Professional Documents

Culture Documents

Performance Notes.: Separated Closure Double Pipe: Type SCDP

Performance Notes.: Separated Closure Double Pipe: Type SCDP

Uploaded by

7761430Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Notes.: Separated Closure Double Pipe: Type SCDP

Performance Notes.: Separated Closure Double Pipe: Type SCDP

Uploaded by

7761430Copyright:

Available Formats

A hairpin design is often more thermally efficient than a traditional shell and tube,

which results in a lower up-front cost and lower overall weight. Our experienced

designers and engineers can meet any custom cooling requirement.

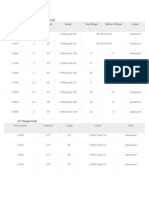

PERFORMANCE NOTES.

• Ideal for applications that require high thermal performance and a compact

footprint

• True countercurrent flow allows for a close temperature approach between the

shell side and tube side fluids, as well as a temperature cross

• Removable bundles are available in two closure options, separated or common,

for required cleaning on both the shell and tube sides

• Non-removable bundles are the cost-effective option when a fixed tubesheet

design is feasible

• Wide temperature differentials are handled without an expansion joint

• Ease of maintenance with a long radius U-bend

• All connections are at one end of the heat exchanger

• Sizes up to 60 in. (150 cm) in diameter and 480 in. (1200 cm) in length

• Materials include carbon steel, 300 series stainless steel, Duplex stainless steel,

copper alloy, chrome-moly alloys, Hastelloy, Inconel, Monel, 254 SMO, alloy

clad/weld overlay

• Designed and fabricated per ASME, TEMA, CRN, PED, CML

REMOVABLE BUNDLE TYPES.

Separated Closure Double Pipe: Type SCDP

• Employs the industry’s most widely used separated head features

• Shell side and tube side closures are separately bolted through, ideal for

applications involving wide temperature or pressure differences between the

shell and tube side fluids

• In cyclic service, separately gasketed closures are more leak resistant compared

to shell and tube designs

• Separate shell and tube side seal configuration. This makes the tube bundle easy

to remove, clean and replace.

• Well suited for large imbalance of flow on shellside

• Long fins are used to achieve high thermal performance with minimal pressure

drop

You might also like

- Air Cooled Heat Exchangers - GEA BrochureDocument16 pagesAir Cooled Heat Exchangers - GEA BrochurenorthstarleoNo ratings yet

- Tema HexDocument7 pagesTema HexPrashanthMNairNo ratings yet

- Selecting Tema HXDocument4 pagesSelecting Tema HXDavitxu1No ratings yet

- Shell and Tube Heat ExchangerDocument7 pagesShell and Tube Heat ExchangerGaurav SharmaNo ratings yet

- Shell & Tube Heat ExchangerDocument28 pagesShell & Tube Heat ExchangerKusmakar Pathak 4-Year B.Tech. Mining EngineeringNo ratings yet

- Excerpt From: Heat ExchangersDocument12 pagesExcerpt From: Heat ExchangersHabib Ben FredjNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- SHT ExchangerDocument55 pagesSHT ExchangerCc12 22tNo ratings yet

- Heat Exchanger: Department of Chemical Engineering, University of Engineering & Technology LahoreDocument31 pagesHeat Exchanger: Department of Chemical Engineering, University of Engineering & Technology LahoreDINESHRAMANUJAMNo ratings yet

- Basics of Double Pipe Heat Exchanger (Heat Transfer Slides)Document38 pagesBasics of Double Pipe Heat Exchanger (Heat Transfer Slides)Asad Imran Munawwar100% (2)

- TEMA Basics of Construction - 07 10Document8 pagesTEMA Basics of Construction - 07 10Zeeshan SajidNo ratings yet

- 104-32 HTDocument8 pages104-32 HTLuis BassoNo ratings yet

- TEMA Type Heat Exchangers PDFDocument4 pagesTEMA Type Heat Exchangers PDFkinjalpatel123450% (1)

- 4 - TEMA StandardDocument16 pages4 - TEMA StandardM.H vafaeiNo ratings yet

- Selection of Shell & Tube Heat Exchangers - TEMA TypesDocument6 pagesSelection of Shell & Tube Heat Exchangers - TEMA TypesCelestine OzokechiNo ratings yet

- SeminarDocument9 pagesSeminardfgfdfggdfNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat ExchangerShivanand YadavNo ratings yet

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDocument2 pages01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNo ratings yet

- Spiral Tube Heat ExchangerDocument2 pagesSpiral Tube Heat ExchangerM AhmadNo ratings yet

- PHT Unit-5 (THEORY)Document81 pagesPHT Unit-5 (THEORY)521 Balaji ONo ratings yet

- Designing AND Optimization OF A Shell and Tube Heat ExchangerDocument8 pagesDesigning AND Optimization OF A Shell and Tube Heat ExchangerAyush SinghNo ratings yet

- ACME DXT Evaporator - PD Leaflet - 06.10 PDFDocument2 pagesACME DXT Evaporator - PD Leaflet - 06.10 PDFhappale2002No ratings yet

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarNo ratings yet

- Interchangers More Used in The Textile IndustryDocument6 pagesInterchangers More Used in The Textile Industrylaura meloNo ratings yet

- Presentation On Shell & Tube ExchangerDocument32 pagesPresentation On Shell & Tube Exchangersaurabhmeshram88No ratings yet

- Chapter No.6: Design of Heat ExchangerDocument35 pagesChapter No.6: Design of Heat ExchangerGlacier RamkissoonNo ratings yet

- Type of Heat ExchangersDocument46 pagesType of Heat ExchangersguravdrNo ratings yet

- Sop PPT2Document16 pagesSop PPT2Anusha SinghNo ratings yet

- CH352 CED Lecture 4Document19 pagesCH352 CED Lecture 4Abhishek UpadhyayulaNo ratings yet

- Basic Construction of Shell & Tube Heat ExchangersDocument12 pagesBasic Construction of Shell & Tube Heat ExchangerslatshareNo ratings yet

- Spiral Tube Heat Exchanger: Optimize Heat Transfer Efficiency and SpaceDocument2 pagesSpiral Tube Heat Exchanger: Optimize Heat Transfer Efficiency and SpaceTeuku Husein FahsyaNo ratings yet

- Heat Exchanger ClasificationDocument55 pagesHeat Exchanger ClasificationNikhil Sawant100% (1)

- Heat Ex Changer Model Selection TypeDocument10 pagesHeat Ex Changer Model Selection TypenoxleekNo ratings yet

- InternDocument22 pagesInternWorld Statistics AnalysisNo ratings yet

- Bringing Efficiency To Heat Transfer: Product LiteratureDocument28 pagesBringing Efficiency To Heat Transfer: Product Literaturescreamingeagle22No ratings yet

- Heat Exchangers: S.SindhuDocument62 pagesHeat Exchangers: S.SindhuShivahari GopalakrishnanNo ratings yet

- Breech LockDocument19 pagesBreech LockNila Gama100% (2)

- Heat Exchanger Design (Theory)Document20 pagesHeat Exchanger Design (Theory)Iqra MubeenNo ratings yet

- Reducerfitting 170215102405Document8 pagesReducerfitting 170215102405Sena DlNo ratings yet

- 418 Heat Ex ChangersDocument57 pages418 Heat Ex ChangersRanjit_Prakash_653100% (1)

- Prime Surface Plate CoilDocument12 pagesPrime Surface Plate CoilGrimmo1979No ratings yet

- Shell and Tube Heat Exchanger DesignDocument25 pagesShell and Tube Heat Exchanger DesignSajid Ali100% (1)

- Heat ExchangersDocument44 pagesHeat Exchangersanthony tiensunNo ratings yet

- Application Note: Sentry Spiral Tube Heat Exchanger Vent Condenser ApplicationDocument2 pagesApplication Note: Sentry Spiral Tube Heat Exchanger Vent Condenser ApplicationraritylimNo ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger Designcoldness_13No ratings yet

- Heat Exchanger SludgeDocument2 pagesHeat Exchanger SludgeRrodriguezz22No ratings yet

- General PipingDocument42 pagesGeneral PipingSHANE MABUGAYNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat Exchangerdieuhien0210No ratings yet

- Advantages and Limitations: Engineered Heat Transfer SolutionsDocument2 pagesAdvantages and Limitations: Engineered Heat Transfer SolutionsMarco CarrieriNo ratings yet

- Heat Operation ExchangersDocument67 pagesHeat Operation ExchangersAkankshya MishraNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Extreme Fiber Elongation CalculationsDocument1 pageExtreme Fiber Elongation Calculations7761430No ratings yet

- Step by Step Methods For WRC 107 (WRC 537) and WRC 297 CDocument13 pagesStep by Step Methods For WRC 107 (WRC 537) and WRC 297 C7761430100% (1)

- PTS1Document1 pagePTS17761430No ratings yet

- 6061 - T6 Aluminum Association I-BeamDocument1 page6061 - T6 Aluminum Association I-Beam7761430No ratings yet

- API 6A Gate Valves-RefDocument3 pagesAPI 6A Gate Valves-Ref7761430No ratings yet

- UG-25 RefDocument1 pageUG-25 Ref7761430No ratings yet

- Anchor Rods (Thread Each End) : Part Number Diameter Length Grade Top Thread Bottom Thread FinishDocument2 pagesAnchor Rods (Thread Each End) : Part Number Diameter Length Grade Top Thread Bottom Thread Finish7761430No ratings yet

- 13 Heat Exchanger TubesheetsDocument1 page13 Heat Exchanger Tubesheets7761430No ratings yet

- Galvanized Anchor Bolts - Light PolesDocument1 pageGalvanized Anchor Bolts - Light Poles7761430No ratings yet

- How To Calculate Markup PercentageDocument4 pagesHow To Calculate Markup Percentage7761430No ratings yet

- Design Problems of Anchoring of Aboveground Steel Tanks: Lyubomir ZdravkovDocument1 pageDesign Problems of Anchoring of Aboveground Steel Tanks: Lyubomir Zdravkov7761430No ratings yet

- Navigating in Catalog Manager: Connect To A DatabaseDocument3 pagesNavigating in Catalog Manager: Connect To A Database7761430No ratings yet

- TPG Mobile Terms and Conditions: 1. The AgreementDocument5 pagesTPG Mobile Terms and Conditions: 1. The Agreement7761430No ratings yet

- Wm1 - Bolt Load Calculation: (Channel Flange)Document5 pagesWm1 - Bolt Load Calculation: (Channel Flange)7761430No ratings yet

- Basics of Pipe Stress Analysis-PartDocument5 pagesBasics of Pipe Stress Analysis-Part7761430No ratings yet

- Error/Warning Messages For WRC107 Analysis 1 Warning - The Ratio Ro/Rm, 0.6313, Must Be 0.0571 and 0.571Document1 pageError/Warning Messages For WRC107 Analysis 1 Warning - The Ratio Ro/Rm, 0.6313, Must Be 0.0571 and 0.5717761430No ratings yet

- Bolt Coating RequirementDocument1 pageBolt Coating Requirement7761430No ratings yet

- More Details About My Computer: Print This Page Component Details Subscore Base Score Determined by Lowest SubscoreDocument1 pageMore Details About My Computer: Print This Page Component Details Subscore Base Score Determined by Lowest Subscore7761430No ratings yet

- Proverb English Translation: LeavesDocument2 pagesProverb English Translation: Leaves7761430No ratings yet

- 3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of ComponentsDocument1 page3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of Components7761430No ratings yet