Professional Documents

Culture Documents

2972-Ratios in Gearing

2972-Ratios in Gearing

Uploaded by

jmorr57Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2972-Ratios in Gearing

2972-Ratios in Gearing

Uploaded by

jmorr57Copyright:

Available Formats

RATIOS

in

GEARING

By GEOMETER of the driven gear in the same direction

as the driving gear; while even total

numbers of gears give reverse rotation.

A

In a compound train of gears, as

CQUAINTANCE w i t h t h e main 2 to 1, the smaller dividing into the at B, rotation is the same for the

principles of gearing enables larger twice; in other words, making first driving and the final driven gear,

manv of the problems met two turns for one turn of the larger. but the two ratios must be multiplied

with in workshop practice, and in The principle applies if there is together to obtain the final one.

design and layout of simple mecha- more than one intermediate or idler With 25 teeth in the first driving gear,

gear, as gears in rotating “ take in ” 60 in the first driven, 30 in the second

nisms, to be solved without diffi- a tooth and “ give out ” one. Hence

culty. In most problems ratios are driving gear and 50 in the second

with 25 teeth in the driving gear and driven, the ratio is:

likely to be involved, for it is 40 in the driven. the ratio is obtained

usually the function of gearing to -3 2 x z!$~~_4t01

achieve definite rates of turning as before: $ = lg = 1 s to 1.

The result would be the same if

without slip. Besides connecting driving a n d driving gear with 30 teeth engaged .

In simple gear trains, as at A , driven shafts, intermediate gears can, driven gear with 60 teeth; and if

ratio is settled by the numbers of however, be employed to settle the driving gear with 25 teeth engaged

teeth in the driving and driven gears, direction of rotation of the driven driven gear with 50 teeth.

without reference to the number of gear, and also to distribute wear if To distribute wear through inter-

teeth in the intermediate or idler gear. this is likely to fall mostly on certain mediate gears, the principle is of the

Thus, with 25 teeth in the driving gear, teeth. Simple gear trains with odd “ hunting tooth ” and is useful where

and 50 in the driven, the ratio is total numbers of gears give’rotation cams may be operated. and where all

the load-would fall over a few teeth.

Thus, as at C, an overhead camshaft

drive can be arranged for 2 to 1 ratio

using appropriate numbers of teeth

in the driving and driven gears, and

odd teeth in the intermediate gears,

the ratio being:

to 1

A car gearbox incorporates com-

pound and three-shaft and four-shaft

PRlMARY S H A F T LAYSHAFT gear trains. In the “ crash ” type, as

00 25 at D. the engine drives the ordinary

shaft, the mainshaft is coupled to the

LEAD-+ t-s- P I T C H axle; and the layshaft is in constant

mesh with the primary shaft, forming

the first ratio of a compound train.

For first, gear W is moved to the

0

‘E right; for second, it is moved to the

left. For third. gear V is moved to

the right; for top-it is moved to the

left, coupling direct primary and

mainshafts. For reverse, another gear

(not shown) is inserted, making a

four-shaft train.

In single-start worm gearing, where

lead and pitch are the same, as at

E, ratio is given by the number of

Y 2 teeth in the worm wheel; but shaft

0:

b

‘4

centres can be adjusted by the radius

F X of the worm. Withmulti ple-start

worms, the number of starts divided

$

into the worm wheel teeth give the

ratio. In a double-start worm, as at

F, lead is twice pitch, with starts

opposite at Y and Z.

8 MAY 1958 MODEL ENGINEER

You might also like

- Catalago Toyota Sas 25 8fg25bDocument316 pagesCatalago Toyota Sas 25 8fg25bMatheus VilsonNo ratings yet

- Re4f03b Re4f04bDocument756 pagesRe4f03b Re4f04bdenis100% (3)

- Diagrama Hidraulico Caterpillar 345cDocument2 pagesDiagrama Hidraulico Caterpillar 345cJose Miguel Gary Vargas100% (1)

- Gear TrainsDocument40 pagesGear TrainssteevecNo ratings yet

- Gear RatioDocument9 pagesGear RatioLekha SejpalNo ratings yet

- Understanding The Threading DialDocument5 pagesUnderstanding The Threading Dialjmorr57No ratings yet

- Enco Manual 110-2034Document39 pagesEnco Manual 110-2034jmorr57No ratings yet

- 1.1.3. Presentation Gears and SprocketsDocument24 pages1.1.3. Presentation Gears and SprocketsJoshua DeLoryNo ratings yet

- Presentation GearboxDocument81 pagesPresentation GearboxVignesh Krish100% (3)

- Gear TrainDocument14 pagesGear TrainShiva SuprithNo ratings yet

- MechanisimsDocument5 pagesMechanisimsIván AguirreNo ratings yet

- Chapter 9 Gear TrainsDocument99 pagesChapter 9 Gear TrainsAmalina100% (1)

- GearDocument21 pagesGeardaniel hambissaNo ratings yet

- Power TrainsDocument33 pagesPower TrainsJohn Lester GinoNo ratings yet

- Ch1 Gear TrainsDocument79 pagesCh1 Gear Trainsخالد المالكيNo ratings yet

- Gear RatioDocument8 pagesGear RatioRakesh PandeyNo ratings yet

- Sterring MechanismDocument3 pagesSterring MechanismPrabu BalakrishnanNo ratings yet

- Me 54 Gear TrainDocument17 pagesMe 54 Gear TrainRemar Joseph CarpinaNo ratings yet

- Gear SystemDocument57 pagesGear SystemWilson LimNo ratings yet

- Gears, Pulley, Drives and SprocketsDocument22 pagesGears, Pulley, Drives and SprocketsibnuNo ratings yet

- Gear Trains - Lecture 10Document22 pagesGear Trains - Lecture 10priyankar007No ratings yet

- 1 - 1 - 3 - A GearsPulleyDrivesSprockets - 1Document22 pages1 - 1 - 3 - A GearsPulleyDrivesSprockets - 1Debra LakeNo ratings yet

- Gears, Pulley Drives, and Sprockets: © 2012 Project Lead The Way, Inc. Principles of EngineeringDocument22 pagesGears, Pulley Drives, and Sprockets: © 2012 Project Lead The Way, Inc. Principles of EngineeringFelix BuselNo ratings yet

- Gears_and_Gear_RatiosDocument27 pagesGears_and_Gear_Ratiostalha 8byt TalhaNo ratings yet

- Lenco CatalogDocument22 pagesLenco CatalogCarlos DiazNo ratings yet

- Adobe Scan 05 May 2023 (2)Document9 pagesAdobe Scan 05 May 2023 (2)dimple gandhiNo ratings yet

- Toothed Gearing: (Chapter-12 R.S. KHURMI)Document35 pagesToothed Gearing: (Chapter-12 R.S. KHURMI)Somnath Somadder100% (1)

- Light Weight PlanetaryDocument8 pagesLight Weight PlanetaryNagy ChristianNo ratings yet

- Synchromesh Gearbox - Construction, Working Principle, Advantages, Disadvantages, and Applications (PDF)Document7 pagesSynchromesh Gearbox - Construction, Working Principle, Advantages, Disadvantages, and Applications (PDF)Kyle LabileNo ratings yet

- Lab Report 3Document3 pagesLab Report 3Hassan MehmoodNo ratings yet

- 1.1.3.a.vex - Ak GearsDocument6 pages1.1.3.a.vex - Ak GearsNaigel BennettNo ratings yet

- TOM 3BT 14-15 Lecture Set-6 - Gear Train - KGDocument52 pagesTOM 3BT 14-15 Lecture Set-6 - Gear Train - KGmercy giftNo ratings yet

- Worms & Worm Gears: Gear DrivesDocument11 pagesWorms & Worm Gears: Gear DrivesNeil RubsNo ratings yet

- ME 2213 (Gear Train)Document36 pagesME 2213 (Gear Train)tanvir2013004No ratings yet

- Ch-5 Toothed Gears - 1Document40 pagesCh-5 Toothed Gears - 1Samar GuptaNo ratings yet

- Finding Gear Ratio Student PagesDocument9 pagesFinding Gear Ratio Student PagesM Jobayer AzadNo ratings yet

- Lecture - 8 - Gear Trains, Simple Gear TrainsDocument19 pagesLecture - 8 - Gear Trains, Simple Gear TrainsMurat Can YüksekNo ratings yet

- GEARSDocument46 pagesGEARSsrsoumyankNo ratings yet

- Activity 1.1.3 Gears - VEX: N 2 GR G R N 1Document6 pagesActivity 1.1.3 Gears - VEX: N 2 GR G R N 1Nate FrieslNo ratings yet

- Gear Ratio: Navigation Search Gear TrainDocument53 pagesGear Ratio: Navigation Search Gear Trainjai karanNo ratings yet

- Balancing of Reciprocating MassesDocument74 pagesBalancing of Reciprocating MassesPinky DeyNo ratings yet

- Introduction To Toothed Gearing, Gear Classification and NomenclatureDocument14 pagesIntroduction To Toothed Gearing, Gear Classification and NomenclatureSharad PawarNo ratings yet

- Excerpt From Bearings ChapterDocument4 pagesExcerpt From Bearings Chapterfog900No ratings yet

- Gear Trains RevisedDocument77 pagesGear Trains RevisedKiran ThunuguntlaNo ratings yet

- Unit4 - 4 - Gear TrainsDocument38 pagesUnit4 - 4 - Gear Trainshung.oheneNo ratings yet

- Chapter 3 (B) - Manual TransmissionDocument56 pagesChapter 3 (B) - Manual Transmissionfaris iqbalNo ratings yet

- Automotive TransmissionDocument128 pagesAutomotive TransmissionjrvinodNo ratings yet

- 1.1.3.A Gears 2022Document15 pages1.1.3.A Gears 2022Suleman KhanNo ratings yet

- Robotics - Gears and Gear RatiosDocument27 pagesRobotics - Gears and Gear Ratiosrajdeepchandra100% (1)

- Chapter 10 (Standard Transmission) PDFDocument42 pagesChapter 10 (Standard Transmission) PDFZIBA KHADIBINo ratings yet

- Gears-General: Shigley's Mechanical Engineering DesignDocument60 pagesGears-General: Shigley's Mechanical Engineering DesignLeandre RobinsonNo ratings yet

- Simpson Planetary Gear Unit: Section 3Document25 pagesSimpson Planetary Gear Unit: Section 3rabitosanNo ratings yet

- Design of Bevel and Worm Gear: Machine Element IIDocument60 pagesDesign of Bevel and Worm Gear: Machine Element IIkibromgidey12No ratings yet

- Gears: What Is A Gear?Document36 pagesGears: What Is A Gear?Diana RivasNo ratings yet

- Efficiency of Planetary GearsetsDocument12 pagesEfficiency of Planetary GearsetskazdanoNo ratings yet

- Lab 07Document8 pagesLab 07tanoli9596No ratings yet

- Conveyor Belt DrivesDocument5 pagesConveyor Belt DrivesMohamad KewAnNo ratings yet

- Conveyor Belt Drives PDFDocument5 pagesConveyor Belt Drives PDFAlmen MatanovićNo ratings yet

- Gear Trains Simple PDFDocument43 pagesGear Trains Simple PDFYuvaraj GNo ratings yet

- U N I T 8 B e L T, C H A I N, G e A R S A N D L A W o F G e A R I N G 8 - 1 I N T R o D U C T I o NDocument42 pagesU N I T 8 B e L T, C H A I N, G e A R S A N D L A W o F G e A R I N G 8 - 1 I N T R o D U C T I o Namit_kushwah1No ratings yet

- Gear BoxDocument29 pagesGear BoxSheikh Zakir100% (1)

- 223 Wylde ChamberDocument1 page223 Wylde Chamberjmorr57No ratings yet

- Grounded WYE: Any Phase Fault To GroundDocument9 pagesGrounded WYE: Any Phase Fault To Groundjmorr57No ratings yet

- 3094-ChuckDocument2 pages3094-Chuckjmorr57No ratings yet

- Fundamentals of Progressive LensesDocument6 pagesFundamentals of Progressive Lensesjmorr57100% (1)

- Deep Groove Ball Bearings Sealed Ball BearingsDocument2 pagesDeep Groove Ball Bearings Sealed Ball Bearingsjmorr57No ratings yet

- Home Download Alex Weir Gnuveau - Networks: Original French Translation of This Document (With Few or Zero Illustrations)Document39 pagesHome Download Alex Weir Gnuveau - Networks: Original French Translation of This Document (With Few or Zero Illustrations)jmorr57No ratings yet

- Shoppracticeforh 00 YateDocument368 pagesShoppracticeforh 00 YateOptimist8100% (5)

- Introduction To ValvesDocument6 pagesIntroduction To ValvesMohamed Al-OdatNo ratings yet

- Range Itr AgriDocument94 pagesRange Itr AgriEvgeniy Kolomiyets100% (1)

- WB146Document10 pagesWB146Anonymous Pk3VzhXUGB100% (1)

- GoMounting KitsDocument11 pagesGoMounting KitsNam PhanNo ratings yet

- Ringo Gate Globe Check ValvesDocument28 pagesRingo Gate Globe Check ValvesRIGOBERTO PONCENo ratings yet

- Butterfly Valves: Fig. 012 - Ari-Zesa Thea Thermo-ApplianceDocument14 pagesButterfly Valves: Fig. 012 - Ari-Zesa Thea Thermo-ApplianceErdincNo ratings yet

- Ulci4 14000XTBDocument1 pageUlci4 14000XTBjori ahuefafreeNo ratings yet

- Shafer AusDocument100 pagesShafer AusSoni Mishra TiwariNo ratings yet

- Pumps-Part 03-By Ramy GhorabaDocument23 pagesPumps-Part 03-By Ramy GhorabaPrashant ManoriNo ratings yet

- Kobelco 6E - Hyd Motors PDFDocument26 pagesKobelco 6E - Hyd Motors PDFHai VanNo ratings yet

- Brake System in Tractor: Presented byDocument27 pagesBrake System in Tractor: Presented byDomnic KibetNo ratings yet

- Assuming That All The Elements of Epicyclic Gear Train Are Moving atDocument15 pagesAssuming That All The Elements of Epicyclic Gear Train Are Moving atMuhammad FarhalNo ratings yet

- Hystea: TransmissionDocument33 pagesHystea: TransmissionMelwyn FernandesNo ratings yet

- Share Swaraj Parts Price List - BZR - 15.09.2020Document508 pagesShare Swaraj Parts Price List - BZR - 15.09.2020सरोज यादव50% (2)

- NOVEC - BOM - 17-01-2020 - Data Center - GLOBAL INCENDIO PDFDocument1 pageNOVEC - BOM - 17-01-2020 - Data Center - GLOBAL INCENDIO PDFRafael PironeNo ratings yet

- New Holland T9.390, T9.450, T9.505, T9.560, T9.615, T9.670Document7 pagesNew Holland T9.390, T9.450, T9.505, T9.560, T9.615, T9.670Luiz PolettiNo ratings yet

- NBC Two WheelerDocument36 pagesNBC Two WheelerBhawani Singh RajawatNo ratings yet

- 1.3.2a.p PriceList - FTDocument10 pages1.3.2a.p PriceList - FTBenNo ratings yet

- Cooperation Partner: XCMG, Lonking, Liugong, Lovol, Changlin, SDLG, Sem, Cnhtc-Sino Truck, Shacman, Foton, HBXH, Weichai Power, China Fuller, EtcDocument2 pagesCooperation Partner: XCMG, Lonking, Liugong, Lovol, Changlin, SDLG, Sem, Cnhtc-Sino Truck, Shacman, Foton, HBXH, Weichai Power, China Fuller, EtcAdemilson Rangel VieiraNo ratings yet

- 20 RT-flex MechanicalDocument43 pages20 RT-flex MechanicalGannavarapu KrishnaNo ratings yet

- Material Compatibility For Steam Turbine 31 KT Utilities 1 and Utilities 2Document6 pagesMaterial Compatibility For Steam Turbine 31 KT Utilities 1 and Utilities 2Garnis NurfadilaNo ratings yet

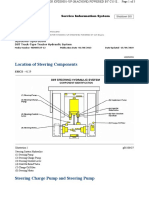

- D8T Location of Steering Components PDFDocument5 pagesD8T Location of Steering Components PDFAlejandro Rodolfo Del campo AlcántarNo ratings yet

- Manual de Partes Toro 0010 InstructionsDocument4 pagesManual de Partes Toro 0010 Instructionscacoman93No ratings yet

- 2Document14 pages2WormInchNo ratings yet

- DJJ 10033-Chapter 5Document45 pagesDJJ 10033-Chapter 5Abbas SeuNo ratings yet

- A-17 PNW Fire Hydrant PT. Internusa Keramik AlamasriDocument3 pagesA-17 PNW Fire Hydrant PT. Internusa Keramik AlamasriMandiri PrimatechNo ratings yet

- Catalogue HortiMax English 2012Document368 pagesCatalogue HortiMax English 2012Thuy PhamNo ratings yet