Professional Documents

Culture Documents

Falcon C Concentrator 2018

Falcon C Concentrator 2018

Uploaded by

evalenciaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Falcon C Concentrator 2018

Falcon C Concentrator 2018

Uploaded by

evalenciaCopyright:

Available Formats

FA LCO N CO NT I N U O US (C) CO N C E NT R ATO R S

A PPL I C AT I O N S RECOVERY DOWN TO 10 MICRONS AND UNIT

CAPACITIES UP TO 100 t/h

■ Primary concentration of tin, tantalum, tungsten, chrome,

cobalt, iron, fine oxidized coal and uranium Falcon C Concentrators are typically used in gravity

■ Scavenging of fine particles lost by low G force processes

recovery applications that require a higher mass yield

and flotation

to concentrate when compared with SB Concentrators.

■ Pre-concentration of heavy minerals

Often utilized for the recovery of valuable fine particles,

K E Y A DVA N TAG E S Falcon C Concentrators are capable of collecting fines

missed by dense medium separators, spirals or any

■ Unit capacities up to 100 t/h

■ The variable frequency drive (VFD) enables control over G force other low G processes.

based on application

Designed for continuous duty, these machines

■ Advanced wear materials and a modular design decreases

downtime and reduces maintenance costs. are able to produce mass yields as high as 40%.

■ High gravitational field (up to 300 G) allows recovery of The primary objective of the Falcon ‘C’s is to

very fine particles maximize recovery and reduce tonnage to

■ No fluidizing water consumption or offline time for downstream processes. The technology is ideal for

concentrate flushing scavenging or pre-concentrating applications as well

■ Produces high density (variable mass yield 0 – 40%) concentrate

since no water is added during processing.

therefore no thickeners required

■ Continuous production of concentrate at >70% solids Reliable test work can lead you to the right

■ Greater than 95% mechanical availability, extremely low

concentrator for your application. Sepro operates

operating costs

laboratory facilities, which generate decisive data

■ Small footprint

■ Fully automated, “one touch” operation that provides the least for scale up to commercial operation.

amount of offline time and highest possible concentrate security

FA LCO N CO NT I N U O US (C) CO N C E NT R ATO R S

S PEC I FI C AT I O N S

MODEL C400 C1000 C2000 C4000**

RECOMMENDED SOLIDS CAPACITY* t/h 1-5 5 - 27 20 - 60 45 - 100

MAX SLURRY CAPACITY m³/hr 17 74 210 400

MAXIMUM FEED PARTICLE SIZE* mm 1.0 1.0 1.0 1.0

MINIMUM EFFECTIVE CAPTURE SIZE µm 10 10 10 10

CONCENTRATE PERCENT SOLIDS % 65 - 72 65 - 72 65 - 72 65 - 72

MAXIMUM FEED PERCENT SOLIDS* % 40 - 45 40 - 45 40 - 45 40 - 45

CONCENTRATE SURFACE AREA m 2

0.25 0.60 1.42 2.64

G-FORCE RANGE upper 300 300 300 300

lower 50 50 50 50

MOTOR POWER kW (HP) 7.5 (10) 15 (20) 30 (40) 75 (100)

PROCESS WATER CONSUMPTION m³/hr NONE REQUIRED

MACHINE WEIGHT kg 1215 2 525 4 615 10 150

WIDTH m 1.22 1.55 1.85 2.36

DIMENSIONS LENGTH m 1.22 1.55 1.85 2.36

HEIGHT m 1.33 2.18 2.67 2.63

*Denotes application specific parameter, consult manufacturer.

**Special applications only, consult manufacturer.

Note: Specifications are subject to change without notice. Equipment may not operate or achieve best performance under maximum capacities.

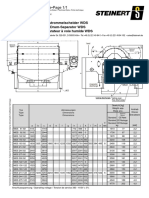

Feed

Feed Rinse Water Feed Pipe

Lights

High

S.G.

Bed Retention

Zone

Heavies

Stratification

Zone

Throttling

Nozzles (30)

Impeller

Lights

Outlet

Heavies Compressed

Outlet Air Supply

(Introduced through Rotating Union) Compressed Air Supply

(Introduced through Rotating Union)

Sepro Mineral Systems Corp.

9850 201 Street, Langley, British Columbia, Canada V1M 4A3

Office: +[1] 604.888.5568 • Fax: +[1] 604.888.5521 • Toll free: +[1] 800.990.5568 North America

sepro@seprosystems.com • www.seprosystems.com

REV 01 • 01/24/2018

You might also like

- 20150806-Modipalm Presentation v2 2010.3Document46 pages20150806-Modipalm Presentation v2 2010.3David CS ChiangNo ratings yet

- How To Formulate UVDocument16 pagesHow To Formulate UVtobass82100% (3)

- SAM Design ExampleDocument110 pagesSAM Design Exampleyyanan1118100% (3)

- Sepro Falcon SB ConcentratorsDocument2 pagesSepro Falcon SB ConcentratorsEDWIN LEONARDO ESPINOZA PACHECONo ratings yet

- Falcon SB Concentrator 2018Document2 pagesFalcon SB Concentrator 2018joslynNo ratings yet

- Falcon Semi-Batch (SB) Concentrators: Coarse and Fine Precious Metal RecoveryDocument2 pagesFalcon Semi-Batch (SB) Concentrators: Coarse and Fine Precious Metal RecoveryYanil QuinteroNo ratings yet

- M11 Falcon UF Concentrator 2018Document2 pagesM11 Falcon UF Concentrator 2018Mamoudou MagassoubaNo ratings yet

- Section4. Technicalspecifications: Falconsemibatch (SB) ConcentratorsDocument2 pagesSection4. Technicalspecifications: Falconsemibatch (SB) ConcentratorsAlejandroZegarraNo ratings yet

- 4 Falcon Semi-Batch (SB) ConcentratorsDocument2 pages4 Falcon Semi-Batch (SB) ConcentratorsLuzgardo MejiaNo ratings yet

- Sepro Falcon C Concentrators PDFDocument2 pagesSepro Falcon C Concentrators PDFEdgard Lozano ContrerasNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- Actaris Multimag TMDocument2 pagesActaris Multimag TMmamduhdjNo ratings yet

- Engineering: GREAT SolutionsDocument4 pagesEngineering: GREAT SolutionsLaura ParkaNo ratings yet

- BEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationDocument2 pagesBEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationFabio ParceroNo ratings yet

- XDS Range BrochureDocument8 pagesXDS Range BrochureJose QuincosNo ratings yet

- Excavator Attachments: Demolition, Recycling and Earth-Moving. Experience Our Hydraulic Attachment ToolsDocument8 pagesExcavator Attachments: Demolition, Recycling and Earth-Moving. Experience Our Hydraulic Attachment ToolsSilvio CeolNo ratings yet

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- Pumps Catalog en PDFDocument36 pagesPumps Catalog en PDFHABIB PIRZADANo ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- GC Compressor Brochure 10-02-20Document6 pagesGC Compressor Brochure 10-02-20arnoldbusaNo ratings yet

- MDW Series enDocument2 pagesMDW Series enRafa Ruiz de OjedaNo ratings yet

- Hydraulic Drifter: Trusted ReputationDocument2 pagesHydraulic Drifter: Trusted ReputationEstyNo ratings yet

- Specialty Turbine Flowmeters: NufloDocument2 pagesSpecialty Turbine Flowmeters: NufloJose CameloNo ratings yet

- Specs For Transformer Oil (Normal Grade)Document9 pagesSpecs For Transformer Oil (Normal Grade)Georgina SuleNo ratings yet

- STERLINGDocument8 pagesSTERLINGHummac MagañaNo ratings yet

- Datasheet Separation Plant HKS 500-3000 TT ENDocument2 pagesDatasheet Separation Plant HKS 500-3000 TT ENAbdelrahman ElsayedNo ratings yet

- 9851 3586 01 - Cop MD20Document4 pages9851 3586 01 - Cop MD20Guifo salvadorNo ratings yet

- 9851 3586 01 COP MD20 BrochureDocument4 pages9851 3586 01 COP MD20 BrochureEduardo MassainiNo ratings yet

- rc1000 PsDocument1 pagerc1000 PsBehnamNo ratings yet

- Hydraulic Drifter: Innovative DesignDocument2 pagesHydraulic Drifter: Innovative DesignEsty50% (2)

- Katalog SIHI Liquid Ring Vacuum PumpsDocument12 pagesKatalog SIHI Liquid Ring Vacuum PumpsTrisna RamadhanNo ratings yet

- Brochure PAS VAR Dewatering Pumps English v06Document20 pagesBrochure PAS VAR Dewatering Pumps English v06Maximo MartinezNo ratings yet

- Specs For Transformer Oil (Super Grade)Document9 pagesSpecs For Transformer Oil (Super Grade)Georgina SuleNo ratings yet

- Mix Designs PFADocument8 pagesMix Designs PFAasif razaNo ratings yet

- Compresor CentrifugoDocument6 pagesCompresor Centrifugoalegria_systemsNo ratings yet

- Sihi Vacuum Lohe Serie 25 - 2 EtapasDocument11 pagesSihi Vacuum Lohe Serie 25 - 2 EtapasRaciel Leon CarlosNo ratings yet

- Scheuch Folder Ligno Entstauber E 120116 01Document8 pagesScheuch Folder Ligno Entstauber E 120116 01MagdalenaNo ratings yet

- Lem 25-50Document8 pagesLem 25-50anthony_vidal100% (1)

- Catalog Serie LEMA 25 - 50Document8 pagesCatalog Serie LEMA 25 - 50Lenin MisariNo ratings yet

- Lower Your Total Cost of Ownership: HelicalDocument2 pagesLower Your Total Cost of Ownership: Helicalankit58497No ratings yet

- WaboCrete SiliconeSeal 0321 DataSheet-2.2023Document4 pagesWaboCrete SiliconeSeal 0321 DataSheet-2.2023marketing.avaneeshNo ratings yet

- Industrial Silencers: "Sounds Like Success"Document11 pagesIndustrial Silencers: "Sounds Like Success"Syed AhsanNo ratings yet

- Gordon Schwing Sludge Pump KSP 315Document3 pagesGordon Schwing Sludge Pump KSP 315Ricardo Salas IparraguirreNo ratings yet

- AHLSTAREndSuctionSingleStage E10083Document28 pagesAHLSTAREndSuctionSingleStage E10083katlego01No ratings yet

- ZENON MBR Tech (Chris Jeffery)Document70 pagesZENON MBR Tech (Chris Jeffery)Srinivas DiviNo ratings yet

- Hydraulic Drifter: Designed For Surface & Underground DrillingDocument2 pagesHydraulic Drifter: Designed For Surface & Underground DrillingEstyNo ratings yet

- Valves PDFDocument12 pagesValves PDFAnonymous HFIQgANMQNo ratings yet

- Ch860 Ch865 Specification Sheet EnglishDocument8 pagesCh860 Ch865 Specification Sheet EnglishEricNo ratings yet

- T30 CatalogueDocument4 pagesT30 CatalogueIronValley SolutionsNo ratings yet

- 818H Power Mizer For Water and Wastewater Treatment Systems PDFDocument4 pages818H Power Mizer For Water and Wastewater Treatment Systems PDFshahqazwsxNo ratings yet

- DAF150Document2 pagesDAF150justin.atkins996No ratings yet

- Demister EnglischDocument2 pagesDemister EnglischBahtiar YudhistiraNo ratings yet

- Data Sheet SFP2860Document2 pagesData Sheet SFP2860Donatas BertasiusNo ratings yet

- The Above-Ground Sulfur Seal From The Makers of Controtrace®Document2 pagesThe Above-Ground Sulfur Seal From The Makers of Controtrace®Javier GarcíaNo ratings yet

- Cameron CCDocument6 pagesCameron CCYogesh Badhe100% (1)

- BmaDocument6 pagesBmaraouf youssefNo ratings yet

- Container Generator Qac Qec Leaflet EnglishDocument8 pagesContainer Generator Qac Qec Leaflet EnglishGem RNo ratings yet

- D25KS/D245S: Rotary Blast Hole DrillsDocument12 pagesD25KS/D245S: Rotary Blast Hole DrillsPeMar León ChangNo ratings yet

- CLP en PDFDocument2 pagesCLP en PDFAnthony FuNo ratings yet

- ST - MB1500 1 - 29 05 20Document12 pagesST - MB1500 1 - 29 05 20CMI SRLNo ratings yet

- 9800 1245 01 - Reversible PlatesDocument8 pages9800 1245 01 - Reversible PlatesalmirNo ratings yet

- Sgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignDocument10 pagesSgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignevalenciaNo ratings yet

- Methods of Chemical Analysis of FluorsparDocument23 pagesMethods of Chemical Analysis of Fluorsparevalencia100% (1)

- Analysis of Acid-Grade Calcium Fluoride (Fluorspar) : Standard Test Methods ForDocument14 pagesAnalysis of Acid-Grade Calcium Fluoride (Fluorspar) : Standard Test Methods ForevalenciaNo ratings yet

- Minerals 09 00222Document11 pagesMinerals 09 00222evalenciaNo ratings yet

- User's Manual 9410500, Rev A, Protector PremierDocument59 pagesUser's Manual 9410500, Rev A, Protector PremierevalenciaNo ratings yet

- Preparing Your LaboratoryDocument12 pagesPreparing Your LaboratoryevalenciaNo ratings yet

- DG - AG-04 MaizeDocument1 pageDG - AG-04 MaizeevalenciaNo ratings yet

- User Instruction Manual 9779401, Rev B, Intelli-SashDocument11 pagesUser Instruction Manual 9779401, Rev B, Intelli-SashevalenciaNo ratings yet

- Beans: Application Field: Agriculture Digestion Application Note DG-AG-06Document1 pageBeans: Application Field: Agriculture Digestion Application Note DG-AG-06evalenciaNo ratings yet

- Roots: Application Field: Agriculture Digestion Application Note DG-AG-08Document1 pageRoots: Application Field: Agriculture Digestion Application Note DG-AG-08evalenciaNo ratings yet

- Ground Vegetable: Application Field: Agriculture Digestion Application Note DG-AG-03Document1 pageGround Vegetable: Application Field: Agriculture Digestion Application Note DG-AG-03evalenciaNo ratings yet

- Agricolture CookbookDocument10 pagesAgricolture CookbookevalenciaNo ratings yet

- DG - AG-01 Pine LeavesDocument1 pageDG - AG-01 Pine LeavesevalenciaNo ratings yet

- Seite - Page 1/1: Nasstrommelscheider WDS Wet-Drum-Separator WDS Séparateur À Voie Humide WDSDocument1 pageSeite - Page 1/1: Nasstrommelscheider WDS Wet-Drum-Separator WDS Séparateur À Voie Humide WDSevalenciaNo ratings yet

- DG - AG-02 Dried Plant TissueDocument1 pageDG - AG-02 Dried Plant TissueevalenciaNo ratings yet

- Tea Leaves: Application Field: Agriculture Digestion Application Note DG-AG-09Document1 pageTea Leaves: Application Field: Agriculture Digestion Application Note DG-AG-09evalenciaNo ratings yet

- And Techniques: Ethos Series Ethos SeriesDocument55 pagesAnd Techniques: Ethos Series Ethos SeriesevalenciaNo ratings yet

- 8000 Series Digital Video Recorder - Quick Start Guide V3.0 - 20181022Document16 pages8000 Series Digital Video Recorder - Quick Start Guide V3.0 - 20181022evalenciaNo ratings yet

- The Paste Thickener Pilot Plant Is Self-Contained and IncludesDocument1 pageThe Paste Thickener Pilot Plant Is Self-Contained and IncludesevalenciaNo ratings yet

- Example of ParagraphsDocument4 pagesExample of ParagraphsAdi HDNo ratings yet

- Open-Hole Wire-Line Logging and InterpretationsDocument61 pagesOpen-Hole Wire-Line Logging and InterpretationsRanjith PremadasanNo ratings yet

- Calculation of Electric Field DistributiDocument9 pagesCalculation of Electric Field DistributiAbouZakariaNo ratings yet

- 3rd Periodical-Phy - SciDocument4 pages3rd Periodical-Phy - SciDhealine JusayanNo ratings yet

- Hydraulics Multiple Choice Questions and Answers - Set 26 - Engineering, Competitive Exams and Jobs PDFDocument9 pagesHydraulics Multiple Choice Questions and Answers - Set 26 - Engineering, Competitive Exams and Jobs PDFl8o8r8d8s8i8v8No ratings yet

- 2019 Science Catalog PDFDocument41 pages2019 Science Catalog PDFJane PhamNo ratings yet

- FlowmeterDocument21 pagesFlowmeterHafizie ZainiNo ratings yet

- 03 Doetsch PDFDocument10 pages03 Doetsch PDFNeelima MishraNo ratings yet

- طرح درس المان محدود 1Document2 pagesطرح درس المان محدود 1s.amir.hosseinieNo ratings yet

- BITZER Output Data: Created On: 16/05/2017 16:44:22Document5 pagesBITZER Output Data: Created On: 16/05/2017 16:44:22Hasan Syaiful INo ratings yet

- ETAG022-2007 April Part 1Document33 pagesETAG022-2007 April Part 1Serban RaduNo ratings yet

- Gujarat Technological University: Electronics and Communication Engineering Subject Code: B.E. 8 SemesterDocument4 pagesGujarat Technological University: Electronics and Communication Engineering Subject Code: B.E. 8 Semestermehul03ecNo ratings yet

- Redesigning The Murphy Bed ProposalDocument19 pagesRedesigning The Murphy Bed Proposalrtk5025100% (2)

- Infusions Tierlist - Infusion TiersDocument1 pageInfusions Tierlist - Infusion TiersXavier TobarNo ratings yet

- 1.06.02 Concrete Placement Lift Fall Heights PDFDocument3 pages1.06.02 Concrete Placement Lift Fall Heights PDFAnilkumar CmNo ratings yet

- 08 Chapter 2Document71 pages08 Chapter 2Ibn LibyaNo ratings yet

- BANDAGES CorrectedDocument41 pagesBANDAGES Correctedaswinipranav100% (1)

- An Approach To Defining Tortuosity and CDocument7 pagesAn Approach To Defining Tortuosity and CvslogNo ratings yet

- Do Compression Set Results Measures Up PDFDocument3 pagesDo Compression Set Results Measures Up PDFzeqs9No ratings yet

- Improved Steam Condenser Gas Removal SystemDocument7 pagesImproved Steam Condenser Gas Removal Systemtfernandes.x18No ratings yet

- Worked Example - Retaining Wall Design - The Structural WorldDocument21 pagesWorked Example - Retaining Wall Design - The Structural WorldXiang YuNo ratings yet

- Statistics Study Guide - ProbabilityDocument5 pagesStatistics Study Guide - ProbabilityldlewisNo ratings yet

- Physics PPT Powerpoint Ni DeksiDocument11 pagesPhysics PPT Powerpoint Ni DeksiMariel Generalao MacapazNo ratings yet

- Activity # 1 States of Matter (Basic)Document6 pagesActivity # 1 States of Matter (Basic)ArebeeJayBelloNo ratings yet

- Industrial Revolution READING AND COMPREHENSIONDocument1 pageIndustrial Revolution READING AND COMPREHENSIONGlee Clases-TallerNo ratings yet

- Physics Kcet 2023Document12 pagesPhysics Kcet 2023Prajwal MNo ratings yet

- Nayati Tilting Boiling and Braising PanDocument8 pagesNayati Tilting Boiling and Braising PanKiyanto PurnomoNo ratings yet

- Solutions To Me N Mine Psa Ix 2013Document104 pagesSolutions To Me N Mine Psa Ix 2013singhji295No ratings yet