Professional Documents

Culture Documents

Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)

Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)

Uploaded by

Anonymous 7aUHXY1vWbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)

Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)

Uploaded by

Anonymous 7aUHXY1vWbCopyright:

Available Formats

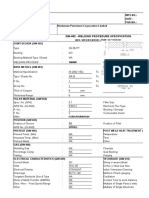

WELDING PROCEDURE SPECIFICATION (WPS) DOC N° PWPS N° 01

Project : TS 100 SEPARATOR REPAIR REV 0

Client :ENI BV TUNISIA PAGE 1 of 1

Welding Procedure Specification WPS N° :01 Date : 10/12/2017

Qualified by PQR No : PQR 03 Revision: 0

Welding Process(es): SMAW/SMAW Standards: ASME IX / Ed 2010

Specification: NA

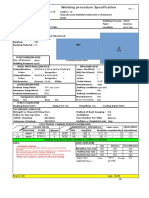

Weld sequence

FILLET WELD

Backing: NA

t1. 25 mm

b. 0 mm

NB: Number of passes is accordance to the thickness

t2. 45 mm

d.

JOINTS (QW -402) POST WELD HEAT TREATMENT (QW -407)

Groove Design : See sketch Temperature : N

Backing: Yes : No.: X Time Range : NA

Backing Material(Type): NA Speed NA

Other : NA

GAS (QW -408)

Shielding Gas : NA

Percent Composition(mixtures): NA

BASE METALS (QW -403) Flow Rate: NA

P.No: 1 To P.No:1 Gas Backing : NA

Specification: S235 Percent Composition(mixtures): NA

Type or Grade: JR Flow Rate: NA

Thickness range: All thickness Other: NA

Pipe Dia : NA

ELECTRICAL CHARACTERISTICS (QW -409)

FILLER METALS (QW -404) DC

F.No. : 3 F.No. : 4 Polarity : EN/EP

A.No. : 1 A.No. : 1 Amps(Range): 80/150

Spec.No (AWS) : A5.28 1 Spec.No (AWS) : A5.1 Volts(Range): 20-30

(Class) : E6010 E7018 Other: Heat imput : 10 - 20 Kj / cm

Size : 2,5 mm Size 3,2 mm

Trade Name: NA Trade Name: ESAB

Electrode Flux (Class): NA Electrode Flux (Class):

Consumable Insert: NA Consumable Insert: TECHNIQUE (QW -410)

Other : NA

String or Weave Bead : String and weave

POSITION (QW -405)

Position of Groove: 3F Orifice or Gas Cup Size: NA

Welding Progression: : NA Initial & Interpass Cleaning: Brushing & Grinding

Position(s) of fillet: All Method of Back Gouging : NA

Other : NA Oscillation NA

Contact Tube to Work Distance NA

PREHEAT (QW -406) Multiple or single Pass(per side): Multiple

Preheat Temp: 150°C Multiple or Single Electrodes : NA

Max Interpass Temp: 150 °C Travel Speed(Range) : 7-12 cm/min

Preheat Maintenance: :150°C Manual, Semi-Automatic or Machine Automatic : Manual

Preheat Type: torche

Other : NA Other : NA

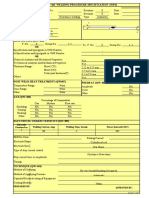

ELECTRODES

Welding Speed Heat Imput

N° Process

Welding progression Diameter Volt. Amp.

(cm/min) (KJ/Cm)

AWS Polarity

mm

1 SMAW Uphill E6010 2,5 DCEN(-) 25/29 60/90 NA NA

2 SMAW Uphill E7018 3,2 DCEP(+) 22/27 80/140 NA NA

3 SMAW Uphill E7018 3,2 DCEP(+) 22/27 80/140 NA NA

Prepared Third Parties

Name HACHICHA Anis Name :PIC

Date 10/12/2017 Date :

Signature Signature:

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Wps Ss r0 AdaniDocument2 pagesWps Ss r0 Adanigunasekhar kamireddiNo ratings yet

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- PQR02 (For SMAW)Document2 pagesPQR02 (For SMAW)workshop13.asaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Electrode Pressure Bar Welding Current, Amp Welding Time, Second Power Source (AC/DC)Document1 pageElectrode Pressure Bar Welding Current, Amp Welding Time, Second Power Source (AC/DC)Mohit TiwariNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

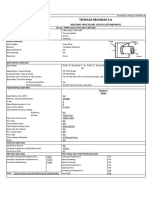

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobini100% (1)

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad BilalNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Larsen & Toubro Minerals & MetalsDocument2 pagesLarsen & Toubro Minerals & MetalsneerajNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- S 001 Link 2Document1 pageS 001 Link 2wael badawiNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet