Professional Documents

Culture Documents

Company Project Sheet No Revision: Section B-B Select Input Unit

Company Project Sheet No Revision: Section B-B Select Input Unit

Uploaded by

Akbar August IndhamaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Company Project Sheet No Revision: Section B-B Select Input Unit

Company Project Sheet No Revision: Section B-B Select Input Unit

Uploaded by

Akbar August IndhamaCopyright:

Available Formats

COMPANY SHEET NO

PROJECT REVISION

SUBJECT PADEYE CHECK DATE 18/09/2014 09:45

COMPUTER CHECKED BY APP. BY

Ref. DWG No. DU400072177_05

Y

Rm P

Ric B

A Roc A

Do

a

0.5(L2+L3)

L1

L2 L3

B

Y

L

Z 4

toc

tic

tm

SECTION B-B

Select input unit mm

Main plate radius Rm : 170.0 mm : 6.7 in

Inner cheeck plate radius Ric : 0.0 mm : 0.0 in

Outter cheeck plate radius Roc : 0.0 mm : 0.0 in

Pin hole diameter Do : 88.0 mm : 3.5 in

Pin diameter Dp : 85.0 mm : 3.3 in

Main plate thickness tm : 80.0 mm : 3.1 in

Inner cheeck plate thickness tic : 0.0 mm : 0.0 in

Outter cheeck plate thickness toc : 0.0 mm : 0.0 in

Length 1 L1 : 120.0 mm : 4.7 in

Length 2 L2 : 321.0 mm : 12.6 in

Length 3 L3 : 170.0 mm : 6.7 in

Length 4 L4 : 491.5 mm : 19.4 in

Material Yield Strength Fy : 345.0 Mpa : 50.0 ksi

Pulling Load P : 293.5 MT : 647.1 kips

Load angle to x-axis a : 60.0 deg

Load angle to z-axis β : 80.0 deg

Safety Factor SF : 1.5

COMPANY SHEET NO

PROJECT REVISION

SUBJECT PADEYE CHECK DATE 18/09/2014 09:45

COMPUTER CHECKED BY APP. BY

2. LOAD CALCULATION

Py Z

P

L2

P

β

a

Px x x

M2

M1

SECTION A-A

L5

Py P

β

Pz

M3

SECTION B-B

Length L5 : L2-0.5(L1+L2) : 4.0 in

Horizontal load phorizontal : SF.p.sin(β).cos(α) : 477.9 kip

Vertical load pvertical : SF.p.sin(β).sin(α) : 827.8 kip

Lateral load plateral : SF.p.cos(β).cos(α) : 84.3 kip

Moment 1 M1 : L1.phorizontal : 1528.5 kip.in

Moment 2 M2 : L5.pvertical : -2217.2 kip.in

Moment 3 M3 : L4.plateral : 1630.6 kip.in

COMPANY SHEET NO

PROJECT REVISION

SUBJECT PADEYE CHECK DATE 18/09/2014 09:45

COMPUTER CHECKED BY APP. BY

3. MAIN PLATE CHECK

Section Properties

Area A : (L2+L3) tm : 60.9 in2

3

Inertia x Ix : tm (L2+L3)/12 : 45.2 in4

Inertia z Iz : (L2+L3)3 tm/12 : 1895.9 in4

Section modulus x Sx : Ix / (0.5 tm) : 28.7 in3

Section modulus z Sz : Ix / (0.5(L2+L3)) : 196.2 in3

Working Stresses

Bending stress x fbx : M3/Sx : 56.8 ksi

Bending stress z fbz : (M1+M2)/Sz : -3.5 ksi

Shear stress fv : 3Phorizontal/2A : 11.8 ksi

Axial stress ft : Pvertical/A : 13.6 ksi

Allowable Stresses

Allowable shear stress Fv : 0.4 Fy : 20.0 ksi

Allowable tension stress Ft : 0.6 Fy : 30.0 ksi

Allowable bending stress-x Fbx : 0.6 Fy : 30.0 ksi

Allowable bending stress-z Fbz : 0.6 Fy : 30.0 ksi

Stress Ratios

Shear stress ratio SR-t : fv / Fv : 0.588 → OK!

Tension stress ratio SR-t : ft / Ft : 0.679 → OK!

In-plane bending stress ratio SR-bx : fbx / Fb : 1.892 → FAIL

Out-plane bending stress ratio SR-bz : fbz / Fb : -0.117 → OK!

Combined tension and bending S.RSR-c : SR-t + SR-bx + SR-bz : 2.454 → FAIL

4. PIN BEARING CHECK

Bearing area Ab : 0.75 Dp (tm+tic+toc) : 7.9 in2

Bearing stress fb : p SF / Ab : 122.8 ksi

Allowable bearing stress Fb : 0.9 Fy : 45.0 ksi

Bearing stress ration SR-b : fb / Fb : 2.726 → OK!!

5. EYE SHEAR CAPACITY

Shear failure

Tension failure

SECTION A-A

36.70407 : 13.4 0

31.24806

Length 6 L6 : assumed = 2Rm : 13.4 in

Shear area Av1 : 2 (tm(Rm-0.5Do) + 2tic(Ric-0.5Do) + 2toc(Roc-0.5Do)) : 31.2 in2

Tension failure surfaces At1 : tm(L6-Do) + 2(2tic(Ric-0.5Do) + 2toc(Roc-0.5Do)) : 31.2 in2

Shear stress fv : p SF / Av : 31.1 ksi

Tension stress ft : p SF / At : 31.1 ksi

Allowable shear stress Fv : 0.4 Fy : 20.0 ksi

Allowable tension stress Fv : 0.45 Fy : 22.5 ksi

Shear stress ratio SR : fv / Fv : 1.6 → OK!!

Tension stress ratio SR : ft / Ft : 1.4 → OK!!

COMPANY SHEET NO

PROJECT REVISION

SUBJECT PADEYE CHECK DATE 18/09/2014 09:45

COMPUTER CHECKED BY APP. BY

6. CHEECK PLATE PULL OUT CAPACITY

Shear failure

Tension failure

Tension failure length L7 : Pi Ric : 0.0 in

Tension failure length L8 : 2(Rm2 + Ric2)0.5 : 13.4 in

Tensile area At2 : L7 tm : 0.0 in2

Shear area Av2 : L8 tm : 42.2 in3

Allowable tensile stress Ft : 0.6 Fy : 30.0 ksi

Allowable shear stress Fv : 0.4 Fy : 20.0 ksi

Allowable load Fp : Ft At2 + Fv Av2 : 843.8 kip

Pulling Load fp : p SF : 970.6 kip

Pullout stress ratio SR : fp / Fp : 1.2 → OK!!

You might also like

- Wistron Raichu - SR 18762 R-1 2Document106 pagesWistron Raichu - SR 18762 R-1 2Muhammad MajidNo ratings yet

- JCB803 PDFDocument2 pagesJCB803 PDFEdmundas Žemaitis100% (1)

- Polypak SealDocument2 pagesPolypak SealZAMFERLENONo ratings yet

- Chiller v10 2018-10-17Document8 pagesChiller v10 2018-10-17Van SonNo ratings yet

- Ac Bridges PDFDocument5 pagesAc Bridges PDFPiara SinghNo ratings yet

- Opampper1019 LRDocument40 pagesOpampper1019 LRBeto YoshidaNo ratings yet

- Pad Eye New ReleaseDocument10 pagesPad Eye New ReleaseEnrique BarajasNo ratings yet

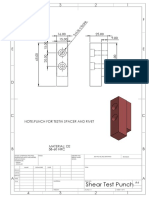

- Shear Test PunchDocument1 pageShear Test PunchMohammad GhousuddinNo ratings yet

- Revision History: Schematics IndexDocument16 pagesRevision History: Schematics IndexCarlos Ramirez GraweNo ratings yet

- Revision History: Schematics IndexDocument15 pagesRevision History: Schematics IndexMarcello AlmeidaNo ratings yet

- OrangePi OnePlus Schematics v2.0Document13 pagesOrangePi OnePlus Schematics v2.0Ernesto Montera jr.No ratings yet

- Calculation Serbaraja 3Document6 pagesCalculation Serbaraja 3Nurfandi DewantoNo ratings yet

- 03 01 05 PDFDocument1 page03 01 05 PDFKR123No ratings yet

- Input Data: Project Usan Deep Water Attachment XXXXXX To Calculation Note Ref. Yyyyyyyyy Rev. ZZDocument5 pagesInput Data: Project Usan Deep Water Attachment XXXXXX To Calculation Note Ref. Yyyyyyyyy Rev. ZZcatullusNo ratings yet

- Orange Pi Zero v1 11Document12 pagesOrange Pi Zero v1 11JederVieiraNo ratings yet

- CEN TOOL Standard Padeyes V4 Rollup Padeye SheaveDocument5 pagesCEN TOOL Standard Padeyes V4 Rollup Padeye SheaveMarvan100% (1)

- Job Information: Engineer Checked ApprovedDocument8 pagesJob Information: Engineer Checked ApprovedBagus Prasetya0% (1)

- SIP DirencDocument3 pagesSIP DirencMustapha DemirNo ratings yet

- Datasheet - Uni JCB YDocument2 pagesDatasheet - Uni JCB YYeisonNo ratings yet

- Locator Pin BDocument1 pageLocator Pin BMangesh KetkarNo ratings yet

- Job Information: Engineer Checked ApprovedDocument12 pagesJob Information: Engineer Checked Approvedhadeer younsNo ratings yet

- Lateral Tee 16'' Sch. 20 With Reinforcement Rev. 02 PDFDocument1 pageLateral Tee 16'' Sch. 20 With Reinforcement Rev. 02 PDFHarryNo ratings yet

- OrangePi Lite2 Schematics v2.0Document14 pagesOrangePi Lite2 Schematics v2.0Yuber RaptorazorNo ratings yet

- Fit-Up Piping B192-5-S2Document22 pagesFit-Up Piping B192-5-S2Prathamesh OmtechNo ratings yet

- PANASONIC CApacitor PDFDocument2 pagesPANASONIC CApacitor PDFLuisNo ratings yet

- C-Hvcoimbr6pf706lxxxx Rev 3Document2 pagesC-Hvcoimbr6pf706lxxxx Rev 3Денис ТимофеевNo ratings yet

- Aubo I10 Brochure 2019 PDFDocument6 pagesAubo I10 Brochure 2019 PDFMiro Mirach PremrlNo ratings yet

- P45-69Z V3.0 Schematic DiagramDocument10 pagesP45-69Z V3.0 Schematic DiagramAhmed El SharkawyNo ratings yet

- NIC Components NPIS - PDocument4 pagesNIC Components NPIS - PNICCompNo ratings yet

- CCNA NoteDocument127 pagesCCNA Notekareng nawNo ratings yet

- Joists With Hole PD6693Document2 pagesJoists With Hole PD6693David O'MearaNo ratings yet

- Dell Alienwarem r2 Compal Edq51 La h351p La f552p La f553p 1 0 Xa00Document109 pagesDell Alienwarem r2 Compal Edq51 La h351p La f552p La f553p 1 0 Xa00013azizNo ratings yet

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 pagesCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNo ratings yet

- Zangovye Patrony Er CatDocument2 pagesZangovye Patrony Er CatAnonymous XuL8i8QNo ratings yet

- Solu HWset 9Document16 pagesSolu HWset 9AmalinaNo ratings yet

- Prociple Scheme LKSN 2022Document1 pageProciple Scheme LKSN 2022KeznaPlayzNo ratings yet

- HMC7P : SpecificationsDocument1 pageHMC7P : SpecificationsjohnNo ratings yet

- Orange Pi-Pc v1 2-PrintDocument14 pagesOrange Pi-Pc v1 2-Printmaicuongdt2No ratings yet

- TERMINAL LUG - Comply With IEC61238-1: Copper Cables OnlyDocument4 pagesTERMINAL LUG - Comply With IEC61238-1: Copper Cables OnlyJustice KNo ratings yet

- XSV Calc V17ADocument2 pagesXSV Calc V17AMuntaser YousifNo ratings yet

- Orange Pi-One-V1 1Document15 pagesOrange Pi-One-V1 1jafobr4152No ratings yet

- Description Dimension Material Standard Cut Ns Len. Q'TY. Len. RADocument1 pageDescription Dimension Material Standard Cut Ns Len. Q'TY. Len. RAmạnh nguyễnNo ratings yet

- c21l MB SCH VC 0314 SMTDocument47 pagesc21l MB SCH VC 0314 SMTMario Rodriguez Jurado0% (1)

- Calculo de AceroDocument1 pageCalculo de AceroChecoValenciaNo ratings yet

- Curved EdgeDocument1 pageCurved EdgeMohit NarwatNo ratings yet

- Assem 2Document1 pageAssem 2Muhammed FikiNo ratings yet

- Document 7Document33 pagesDocument 7Cristhian HANo ratings yet

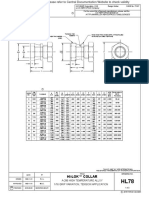

- HL78Document2 pagesHL78Renato WatanabeNo ratings yet

- Drawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDocument2 pagesDrawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDylanLiNo ratings yet

- CD CM OverridesDocument51 pagesCD CM OverridesSai SushankNo ratings yet

- NanoPi NEO 1606 SchematicDocument11 pagesNanoPi NEO 1606 SchematicNikolayVinnikNo ratings yet

- Digital Tilt Sensor SCH PDFDocument2 pagesDigital Tilt Sensor SCH PDFRafael Pereira AzevedoNo ratings yet

- Job No Sheet No RevDocument1 pageJob No Sheet No RevAngelNo ratings yet

- Sandwich Plates Nominal Size 16: Porting Pattern To DIN 24 340 Form A ISO 4401and CETOP-RP 121 HDocument26 pagesSandwich Plates Nominal Size 16: Porting Pattern To DIN 24 340 Form A ISO 4401and CETOP-RP 121 HAshaNo ratings yet

- Job Information: Job No Sheet No RevDocument15 pagesJob Information: Job No Sheet No RevRommel AzoresNo ratings yet

- RPM Elektronik Asansör Ltd. ŞtiDocument12 pagesRPM Elektronik Asansör Ltd. ŞtisundarNo ratings yet

- Dell 13-7370 7570 7373 7573 Kylo Ren 13 Y5HR3 16839-1 REV-1Document106 pagesDell 13-7370 7570 7373 7573 Kylo Ren 13 Y5HR3 16839-1 REV-1Carlos MarceloNo ratings yet

- ETABS 2016 16.0.2 - Print View - Typical Concrete Beam Elevation 3SDocument1 pageETABS 2016 16.0.2 - Print View - Typical Concrete Beam Elevation 3Sعبدالحكيم عبدالوهابNo ratings yet

- Analysis of The Double AIO Devices With Poles 25cm Dia.Document15 pagesAnalysis of The Double AIO Devices With Poles 25cm Dia.Civil Engineering worldNo ratings yet