Professional Documents

Culture Documents

4 PDF

4 PDF

Uploaded by

walid dawoudCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4700 Ofs - 6610239659Document2 pages4700 Ofs - 6610239659ALEJO100% (1)

- Recruitment For The Post of Office AttendantDocument2 pagesRecruitment For The Post of Office AttendantrajnagpNo ratings yet

- DCVD03Document52 pagesDCVD03Khin Myint WaiNo ratings yet

- Ejemplo 51 Calculo FEM Con AdinaDocument20 pagesEjemplo 51 Calculo FEM Con AdinaJorge Gustavo HilgenbergNo ratings yet

- Clifford Stott and Geoff Pearson London: Pennant Books, 2007. 345 Pp. 17.99. ISBN 1906015058. Reviewed by ANTHONY KING, University of Exeter, UKDocument5 pagesClifford Stott and Geoff Pearson London: Pennant Books, 2007. 345 Pp. 17.99. ISBN 1906015058. Reviewed by ANTHONY KING, University of Exeter, UKiuliaNo ratings yet

- Ganpat University U.V. Patel College of Engineering Mechatronics Engineering Department Experiment: - 4Document5 pagesGanpat University U.V. Patel College of Engineering Mechatronics Engineering Department Experiment: - 4Jaygopal SharmaNo ratings yet

- Assignment 3Document7 pagesAssignment 3Midhun MNo ratings yet

- Second Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenDocument10 pagesSecond Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Statistics Is The Science of Using Information Discovered From Studying NumbersDocument3 pagesStatistics Is The Science of Using Information Discovered From Studying NumbersAMIN BUHARI ABDUL KHADERNo ratings yet

- Trial SPM MT 2014 Jawapan K2Document12 pagesTrial SPM MT 2014 Jawapan K2Mohd Ellif SarianNo ratings yet

- Types of Forging OperationsDocument6 pagesTypes of Forging OperationsAshutosh SinghNo ratings yet

- AsdaDocument1 pageAsdaShim ShimranNo ratings yet

- AI UNIT 2 Lecture 3Document16 pagesAI UNIT 2 Lecture 3Sunil NagarNo ratings yet

- Heavy Engineering Corporation Project ReportDocument28 pagesHeavy Engineering Corporation Project ReportAshish jhaNo ratings yet

- Autodesk Revit BIM Object User Guide July 13Document7 pagesAutodesk Revit BIM Object User Guide July 13Liam JonesNo ratings yet

- Very Basic GSADocument46 pagesVery Basic GSATim ChongNo ratings yet

- Bro Miras RsuDocument4 pagesBro Miras RsuazzszoNo ratings yet

- Summative Assessment 7.2.2 I. MULTIPLE CHOICE. Directions: Choose The Correct Answer by Writing The Letter of Your ChoiceDocument3 pagesSummative Assessment 7.2.2 I. MULTIPLE CHOICE. Directions: Choose The Correct Answer by Writing The Letter of Your ChoiceGen-GenAlcantaraBaldadoNo ratings yet

- ANGELIC DNA - 170726 PDFDocument9 pagesANGELIC DNA - 170726 PDFRomina LorenaNo ratings yet

- C A PerryDocument17 pagesC A PerryInfanta mary33% (3)

- Module 1 Fundamentals of Auditing and Assurance ServicesDocument28 pagesModule 1 Fundamentals of Auditing and Assurance ServicesMary Grace Dela CruzNo ratings yet

- Group 2 Specification: 1. Major ComponentDocument12 pagesGroup 2 Specification: 1. Major ComponentREMZONANo ratings yet

- Ivens Ellen Final Year 2020 2Document4 pagesIvens Ellen Final Year 2020 2api-527207076No ratings yet

- 1-Nature and Elements of CommunicationDocument26 pages1-Nature and Elements of CommunicationCris VillarbaNo ratings yet

- A REPORT OF SIX-WPS OfficeDocument10 pagesA REPORT OF SIX-WPS OfficeAjay KNo ratings yet

- Hand Signals by DriversDocument8 pagesHand Signals by DriversTanhaDilTanhaSafarNo ratings yet

- Evaluation and Implementation of UV Disinfection Technologies at Two Wastewater Treatment Facilities in CharlotteDocument8 pagesEvaluation and Implementation of UV Disinfection Technologies at Two Wastewater Treatment Facilities in CharlotteETNo ratings yet

- ADIDSE Learning Plan 1 (Sets and Cardinality)Document2 pagesADIDSE Learning Plan 1 (Sets and Cardinality)Maron QuiambaoNo ratings yet

- Bridge Loading in Malaysia Past Present and The FuDocument12 pagesBridge Loading in Malaysia Past Present and The FuOscarKonzultNo ratings yet

- KnowledgeDocument33 pagesKnowledgepiping stressNo ratings yet

4 PDF

4 PDF

Uploaded by

walid dawoudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 PDF

4 PDF

Uploaded by

walid dawoudCopyright:

Available Formats

Evaluation and Repair of Masonry Construction

Michael Schuller1, Wayne Ruth2, Celina Yan3, Shan Wo4

1,4

Atkinson-Noland & Associates, 2619 Spruce Street, Boulder, Colorado, USA

2

Masonry Solutions International, 10815 Beaver Dam Road Suite D, Hunt Valley, Maryland, USA

3

Masonry Solutions International, Shanghai, China

1

mschuller@ana-usa.com; 2wtruth@masonrysolutions.com; 3cyan@masonrysolutions.com; 4swo@ana-usa.com

This paper discusses the general process of masonry

Abstract – Many existing masonry buildings require repair or evaluation and strengthening by following a project to

strengthening to address long-term deterioration effects, structural reinforce an historic masonry building. With a renovation

deficiencies, or concerns regarding seismic performance. This paper program underway, this multi-story heritage building located at

follows a project to retrofit an historic masonry building as a case a prominent U.S. university campus was found deficient in

study to present the process of evaluation and repair. Nondestructive capacity to withstand new design loads. The proposed retrofit

and in-place test methods are used to evaluate existing construction scheme included a change of use that required larger open

to identify as-built conditions and masonry engineering properties. spaces within the building; subsequent changes to roof and

Load-bearing capacity of walls are then augmented by installation floor framing led to the introduction of large structural loads at

of internal reinforcing bars and injection of voids using a discrete points throughout the exterior building envelope.

Compatible Injection Fill (CIF). Unique to this application is

installation of a series of diagonal stitching bars to confine the Concern regarding the stability of these walls and the ability of

masonry and enhance masonry compression response. the poorly-constructed brickwork to carry new structural loads

led to the decision to retrofit the walls through a combination

Keywords - nondestructive evaluation, masonry, injection, rein- of internal reinforcement and stabilization with compatible

forcement, stabilization, repair injection fill.

I. INTRODUCTION II. STRUCTURAL EVALUATION

Masonry is the world’s most common building material, Most projects involving heritage construction prohibit

existing as adobe, brick, concrete masonry, and stone specimen removal for laboratory testing and opening of

construction. These types of masonry units have been used for destructive probes to investigate internal wall construction.

thousands of years for both utilitarian and monumental Construction and design professionals may turn to

structures, most often as load-bearing walls in building nondestructive and in-place evaluation methods to obtain

structures, as masonry arch bridges, or as retaining walls. critical information on as-built conditions, location of cracks or

Unreinforced masonry has excellent resistance to compression other deterioration, and material engineering properties [2,3].

loads but can suffer dramatic and brittle failure when subjected

to lateral shear forces which may develop due to seismic A. As-Built and Existing Condition

loading or high winds. A wide range of nondestructive and in-place methods are

Engineering for historic construction must follow basic available for evaluating existing masonry construction.

preservation theory including the principle of minimal Rebound Hardness: Measures surface hardness of

intervention, the concept of authenticity, and the principle of masonry units or mortar; useful for evaluation of relative

material compatibility. Strengthening measures used with material properties.

historic structures must be optimized for each building to

minimize the work and to avoid altering any visible character- Metal Location: Magnetic or eddy-current probes are

defining features. Internal strengthening approaches are used to locate embedded metals such as reinforcement, ties,

preferred, rather than structural overlays or external and anchors. Equipment permits accurate location and depth

strengthening that may hide or otherwise change the historic of metals and an estimate of the relative size of embedded

appearance. Dismantlement and rebuilding destroys a metals.

building’s authenticity and is usually avoided in order to

Stress Wave Transmission: Low frequency sonic waves

maintain the building’s appearance and workmanship of the

are often used to evaluate masonry by evaluating the velocity,

original construction.

frequency, and energy content of waves passing through a

Particularly important with preservation projects is the wall section. Ultrasonic pulse velocity (UPV) methods may

concept that any materials used to repair historic construction be used with competent masonry; historic construction is

must have engineering properties similar to those of the often too attenuative for UPV methods. Data from stress

original materials. The engineer has to carefully consider repair wave techniques can also be processed with tomographic

materials to ensure the stiffness, strength, moisture absorption, imaging software to provide 3-dimensional representation of

and water vapour transmission characteristics match those of internal anomalies.

the original substrate materials. Use of modern high strength,

Impact-Echo: Evaluation of stress waves in the frequency

high stiffness materials such as epoxies can be detrimental to

domain permits identification of sub-surface features such as

durability and structural response of historic masonry

cracks or voids and the thickness of individual masonry

construction [1].

wythes.

Surface Penetrating Radar (SPR): Microwave energy is such as masonry strength and stiffness. In-place methods are

reflected at boundaries between materials having varying used to measure masonry material properties.

dielectric constants, thus providing information on the

location and depth of embedded anomalies [4]. SPR is Unique to masonry are in-place evaluation methods using

particularly useful for locating metals, internal voids, and flatjacks. Flatjacks are thin hydraulic bladders inserted into

wall thickness. mortar joints. Once pressurized, flatjacks impose stress on the

surrounding masonry. Surface strains during loading cycles are

Infrared Thermography (IRT): Measurement of infrared measured using mechanical or electronic gages.

radiation emitted from a material’s surface can provide

information on near-surface voids, the presence of moisture, The state of existing compression stress can be measured

and internal wall construction. using a simple process of stress relief following the flatjack

method of ASTM C1196. The in place stress test is useful for

Borescope: While not entirely nondestructive, borescopes determining applied loads, calibrating analytical models, or

provide visual verification of internal anomalies detected detecting stress gradients across a wall cross section.

using nondestructive methods. Borescope examination

requires insertion of a small-diameter fibre optic wand in Masonry stress-strain response can be measured in-place

holes drilled into masonry mortar joints. using the deformability test method of ASTM C1197. Flatjacks

are inserted into two slots, separated by several masonry

Mortar rebound hardness was used on this project to courses. Flatjacks are pressurized simultaneously, subjecting

evaluate relative properties of original mortar and pointing the masonry between flatjacks to a state of compressive stress.

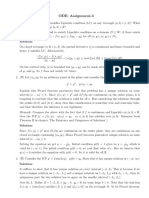

mortar used as part of prior repairs (Fig. 1). Data from mortar A series of flatjack deformability tests were conducted at the

rebound tests was used to specify an appropriate compatible subject building to evaluate masonry compression stiffness and

replacement mortar and to identify locations where strength. A test setup and typical results are provided in Fig. 3.

incompatible repair mortars were used during prior

maintenance work.

Flatjack Test #3

500

450

400

350

Stress, psi

300

250

200

150

100

50

0

0 0.001 0.002 0.003 0.004 0.005 0.0

Strain, in./in.

Fig. 3 Masonry deformability test conducted using the flatjack method. Test

setup shown at left; at right is a typical stress-strain curve. Masonry

compressive strength was measured to be in the range of 450 psi.

Fig. 1 Mortar rebound hardness, measured here using a pendulum hammer.

Masonry bed joint mortar shear strength can be measured

Radar scanning was useful for identifying the presence of using one of three alternative methods described in ASTM

hidden diagonal header courses and also for locating internal C1531. The approach is valid for masonry constructed with

wall voids requiring injection stabilization (Fig. 2). relatively strong units and weak mortar, where shear capacity is

dominated by development of diagonal stairstep cracks through

mortar joints. A field adaptation of the bond wrench method

described by ASTM C1072 permits in-place evaluation of

mortar-unit flexural tensile bond strength.

III. STRUCTURAL STRENGTHENING

Structural adequacy of historic masonry construction is

Exterior wall face typically limited by geometric constraints and stability issues

rather than strength. Historic buildings were built with massive

wall sections and perform well structurally if a) there is

adequate connection between wythes; b) walls are connected to

“Diagonal header” brick

floor and roof diaphragms; c) applied compressive stress is

limited to no more than 20 percent of the masonry strength; d)

Fig. 2 Walls were built of poor quality construction (left) with many internal applied tension and shear stresses are low. Strengthening may

voids. Surface penetrating radar was used to locate voids and also identify be required to address deficiencies in the original construction,

hidden header locations. Hidden “diagonal” headers were missing at many the accumulated effects of years of weather exposure, or to

locations, requiring remedial tie installation. The radar trace at lower right enhance the structure’s ability to resist seismic excitation and

shows strong reflections at each header brick location.

high wind loads [5].

B. Engineering Properties

A. Strengthening Methods

Nondestructive test methods provide information on

Dry-fix remedial ties are often used to provide connection

relative material conditions and general masonry distress but

between masonry wythes; these ties require drilling a pilot hole

results are not directly correlated with engineering properties

and insertion of a helical stainless steel tie using a hammering

action. Anchors are used to resist structural loads. Anchors

grouted in place using cementitious materials are preferred locations were conventional reinforcement was not possible,

over chemical epoxy anchors for their fire resistance and addition of new stainless steel reinforcing followed a diagonal

compatibility with historic building materials. stitching method. The “drill and bond” method distributes

structural tension demand among reinforcing bars [9]. The

Internal voids are often found in historic masonry method has been used on dozens of buildings throughout

construction, appearing as construction defects or resulting Europe, the Middle East, and Japan, and this project represents

from movement of masonry units over time. Injection of its first use within the United States.

Compatible Injection Fill (CIF) at low pressure (less than 1 bar)

is the predominate method used to fill internal voids and ensure The size and spacing of diagonal stitching anchors was

monolithic behaviour between masonry wythes [5,6]. CIF designed based on the expected lateral spreading that occurs in

materials are formulated to be compatible with historic the presence of compression stress as a result of the Poisson

materials, having similar strength, stiffness, and water vapour effect (Fig. 4). New confinement reinforcement was designed

transmission to the substrate. Injecting internal voids with CIF to resist all the resulting lateral tension. Thousands of discrete

also enhances a wall’s ability to resist moisture penetration [7]. reinforcing pieces of varying geometries were accurately

positioned within the historic walls (). The combination of

Structural strengthening typically requires adding steel injection and new internal reinforcement effectively confines

reinforcement to masonry walls, installation of external steel the highly stressed masonry sections, offering new possibilities

frames, or use of concrete overlays. Internal reinforcement for augmenting historic masonry construction in situations

schemes are preferred for use with historic construction to where it must resist new loads.

avoid changing the building’s appearance.

Stainless steel reinforcement may be inserted into slots cut

in mortar joints. Thin stainless steel or galvanized wires are

often used in such a fashion to stitch walls together at cracks.

Structural enhancement to increase masonry flexural strength,

shear strength, and ductility requires installation of large-

diameter bars in holes cored within masonry walls [6].

Reinforced cores are injected with CIF to bond reinforcement

to surrounding masonry, completing the repair.

B. Strengthening Approach

Radar scans located many voids throughout the masonry

construction and a lack of appropriate header courses

connecting brick wythes. These deficiencies were addressed by

a combination of pinning and CIF injection. A series of helical

pins were first installed to tie face brick to backup masonry at

locations where header brick were missing. Hydrated lime and

cement-based CIF was used to fill cracks and voids within the

historic walls to ensure composite action between the multiple

wythes at bearing walls. CIF formulations were custom

developed to be compatible with the host wall constituent

materials. No polymers or epoxies were utilized. The main

function of the CIF in this case was to bond the masonry

backup to the exterior brick facing. In addition to the structural

Fig. 4 Design detail showing diagonal stitching installed as confinement

benefits of internal void filling, water penetration from wind reinforcement: wall section (top) and horizontal plan section (bottom).

driven rain was reduced as a result of the injection. Stainless steel tubes inserted into drilled holes were injected with CIF to bond

new reinforcement to surrounding masonry.

The building was being renovated to include large open

spaces to meet the University’s educational needs. At areas of C. Post-Repair Quality Assurance

new concentrated loads a novel stainless steel stitching

Internal strengthening measures are by their very nature

program was utilized in conjunction with injection remediation

hidden from view and advanced quality assurance measures

to augment the masonry’s inherent compressive capacity

must be adopted to ensure project objectives are met.

throughout the new load paths. Research with historic masonry

Nondestructive evaluation methods are useful for determining

shows that creep effects can be a consideration at stress levels

the quality of internal strengthening measures. The location of

as low as 0.2 times the masonry compressive strength, and that

added reinforcement, anchors, and ties can be verified using a

creep effects are considerable when applied stresses exceed 0.6

pachometer or SPR. SPR was also used in this case to verify

time the masonry compressive strength [8]. The structural

internal voids were properly filled by CIF injection. Radar

design called for compressive stress in excess of 0.4 times the

traces taken before and after injection of an historic masonry

compressive strength and a diffused network of thin, vertical

wall are shown in Fig. 5. Prior to injection, many internal voids

cracks was observed below some existing roof truss bearing

are noticeable. After injection, radar returned almost no

locations. Hence there was a concern that new structural loads

reflections from internal anomalies, indicating the solid nature

could lead to future instability.

of the repaired wall. The fully strengthened and renovated

Horizontal confinement reinforcement was installed within building retains its original historic appearance (Fig. 6).

masonry walls to enhance compression response in the vicinity

of new structural bearing points. At some locations

confinement reinforcement was installed in mortar joints. At

Eighth International Conference on Structural Faults and Repairs

Pre-injection; many Conference, London, July 1999.

internal voids [6] D.W. Harvey, Jr., W.T. Ruth, M.P. Schuller, “Internal Strengthening of

Historic Clay Brick Masonry Pump Houses in New Orleans,” 8th

International Conference on Structural Analysis of Historical

Constructions, Wroclaw, Poland, October 2012.

[7] C. Citto, A. Geister, and D. Harvey, “Feasibility of Integral Water

Repellent Admixtures in Low Pressure Compatible Injected Fill Grouts,”

Post-injection; Proceedings of the 12th International Conference on Structural Repairs

internal voids filled and Maintenance of Heritage Architecture, Chianciano Terme, Italy,

September 2011.

[8] A. Anzani, R. Mirabella, L Binda, “Time-Dependent Behaviour of

Masonry: Experimental Results and Numerical Analysis,” STREMA

Fig. 5 Sample radar traces showing internal masonry wall condition before Proceedings, Bath, England, June 1993.

injection (top) with many internal voids as indicated by multiple reflections [9] F. Lizzi, “Preserving the Original Static Scheme in the Consolidation of

within the radar trace. Following injection the radar trace shows the wall to be Old Buildings,” Proceedings of the International Association for Bridge

essentially solid (bottom) with no significant reflections. and Structural Engineering, 1983.

Michael P. Schuller, P.E., BSCE (1987), MSCE

(1989) University of Colorado, USA. Mr. Schuller is

a consulting engineer and president of Atkinson-

Noland & Associates in Boulder, Colorado, with

over 20 years’ experience specializing in structural

behaviour, evaluation, and repair of masonry

buildings. He has conducted research projects for

federal agencies and private firms, and has over 80

publications relating to evaluation, repair, and

structural behaviour of concrete and masonry

structures, and is a co-author of a book titled Nondestructive Evaluation and

Testing of Masonry Structures. He is a Fellow of The Masonry Society and a

member of the Association for Preservation Technology College of Fellows.

Fig. 6 The building’s final appearance remained unaltered after all structural

Wayne T. Ruth, BMGT (1974, University of

strengthening measures were completed.

Maryland, USA. Mr. Ruth began his career as a

master bricklayer and stonemason. He was president

IV. CONCLUSIONS of the Baltimore Building Congress, American

Subcontractor’s Association, Construction Industry

Engineering efforts involving heritage masonry Educational Foundation, and national president of

construction require a unique approach. Heritage preservation the American Subcontractor’s Association. He is

projects are by nature multi-disciplinary, requiring close currently president and chief executive officer of

collaboration between the design-side (architects and engineers) Masonry Solutions International, Inc., a firm

and the construction side (injection professionals) to develop specializing in invisible structural solutions for

heritage structures. He has authored and co-authored

materials and protocols suitable for use with the historic numerous academic papers on various heritage masonry and masonry injection

building. Nondestructive evaluation and in-place test methods issues. He recently introduced the Gruenstark anchor system for strengthening

are used extensively with historic construction to avoid and stabilizing masonry construction.

damaging sensitive and culturally significant materials. Repair

materials used with historic construction must be custom- Celina Yan, BA International Business

Management (2006 Saxon Hogeschool, Netherlands)

developed for compatibility to match the strength, stiffness,

is vice president of Asia and Pacific operations for

and moisture vapour transmission properties of historic Masonry Solutions International. She has 6 years of

materials. In this case the aesthetics of the heritage masonry experience with the steel industry including use of

were unchanged despite the extensive nature of the wall stainless steel reinforcement for strengthening

injection, stitching, and the structural enhancement. historic masonry construction. She is based in

Shanghai.

REFERENCES

[1] L. Binda, G. Baronio, C. Tiraboschi, “Repair of Brick-Masonries by

Injection of Grouts: Experimental Research,” CNR-GNDT International

Workshop, Effectiveness of Injection Techniques for Retrofitting of Shan I. Wo, BSME Cornell University, USA, 2000,

Stone and Brick Masonry Walls in Seismic Areas, Polytechnic MSCE, University of Colorado, USA, (in progress).

University of Milan, Italy, 1992. Ms. Wo is a structural engineer and principal with

[2] M.P. Schuller, “Nondestructive Testing and Damage Assessment of Atkinson-Noland & Associates. Since joining the

Masonry Structures,” Journal of Progress in Structural Engineering and firm in 2003, she has worked on projects that involve

Materials, Vol. 5, No. 4, John Wiley & Sons, 2003. the nondestructive evaluation of modern and historic

[3] D.W. Harvey, Jr., M.P. Schuller, “Nondestructive Evaluation: Masonry, structures, condition assessment of buildings,

Practice Points”, Association for Preservation Technology International masonry repair and strengthening, construction

Bulletin, Springfield, Il, August 2010. administration, and laboratory research and testing.

[4] D.B. Woodham, and L. Conyers, “Evaluation of Inaccessible Elements of Ms. Wo is a member of the Rocky Mountain

a Cathedral using Ground Penetrating Radar,” Proceedings of the 12th Masonry Institute, The Masonry Society, and the

International Brick and Block Masonry Conference, Madrid, Spain, June, Association for Preservation Technology International (APT). She is a board

2000. member of the Rocky Mountain Chapter of APT.

[5] R. van der Hoeven, S. Brokken, M. Schuller, and W. Ruth “Masonry

Seismic Stabilization Using Grout Injection Repair,” Proceedings of the

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4700 Ofs - 6610239659Document2 pages4700 Ofs - 6610239659ALEJO100% (1)

- Recruitment For The Post of Office AttendantDocument2 pagesRecruitment For The Post of Office AttendantrajnagpNo ratings yet

- DCVD03Document52 pagesDCVD03Khin Myint WaiNo ratings yet

- Ejemplo 51 Calculo FEM Con AdinaDocument20 pagesEjemplo 51 Calculo FEM Con AdinaJorge Gustavo HilgenbergNo ratings yet

- Clifford Stott and Geoff Pearson London: Pennant Books, 2007. 345 Pp. 17.99. ISBN 1906015058. Reviewed by ANTHONY KING, University of Exeter, UKDocument5 pagesClifford Stott and Geoff Pearson London: Pennant Books, 2007. 345 Pp. 17.99. ISBN 1906015058. Reviewed by ANTHONY KING, University of Exeter, UKiuliaNo ratings yet

- Ganpat University U.V. Patel College of Engineering Mechatronics Engineering Department Experiment: - 4Document5 pagesGanpat University U.V. Patel College of Engineering Mechatronics Engineering Department Experiment: - 4Jaygopal SharmaNo ratings yet

- Assignment 3Document7 pagesAssignment 3Midhun MNo ratings yet

- Second Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenDocument10 pagesSecond Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Statistics Is The Science of Using Information Discovered From Studying NumbersDocument3 pagesStatistics Is The Science of Using Information Discovered From Studying NumbersAMIN BUHARI ABDUL KHADERNo ratings yet

- Trial SPM MT 2014 Jawapan K2Document12 pagesTrial SPM MT 2014 Jawapan K2Mohd Ellif SarianNo ratings yet

- Types of Forging OperationsDocument6 pagesTypes of Forging OperationsAshutosh SinghNo ratings yet

- AsdaDocument1 pageAsdaShim ShimranNo ratings yet

- AI UNIT 2 Lecture 3Document16 pagesAI UNIT 2 Lecture 3Sunil NagarNo ratings yet

- Heavy Engineering Corporation Project ReportDocument28 pagesHeavy Engineering Corporation Project ReportAshish jhaNo ratings yet

- Autodesk Revit BIM Object User Guide July 13Document7 pagesAutodesk Revit BIM Object User Guide July 13Liam JonesNo ratings yet

- Very Basic GSADocument46 pagesVery Basic GSATim ChongNo ratings yet

- Bro Miras RsuDocument4 pagesBro Miras RsuazzszoNo ratings yet

- Summative Assessment 7.2.2 I. MULTIPLE CHOICE. Directions: Choose The Correct Answer by Writing The Letter of Your ChoiceDocument3 pagesSummative Assessment 7.2.2 I. MULTIPLE CHOICE. Directions: Choose The Correct Answer by Writing The Letter of Your ChoiceGen-GenAlcantaraBaldadoNo ratings yet

- ANGELIC DNA - 170726 PDFDocument9 pagesANGELIC DNA - 170726 PDFRomina LorenaNo ratings yet

- C A PerryDocument17 pagesC A PerryInfanta mary33% (3)

- Module 1 Fundamentals of Auditing and Assurance ServicesDocument28 pagesModule 1 Fundamentals of Auditing and Assurance ServicesMary Grace Dela CruzNo ratings yet

- Group 2 Specification: 1. Major ComponentDocument12 pagesGroup 2 Specification: 1. Major ComponentREMZONANo ratings yet

- Ivens Ellen Final Year 2020 2Document4 pagesIvens Ellen Final Year 2020 2api-527207076No ratings yet

- 1-Nature and Elements of CommunicationDocument26 pages1-Nature and Elements of CommunicationCris VillarbaNo ratings yet

- A REPORT OF SIX-WPS OfficeDocument10 pagesA REPORT OF SIX-WPS OfficeAjay KNo ratings yet

- Hand Signals by DriversDocument8 pagesHand Signals by DriversTanhaDilTanhaSafarNo ratings yet

- Evaluation and Implementation of UV Disinfection Technologies at Two Wastewater Treatment Facilities in CharlotteDocument8 pagesEvaluation and Implementation of UV Disinfection Technologies at Two Wastewater Treatment Facilities in CharlotteETNo ratings yet

- ADIDSE Learning Plan 1 (Sets and Cardinality)Document2 pagesADIDSE Learning Plan 1 (Sets and Cardinality)Maron QuiambaoNo ratings yet

- Bridge Loading in Malaysia Past Present and The FuDocument12 pagesBridge Loading in Malaysia Past Present and The FuOscarKonzultNo ratings yet

- KnowledgeDocument33 pagesKnowledgepiping stressNo ratings yet