Professional Documents

Culture Documents

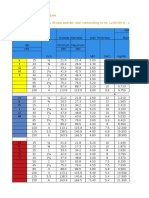

Technical Data of Pipes Conforming To DIN: 2440: J J S ST T T T

Technical Data of Pipes Conforming To DIN: 2440: J J S ST T T T

Uploaded by

Rajendran NairOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data of Pipes Conforming To DIN: 2440: J J S ST T T T

Technical Data of Pipes Conforming To DIN: 2440: J J S ST T T T

Uploaded by

Rajendran NairCopyright:

Available Formats

J

S T

Technical Data of Pipes Conforming To DIN: 2440

Mass of Tube Pipe Thread Sockets

Normal Outside Wall

Size Diameter Thickness Thread No. of Thread Min. Outside Min.

Plain End Socketed Diameter Length

In 25.4mm Diameter

DN Min.(mm) Max.(mm) mm Kg/m Kg/m mm mm

15 21.0 21.8 2.65 1.22 1.23 20.955 14 26.4 34

20 26.5 27.3 2.65 1.58 1.59 26.441 14 31.8 36

25 33.3 34.2 3.25 2.44 2.46 33.249 11 39.5 43

32 42.0 42.9 3.25 3.14 3.17 41.910 11 48.3 48

40 47.9 48.8 3.25 3.61 3.65 47.803 11 54.5 48

50 59.7 60.8 3.65 5.10 5.17 59.614 11 66.3 56

65 75.3 76.6 3.65 6.51 6.63 75.184 11 82.0 65

80 88.0 89.5 4.05 8.47 8.64 87.884 11 95.0 71

100 113.1 115.0 4.50 12.10 12.40 113.030 11 122.0 83

125 138.5 140.8 4.85 16.20 16.70 138.430 11 147.0 92

150 163.9 166.5 4.85 19.20 19.80 163.830 11 175.0 92

Technical Data of Pipes Conforming To DIN: 2441

Mass of Tube Pipe Thread Sockets

Normal Outside Wall

Size Diameter Thickness Thread No. of Thread Min. Outside Min.

Plain End Socketed Length

Diameter In 25.4mm Diameter

DN Min.(mm) Max.(mm) mm Kg/m Kg/m mm mm

15 21.0 21.8 3.25 1.45 1.46 20.955 14 26.4 34

20 26.5 27.3 3.25 1.90 1.91 26.441 14 31.8 36

25 33.3 34.2 4.05 2.97 2.99 32.249 11 39.5 43

32 42.0 42.9 4.05 3.84 3.87 41.910 11 48.3 48

40 47.9 48.8 4.05 4.43 4.47 47.803 11 54.5 48

50 59.7 60.8 4.50 6.17 6.24 59.614 11 66.3 56

65 75.3 76.6 4.50 7.90 8.02 75.184 11 82.0 65

80 88.0 89.5 4.85 10.10 10.30 87.884 11 95.0 71

100 113.1 115.0 5.40 14.40 14.70 113.030 11 122.0 83

125 138.5 140.8 5.40 17.80 18.30 138.430 11 147.0 92

150 163.9 166.5 5.40 21.20 21.80 163.830 11 174.0 92

Tolerances

Outside Diameter : As Per Above Table

Wall Thickness : -12.5%

Weight : Single Tube For Lot of 10 Tons

±10% ±7.5%

Testing

Leak Tightness Test 100% Hydrostatic At 50 Bar or Online Eddy Current Testing

For Tubes Upto & Including DN 25 For Tubes Above DN 25 & Upto DN 50

Bending Angle 90° Bending Angle 90°

Bend Test

Bending Radius 3 Times To The OD of Tube Bending Radius 3.5 Times To The OD of Tube

Weld Position 12 O' Clock & 3 O' Clock Weld Position 12 O' Clock & 3 O' Clock

For Tubes DN 65 & Above

Flattening Test

Flatten Up To 2/3 of Tube Dia Without Crack In Weld: Weld Position 12 O' Clock & 3 O'clock

Galvanizing Zinc Coating = 400 gm/sq m (minimum), Zinc Layer Thickness = 56 Microns

Mechanical Properties

Yield Strength 185 N/sq. mm (minimum)

310 To 540 N/sq.mm For Wall Thickness < 3 mm

Tensile Strength

290 To 510 N/sq.mm For Wall Thickness ³ 3 mm

% Elongation Thickness ³ 2 & < 3 mm ³ 3 & £ 40 mm

% Elongation 14 18

Raw Material As Per St 33.2 Conforming To DIN 17100

EN- 39 / BS: 1139 17

You might also like

- ASME B16.47 - Serie ADocument1 pageASME B16.47 - Serie Ajose2192No ratings yet

- ASME B16.47 Series A FlangeDocument5 pagesASME B16.47 Series A FlangenaspauzanNo ratings yet

- ANSI-ASME B16.47 Series A (MSS SP44) Weld Neck Flange 150lbDocument1 pageANSI-ASME B16.47 Series A (MSS SP44) Weld Neck Flange 150lbMarcoNo ratings yet

- ASME B16.47 Series B FlangeDocument4 pagesASME B16.47 Series B Flange41h189No ratings yet

- Slip On Flanges ANSI B16.5 300lbsDocument1 pageSlip On Flanges ANSI B16.5 300lbskannu19802550No ratings yet

- ASME B16.47 Series A FlangeDocument5 pagesASME B16.47 Series A FlangeFikret YenenNo ratings yet

- Ansi B16.47 FlangeDocument9 pagesAnsi B16.47 FlangeAVNo ratings yet

- Asme b1647 Series A FlangeDocument5 pagesAsme b1647 Series A Flangeajay katrojNo ratings yet

- Tablas de Medidas PC300-350Document11 pagesTablas de Medidas PC300-350Frank Felipe Cruz ChavezNo ratings yet

- Long Welding Neck Product Range Catalogue PDFDocument13 pagesLong Welding Neck Product Range Catalogue PDFfabioNo ratings yet

- Jis g3466-3Document1 pageJis g3466-3Nhuận PhạmNo ratings yet

- ANSI-ASME B16.47 Series B Weld Neck Flange 150lbDocument1 pageANSI-ASME B16.47 Series B Weld Neck Flange 150lbVilas AndhaleNo ratings yet

- M.S. Pipe WeightDocument1 pageM.S. Pipe WeightMARUTI CONSULTANTSNo ratings yet

- Stub EndDocument1 pageStub EndDiky AfriantNo ratings yet

- ASME Flange B16.5 Chart 600 LBDocument5 pagesASME Flange B16.5 Chart 600 LBKarthikeyan VisvakNo ratings yet

- Table-1 Properties of Rolled Steel SectionsDocument40 pagesTable-1 Properties of Rolled Steel Sectionsramanathan appu0% (1)

- ANSI-ASME B16.47 Series A (MSS SP44) Weld Neck Flange 600lb PDFDocument1 pageANSI-ASME B16.47 Series A (MSS SP44) Weld Neck Flange 600lb PDFLeito Leito RodriguezNo ratings yet

- Blind Flanges - ANSI B16.5: Class 150 LBDocument2 pagesBlind Flanges - ANSI B16.5: Class 150 LBYadav ShwetaNo ratings yet

- Jis g3444-1 PDFDocument1 pageJis g3444-1 PDFbkprodhNo ratings yet

- Jis g3444-1 PDFDocument1 pageJis g3444-1 PDFRokhmatuSivaNo ratings yet

- ANSI B16.5 Flange CatalogueDocument14 pagesANSI B16.5 Flange Catalogue김명래No ratings yet

- Katalog MKM GSW - Jisg3537Document1 pageKatalog MKM GSW - Jisg3537Lintang SamuderaNo ratings yet

- Coupling Forged Steel Astm A105 Class 3000 SWDocument1 pageCoupling Forged Steel Astm A105 Class 3000 SWWilliam DelgadoNo ratings yet

- PPRC Pressure CalculationsDocument2 pagesPPRC Pressure CalculationsHadeed IlyasNo ratings yet

- JIS G3466 - Thailand - CONTENT1011579693989745Document1 pageJIS G3466 - Thailand - CONTENT1011579693989745Nguyễn Tiến TùngNo ratings yet

- Stud EndsDocument2 pagesStud EndsSubbuVadarevuNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- Tubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SDocument3 pagesTubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SSmithSaitAlarconPintoNo ratings yet

- Circular Hollow Section - Cold FormedDocument4 pagesCircular Hollow Section - Cold Formedmajkil1988No ratings yet

- ASME ANSI B16.25 Butt Welding EndsDocument4 pagesASME ANSI B16.25 Butt Welding EndsFernandoNo ratings yet

- Gi Pipe Size Is 1239Document4 pagesGi Pipe Size Is 1239sshnvlNo ratings yet

- Standared WeightDocument16 pagesStandared WeightKish Shan S SubediNo ratings yet

- SSPCDocument2 pagesSSPCmir31721No ratings yet

- Sifat-Sifat Penampang Pipa Fy 1600 kg/cm2: Diam. Thick. A P V I WDocument7 pagesSifat-Sifat Penampang Pipa Fy 1600 kg/cm2: Diam. Thick. A P V I WNovly IbrahimNo ratings yet

- GRE Piping Data SheetsDocument18 pagesGRE Piping Data SheetsErbol KarzhaubaiulyNo ratings yet

- 45º Elbows: Standard WeightDocument2 pages45º Elbows: Standard WeightcuznadiNo ratings yet

- Ocal Blue Conduit PVCDocument3 pagesOcal Blue Conduit PVCluiszc2988No ratings yet

- Brosur Baja Gunung Raja Paksi Rectangular PipeDocument2 pagesBrosur Baja Gunung Raja Paksi Rectangular PipeRobbi Shobri Rakhman100% (1)

- RectangularPipe PDFDocument2 pagesRectangularPipe PDFAndhika MaulanaNo ratings yet

- Rectangular PipeDocument2 pagesRectangular PipeDeri FerdinaNo ratings yet

- RectangularPipe PDFDocument2 pagesRectangularPipe PDFYohan S.No ratings yet

- Blind Flanges ANSI B16.5 600lbsDocument1 pageBlind Flanges ANSI B16.5 600lbsvinonaguNo ratings yet

- Tubos PVCDocument4 pagesTubos PVCcesar paitanNo ratings yet

- WN 300Document7 pagesWN 300ANANDAN NNo ratings yet

- ASME Flange B16.5 Chart 300 LBDocument5 pagesASME Flange B16.5 Chart 300 LBvincentNo ratings yet

- Schedule 40 Steel Pipe - SCH 40 Steel Pipe Dimensions - SCH 40 Steel Pipe Pressure Rating - SCH 40 Pipe PriceDocument8 pagesSchedule 40 Steel Pipe - SCH 40 Steel Pipe Dimensions - SCH 40 Steel Pipe Pressure Rating - SCH 40 Pipe PriceSaira WaqasNo ratings yet

- Schedule 40 MS PipesDocument2 pagesSchedule 40 MS PipesASIM MURTAZANo ratings yet

- ANSI Fittings Butt Welded Dimensions - ANSI - B-16.9 - 16.28 - MSS - SP-43Document3 pagesANSI Fittings Butt Welded Dimensions - ANSI - B-16.9 - 16.28 - MSS - SP-43PeterDonerNo ratings yet

- Codo 90Document1 pageCodo 90RoLopNo ratings yet

- Data Sheet - Carbon Steel Pipe - Fiorella RepreDocument5 pagesData Sheet - Carbon Steel Pipe - Fiorella RepreNéstor Ramírez PeñalozaNo ratings yet

- Orrcon Steel Chequer PlateDocument1 pageOrrcon Steel Chequer PlateOliver HermosaNo ratings yet

- Flange Carbon Steel ANSI CatalogDocument4 pagesFlange Carbon Steel ANSI CatalogKhonlong TangNo ratings yet

- Pipe Flow CalculatorDocument2 pagesPipe Flow CalculatordavideristixNo ratings yet

- Buttweld FittingsDocument6 pagesButtweld FittingsSaleem JaradatNo ratings yet

- Multi-Party and Multi-Contract Arbitration in the Construction IndustryFrom EverandMulti-Party and Multi-Contract Arbitration in the Construction IndustryNo ratings yet

- Speech and Audio Signal Processing: Processing and Perception of Speech and MusicFrom EverandSpeech and Audio Signal Processing: Processing and Perception of Speech and MusicRating: 5 out of 5 stars5/5 (1)