Professional Documents

Culture Documents

2016.10.18 Esp

2016.10.18 Esp

Uploaded by

prillaCopyright:

Available Formats

You might also like

- Reda Esp CatalogDocument548 pagesReda Esp CatalogPED SARIRNo ratings yet

- Af33 5Document44 pagesAf33 5ivanmedalla100% (6)

- ESP 9 Step Design PDFDocument31 pagesESP 9 Step Design PDFDwiki Ramadhani100% (2)

- Well Head and X Mas TreeDocument3 pagesWell Head and X Mas TreeDipankar NathNo ratings yet

- Completion Application ManualDocument42 pagesCompletion Application ManualKHALEDFEKAIR100% (1)

- Use of Coiled Tubing As A Velocity StringDocument3 pagesUse of Coiled Tubing As A Velocity StringMark Johnson100% (1)

- Artificial Lift Training - CopieDocument141 pagesArtificial Lift Training - CopiesereptNo ratings yet

- Pertemuan12 ESP 04042016 13042016Document192 pagesPertemuan12 ESP 04042016 13042016Priozky Pratama Purba100% (1)

- Wo Esp DevelopmentsDocument6 pagesWo Esp DevelopmentsHamed GeramiNo ratings yet

- Electric Submersible Pumps For The Petroleum IndustryDocument20 pagesElectric Submersible Pumps For The Petroleum Industrysouthli100% (1)

- ESP 9-Step DesignDocument31 pagesESP 9-Step Designeng.osama100% (2)

- 05 Artificial LiftDocument83 pages05 Artificial LiftPaoloPinard100% (1)

- Design Overview: Basic Design and Maintenance InstructionsDocument8 pagesDesign Overview: Basic Design and Maintenance InstructionsOctopusNo ratings yet

- 2011 ESP WorkshopDocument41 pages2011 ESP Workshopuekiiiiii23No ratings yet

- SD4-6 - Final ESP Design PDFDocument11 pagesSD4-6 - Final ESP Design PDFkonan84167% (3)

- Application Engineering: Reda Esp System ComponentsDocument4 pagesApplication Engineering: Reda Esp System Componentselsayed amerNo ratings yet

- Chapter 01 IntroductionDocument12 pagesChapter 01 Introductiondewidar1234100% (1)

- Esp Failure NomenclatureDocument35 pagesEsp Failure Nomenclaturedillipsh123No ratings yet

- NOVOMET. Instruction of Tap and Power Rating CalculationDocument3 pagesNOVOMET. Instruction of Tap and Power Rating CalculationmolanoavilaNo ratings yet

- 7 European Electric Submersible Pump Round Table Aberdeen, ScotlandDocument8 pages7 European Electric Submersible Pump Round Table Aberdeen, Scotlandshy_boyNo ratings yet

- ESP Start-Up and OperationDocument46 pagesESP Start-Up and OperationazareiforoushNo ratings yet

- Zenith Gauge PDFDocument2 pagesZenith Gauge PDFCarlos EscobarNo ratings yet

- Total Dynamic Head - TDHDocument37 pagesTotal Dynamic Head - TDHs pNo ratings yet

- 2004 Gas Lift SeminarDocument317 pages2004 Gas Lift SeminarNgọc Hiệp LêNo ratings yet

- 46 EspDocument35 pages46 EspHichem FakhfekhNo ratings yet

- OF11-0007R00 LWM PCP Data Sheet PDFDocument2 pagesOF11-0007R00 LWM PCP Data Sheet PDFShadySadanyNo ratings yet

- Artificial Lift MethodsDocument57 pagesArtificial Lift MethodsHaseen KaurNo ratings yet

- 4 Run Life OpsDocument29 pages4 Run Life Opshatem_eldawyNo ratings yet

- SRP 161203072620Document27 pagesSRP 161203072620Muhammad N BashashaNo ratings yet

- PMP IntakeDocument23 pagesPMP IntakeRiyan YonathanNo ratings yet

- ESPCatalogOCT2013 PDFDocument218 pagesESPCatalogOCT2013 PDFSteve MarfissiNo ratings yet

- Chapter 10 Recommended Practice For ESP Failure Analysis PDFDocument64 pagesChapter 10 Recommended Practice For ESP Failure Analysis PDFedwinNo ratings yet

- Electrical Submersible PumpDocument8 pagesElectrical Submersible Pumpmsyahir_chNo ratings yet

- ESP Failure Analysis of Forties Experience ApacheDocument14 pagesESP Failure Analysis of Forties Experience ApacheMohamed AshrafNo ratings yet

- SPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field DevelopmentDocument17 pagesSPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field Developmentmahmoud korieshNo ratings yet

- 05 IntakesDocument42 pages05 Intakesام فاطمة البطاطNo ratings yet

- ESP Design ProjectDocument26 pagesESP Design ProjectOloum UshoNo ratings yet

- ESP Systems EquipmentDocument28 pagesESP Systems EquipmentAdam Rohman SAZZYSAQQASASHANo ratings yet

- Tubing Performance VLPDocument4 pagesTubing Performance VLPDhiaa LaMiNo ratings yet

- Electric Submersible Pumps (ESP) PDFDocument31 pagesElectric Submersible Pumps (ESP) PDFFernandoEnriqueCalveteGonzález100% (2)

- Electric Submersible PumpsDocument17 pagesElectric Submersible PumpsFranklyn Frank100% (3)

- ESP Pump Selection, Evaluation Improve Well Inflow, Volumes - Oil & Gas JournalDocument7 pagesESP Pump Selection, Evaluation Improve Well Inflow, Volumes - Oil & Gas JournaljoreliNo ratings yet

- Altec Basic Gas Lift Training PDFDocument89 pagesAltec Basic Gas Lift Training PDFMauroNo ratings yet

- Artificial Lift: Electric Submersible Pumps ESPDocument47 pagesArtificial Lift: Electric Submersible Pumps ESPVlassis SarantinosNo ratings yet

- Chapter 04 SealDocument25 pagesChapter 04 Sealdewidar1234100% (1)

- Velocity String Installation and Performance ReviewDocument13 pagesVelocity String Installation and Performance ReviewSilicon Density100% (1)

- 18 Select PDFDocument20 pages18 Select PDFام فاطمة البطاطNo ratings yet

- ESP - Artificial LiftDocument46 pagesESP - Artificial LiftAYUNo ratings yet

- ESP Reliability Theory and Failure AnalysisDocument1 pageESP Reliability Theory and Failure Analysisazareiforoush100% (1)

- Esp System Start-Up, Commissioning and Operation - LastDocument42 pagesEsp System Start-Up, Commissioning and Operation - LastAnonymous 4hOjnj5100% (1)

- 2.2 Basic Coil Tubing Oprtn (Compatibility Mode)Document96 pages2.2 Basic Coil Tubing Oprtn (Compatibility Mode)Harisma Bagus100% (1)

- ESP Standard SizingDocument131 pagesESP Standard Sizingmohamed gamal100% (2)

- Esp Systems PresentationDocument12 pagesEsp Systems Presentationmozhi.shNo ratings yet

- Coiled TubingDocument146 pagesCoiled TubingNizar Ali100% (1)

- Appendix: 1 Dr. Alpheus Igbokoyi PTT Well PerformanceDocument25 pagesAppendix: 1 Dr. Alpheus Igbokoyi PTT Well PerformanceCharles Adefemi OmowoleNo ratings yet

- Vibration Analysis of ESPDocument13 pagesVibration Analysis of ESPNelton AlarcónNo ratings yet

- Peng 2016Document11 pagesPeng 2016NileshgordeNo ratings yet

- 014 ESP 01 Amir Arsalan Abbasi 1706800367Document19 pages014 ESP 01 Amir Arsalan Abbasi 1706800367Mohamed ElshoraNo ratings yet

- Desain Ulang Pompa Eletrical SubmersibleDocument30 pagesDesain Ulang Pompa Eletrical SubmersibleSena gilang AndreanNo ratings yet

- Hussain 2020Document13 pagesHussain 2020arash hazratiNo ratings yet

- Micro-Hydro Power Plant: Research Scholar Muhammad Naeem DEE161002Document45 pagesMicro-Hydro Power Plant: Research Scholar Muhammad Naeem DEE161002happyworryNo ratings yet

- 2009 Report Solar EnergyDocument80 pages2009 Report Solar EnergypaulwaNo ratings yet

- Spectrum and Signal Analys - Pulsed RF (Agilent)Document29 pagesSpectrum and Signal Analys - Pulsed RF (Agilent)Wesley GeorgeNo ratings yet

- SE350 Voltage Regulator Instruction Manual: A Regal BrandDocument4 pagesSE350 Voltage Regulator Instruction Manual: A Regal BrandGustavo GrisalesNo ratings yet

- Lect - 5 Boolean AlgebraDocument45 pagesLect - 5 Boolean Algebrashivam007100% (2)

- 3adw000078r0301 Dcs5 Software Descr e CDocument228 pages3adw000078r0301 Dcs5 Software Descr e Caninda_dNo ratings yet

- Installation Manual - Jinko NDocument33 pagesInstallation Manual - Jinko NNarasimha DvlNo ratings yet

- Series and Parallel Circuit QuestionsDocument4 pagesSeries and Parallel Circuit Questionsphydotsi100% (2)

- 1320083C - Plano Electrico 2018Document88 pages1320083C - Plano Electrico 2018Adhemar Vasquez AlburquequeNo ratings yet

- Types of MicsDocument14 pagesTypes of Micsapi-462777064No ratings yet

- Design and Implementation of An IoT Based Solar Powered Inverter Control SystemDocument12 pagesDesign and Implementation of An IoT Based Solar Powered Inverter Control SystemabdullahiNo ratings yet

- ITS AXX - Users Manual 4886988Document16 pagesITS AXX - Users Manual 4886988alejandraNo ratings yet

- Infineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Document15 pagesInfineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Jeferson TorresNo ratings yet

- Fairchild Fds PDFDocument2 pagesFairchild Fds PDFMichaelNo ratings yet

- Chapter 1Document36 pagesChapter 1Umesh ChandraNo ratings yet

- Bateria RA12-200D.2019Document2 pagesBateria RA12-200D.2019ElkQuyqueNo ratings yet

- GitHub - Threeme3:Usdx: Simple and Experimental (Class-E Driven) SSB Transceiver.Document1 pageGitHub - Threeme3:Usdx: Simple and Experimental (Class-E Driven) SSB Transceiver.pmarks4550No ratings yet

- Amplifier Is The Generic Term Used To Describe A Circuit Which Produces and Increased Version of Its Input SignalDocument4 pagesAmplifier Is The Generic Term Used To Describe A Circuit Which Produces and Increased Version of Its Input SignalChahat NoorNo ratings yet

- Ottlite Executive Desk Lamp ManualDocument1 pageOttlite Executive Desk Lamp ManualVlad60% (5)

- A340h TransferDocument5 pagesA340h TransferPushkar NathNo ratings yet

- 1 Triad AbcDocument4 pages1 Triad AbcAnamulKabirNo ratings yet

- Electric Traction McqsDocument27 pagesElectric Traction McqsEngrAneelKumarAkhani100% (1)

- Guia de Uso QuadnetDocument28 pagesGuia de Uso Quadnetamartins1974No ratings yet

- Apollo XP95 SWITCH MONITORDocument3 pagesApollo XP95 SWITCH MONITORjuankaldeNo ratings yet

- Repeaters XE PDFDocument12 pagesRepeaters XE PDFenzzo molinariNo ratings yet

- lec7PS PDFDocument24 pageslec7PS PDFShantha KumarNo ratings yet

- KA5x03xx-SERIES: KA5H0365R, KA5M0365R, KA5L0365R KA5H0380R, KA5M0380R, KA5L0380R Fairchild Power Switch (FPS)Document14 pagesKA5x03xx-SERIES: KA5H0365R, KA5M0365R, KA5L0365R KA5H0380R, KA5M0380R, KA5L0380R Fairchild Power Switch (FPS)vetchboyNo ratings yet

- Induction Generators For Wind PowerDocument2 pagesInduction Generators For Wind PowerworkseesNo ratings yet

- Melles Photodiodes Integrating Spherres AmplifiersDocument9 pagesMelles Photodiodes Integrating Spherres AmplifiersnorbertscribdNo ratings yet

- DatasheetDocument2 pagesDatasheetTufan ÜnalNo ratings yet

2016.10.18 Esp

2016.10.18 Esp

Uploaded by

prillaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2016.10.18 Esp

2016.10.18 Esp

Uploaded by

prillaCopyright:

Available Formats

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Electrical Submersible Pump/REDA Course

By: Panca S Widiantoro

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

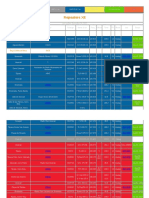

Class Schedule

Instructor: Panca S Widiantoro

Phone: 0821 38 578 625

E-mail: pancasuciwidiantoro@gmail.com

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Course Outline

1. Introduction to Electrical Submersible Pump/REDA

2. History and evolution of ESPs

3. Principle of ESP

4. ESP Component

Subsurface component

Surface component

5. Nodal Analysis

6. Total Dynamic Head

7. ESP Design

Manual Calculation (using Ms.Excel)

Software Calculation (using Prosper Software)

8. New ESP Innovation

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP (concept of Artificial Lift)

Natural flow

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP (concept of Artificial Lift)

How to lift the fluid ?

- Decrease the fluid

Psep Pwh

gradient in the tubing

- Add some extra

energy to push fluid

well from bottom hole No - Flow Well

Gradient

?

to the surface

Solution :

Energy

Use the artificial lift ?

Pwf

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP (concept of Artificial Lift)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP (Artificial Lift Method)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP (Artificial Lift Method)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Comparison of Lift Methods

Typical Artificial Lift Application Range

Ft./Lift

12,000

11,000

10,000

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000 20,000 30,000 40,000 50,000 BPD

Rod PC Pumps Hydraulic Lift Submersible Pump Gas Lift

Pumps

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Electrical Submersible Pumping

• Second most commonly used method worldwide (+100,000 wells)

• Used massively in Russia and in significant number of wells in US

• Responsible for the highest amount of total fluids produced (oil and water) by

any artificial lift method and an ideal method for high water cut wells

• Problems with sand production, high gas liquid ratio and high bottom hole

temperatures

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

ESP video

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

The system’s surface equipment includes transformers, a switchboard, junction

box and surface power cables. Power passes through a cable running from the

transformer to the switchboard and junction box, then to the wellhead

The ESP downhole assembly is located in the well at the bottom of the tubing.

The motor, seal, intake and pump assembly, along with the power cable, goes in

the well as the tubing is run.

Below the pump is an intake that allows fluid to enter the pump. Below the intake

is a gas separator and a protector or seal, which equalizes internal and external

pressures and protects the motor from well fluids. At the bottom is a motor that

drives the pump. The assembly is positioned in the well above the perforations;

this allows fluid entering the intake to flow past the motor and cool it.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Benefits of ESPs

They can be economically designed for both oil and water wells, at production

rates ranging from 200 to 60,000 B/D and at depths of .up to 15,000 feet.

They can be used in crooked or deviated wells. DLS < 9 degrees/100ft

They have a relatively small “surface footprint,” and so are appropriate for use in

offshore, urban or other confined locations. They are relatively simple to operate.

They generally provide low lifting costs for high fluid volumes.

They make it easy to apply corrosion and scale treatments.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Limitations of ESPs

They are generally limited to single-zone completions

They requires a source of high-voltage electric power

The presence of a power cable alongside the tubing string can make it more

difficult to run or pull tubing.

They are not particularly good at handling gas and solids production.

Analyzing the system performance can be a challenge.

Power cables may deteriorate in high temperature conditions—400 degrees

Fahrenheit (about 200 degrees Celsius) is their general upper limit with respect

to operating temperature.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

History and Evolution of ESP

REDA: Russian Electric Dynamo of Arutunoff estalished

in 1930 in Bartlesville, OK

Armais Arutunoff

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

History and Evolution of ESP

Armais Arutunof

Develop ESP for Purchased by

dewatering mines and Schlumberger

Got US Patent

ship

Rotary Gas Separator

Introduced

Test ESP in horizontal

position

1910 1916 1926 1950 1970 1977 1998

Found Seal with mechanical

seals Introduced VSD

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

History and Evolution of ESP

ESP providers nowadays:

1. Schlumberger-REDA (Bartlesville, OK)

2. Centrilift – Baker Hughes (Claremore, OK)

3. Weatherford

4. Wood Group ESP - GE (Oklahoma city, OK)

5. ALNAS (Russia)

6. Novomet

7. EJP (Local Indonesia)

8. Etc..

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Principle of ESP

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Components

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

−Subsurface components

• Cable

• Motor

• Seal Section/Protector

• Gas Separator (Optional)

• Pump

• Sensor (Optional)

• Drain Valve

• Check Valve

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Electric Cable

A power cable runs from the junction box then through the wellhead and all the

way to the bottom to supply power to the pump motor.

Cable is available in round and flat styles

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Subsurface Components – Cable Amperage

The first consideration in selecting cables is amperage. The limits on amperage

for cables containing copper conductors are as follows:

Note that the cable with the smaller number has the larger diameter. Thus, a

Number 1 cable can carry a maximum of 115 amps.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Subsurface Components – Voltage Drop

The second selection consideration is the voltage drop that will occur between

the wellhead and the pump. Normally, the maximum voltage drop for an

electrical cable is about 30V per 1000 feet.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Motor

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Seal/Protector

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Gas Separator

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Subsurface Components – Gas Separator

Separates the free gas in order to reduce the quantity of gas that flows into the

pump.

There are two types: static and rotary gas separator.

Static: No applying any additional mechanical force. They provide a tortuous

path that turns the fluid stream and moves it down toward the inlet ports. Some

of the free gas accompanies the liquid to the intake and a portion is separated.

Dynamic gas separators, on the other hand, actually impart energy to the fluid

to separate the vapor from the fluid.

http://www.woodgroup-esp.com/products/Pages/GasSeparators.aspx

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Subsurface Components – Gas Separator

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Gas Separator

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Gas Separator (AGH)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Gas Separator (Poseidon)

Can handle free gas content up to 75%

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Pump

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

ESP Classification

ESPs can be classified into two main categories: Radial flow and Mixed flow

Radial Flow Pump

Mixed Flow Pump

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Pump

Each stage consists of an impeller and a diffuser

The rotating impeller takes the fluids and imparts kinetic energy from the

rotating shaft to the fluids

The stationary diffuser converts the kinetic energy of the fluids into pressure

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Pump

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Pump

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Pump

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Pump

https://www.scribd.com/doc/135870869/Schlumberger-ESP-Catalog-pdf

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

ESP Classifications

The performance characteristics of stages at the best efficiency point is a function

of a dimensionless number called specific speed

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

ESP Classifications

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Subsurface ESP Components

Subsurface Components – Check Valve

A check valve is installed about two to three

joints above the ESP pump to maintain a full

liquid column in the tubing string during

equipment shut down periods. It prevent leaking

of the fluid from the tubing down through the

pump when the pump is not running.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Surface ESP Components

Surface Components – Check Valve

Surface components

• Transformers (Primary and Secondary)

• Switchboard or Variable Speed Drive or Soft Start

• Junction Box

• Wellhead

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Surface ESP Components

Surface Components - Transformer

transformer system is used to step-up

or step-down the voltage from the

primary line to the motor of the

submersible pump. Because a range

of operating voltages may be used for

submersible pump motors, the

transformer must be compatible with

the selection of the motor voltage.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Surface ESP Components

Surface Components - Switchboard

The switchboard controls the pump motor

and provides overload and underload

protection.

Protection against overload is needed to

keep the motor windings from burning.

Protection during underload is needed

because low fluid flow rates will prevent

adequate cooling of the motor.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Surface ESP Components

Surface Components – Junction Box/ vent Box

The junction box connects the power cable from the switchboard to the power

cable from the well. It provides an explosion-free vent to the atmosphere for

any gas that might migrate up the power cable from the wellbore.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Surface ESP Components

Surface Components – VSD

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Surface ESP Components

Surface Components – Wellhead

Must provide means for installing the cable with adequate seal

May include adjustable chokes, bleeding valves

Onshore wellheads have a rubber seal and offshore have a electric mandrel

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

Surface Components – Wellhead

The Safe-T-Lok is supplied with factory molded cable on both the top and the

bottom. The lower cable will be spliced to the ESP cable, and the top cable

will connected to the junction box.

The Safe-T-Lok is installed in the wellhead by feeding through the tubing

hanger from below

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Introduction to ESP

ESP Operating Principles

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

If you guys understood everything about

“ESP”

Let us have a coffee and smoking

break!!!

aram

aram Gudang G

aram Gudang G

Gudang G

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Nodal Analysis

1 Phase IPR

2 Phase IPR

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Nodal Analysis

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Nodal Analysis

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Nodal Analysis

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Nodal Analysis

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Nodal Analysis

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Nodal Analysis

Natural Flow With Pump

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Total Dynamic Head (TDH)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Total Dynamic Head (TDH)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Total Dynamic Head (TDH)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Total Dynamic Head (TDH)

4000 ft

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Total Dynamic Head (TDH)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Total Dynamic Head (TDH)

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

For 2 7/8 “, friction = 200*6.5 = 1300 ft of loss 2

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

Total Dynamic Head (TDH)

Total Dynamic Head = Fluid level + Tubing friction + Back pressure

Wellbore

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016 ESP Pressure Gradient

Wellhead pressure

Liquid Level

Total Dynamic Head Discharge Pressure

Suction Pressure

Bottomhole pressure

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Design

1. Using MS Excel

2. Using Software

API 11S4

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Innovation

Coil Tuibing Deployed ESP System

Cable suspended and coil tubing

ESPs can also be used. They can

also be used to kick-off wells,

clean wells after a frac job and test

wells

Figure on the side is the coil tubing

deployed ESP system.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Innovation

Coil Tuibing Deployed ESP System - Offshore

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Innovation

Coil Tuibing Deployed ESP System - Offshore

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Innovation

Cable Suspended ESP System

Cable Suspended ESP:

• The unit is lowered in the well without using a tubing. It is

suspended from a cable and the power cable is banded to it.

• A special seating element supports the pump and

provides locking to avoid excessive torque on the cable.

• Differently from the conventional installations, the motor

is located above the pump.

• The system produces through the annular.

• It main advantage is the reduction in al costs associated

with tubing pulling job, specially offshore

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Innovation

Combination between ESP and Gas Lift (Hybrid system)

Some installations combine ESP

with other artificial lift methods

• ESP and Gas lift

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Innovation

Subsurface Components –ESP Bypass System

Wireline or coiled tubing plugs can be supplied to seat in a nipple

profile in the Y-tool to enable intervention or logging operations

without retrieval of the completion

Can be also used for installing two parallel ESPs in the well.

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

ESP Innovation

Shuttle ESP

Advantages:

1. Low installation and WO

cost

2. Using minimal crew when

installation process

3. Suitable for low oil price

condition

Electrical Submersible Pump

Training and Talk “ESP” AKAMIGAS Balongan

Indramayu, Oct 2016

THANK YOU

Empowering People

Electrical Submersible Pump

You might also like

- Reda Esp CatalogDocument548 pagesReda Esp CatalogPED SARIRNo ratings yet

- Af33 5Document44 pagesAf33 5ivanmedalla100% (6)

- ESP 9 Step Design PDFDocument31 pagesESP 9 Step Design PDFDwiki Ramadhani100% (2)

- Well Head and X Mas TreeDocument3 pagesWell Head and X Mas TreeDipankar NathNo ratings yet

- Completion Application ManualDocument42 pagesCompletion Application ManualKHALEDFEKAIR100% (1)

- Use of Coiled Tubing As A Velocity StringDocument3 pagesUse of Coiled Tubing As A Velocity StringMark Johnson100% (1)

- Artificial Lift Training - CopieDocument141 pagesArtificial Lift Training - CopiesereptNo ratings yet

- Pertemuan12 ESP 04042016 13042016Document192 pagesPertemuan12 ESP 04042016 13042016Priozky Pratama Purba100% (1)

- Wo Esp DevelopmentsDocument6 pagesWo Esp DevelopmentsHamed GeramiNo ratings yet

- Electric Submersible Pumps For The Petroleum IndustryDocument20 pagesElectric Submersible Pumps For The Petroleum Industrysouthli100% (1)

- ESP 9-Step DesignDocument31 pagesESP 9-Step Designeng.osama100% (2)

- 05 Artificial LiftDocument83 pages05 Artificial LiftPaoloPinard100% (1)

- Design Overview: Basic Design and Maintenance InstructionsDocument8 pagesDesign Overview: Basic Design and Maintenance InstructionsOctopusNo ratings yet

- 2011 ESP WorkshopDocument41 pages2011 ESP Workshopuekiiiiii23No ratings yet

- SD4-6 - Final ESP Design PDFDocument11 pagesSD4-6 - Final ESP Design PDFkonan84167% (3)

- Application Engineering: Reda Esp System ComponentsDocument4 pagesApplication Engineering: Reda Esp System Componentselsayed amerNo ratings yet

- Chapter 01 IntroductionDocument12 pagesChapter 01 Introductiondewidar1234100% (1)

- Esp Failure NomenclatureDocument35 pagesEsp Failure Nomenclaturedillipsh123No ratings yet

- NOVOMET. Instruction of Tap and Power Rating CalculationDocument3 pagesNOVOMET. Instruction of Tap and Power Rating CalculationmolanoavilaNo ratings yet

- 7 European Electric Submersible Pump Round Table Aberdeen, ScotlandDocument8 pages7 European Electric Submersible Pump Round Table Aberdeen, Scotlandshy_boyNo ratings yet

- ESP Start-Up and OperationDocument46 pagesESP Start-Up and OperationazareiforoushNo ratings yet

- Zenith Gauge PDFDocument2 pagesZenith Gauge PDFCarlos EscobarNo ratings yet

- Total Dynamic Head - TDHDocument37 pagesTotal Dynamic Head - TDHs pNo ratings yet

- 2004 Gas Lift SeminarDocument317 pages2004 Gas Lift SeminarNgọc Hiệp LêNo ratings yet

- 46 EspDocument35 pages46 EspHichem FakhfekhNo ratings yet

- OF11-0007R00 LWM PCP Data Sheet PDFDocument2 pagesOF11-0007R00 LWM PCP Data Sheet PDFShadySadanyNo ratings yet

- Artificial Lift MethodsDocument57 pagesArtificial Lift MethodsHaseen KaurNo ratings yet

- 4 Run Life OpsDocument29 pages4 Run Life Opshatem_eldawyNo ratings yet

- SRP 161203072620Document27 pagesSRP 161203072620Muhammad N BashashaNo ratings yet

- PMP IntakeDocument23 pagesPMP IntakeRiyan YonathanNo ratings yet

- ESPCatalogOCT2013 PDFDocument218 pagesESPCatalogOCT2013 PDFSteve MarfissiNo ratings yet

- Chapter 10 Recommended Practice For ESP Failure Analysis PDFDocument64 pagesChapter 10 Recommended Practice For ESP Failure Analysis PDFedwinNo ratings yet

- Electrical Submersible PumpDocument8 pagesElectrical Submersible Pumpmsyahir_chNo ratings yet

- ESP Failure Analysis of Forties Experience ApacheDocument14 pagesESP Failure Analysis of Forties Experience ApacheMohamed AshrafNo ratings yet

- SPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field DevelopmentDocument17 pagesSPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field Developmentmahmoud korieshNo ratings yet

- 05 IntakesDocument42 pages05 Intakesام فاطمة البطاطNo ratings yet

- ESP Design ProjectDocument26 pagesESP Design ProjectOloum UshoNo ratings yet

- ESP Systems EquipmentDocument28 pagesESP Systems EquipmentAdam Rohman SAZZYSAQQASASHANo ratings yet

- Tubing Performance VLPDocument4 pagesTubing Performance VLPDhiaa LaMiNo ratings yet

- Electric Submersible Pumps (ESP) PDFDocument31 pagesElectric Submersible Pumps (ESP) PDFFernandoEnriqueCalveteGonzález100% (2)

- Electric Submersible PumpsDocument17 pagesElectric Submersible PumpsFranklyn Frank100% (3)

- ESP Pump Selection, Evaluation Improve Well Inflow, Volumes - Oil & Gas JournalDocument7 pagesESP Pump Selection, Evaluation Improve Well Inflow, Volumes - Oil & Gas JournaljoreliNo ratings yet

- Altec Basic Gas Lift Training PDFDocument89 pagesAltec Basic Gas Lift Training PDFMauroNo ratings yet

- Artificial Lift: Electric Submersible Pumps ESPDocument47 pagesArtificial Lift: Electric Submersible Pumps ESPVlassis SarantinosNo ratings yet

- Chapter 04 SealDocument25 pagesChapter 04 Sealdewidar1234100% (1)

- Velocity String Installation and Performance ReviewDocument13 pagesVelocity String Installation and Performance ReviewSilicon Density100% (1)

- 18 Select PDFDocument20 pages18 Select PDFام فاطمة البطاطNo ratings yet

- ESP - Artificial LiftDocument46 pagesESP - Artificial LiftAYUNo ratings yet

- ESP Reliability Theory and Failure AnalysisDocument1 pageESP Reliability Theory and Failure Analysisazareiforoush100% (1)

- Esp System Start-Up, Commissioning and Operation - LastDocument42 pagesEsp System Start-Up, Commissioning and Operation - LastAnonymous 4hOjnj5100% (1)

- 2.2 Basic Coil Tubing Oprtn (Compatibility Mode)Document96 pages2.2 Basic Coil Tubing Oprtn (Compatibility Mode)Harisma Bagus100% (1)

- ESP Standard SizingDocument131 pagesESP Standard Sizingmohamed gamal100% (2)

- Esp Systems PresentationDocument12 pagesEsp Systems Presentationmozhi.shNo ratings yet

- Coiled TubingDocument146 pagesCoiled TubingNizar Ali100% (1)

- Appendix: 1 Dr. Alpheus Igbokoyi PTT Well PerformanceDocument25 pagesAppendix: 1 Dr. Alpheus Igbokoyi PTT Well PerformanceCharles Adefemi OmowoleNo ratings yet

- Vibration Analysis of ESPDocument13 pagesVibration Analysis of ESPNelton AlarcónNo ratings yet

- Peng 2016Document11 pagesPeng 2016NileshgordeNo ratings yet

- 014 ESP 01 Amir Arsalan Abbasi 1706800367Document19 pages014 ESP 01 Amir Arsalan Abbasi 1706800367Mohamed ElshoraNo ratings yet

- Desain Ulang Pompa Eletrical SubmersibleDocument30 pagesDesain Ulang Pompa Eletrical SubmersibleSena gilang AndreanNo ratings yet

- Hussain 2020Document13 pagesHussain 2020arash hazratiNo ratings yet

- Micro-Hydro Power Plant: Research Scholar Muhammad Naeem DEE161002Document45 pagesMicro-Hydro Power Plant: Research Scholar Muhammad Naeem DEE161002happyworryNo ratings yet

- 2009 Report Solar EnergyDocument80 pages2009 Report Solar EnergypaulwaNo ratings yet

- Spectrum and Signal Analys - Pulsed RF (Agilent)Document29 pagesSpectrum and Signal Analys - Pulsed RF (Agilent)Wesley GeorgeNo ratings yet

- SE350 Voltage Regulator Instruction Manual: A Regal BrandDocument4 pagesSE350 Voltage Regulator Instruction Manual: A Regal BrandGustavo GrisalesNo ratings yet

- Lect - 5 Boolean AlgebraDocument45 pagesLect - 5 Boolean Algebrashivam007100% (2)

- 3adw000078r0301 Dcs5 Software Descr e CDocument228 pages3adw000078r0301 Dcs5 Software Descr e Caninda_dNo ratings yet

- Installation Manual - Jinko NDocument33 pagesInstallation Manual - Jinko NNarasimha DvlNo ratings yet

- Series and Parallel Circuit QuestionsDocument4 pagesSeries and Parallel Circuit Questionsphydotsi100% (2)

- 1320083C - Plano Electrico 2018Document88 pages1320083C - Plano Electrico 2018Adhemar Vasquez AlburquequeNo ratings yet

- Types of MicsDocument14 pagesTypes of Micsapi-462777064No ratings yet

- Design and Implementation of An IoT Based Solar Powered Inverter Control SystemDocument12 pagesDesign and Implementation of An IoT Based Solar Powered Inverter Control SystemabdullahiNo ratings yet

- ITS AXX - Users Manual 4886988Document16 pagesITS AXX - Users Manual 4886988alejandraNo ratings yet

- Infineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Document15 pagesInfineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Jeferson TorresNo ratings yet

- Fairchild Fds PDFDocument2 pagesFairchild Fds PDFMichaelNo ratings yet

- Chapter 1Document36 pagesChapter 1Umesh ChandraNo ratings yet

- Bateria RA12-200D.2019Document2 pagesBateria RA12-200D.2019ElkQuyqueNo ratings yet

- GitHub - Threeme3:Usdx: Simple and Experimental (Class-E Driven) SSB Transceiver.Document1 pageGitHub - Threeme3:Usdx: Simple and Experimental (Class-E Driven) SSB Transceiver.pmarks4550No ratings yet

- Amplifier Is The Generic Term Used To Describe A Circuit Which Produces and Increased Version of Its Input SignalDocument4 pagesAmplifier Is The Generic Term Used To Describe A Circuit Which Produces and Increased Version of Its Input SignalChahat NoorNo ratings yet

- Ottlite Executive Desk Lamp ManualDocument1 pageOttlite Executive Desk Lamp ManualVlad60% (5)

- A340h TransferDocument5 pagesA340h TransferPushkar NathNo ratings yet

- 1 Triad AbcDocument4 pages1 Triad AbcAnamulKabirNo ratings yet

- Electric Traction McqsDocument27 pagesElectric Traction McqsEngrAneelKumarAkhani100% (1)

- Guia de Uso QuadnetDocument28 pagesGuia de Uso Quadnetamartins1974No ratings yet

- Apollo XP95 SWITCH MONITORDocument3 pagesApollo XP95 SWITCH MONITORjuankaldeNo ratings yet

- Repeaters XE PDFDocument12 pagesRepeaters XE PDFenzzo molinariNo ratings yet

- lec7PS PDFDocument24 pageslec7PS PDFShantha KumarNo ratings yet

- KA5x03xx-SERIES: KA5H0365R, KA5M0365R, KA5L0365R KA5H0380R, KA5M0380R, KA5L0380R Fairchild Power Switch (FPS)Document14 pagesKA5x03xx-SERIES: KA5H0365R, KA5M0365R, KA5L0365R KA5H0380R, KA5M0380R, KA5L0380R Fairchild Power Switch (FPS)vetchboyNo ratings yet

- Induction Generators For Wind PowerDocument2 pagesInduction Generators For Wind PowerworkseesNo ratings yet

- Melles Photodiodes Integrating Spherres AmplifiersDocument9 pagesMelles Photodiodes Integrating Spherres AmplifiersnorbertscribdNo ratings yet

- DatasheetDocument2 pagesDatasheetTufan ÜnalNo ratings yet