Professional Documents

Culture Documents

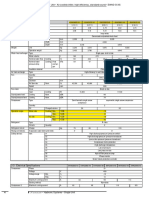

Above Calculation Is For One Spring Below Calculation Is For Two Springs

Above Calculation Is For One Spring Below Calculation Is For Two Springs

Uploaded by

Tuấn VũCopyright:

Available Formats

You might also like

- Crane Tp410 Fluid FlowDocument133 pagesCrane Tp410 Fluid FlowLucia Lorenzini100% (8)

- TEMA Spec SheetDocument1 pageTEMA Spec SheetvikzefgNo ratings yet

- ACFR Conductor SpecDocument20 pagesACFR Conductor SpecHope DandaraNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGupta100% (1)

- Conductor Sag and Tension CalculatorDocument12 pagesConductor Sag and Tension CalculatorJetn SrisuthumNo ratings yet

- Liquid Expansion ReliefDocument14 pagesLiquid Expansion Reliefpetrochem100% (2)

- Electric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Document3 pagesElectric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Tuấn VũNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- FJ DT VRF S 2pipe 071205 VD002E14-NovoDocument2 pagesFJ DT VRF S 2pipe 071205 VD002E14-NovoSlobodan AnticNo ratings yet

- Design Calculation of Shaft/Pin/Axle: 1.0 Basic DataDocument3 pagesDesign Calculation of Shaft/Pin/Axle: 1.0 Basic DatapkvchoudharyNo ratings yet

- Creep Calculation by Colin Bayliss & Brain HardyDocument1 pageCreep Calculation by Colin Bayliss & Brain HardyVenkatasubramanian Iyer100% (1)

- Tugas 1 Mata Kuliah Elemen Mesin 2 Minggu, 22 September 2019Document4 pagesTugas 1 Mata Kuliah Elemen Mesin 2 Minggu, 22 September 2019sekarayuNo ratings yet

- Weld CalculatorDocument6 pagesWeld Calculatorshahid khanNo ratings yet

- Charcoal Tower Pressure Drop CalculationDocument5 pagesCharcoal Tower Pressure Drop CalculationNalin GujaratiNo ratings yet

- Perhitungan Shaft Pulley ConveyorDocument5 pagesPerhitungan Shaft Pulley ConveyorRiska DamayantiNo ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- Penstock Thickness CaclDocument44 pagesPenstock Thickness CaclAnonymous sfkedkym100% (1)

- Sandy Drifterz, Vcet: Madurai, Tamil NaduDocument15 pagesSandy Drifterz, Vcet: Madurai, Tamil NaduNaveenNo ratings yet

- Hitungan Structure Beban AtapDocument3 pagesHitungan Structure Beban Atapdimas cahyoNo ratings yet

- Tech - Spec.ACSR 95.15Document1 pageTech - Spec.ACSR 95.15Ilir DalipiNo ratings yet

- Shell&Tube TEMAsheet 1Document1 pageShell&Tube TEMAsheet 1Rikiya FebriyanNo ratings yet

- AgitatorDocument6 pagesAgitatorSung Woong MoonNo ratings yet

- Penstock Thickness Cacl.Document44 pagesPenstock Thickness Cacl.Anonymous sfkedkymNo ratings yet

- Agitator CalculationsDocument12 pagesAgitator Calculationspankit mehtaNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- General Data: Bending StessesDocument8 pagesGeneral Data: Bending Stessesprajakt_pieNo ratings yet

- 20 5T PDFDocument3 pages20 5T PDFMUBASHSHIR HELALNo ratings yet

- Load Factor Load: Project:-Location: - Design Code: Designed by DateDocument1 pageLoad Factor Load: Project:-Location: - Design Code: Designed by DateSantosh BapuNo ratings yet

- Carrier 7.5TRDocument2 pagesCarrier 7.5TRbrian mmec2020No ratings yet

- Calculate Scaffolding Inedependent Common TowerTube 4mmDocument4 pagesCalculate Scaffolding Inedependent Common TowerTube 4mmDunya Fildzah100% (1)

- M. Farhan Alfarabi. (4318218004)Document2 pagesM. Farhan Alfarabi. (4318218004)Farhan AlfarabiNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- Steel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectDocument1 pageSteel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectCaspian DattaNo ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDocument2 pagesSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanNo ratings yet

- Slab DesignDocument6 pagesSlab DesignKanchan Raja SinghNo ratings yet

- Shincoil CompressionDocument98 pagesShincoil CompressionVNK90No ratings yet

- Motor Data Sheet 18. KW 4 PoleDocument1 pageMotor Data Sheet 18. KW 4 Poledeepak kumarNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Data Sheet EVMSG15 2N6Q1BEGE 3.0Document7 pagesData Sheet EVMSG15 2N6Q1BEGE 3.0Edilberto Alegato (EPPI)No ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Datasheet LF GZTACSR 420-50 TWDocument1 pageDatasheet LF GZTACSR 420-50 TWTú Trần TuấnNo ratings yet

- Daikin EWAD-DDocument1 pageDaikin EWAD-DsalahcalimeroNo ratings yet

- CATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 DrakeDocument12 pagesCATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 Drakedursun_yerlikaya100% (2)

- Spring Design: GD N PC yDocument2 pagesSpring Design: GD N PC yAshokNo ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- C - 1531 RLDocument11 pagesC - 1531 RLPand AemonaEonNo ratings yet

- 25kW Ac Units PDFDocument1 page25kW Ac Units PDFChrisNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

- Piezo Material Properties Data Sheet 20201112Document1 pagePiezo Material Properties Data Sheet 20201112Trương Anh DuyNo ratings yet

- RAD Product Leaflet 2-3-2011Document32 pagesRAD Product Leaflet 2-3-2011sohan24820% (1)

- Electrical Machine Design: Item NoDocument3 pagesElectrical Machine Design: Item NoJv RodriguezNo ratings yet

- Jis G-3444Document10 pagesJis G-3444Maulana YusufNo ratings yet

- 1MB1553 2DB03 4JB4 Z B02 Datasheet enDocument2 pages1MB1553 2DB03 4JB4 Z B02 Datasheet enadriansya7No ratings yet

- Heat Exchanger Specification SheetDocument4 pagesHeat Exchanger Specification SheetAnita PanthiNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Level Transmitter C To C StatusDocument3 pagesLevel Transmitter C To C StatusTuấn VũNo ratings yet

- Pump SizingDocument31 pagesPump SizingTuấn VũNo ratings yet

- Boiler CalcDocument235 pagesBoiler CalcTuấn VũNo ratings yet

- Curriculum Vitae: Contact InformationDocument4 pagesCurriculum Vitae: Contact InformationTuấn VũNo ratings yet

- Ho Trong Tuong - Automatic Engineer: Fujitsu Computer Products of Vietnam, Inc Equipment EngineerDocument6 pagesHo Trong Tuong - Automatic Engineer: Fujitsu Computer Products of Vietnam, Inc Equipment EngineerTuấn VũNo ratings yet

- Comment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Document2 pagesComment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Tuấn Vũ0% (1)

- Nâng c ấp Windows 7/8.1 lên Win 10 giữ nguyên b ản quyền cũDocument7 pagesNâng c ấp Windows 7/8.1 lên Win 10 giữ nguyên b ản quyền cũTuấn VũNo ratings yet

- 131 AcDocument25 pages131 AcTuấn VũNo ratings yet

- Calculation Pressure Drop For Filter Element: Apsl 8774Document2 pagesCalculation Pressure Drop For Filter Element: Apsl 8774Tuấn VũNo ratings yet

- Maq Fall03 Strategicbudgetingcasestudy PDFDocument10 pagesMaq Fall03 Strategicbudgetingcasestudy PDFYana Aida FitriahNo ratings yet

- VOLVO EC210B FX EC210BFX EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC210B FX EC210BFX EXCAVATOR Service Repair Manual PDFfjjsjekdmme100% (1)

- FX Training Center: Aviation KnowledgeDocument12 pagesFX Training Center: Aviation KnowledgeFahmi PrayogiNo ratings yet

- FMA RegsDocument361 pagesFMA RegsJiong SoonNo ratings yet

- Application of FMEA in An Aluminium Pot Manufacturing IndustryDocument5 pagesApplication of FMEA in An Aluminium Pot Manufacturing IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Abb Weather ProofDocument58 pagesAbb Weather ProofEhsan ShaukatNo ratings yet

- Welcome To The World of Green Building-ParrywareDocument17 pagesWelcome To The World of Green Building-ParrywareShaik ShoebNo ratings yet

- Porta Cabin Tech SpecDocument6 pagesPorta Cabin Tech SpecFARES BEN MESSAOUDNo ratings yet

- 28-0818RA4LIFE Referencesdoc Jan2018Document15 pages28-0818RA4LIFE Referencesdoc Jan2018tuvosipNo ratings yet

- A Power Analysis Toolbox For MATLAB SimulinkDocument6 pagesA Power Analysis Toolbox For MATLAB SimulinkAhmed58seribegawanNo ratings yet

- MNP FlowsDocument6 pagesMNP FlowsSandeep Reddy Vajrala100% (1)

- TDA7449Document21 pagesTDA7449Sambhu Dharmadevan VU3KQFNo ratings yet

- White Paper Business Analysis Center of Excellence v2 2007 PDFDocument17 pagesWhite Paper Business Analysis Center of Excellence v2 2007 PDFtippurajNo ratings yet

- Ebalance A Stata Package For Entropy BalancingDocument18 pagesEbalance A Stata Package For Entropy BalancingGerardo DamianNo ratings yet

- Topographic Map of Metcalf GapDocument1 pageTopographic Map of Metcalf GapHistoricalMapsNo ratings yet

- Manitou SM - ME318 3 Di 4Document65 pagesManitou SM - ME318 3 Di 4mirko coppini100% (2)

- Satellite - Wikipedia, The Free EncyclopediaDocument21 pagesSatellite - Wikipedia, The Free Encyclopediamingt510% (1)

- Mochammad Rafli Rayhan Hidayat - SPWM BIPOLARDocument4 pagesMochammad Rafli Rayhan Hidayat - SPWM BIPOLARrafli rayhanNo ratings yet

- LINSEIS Thermal Conductivity v4 CompressedDocument20 pagesLINSEIS Thermal Conductivity v4 CompressedsayarersNo ratings yet

- Kebutuhan Beton - Update 080922Document1 pageKebutuhan Beton - Update 080922daraNo ratings yet

- ST pk2 A2Document32 pagesST pk2 A2dasdfa serasdNo ratings yet

- Unit 6 - Week 5: Week 05-Assignment 5-Manufacturing Process Technology Part-1Document5 pagesUnit 6 - Week 5: Week 05-Assignment 5-Manufacturing Process Technology Part-1KKNo ratings yet

- 721007-620005-Computer Oriented Numerical MethodsDocument2 pages721007-620005-Computer Oriented Numerical MethodsTijo L PeterNo ratings yet

- IIB WSSecurityDocument65 pagesIIB WSSecuritydiva100% (1)

- GitHub TrainingDocument21 pagesGitHub Trainingcyberfox786No ratings yet

- Manual de OperadorDocument246 pagesManual de OperadorJesus CastilloNo ratings yet

- Profile As A Professional EngineerDocument3 pagesProfile As A Professional EngineerAdnan MunirNo ratings yet

- NEM Declaration Form (TNB Contract)Document2 pagesNEM Declaration Form (TNB Contract)Kian Keong Yee100% (1)

- Zelio Control RM35TF30 PDFDocument3 pagesZelio Control RM35TF30 PDFYamith DavidNo ratings yet

- Google Play Supported Devices - Sheet 1Document193 pagesGoogle Play Supported Devices - Sheet 1Miguel S SNo ratings yet

Above Calculation Is For One Spring Below Calculation Is For Two Springs

Above Calculation Is For One Spring Below Calculation Is For Two Springs

Uploaded by

Tuấn VũOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Above Calculation Is For One Spring Below Calculation Is For Two Springs

Above Calculation Is For One Spring Below Calculation Is For Two Springs

Uploaded by

Tuấn VũCopyright:

Available Formats

Wire Thickness (diameter) 0.

218

Inside Diam ID 2.00

Mean Coil Diameter 2.218

Overall length (OAL) 28

Right or Left hand spring Right

End Treatment radial tang

Weight of Door 173

Height of Door 7

Drum Radius 2

Drum Diameter 4

torque calculated 28.83333333

torque calculated per door weight 346

Dead Coils 5

Number of active coils 123.440367

E 2.85E+07

F 7.5

π 3.14159

K 23.0808594

Torque (one spring) 173.1064455

Spring index 10.17431193

Density of the material (lb/cu-in) 0.283

Mass weight of spring 9.453709253

Wahl correction factor for stress 1.142

Bending stress from torsion, per turn (psi) = S 170194

Recommended stress limit (after Wahl correction) = S*Kw 194395

ABOVE CALCULATION IS FOR ONE SPRING

Below CALCULATION IS FOR TWO SPRINGS

For two springs torque = 346.212891

Spring cost at $3.50/lb $33.09

Therefore, two springs without (cones, cones assy, shipping & handling = ) $66.18

inch =d

inch

inch =D

inch

hand

lbs

ft

inch

ft*lbs

in*lbs

5 to 10, depending on winding cones

psi Young's modulus of the material (psi) ASTM A229 oil-tempered wire)

# turns applied for standard residential garage door

K = π * E * d^4 / (32*D*N) ; Spring rate (IPPT)

in lbs T=K*F

C = D/d

lb/cu-in rho = 0.283 lb/cu-in (ASTM A229 oil-tempered wire)

lbs M = rho * L/d*pi*D * pi*d^2/4

Kw = (4C-1)/(4C-4) + 0.615/C

(psi) S = 32*T/(π*d^3)

= S * Kw < = 242 Kpsi (10,000 cycle life)

< = 200 Kpsi (25,000 cycle life)

< = 175 Kpsi (50,000 cycle life)

< = 150 Kpsi (100,000 cycle life)

You might also like

- Crane Tp410 Fluid FlowDocument133 pagesCrane Tp410 Fluid FlowLucia Lorenzini100% (8)

- TEMA Spec SheetDocument1 pageTEMA Spec SheetvikzefgNo ratings yet

- ACFR Conductor SpecDocument20 pagesACFR Conductor SpecHope DandaraNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGupta100% (1)

- Conductor Sag and Tension CalculatorDocument12 pagesConductor Sag and Tension CalculatorJetn SrisuthumNo ratings yet

- Liquid Expansion ReliefDocument14 pagesLiquid Expansion Reliefpetrochem100% (2)

- Electric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Document3 pagesElectric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Tuấn VũNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- FJ DT VRF S 2pipe 071205 VD002E14-NovoDocument2 pagesFJ DT VRF S 2pipe 071205 VD002E14-NovoSlobodan AnticNo ratings yet

- Design Calculation of Shaft/Pin/Axle: 1.0 Basic DataDocument3 pagesDesign Calculation of Shaft/Pin/Axle: 1.0 Basic DatapkvchoudharyNo ratings yet

- Creep Calculation by Colin Bayliss & Brain HardyDocument1 pageCreep Calculation by Colin Bayliss & Brain HardyVenkatasubramanian Iyer100% (1)

- Tugas 1 Mata Kuliah Elemen Mesin 2 Minggu, 22 September 2019Document4 pagesTugas 1 Mata Kuliah Elemen Mesin 2 Minggu, 22 September 2019sekarayuNo ratings yet

- Weld CalculatorDocument6 pagesWeld Calculatorshahid khanNo ratings yet

- Charcoal Tower Pressure Drop CalculationDocument5 pagesCharcoal Tower Pressure Drop CalculationNalin GujaratiNo ratings yet

- Perhitungan Shaft Pulley ConveyorDocument5 pagesPerhitungan Shaft Pulley ConveyorRiska DamayantiNo ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- Penstock Thickness CaclDocument44 pagesPenstock Thickness CaclAnonymous sfkedkym100% (1)

- Sandy Drifterz, Vcet: Madurai, Tamil NaduDocument15 pagesSandy Drifterz, Vcet: Madurai, Tamil NaduNaveenNo ratings yet

- Hitungan Structure Beban AtapDocument3 pagesHitungan Structure Beban Atapdimas cahyoNo ratings yet

- Tech - Spec.ACSR 95.15Document1 pageTech - Spec.ACSR 95.15Ilir DalipiNo ratings yet

- Shell&Tube TEMAsheet 1Document1 pageShell&Tube TEMAsheet 1Rikiya FebriyanNo ratings yet

- AgitatorDocument6 pagesAgitatorSung Woong MoonNo ratings yet

- Penstock Thickness Cacl.Document44 pagesPenstock Thickness Cacl.Anonymous sfkedkymNo ratings yet

- Agitator CalculationsDocument12 pagesAgitator Calculationspankit mehtaNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- General Data: Bending StessesDocument8 pagesGeneral Data: Bending Stessesprajakt_pieNo ratings yet

- 20 5T PDFDocument3 pages20 5T PDFMUBASHSHIR HELALNo ratings yet

- Load Factor Load: Project:-Location: - Design Code: Designed by DateDocument1 pageLoad Factor Load: Project:-Location: - Design Code: Designed by DateSantosh BapuNo ratings yet

- Carrier 7.5TRDocument2 pagesCarrier 7.5TRbrian mmec2020No ratings yet

- Calculate Scaffolding Inedependent Common TowerTube 4mmDocument4 pagesCalculate Scaffolding Inedependent Common TowerTube 4mmDunya Fildzah100% (1)

- M. Farhan Alfarabi. (4318218004)Document2 pagesM. Farhan Alfarabi. (4318218004)Farhan AlfarabiNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- Steel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectDocument1 pageSteel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectCaspian DattaNo ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDocument2 pagesSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanNo ratings yet

- Slab DesignDocument6 pagesSlab DesignKanchan Raja SinghNo ratings yet

- Shincoil CompressionDocument98 pagesShincoil CompressionVNK90No ratings yet

- Motor Data Sheet 18. KW 4 PoleDocument1 pageMotor Data Sheet 18. KW 4 Poledeepak kumarNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Data Sheet EVMSG15 2N6Q1BEGE 3.0Document7 pagesData Sheet EVMSG15 2N6Q1BEGE 3.0Edilberto Alegato (EPPI)No ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Datasheet LF GZTACSR 420-50 TWDocument1 pageDatasheet LF GZTACSR 420-50 TWTú Trần TuấnNo ratings yet

- Daikin EWAD-DDocument1 pageDaikin EWAD-DsalahcalimeroNo ratings yet

- CATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 DrakeDocument12 pagesCATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 Drakedursun_yerlikaya100% (2)

- Spring Design: GD N PC yDocument2 pagesSpring Design: GD N PC yAshokNo ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- C - 1531 RLDocument11 pagesC - 1531 RLPand AemonaEonNo ratings yet

- 25kW Ac Units PDFDocument1 page25kW Ac Units PDFChrisNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

- Piezo Material Properties Data Sheet 20201112Document1 pagePiezo Material Properties Data Sheet 20201112Trương Anh DuyNo ratings yet

- RAD Product Leaflet 2-3-2011Document32 pagesRAD Product Leaflet 2-3-2011sohan24820% (1)

- Electrical Machine Design: Item NoDocument3 pagesElectrical Machine Design: Item NoJv RodriguezNo ratings yet

- Jis G-3444Document10 pagesJis G-3444Maulana YusufNo ratings yet

- 1MB1553 2DB03 4JB4 Z B02 Datasheet enDocument2 pages1MB1553 2DB03 4JB4 Z B02 Datasheet enadriansya7No ratings yet

- Heat Exchanger Specification SheetDocument4 pagesHeat Exchanger Specification SheetAnita PanthiNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Level Transmitter C To C StatusDocument3 pagesLevel Transmitter C To C StatusTuấn VũNo ratings yet

- Pump SizingDocument31 pagesPump SizingTuấn VũNo ratings yet

- Boiler CalcDocument235 pagesBoiler CalcTuấn VũNo ratings yet

- Curriculum Vitae: Contact InformationDocument4 pagesCurriculum Vitae: Contact InformationTuấn VũNo ratings yet

- Ho Trong Tuong - Automatic Engineer: Fujitsu Computer Products of Vietnam, Inc Equipment EngineerDocument6 pagesHo Trong Tuong - Automatic Engineer: Fujitsu Computer Products of Vietnam, Inc Equipment EngineerTuấn VũNo ratings yet

- Comment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Document2 pagesComment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Tuấn Vũ0% (1)

- Nâng c ấp Windows 7/8.1 lên Win 10 giữ nguyên b ản quyền cũDocument7 pagesNâng c ấp Windows 7/8.1 lên Win 10 giữ nguyên b ản quyền cũTuấn VũNo ratings yet

- 131 AcDocument25 pages131 AcTuấn VũNo ratings yet

- Calculation Pressure Drop For Filter Element: Apsl 8774Document2 pagesCalculation Pressure Drop For Filter Element: Apsl 8774Tuấn VũNo ratings yet

- Maq Fall03 Strategicbudgetingcasestudy PDFDocument10 pagesMaq Fall03 Strategicbudgetingcasestudy PDFYana Aida FitriahNo ratings yet

- VOLVO EC210B FX EC210BFX EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC210B FX EC210BFX EXCAVATOR Service Repair Manual PDFfjjsjekdmme100% (1)

- FX Training Center: Aviation KnowledgeDocument12 pagesFX Training Center: Aviation KnowledgeFahmi PrayogiNo ratings yet

- FMA RegsDocument361 pagesFMA RegsJiong SoonNo ratings yet

- Application of FMEA in An Aluminium Pot Manufacturing IndustryDocument5 pagesApplication of FMEA in An Aluminium Pot Manufacturing IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Abb Weather ProofDocument58 pagesAbb Weather ProofEhsan ShaukatNo ratings yet

- Welcome To The World of Green Building-ParrywareDocument17 pagesWelcome To The World of Green Building-ParrywareShaik ShoebNo ratings yet

- Porta Cabin Tech SpecDocument6 pagesPorta Cabin Tech SpecFARES BEN MESSAOUDNo ratings yet

- 28-0818RA4LIFE Referencesdoc Jan2018Document15 pages28-0818RA4LIFE Referencesdoc Jan2018tuvosipNo ratings yet

- A Power Analysis Toolbox For MATLAB SimulinkDocument6 pagesA Power Analysis Toolbox For MATLAB SimulinkAhmed58seribegawanNo ratings yet

- MNP FlowsDocument6 pagesMNP FlowsSandeep Reddy Vajrala100% (1)

- TDA7449Document21 pagesTDA7449Sambhu Dharmadevan VU3KQFNo ratings yet

- White Paper Business Analysis Center of Excellence v2 2007 PDFDocument17 pagesWhite Paper Business Analysis Center of Excellence v2 2007 PDFtippurajNo ratings yet

- Ebalance A Stata Package For Entropy BalancingDocument18 pagesEbalance A Stata Package For Entropy BalancingGerardo DamianNo ratings yet

- Topographic Map of Metcalf GapDocument1 pageTopographic Map of Metcalf GapHistoricalMapsNo ratings yet

- Manitou SM - ME318 3 Di 4Document65 pagesManitou SM - ME318 3 Di 4mirko coppini100% (2)

- Satellite - Wikipedia, The Free EncyclopediaDocument21 pagesSatellite - Wikipedia, The Free Encyclopediamingt510% (1)

- Mochammad Rafli Rayhan Hidayat - SPWM BIPOLARDocument4 pagesMochammad Rafli Rayhan Hidayat - SPWM BIPOLARrafli rayhanNo ratings yet

- LINSEIS Thermal Conductivity v4 CompressedDocument20 pagesLINSEIS Thermal Conductivity v4 CompressedsayarersNo ratings yet

- Kebutuhan Beton - Update 080922Document1 pageKebutuhan Beton - Update 080922daraNo ratings yet

- ST pk2 A2Document32 pagesST pk2 A2dasdfa serasdNo ratings yet

- Unit 6 - Week 5: Week 05-Assignment 5-Manufacturing Process Technology Part-1Document5 pagesUnit 6 - Week 5: Week 05-Assignment 5-Manufacturing Process Technology Part-1KKNo ratings yet

- 721007-620005-Computer Oriented Numerical MethodsDocument2 pages721007-620005-Computer Oriented Numerical MethodsTijo L PeterNo ratings yet

- IIB WSSecurityDocument65 pagesIIB WSSecuritydiva100% (1)

- GitHub TrainingDocument21 pagesGitHub Trainingcyberfox786No ratings yet

- Manual de OperadorDocument246 pagesManual de OperadorJesus CastilloNo ratings yet

- Profile As A Professional EngineerDocument3 pagesProfile As A Professional EngineerAdnan MunirNo ratings yet

- NEM Declaration Form (TNB Contract)Document2 pagesNEM Declaration Form (TNB Contract)Kian Keong Yee100% (1)

- Zelio Control RM35TF30 PDFDocument3 pagesZelio Control RM35TF30 PDFYamith DavidNo ratings yet

- Google Play Supported Devices - Sheet 1Document193 pagesGoogle Play Supported Devices - Sheet 1Miguel S SNo ratings yet