 5.4

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 19

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 5.5 M 5.5

F 5.6 M 5.6

F 5.7 M 5.7

;

F 6.0 M 6.0

F 6.1 M 6.1

F 6.2 M 6.2

F 6.3 M 6.3

F 6.4 M 6.4

F 6.5 M 6.5

F 6.6 M 6.6

F 6.7 M 6.7

;

F 7.0 M 7.0

F 7.1 M 7.1

F 7.2 M 7.2

F 7.3 M 7.3

F 7.4 M 7.4

F 7.5 M 7.5

F 7.6 M 7.6

F 7.7 M 7.7

F 8.0 M 8.0

F 8.1 M 8.1

F 8.2 M 8.2

F 8.3 M 8.3

F 8.4 M 8.4

F 8.5 M 8.5

F 8.6 M 8.6

F 8.7 M 8.7

;

F 9.0 M 9.0 turret drive: WS at automatic

F 9.1 M 9.1 turret drive: WS at manual

F 9.2 M 9.2 turret drive: WS at threading operation

F 9.3 M 9.3

F 9.4 M 9.4 hf for pulse

F 9.5 M 9.5 turret drive: is at automatic

F 9.6 M 9.6 turret drive: is at manual

F 9.7 M 9.7 turret drive: is at threading operation

;

F 10.0 M 10.0 enable safety doors winder

F 10.1 M 10.1

F 10.2 M 10.2

F 10.3 M 10.3

F 10.4 M 10.4

F 10.5 M 10.5

F 10.6 M 10.6

F 10.7 M 10.7

;

F 11.0 M 11.0

F 11.1 M 11.1

F 11.2 M 11.2

F 11.3 M 11.3

F 11.4 M 11.4

F 11.5 M 11.5

F 11.6 M 11.6

F 11.7 M 11.7

;

F 12.0 M 12.0 diameter rewinder A/B larger diamet.max.

F 12.1 M 12.1 diameter monitoring rewinder A/B (alarm)

F 12.2 M 12.2 hf reset run time

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 20

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 12.3 M 12.3 pulse reset off after T 38

F 12.4 M 12.4 hf for pulse

F 12.5 M 12.5

F 12.6 M 12.6

F 12.7 M 12.7

;

F 13.0 M 13.0 hydraulic/pneumatic: pressure available

F 13.1 M 13.1 pneumatic: mains pressure ok

F 13.2 M 13.2

F 13.3 M 13.3

F 13.4 M 13.4

F 13.5 M 13.5 hydraulics: machine off

F 13.6 M 13.6 hydraulics: quick-stop

F 13.7 M 13.7 hydraulics: e-stop

;

F 14.0 M 14.0

F 14.1 M 14.1

F 14.2 M 14.2

F 14.3 M 14.3

F 14.4 M 14.4

F 14.5 M 14.5

F 14.6 M 14.6

F 14.7 M 14.7

;

F 15.0 M 15.0 rewinder A: on to n=0

F 15.1 M 15.1 rewinder A: n=0

F 15.2 M 15.2

F 15.3 M 15.3

F 15.4 M 15.4

F 15.5 M 15.5 rewinder A: machine off

F 15.6 M 15.6 rewinder A: machine quick stop

F 15.7 M 15.7 rewinder A: machine e-stop

;

F 16.0 M 16.0 start send direct to Dornier

F 16.1 M 16.1 fault: e-stop Take-Up

F 16.2 M 16.2 fault: fault Take-Up

F 16.3 M 16.3 Take-Up ready to start

F 16.4 M 16.4 rewinder A: frictiontest not possible

F 16.5 M 16.5 rewinder A: frictiontest finished

F 16.6 M 16.6

F 16.7 M 16.7 rewinder A: enable threading

;

F 17.0 M 17.0

F 17.1 M 17.1

F 17.2 M 17.2

F 17.3 M 17.3

F 17.4 M 17.4 enable M-regul.from pos.winding carriage

F 17.5 M 17.5 fast up to gap

F 17.6 M 17.6

F 17.7 M 17.7 start roll carr. from length or diameter

;

F 18.0 M 18.0 cones A: on to n=0

F 18.1 M 18.1 cones A: n=0

F 18.2 M 18.2

F 18.3 M 18.3

F 18.4 M 18.4

F 18.5 M 18.5 cones A: machine off

F 18.6 M 18.6 cones A: machine quick-stop

F 18.7 M 18.7 cones A: machine e-stop

;

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 21

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 19.0 M 19.0 cones A: chucked and locked

F 19.1 M 19.1 cones A: released

F 19.2 M 19.2 cones A: in center position

F 19.3 M 19.3 cones A: chucked by Simadyn-D, stored

F 19.4 M 19.4 cones A: open 2mm

F 19.5 M 19.5

F 19.6 M 19.6

F 19.7 M 19.7

;

F 20.0 M 20.0 rewinder B: on to n=0

F 20.1 M 20.1 rewinder B: n=0

F 20.2 M 20.2

F 20.3 M 20.3

F 20.4 M 20.4

F 20.5 M 20.5 rewinder B: machine off

F 20.6 M 20.6 rewinder B: machine quick-stop

F 20.7 M 20.7 rewinder B: machine e-stop

;

F 21.0 M 21.0

F 21.1 M 21.1

F 21.2 M 21.2

F 21.3 M 21.3

F 21.4 M 21.4 rewinder B: frictiontest not possible

F 21.5 M 21.5 rewinder B: frictiontest finished

F 21.6 M 21.6

F 21.7 M 21.7 rewinder B: enable threading

;

F 22.0 M 22.0

F 22.1 M 22.1

F 22.2 M 22.2

F 22.3 M 22.3

F 22.4 M 22.4

F 22.5 M 22.5

F 22.6 M 22.6

F 22.7 M 22.7

;

F 23.0 M 23.0 cones B: on to n=0

F 23.1 M 23.1 cones B: n=0

F 23.2 M 23.2

F 23.3 M 23.3

F 23.4 M 23.4

F 23.5 M 23.5 cones B: machine off

F 23.6 M 23.6 cones B: machine quick-stop

F 23.7 M 23.7 cones B: machine e-stop

;

F 24.0 M 24.0 cones B: chucked and locked

F 24.1 M 24.1 cones B: released

F 24.2 M 24.2 cones B: in center position

F 24.3 M 24.3 cones B: chucked by Simadyn-D, stored

F 24.4 M 24.4 cones B: open 2mm

F 24.5 M 24.5

F 24.6 M 24.6

F 24.7 M 24.7

;

F 25.0 M 25.0

F 25.1 M 25.1

F 25.2 M 25.2

F 25.3 M 25.3

F 25.4 M 25.4

F 25.5 M 25.5

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 22

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 25.6 M 25.6

F 25.7 M 25.7

F 26.0 M 26.0 guide roller A: on to n=0

F 26.1 M 26.1 guide roller A: n=0

F 26.2 M 26.2

F 26.3 M 26.3

F 26.4 M 26.4

F 26.5 M 26.5 guide roller A: machine off

F 26.6 M 26.6 guide roller A: machine quick-stop

F 26.7 M 26.7 guide roller A: machine e-stop

;

F 27.0 M 27.0

F 27.1 M 27.1

F 27.2 M 27.2

F 27.3 M 27.3

F 27.4 M 27.4 guide roller A:frictiontest not possible

F 27.5 M 27.5 guide roller A: frictiontest finished

F 27.6 M 27.6

F 27.7 M 27.7 guide roller A: enable threading

;

F 28.0 M 28.0 guide roller B: on to n=0

F 28.1 M 28.1 guide roller B: n=0

F 28.2 M 28.2

F 28.3 M 28.3

F 28.4 M 28.4

F 28.5 M 28.5 guide roller B: machine off

F 28.6 M 28.6 guide roller B: machine quick-stop

F 28.7 M 28.7 guide roller B: machine e-stop

;

F 29.0 M 29.0

F 29.1 M 29.1

F 29.2 M 29.2

F 29.3 M 29.3

F 29.4 M 29.4 guide roller B:frictiontest not possible

F 29.5 M 29.5 guide roller B: frictiontest finished

F 29.6 M 29.6

F 29.7 M 29.7 guide roller B: enable threading

;

F 30.0 M 30.0 contact roller: on to n=0

F 30.1 M 30.1 contact roller: n=0

F 30.2 M 30.2

F 30.3 M 30.3

F 30.4 M 30.4

F 30.5 M 30.5 contact roller: machine off

F 30.6 M 30.6 contact roller: machine quick-stop

F 30.7 M 30.7 contact roller: machine e-stop

;

F 31.0 M 31.0

F 31.1 M 31.1

F 31.2 M 31.2

F 31.3 M 31.3

F 31.4 M 31.4 contact roller:frictiontest not possible

F 31.5 M 31.5 contact roller: frictiontest finished

F 31.6 M 31.6

F 31.7 M 31.7

;

F 32.0 M 32.0 tension measuring roll: on to n=0

F 32.1 M 32.1 tension measuring roll: n=0

F 32.2 M 32.2

F 32.3 M 32.3

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 23

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 32.4 M 32.4

F 32.5 M 32.5 tension measuring roll: machine off

F 32.6 M 32.6 tension measuring roll:machine quick-stp

F 32.7 M 32.7 tension measuring roll: machine e-stop

;

F 33.0 M 33.0

F 33.1 M 33.1

F 33.2 M 33.2

F 33.3 M 33.3

F 33.4 M 33.4 tens.meas.roll:frictiontest not possible

F 33.5 M 33.5 tens.meas.roll: frictiontest finished

F 33.6 M 33.6

F 33.7 M 33.7

F 34.0 M 34.0 turret drive: on to n=0

F 34.1 M 34.1 turret drive: n=0

F 34.2 M 34.2 turret drive: fault track control FB60

F 34.3 M 34.3

F 34.4 M 34.4

F 34.5 M 34.5 turret drive: machine off

F 34.6 M 34.6 turret drive: machine quick-stop

F 34.7 M 34.7 turret drive: machine e-stop

;

F 35.0 M 35.0

F 35.1 M 35.1

F 35.2 M 35.2

F 35.3 M 35.3

F 35.4 M 35.4

F 35.5 M 35.5

F 35.6 M 35.6

F 35.7 M 35.7 turret drive: in threading position

;

F 36.0 M 36.0 transport drive: on to n=0

F 36.1 M 36.1 transport drive: n=0

F 36.2 M 36.2

F 36.3 M 36.3

F 36.4 M 36.4 transport drive:frictiontest not possibl

F 36.5 M 36.5 transport drive: frictiontest finished

F 36.6 M 36.6 transport drive: machine quick-stop

F 36.7 M 36.7 transport drive: machine e-stop

;

F 37.0 M 37.0

F 37.1 M 37.1

F 37.2 M 37.2

F 37.3 M 37.3

F 37.4 M 37.4

F 37.5 M 37.5

F 37.6 M 37.6 winding carriage in front

F 37.7 M 37.7 winding carriage in rear

;

F 38.0 M 38.0 cross cutter: on to n=0

F 38.1 M 38.1 cross cutter: n=0

F 38.2 M 38.2

F 38.3 M 38.3

F 38.4 M 38.4

F 38.5 M 38.5 cross cutter: machine off

F 38.6 M 38.6 cross cutter: machine quick-stop

F 38.7 M 38.7 cross cutter: machine e-stop

;

F 39.0 M 39.0

F 39.1 M 39.1

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 24

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 39.2 M 39.2

F 39.3 M 39.3

F 39.4 M 39.4

F 39.5 M 39.5

F 39.6 M 39.6

F 39.7 M 39.7 cross-cutting device: basic position

;

F 40.0 M 40.0

F 40.1 M 40.1

F 40.2 M 40.2

F 40.3 M 40.3

F 40.4 M 40.4

F 40.5 M 40.5

F 40.6 M 40.6

F 40.7 M 40.7

;

F 41.0 M 41.0 material on winder A in unloading posit.

F 41.1 M 41.1 material on winder A

F 41.2 M 41.2 winder a jog to n=0

F 41.3 M 41.3 winder a: on

F 41.4 M 41.4 winder a on or jog to n=0

F 41.5 M 41.5

F 41.6 M 41.6 spreader unit: moved on

F 41.7 M 41.7 spreader unit: moved off

;

F 42.0 M 42.0 material on winder B in unloading posit.

F 42.1 M 42.1 material on winder B

F 42.2 M 42.2 winder b jog to n=0

F 42.3 M 42.3 winder b: on

F 42.4 M 42.4 winder b on or jog to n=0

F 42.5 M 42.5

F 42.6 M 42.6

F 42.7 M 42.7

;

F 43.0 M 43.0

F 43.1 M 43.1

F 43.2 M 43.2

F 43.3 M 43.3

F 43.4 M 43.4

F 43.5 M 43.5

F 43.6 M 43.6

F 43.7 M 43.7

;

F 44.0 M 44.0 threading device: enable

F 44.1 M 44.1

F 44.2 M 44.2

F 44.3 M 44.3

F 44.4 M 44.4

F 44.5 M 44.5

F 44.6 M 44.6

F 44.7 M 44.7

;

F 45.0 M 45.0

F 45.1 M 45.1

F 45.2 M 45.2

F 45.3 M 45.3

F 45.4 M 45.4

F 45.5 M 45.5

F 45.6 M 45.6

F 45.7 M 45.7

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 25

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

;

F 46.0 M 46.0

F 46.1 M 46.1

F 46.2 M 46.2

F 46.3 M 46.3

F 46.4 M 46.4

F 46.5 M 46.5

F 46.6 M 46.6

F 46.7 M 46.7

;

F 47.0 M 47.0 rewind handling: automatic mode

F 47.1 M 47.1 rewind handling: manual mode

F 47.2 M 47.2

F 47.3 M 47.3

F 47.4 M 47.4

F 47.5 M 47.5 rewind handling: machine off

F 47.6 M 47.6 rewind handling: machine quick-stop

F 47.7 M 47.7 rewind handling: machine e-stop

;

F 48.0 M 48.0 rewind handling: in front and top

F 48.1 M 48.1

F 48.2 M 48.2

F 48.3 M 48.3

F 48.4 M 48.4

F 48.5 M 48.5

F 48.6 M 48.6 rewind handling:unloading cycle complete

F 48.7 M 48.7 rewind handling: moved back

;

F 49.0 M 49.0

F 49.1 M 49.1

F 49.2 M 49.2

F 49.3 M 49.3

F 49.4 M 49.4

F 49.5 M 49.5

F 49.6 M 49.6

F 49.7 M 49.7

;

F 50.0 M 50.0 WA to unload.pos: enable

F 50.1 M 50.1 WA to unload.pos: winding carriage back.

F 50.2 M 50.2 WA to unload.pos: start turret

F 50.3 M 50.3 WA to unload.pos: turret drive off

F 50.4 M 50.4 WA to unload.pos: wind.carriage forward

F 50.5 M 50.5 WA to unload.pos: cross cutter up

F 50.6 M 50.6 WA to unload.pos: cross cutter forward

F 50.7 M 50.7 WA to unload.pos: cross cutter backward

;

F 51.0 M 51.0 WA to unload.pos: active

F 51.1 M 51.1

F 51.2 M 51.2

F 51.3 M 51.3

F 51.4 M 51.4

F 51.5 M 51.5

F 51.6 M 51.6 roll change after threading complete

F 51.7 M 51.7 WA to unload.pos: turret cycle complete

;

F 52.0 M 52.0 WB to unload.pos: enable

F 52.1 M 52.1 WB to unload.pos: winding carriage back

F 52.2 M 52.2 WB to unload.pos: start turret

F 52.3 M 52.3 WB to unload.pos: turret drive off

F 52.4 M 52.4 WB to unload.pos: wind.carriage forward

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 26

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 52.5 M 52.5 WB to unload.pos: cross cutter up

F 52.6 M 52.6 WB to unload.pos: cross cutter forward

F 52.7 M 52.7 WB to unload.pos: cross cutter backward

;

F 53.0 M 53.0 WB to unload.pos: active

F 53.1 M 53.1

F 53.2 M 53.2

F 53.3 M 53.3

F 53.4 M 53.4

F 53.5 M 53.5

F 53.6 M 53.6

F 53.7 M 53.7 WB to unload.pos: turret cycle complete

;

F 54.0 M 54.0

F 54.1 M 54.1

F 54.2 M 54.2

F 54.3 M 54.3

F 54.4 M 54.4

F 54.5 M 54.5

F 54.6 M 54.6

F 54.7 M 54.7

;

F 55.0 M 55.0 rewind handling: forward

F 55.1 M 55.1 rewind handling: up

F 55.2 M 55.2 rewind handling: cones release

F 55.3 M 55.3 rewind handling: backward

F 55.4 M 55.4 rewind handling: enable coil unload

F 55.5 M 55.5 rewind handling: cones move to center

F 55.6 M 55.6

F 55.7 M 55.7

;

F 56.0 M 56.0 rewind handling: forward

F 56.1 M 56.1 rewind handling: cones chuck

F 56.2 M 56.2 rewind handling: down

F 56.3 M 56.3 rewind handling: backward

F 56.4 M 56.4

F 56.5 M 56.5

F 56.6 M 56.6 coil has been removed

F 56.7 M 56.7 core taken-over by crane

;

F 61.2 M 61.2

F 61.3 M 61.3

F 61.4 M 61.4

F 61.5 M 61.5

F 61.6 M 61.6

F 61.7 M 61.7

;

F 62.0 M 62.0

F 62.1 M 62.1

F 62.2 M 62.2

F 62.3 M 62.3

F 62.4 M 62.4

F 62.5 M 62.5

F 62.6 M 62.6

F 62.7 M 62.7

;

F 63.0 M 63.0

F 63.1 M 63.1

F 63.2 M 63.2

F 63.3 M 63.3

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 27

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 63.4 M 63.4

F 63.5 M 63.5

F 63.6 M 63.6

F 63.7 M 63.7

;

F 64.0 M 64.0

F 64.1 M 64.1

F 64.2 M 64.2

F 64.3 M 64.3

F 64.4 M 64.4 pos.turret slow winder A to winding pos.

F 64.5 M 64.5 pos.turret slow winder B to winding pos.

F 64.6 M 64.6

F 64.7 M 64.7

;

F 65.0 M 65.0 position winder B: in winding position

F 65.1 M 65.1

F 65.2 M 65.2

F 65.3 M 65.3

F 65.4 M 65.4 position winder A: in winding position

F 65.5 M 65.5

F 65.6 M 65.6

F 65.7 M 65.7

;

F 66.0 M 66.0

F 66.1 M 66.1

F 66.2 M 66.2

F 66.3 M 66.3

F 66.4 M 66.4

F 66.5 M 66.5

F 66.6 M 66.6

F 66.7 M 66.7

;

F 67.0 M 67.0

F 67.1 M 67.1

F 67.2 M 67.2

F 67.3 M 67.3

F 67.4 M 67.4

F 67.5 M 67.5

F 67.6 M 67.6

F 67.7 M 67.7

;

F 68.0 M 68.0

F 68.1 M 68.1

F 68.2 M 68.2

F 68.3 M 68.3

F 68.4 M 68.4

F 68.5 M 68.5

F 68.6 M 68.6

F 68.7 M 68.7

;

F 69.0 M 69.0

F 69.1 M 69.1

F 69.2 M 69.2

F 69.3 M 69.3

F 69.4 M 69.4

F 69.5 M 69.5

F 69.6 M 69.6

F 69.7 M 69.7

;

F 79.0 M 79.0

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 28

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 79.1 M 79.1

F 79.2 M 79.2

F 79.3 M 79.3

F 79.4 M 79.4

F 79.5 M 79.5

F 79.6 M 79.6

F 79.7 M 79.7

;

F 80.0 M 80.0 frictiontest abort from PC

F 80.1 M 80.1 frictiontest start from PC

F 80.2 M 80.2 frictiontest tens.meas.roll on from PC

F 80.3 M 80.3 frictiontest contact roller on from PC

F 80.4 M 80.4 frictiontest guide roller A on from PC

F 80.5 M 80.5 frictiontest guide roller B on from PC

F 80.6 M 80.6 frictiontest rewinder A on from PC

F 80.7 M 80.7 frictiontest rewinder B on from PC

;

F 81.0 M 81.0 frictiontest finished -> PC

F 81.1 M 81.1 frictiontest not possible at PC

F 81.2 M 81.2 frictiontest tens.meas.roll act -> from

F 81.3 M 81.3 frictiontest contact roll active -> PC

F 81.4 M 81.4 frictiontest transport active -> PC

F 81.5 M 81.5 frictiontest guide roller B act. -> PC

F 81.6 M 81.6 frictiontest rewinder A active -> PC

F 81.7 M 81.7 frictiontest rewinder B active -> PC

;

F 82.0 M 82.0 frictiontest transport drive on from PC

F 82.1 M 82.1

F 82.2 M 82.2

F 82.3 M 82.3

F 82.4 M 82.4

F 82.5 M 82.5

F 82.6 M 82.6

F 82.7 M 82.7

;

F 83.0 M 83.0 frictiontest guide roller A act.from PC

F 83.1 M 83.1

F 83.2 M 83.2

F 83.3 M 83.3

F 83.4 M 83.4

F 83.5 M 83.5

F 83.6 M 83.6

F 83.7 M 83.7

;

F 100.0 M 100.0 flag logic == 0 ==

F 100.1 M 100.1 flag logic == 1 ==

F 100.2 M 100.2 startup-flag

F 100.3 M 100.3

F 100.4 M 100.4

F 100.5 M 100.5 detection bit, fault message detected

F 100.6 M 100.6 detection bit,prompting message detected

F 100.7 M 100.7

;

F 101.0 M 101.0

F 101.1 M 101.1

F 101.2 M 101.2

F 101.3 M 101.3

F 101.4 M 101.4

F 101.5 M 101.5

F 101.6 M 101.6

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 29

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 101.7 M 101.7

;

F 111.0 <- Sim D M 111.0 rewinder A: web break <- Sim D

F 111.1 <- Sim D M 111.1 rewinder A: drive is synchronou<- Sim D

F 111.2 <- Sim D M 111.2 rewinder A: n=0 <- Sim D

;

F 110.1 <- Sim D M 110.1 guide roller A: drive is synchr<- Sim D

F 110.2 <- Sim D M 110.2 guide roller A: n=0 <- Sim D

;

F 112.1 <- Sim D M 112.1 guide roller B: drive is synchr<- Sim D

F 112.2 <- Sim D M 112.2 guide roller B: n=0 <- Sim D

;

F 113.0 <- Sim D M 113.0 rewinder B: web break <- Sim D

F 113.1 <- Sim D M 113.1 rewinder B: drive is synchronou<- Sim D

F 113.2 <- Sim D M 113.2 rewinder B: n=0 <- Sim D

;

F 115.1 <- Sim D M 115.1 tens.meas.roll: drive is synchr<- Sim D

F 115.2 <- Sim D M 115.2 tens.meas.roll: n=0 <- Sim D

;

F 114.1 <- Sim D M 114.1 contact roller: drive is synchr.

F 114.2 <- Sim D M 114.2 contact roller: n=0

F 114.3 <- Sim D M 114.3 spare

F 114.4 <- Sim D M 114.4 rewinder A: stop, running length reached

F 114.5 <- Sim D M 114.5 rewinder A: stop, diameter presel. reach

F 114.6 <- Sim D M 114.6 rewinder B: stop, running length reached

F 114.7 <- Sim D M 114.7 rewinder B: stop, diameter presel. reach

;

F 117.0 <- Sim D M 117.0 turret drive: n=0 <- Sim D

F 117.1 <- Sim D M 117.1 spare <- Sim D

F 117.2 <- Sim D M 117.2 spare <- Sim D

F 117.3 <- Sim D M 117.3 spare <- Sim D

F 117.4 <- Sim D M 117.4 winding carr. contact wind. act.<- Sim D

F 117.5 <- Sim D M 117.5 winding carr. gap winding active<- Sim D

F 117.6 <- Sim D M 117.6 spare <- Sim D

F 117.7 <- Sim D M 117.7 spare <- Sim D

;

F 116.0 <- Sim D M 116.0

F 116.1 <- Sim D M 116.1 x-cut knife: n=0 <- SIM-D

;

F 119.1 <- Sim D M 119.1 idler roller B: drive is synchr<- Sim D

F 119.2 <- Sim D M 119.2 idler roller B: n=0 <- Sim D

;

F 120.0 -> Sim D M 120.0 rewinder A: web break -> SIM-D

F 120.1 -> Sim D M 120.1 rewinder A: frictiontest active -> SIM-D

F 120.2 -> Sim D M 120.2 rewinder A: enable diam. calc. -> SIM-D

F 120.3 -> Sim D M 120.3 rewinder A: reset diam. calcul. -> SIM-D

F 120.4 -> Sim D M 120.4 rewinder A: inc.tens. at turret.-> SIM-D

F 120.5 -> Sim D M 120.5 rewinder A: overspeed on -> SIM-D

F 120.6 -> Sim D M 120.6 rewinder A: overspeed analog

F 120.7 -> Sim D M 120.7 rewinder A: overspeed minimal

;

F 121.0 -> Sim D M 121.0 rewinder A: enable n-regulator -> SIM-D

F 121.1 -> Sim D M 121.1 rewinder A: enable torque-reg. -> SIM-D

F 121.2 -> Sim D M 121.2 rewinder A: start synchronize -> SIM-D

F 121.3 -> Sim D M 121.3 rewinder A: Vset on -> SIM-D

F 121.4 -> Sim D M 121.4 rewinder A: enable tension reg. -> SIM-D

F 121.5 -> Sim D M 121.5 rewinder A: active (winding pos)-> SIM-D

F 121.6 -> Sim D M 121.6 rewinder A: reduced tension on -> SIM-D

F 121.7 -> Sim D M 121.7 rewinder A: increase tension on -> SIM-D

;

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 30

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 122.4 -> Sim D M 122.4 rewinder A: jog -> SIM-D

F 122.5 -> Sim D M 122.5 rewinder A: jog backwards -> SIM-D

;

F 123.0 -> Sim D M 123.0 guide roller A: enable n-regul. -> SIM-D

F 123.1 -> Sim D M 123.1 guide roller A: enable M-regul. -> SIM-D

F 123.2 -> Sim D M 123.2 guide roller A: start synchron. -> SIM-D

F 123.3 -> Sim D M 123.3 guide roller A: Vset on -> SIM-D

F 123.4 -> Sim D M 123.4 guide roller A: jog -> SIM-D

F 123.5 -> Sim D M 123.5 guide roller A: jog backwards -> SIM-D

F 123.6 -> Sim D M 123.6 guide roller A: frictiontest -> SIM-D

F 123.7 -> Sim D M 123.7 guide roller A: turn direction -> SIM-D

;

F 124.0 -> Sim D M 124.0 rewinder B: web break -> SIM-D

F 124.1 -> Sim D M 124.1 rewinder B: frictiontest active -> SIM-D

F 124.2 -> Sim D M 124.2 rewinder B: enable diam. calc. -> SIM-D

F 124.3 -> Sim D M 124.3 rewinder B: reset diam. calcul. -> SIM-D

F 124.4 -> Sim D M 124.4 rewinder B: inc.tens. at turret.-> SIM-D

F 124.5 -> Sim D M 124.5 rewinder B: overspeed on -> SIM-D

F 124.6 -> Sim D M 124.6 rewinder B: overspeed analog

F 124.7 -> Sim D M 124.7 rewinder B: overspeed minimal

;

F 125.0 -> Sim D M 125.0 rewinder B: enable n-regulator -> SIM-D

F 125.1 -> Sim D M 125.1 rewinder B: enable torque-reg. -> SIM-D

F 125.2 -> Sim D M 125.2 rewinder B: start synchronize -> SIM-D

F 125.3 -> Sim D M 125.3 rewinder B: Vset on -> SIM-D

F 125.4 -> Sim D M 125.4 rewinder B: enable tension reg. -> SIM-D

F 125.5 -> Sim D M 125.5 rewinder B: active (winding pos)-> SIM-D

F 125.6 -> Sim D M 125.6 rewinder B: reduced tension on -> SIM-D

F 125.7 -> Sim D M 125.7 rewinder B: increase tension on -> SIM-D

;

F 126.4 -> SIM D M 126.4 rewinder B: jog

F 126.5 -> SIM D M 126.5 rewinder B: jog backwards

;

F 127.0 -> Sim D M 127.0 guide roller B: enable n-regul. -> SIM-D

F 127.1 -> Sim D M 127.1 guide roller B: enable M-regul. -> SIM-D

F 127.2 -> Sim D M 127.2 guide roller B: start synchron. -> SIM-D

F 127.3 -> Sim D M 127.3 guide roller B: Vset on -> SIM-D

F 127.4 -> Sim D M 127.4 guide roller B: jog -> SIM-D

F 127.5 -> Sim D M 127.5 guide roller B: jog backwards -> SIM-D

F 127.6 -> Sim D M 127.6 guide roller B: frictiontest -> SIM-D

F 127.7 -> Sim D M 127.7 guide roller B: turn direction -> SIM-D

;

F 129.5 -> Sim D M 129.5 constant value 1 nip pressure -> SIM-D

F 129.6 -> SIm D M 129.6 constant value 2 nip pressure -> SIM-D

;

F 131.0 -> Sim D M 131.0 ten. mess.roll enable n-regul. -> SIM-D

F 131.1 -> Sim D M 131.1 ten. mess.roll enable M-regul. -> SIM-D

F 131.2 -> Sim D M 131.2 ten. mess.roll start synchron. -> SIM-D

F 131.3 -> Sim D M 131.3 ten. mess.roll Vset on -> SIM-D

F 131.4 -> Sim D M 131.4 ten. mess.roll jog -> SIM-D

F 131.5 -> Sim D M 131.5 ten. mess.roll jog backwards -> SIM-D

F 131.6 -> Sim D M 131.6 ten. mess.roll frictiontest -> SIM-D

F 131.7 -> Sim D M 131.7 ten. mess.roll turn direction -> SIM-D

;

F 133.0 -> Sim D M 133.0 contact roller enable n-regul. -> SIM-D

F 133.1 -> Sim D M 133.1 contact roller enable M-regul. -> SIM-D

F 133.2 -> Sim D M 133.2 contact roller start synchron. -> SIM-D

F 133.3 -> Sim D M 133.3 contact roller Vset on -> SIM-D

F 133.4 -> Sim D M 133.4 contact roller jog -> SIM-D

F 133.5 -> Sim D M 133.5 contact roller jog backwards -> SIM-D

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 31

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

F 133.6 -> Sim D M 133.6 contact roller frictiontest -> SIM-D

F 133.7 -> Sim D M 133.7 contact roller turn direction -> SIM-D

;

F 137.2 -> Sim D M 137.2 winding carriage: backward -> SIM-D

F 137.3 -> Sim D M 137.3 winding carriage: enable -> SIM-D

F 137.4 -> Sim D M 137.4 winding carr.: enable contact w.-> SIM-D

F 137.5 -> Sim D M 137.5 winding carriage: enable gap w. -> SIM-D

F 137.6 -> Sim D M 137.6 enable nip pressure of pulsor -> SIM-D

F 137.7 -> SIm D M 137.7 pulsor regulation -> SIM-D

;

F 139.0 -> Sim-D M 139.0 x-cut-knife: enable n-regulator

F 139.1 -> SIm D M 139.1 x-cut-knife: start knife slitting

F 139.2 -> Sim-D M 139.2 x-cut-knife: knife backward

F 139.3 -> SIm D M 139.3 x-cut-knife: park position

F 139.4 -> Sim-D M 139.4 x-cut-knife: end position

F 139.5 -> Sim D M 139.5 x-cut-knife: start ->cut position

F 139.6 -> Sim-D M 139.6 x-cut-knife: start backwards to cut pos.

F 139.7 -> Sim D M 139.7 x-cut knife: cut position (initiator)

;

F 141.0 -> Sim D M 141.0 idler roller enable n-regul. -> SIM-D

F 141.1 -> Sim D M 141.1 idler roller enable M-regul. -> SIM-D

F 141.2 -> Sim D M 141.2 idler roller start synchron. -> SIM-D

F 141.3 -> Sim D M 141.3 idler roller Vset on -> SIM-D

F 141.4 -> Sim D M 141.4 idler roller jog -> SIM-D

F 141.5 -> Sim D M 141.5 idler roller jog backwards -> SIM-D

F 141.6 -> Sim D M 141.6 idler roller frictiontest -> SIM-D

F 141.7 -> Sim D M 141.7 idler roller turn direction -> SIM-D

;

F 199.0 M 199.0 ET 100 ok in startup-test

F 199.1 M 199.1 ET 100 datablock-error

F 199.2 M 199.2 ET 100 ok in cycle-test

F 199.3 M 199.3

F 199.4 M 199.4

F 199.5 M 199.5

F 199.6 M 199.6

F 199.7 M 199.7

;

T 0 T0 flash frequency

T 1 T1 pulse change spare faults

T 2 T2 pulse e-stop

T 3 T3

T 4 T4 pneumatic mains pressure ok

T 5 T5

T 6 T6 time after reset emergency stop

T 7 T7

T 8 T8

T 9 T9 e-stop from simadyn

T 10 T 10 monit. time rewinder switch to automatic

T 11 T 11 pulse reset length

T 12 T 12 pulse reset length

T 13 T 13 monitoring drive winding carriage

T 14 T 14 winding carriage overload

T 15 T 15 monitoring oscilation rewinder A

T 16 T 16 oscilation rewinder A overload

T 17 T 17 monitoring oscillation rewinder B

T 18 T 18 oscillation rewinder B overload

T 19 T 19 cones A: open 2mm delayed

T 20 T 20 cones B: open 2mm delayed

T 21 T 21 pulse turret finished

T 22 T 22 winding carriage slow forward delay on

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 32

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

T 23 T 23 winding carriage slow backward delay on

T 24 T 24 winding carriage fast forward delay on

T 25 T 25 winding carriage fast backward delay on

T 26 T 26 M-regula. off from pos. winding carriage

T 27 T 27 M-regulat. on from pos. winding carriage

T 28 T 28 oil filter monitoring hydraulic

T 29 T 29 signal time to crane: roll enable

T 30 T 30 cones A: chuck with delay

T 31 T 31 cones A: release with delay

T 32 T 32 cones A: delayed sidelay on

T 33 T 33 run time winding carriage backward

T 34 T 34

T 35 T 35 cones B: chuck with delay

T 36 T 36 cones B: release with delay

T 37 T 37 cones B: delayed sidelay on

T 38 T 38 reset run time

T 39 T 39 ht reset run time

T 40 T 40

T 41 T 41 rewinder A: delayed F-regulator on

T 42 T 42 rewinder B: delayed F-regulator on

T 43 T 43 reset diameter at threading start

T 44 T 44 enable diameter scrap roll

T 45 T 45

T 46 T 46

T 47 T 47

T 48 T 48 pulse constant value 1 act. contact wind

T 49 T 49

T 50 T 50 rewinder A: delayed x-cut-device up

T 51 T 51 rewinder A: delayed start cut

T 52 T 52 rewinder A: delayed x-cut-knife back

T 53 T 53

T 54 T 54

T 55 T 55 rewinder B: delayed x-cut-device up

T 56 T 56 rewinder B: delayed start cut

T 57 T 57 rewinder B: delayed x-cut-knife back

T 58 T 58

T 59 T 59 turret drive: pulse position reached

T 60 T 60 turret drive: time start-up signal

T 61 T 61 turret drive: delay brake open after on

T 62 T 62

T 63 T 63 turret disk: brake open delayed

T 64 T 64 turret drive: del. off after brake close

T 65 T 65

T 66 T 66

T 67 T 67

T 68 T 68

T 69 T 69

T 70 T 70 time monitoring thread-in material PB-1

T 71 T 71 time monitoring thread-in material PB-2

T 72 T 72

T 73 T 73 time monitoring close cones A

T 74 T 74 time monitoring open cones A

T 75 T 75 time monitoring close cones B

T 76 T 76 time monitoring open cones B

T 77 T 77

T 78 T 78 guide roller A on after winder on

T 79 T 79 guide roller B on after winder on

T 80 T 80 tens.meas.roll: drv.delayed off aft.faul

T 81 T 81 tens.meas.roll: monit.time holding brake

T 82 T 82 tens.meas.roll: feedback mains contactor

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 33

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

T 83 T 83 contact roller:drv.delayed off aft.fault

T 84 T 84 contact roller: monit.time holding brake

T 85 T 85 contact roller: feedback mains contactor

T 86 T 86 guide roller A:drv.delayed off aft.fault

T 87 T 87 guide roller B:drv.delayed off aft.fault

T 88 T 88

T 89 T 89

T 90 T 90 guide roller A: release auto coil change

T 91 T 91 guide roller B: release auto coil change

T 92 T 92 rewinder A: drv. delayed off after fault

T 93 T 93 rewinder A: monitor.time holding brake

T 94 T 94 rewinder A: feedback mains contactor

T 95 T 95 rewinder B: drv. delayed off after fault

T 96 T 96 rewinder B: monitor.time holding brake

T 97 T 97 rewinder B: feedback mains contactor

T 98 T 98 turret drive: drv. delayed off aft.fault

T 99 T 99 turret drive: monitor.time holding brake

T 100 T 100 turret drive: feedback mains contactor

T 101 T 101

T 102 T 102

T 103 T 103

T 104 T 104

T 105 T 105

T 106 T 106

T 107 T 107

T 108 T 108

T 109 T 109

T 110 T 110 rewind.handling unloading cycle complete

T 111 T 111

T 112 T 112

T 113 T 113

T 114 T 114

T 115 T 115

T 116 T 116

T 117 T 117

T 118 T 118

T 119 T 119

T 120 T 120

T 121 T 121

T 122 T 122

T 123 T 123

T 124 T 124

T 125 T 125

T 126 T 126

T 127 T 127

C 0 Z0

C 1 Z1 used for counting web breaks 0999

C 2 Z2 used for counting web breaks 10009999

C 3 Z3

C 4 Z4

C 5 Z5

C 6 Z6

C 7 Z7

C 8 Z8

C 9 Z9

C 10 Z 10

C 11 Z 11

C 12 Z 12

C 13 Z 13

C 14 Z 14

File: 0301E0ST Prog:

- Symbolic table - Checked:

Mod: 3/6/1996 15:32s Date: 4/11c Page: 34

S5/S7 for Windows® - (c) 1993 - 2009 IBH softec GmbH

Symbol Operand Comment

C 15 Z 15