Professional Documents

Culture Documents

16 - Electronics Level 3 - 2018

16 - Electronics Level 3 - 2018

Uploaded by

Nikhil ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16 - Electronics Level 3 - 2018

16 - Electronics Level 3 - 2018

Uploaded by

Nikhil ShahCopyright:

Available Formats

Sample Test Project

Regional Skill Competition – Level 3

Skill 16– Electronics

Category: Manufacturing and Engineering Technology

Version 3 – May 2018 Skill – Electronics 1

Table of Contents

A. Preface .............................................................................................................................3

B. Test Project .....................................................................................................................4

C. Marking Scheme..............................................................................................................6

D. Infrastructure List ...........................................................................................................9

E. Instructions for candidates ..........................................................................................10

F. Health, Safety, and Environment ..................................................................................11

Version 3 – May 2018 Skill – Electronics 2

Section - A

A. Preface

Skill Explained:

The electronics industry is very diverse and has evolved into several specialisms. Some

technicians/engineers will work across many aspects of electronics, but increasing specialization

and technical developments means that specialist technician/engineers are widely employed. The

key areas of specialism which can be seen as careers in their own right include Designing of

prototype circuits to specifications. Developing and designing PCB for the given circuit. The

assembly of electronic component on PCB, testing, provision of customer support, service and

maintenance.

The electronics specialist will work with a wide range of tools, specialist hi-tech equipment and

materials. Increasingly, computers and specialist software for communications technology is

embedded into the work. In addition, tasks will also require the use of specialist hand tools for the

assembly and maintenance of circuits and surface mounted technology.

Eligibility Criteria (for IndiaSkills 2018 and WorldSkills 2019):

Competitors born on or after 01 Jan 1997 are only eligible to attend the Competition.

Total Duration: 12 Hrs

Version 3 – May 2018 Skill – Electronics 3

Section - B

B. Test Project

Task A – BLOCK DIGRAM AND SCHEMATIC DESIGN

Smoke Detector using MQ2 Gas Sensor and Arduino.

Competitor Instruction Sheet

You have 180 Minutes (3 hrs) to complete this task

You are to complete designs, keep in the mind the following observations

1. Please complete the design according to the following requirements.

2. Use only the component from the part list of your designs.

3. You may not need all components in the parts list.

4. You can start using PCB design only after submitting the paper schematic.

Competitors can read component data sheet that is provided with only personal computer which

contains data sheet pack. The hard copies brought by competitor can’t be used, but competitors

can read the hard copies provided with competition organizer.

When you have completed your designs you are to submit to the Expert. You will then be given

the schematic solution for schematic entry into PCB design software. You cannot start your PCB

design in this phase of the Test Project.

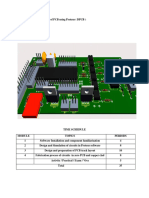

Task B – Designing of Printed Circuit Board

Competitor Instruction Sheet

You have 240 Minutes (4 hrs) to complete this task

1. Design printed circuit board using PCB design software tool with simulation output.

2. Prepare the PCB design as per specified position of components in shown figures.

3. Complete the design, save PCB Gerber files in the pen drive.

4. Create a BOM, containing all information for your schematic design.

5. Create a pdf files as requested in the statement.

6. Prepare a 3D-visulizer copy as shown in Fig.

7. Follow the rules as specified in the statement.

NOTE: Submit the following PCB Gerber files to the experts in the USB sticks.

Top layer

Bottom Layer

Version 3 – May 2018 Skill – Electronics 4

Keep Out Layer (Dimension)

NC Drill File

Submit the following files as *.pdf Data

All schematics

PCB Top Layer routing/split plain

PCB Bottom Layer routing/split plain

Component Placement Side & 3D-picture.

PCB should be double side PCB.

Task C – Build and Test Hardware design project on the given PCB.

Competitor Instruction Sheet

You have 240 Minutes to complete this task.

1. Assemble PCB, calibrate and check its operation.

2. Place and solder the components at appropriate place.

3. Record and note the input and output voltages with given load.

4. Completing the project, submit all the product and documents.

NOTE: submit all the assembled PCB, with all the left-over components & Tools.

Task D – Answer the questions related to this project (MCQ)

You have 60 Minutes to complete this task

Re Check the circuit and answer the given questions.

Note: Answer sheet provided for writing the answer.

Version 3 – May 2018 Skill – Electronics 5

Section – C

C. Marking Scheme

The Assessment is done by awarding points by adopting two methods, Measurement and Judgments

• Measurement – One which is measurable

• Judgments – Based on Industry expectations

• Aspects are criteria’s which are judged for assessment

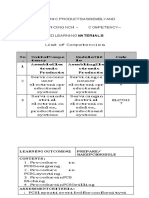

Block Diagram & Schematic Design:

Aspect Mark

Marking Criteria or Description Requirement Max Mark

ID Awarded

For both the

1.1 Block diagram 2

section.

1.2 Circuit diagram 3

1.3 Connections from Arduino board 2

1.4 Connections to 16x2 LCD 2

1.5 Power supply points 3

1.6 Identification &connection to MCU 2

1.7 Identification of components. 1

1.8 Placement of component on the schematics 2

1.9 Connection to component 1

1.10 Neatness in drawing schematic diagram 2

Total Marks 20

Designing of Printed Circuit Board

Mark

Aspect Max

Marking Criteria or Description Requirement Awarde

ID Mark

d

1.1 Schematic on PCB design software 2

1.2 Understanding schematic tools 2

1.3 Component Positioning schematic 3

1.4 Component Positioning on schematics. 3

1.5 Understanding on PCB layout operation 2

1.6 Component organization on PCB layout software. 2

Version 3 – May 2018 Skill – Electronics 6

1.7 PCB Design Quality: Difference in the track widths 2

1.8 PCB file generation & pdf files 2

1.9 PCB layout and Component Positioning 2

1.10 PCB layout and Component Positioning of sensor 2

1.11 PCB layout and Component Positioning of MCU 2

1.12 PCB routing as per IPC standards. 2

1.13 Simulation output. 2

1.14 Overall design flow. 2

30

Total

Build and Test Hardware design project on the given PCB.

Mark

Aspect Max

Marking Criteria or Description Requirement Awarde

ID Mark

d

1.1 The application of electronic principles 2

1.2 Component Forming 2

1.3 Component Placement 2

1.4 Component Soldering Quality 2

1.5 Component Orientation 2

Design without any correction (no cutting of

1.6 2

tracks or rewiring.

1.7 Assembled quality 2

1.8 Functionality/Operation Check 2

Functionality/Operation Check

1.9 2

Operating condition

1.10 Measurement tools used in electronic assembly 3

The purposes and functions of components to

1.11 2

fulfil required tasks

1.12 Proper tools used for soldering. 2

1.13 Cleaning and neatness’. 2

1.14 Overall design output. 3

Total : 30

Version 3 – May 2018 Skill – Electronics 7

Answer the questions related to this project (MCQ)

Aspect Max Mark

Marking Criteria or Description Requirement

ID Mark Awarded

Safe working practices adhered to

1.1 1

throughout task

1.2 MCQ 18

1.3 Task completed in allocated time. 1

Total Marks 20

Version 3 – May 2018 Skill – Electronics 8

Section - D

D. Infrastructure List

• Infrastructure List (Tool and equipment including raw material)

• The quantity is given for each candidate

S. Item Requirements/Specification Qty

No.

1 Workbench 2’x3’ 2

2 Soldering iron 25 W 1

3 Soldering iron stand Metal 1

4 Solder wire 0.6/0.7/0.8mm 100gm

5 Magnifying glass Hand/table mounted 1

6 Calculator Scientific 1

7 Desktop/Laptop with PCB I3,4gb,500gb HDD or higher 1

designing & simulation

software.

8 Printer Deskjet/LaserJet 1

9 Electronics components As per specified in the task 1 set.

10 Multimeter Digital 3 ½ digit 1

11 Paper A4 Size 6

12 Pen/Pencil/Eraser Blue/HB 2

13 Power Supply Digital Power supply 3-15V/5A 1

14 Power Socket AC socket 3

15 ESD Mat 2’x3’ 2

16 ESD point Grounding point 2

17 ESD wrist Band ESD compliance 1

18 Cleaning brush 1

19 Cleaning solution PCB cleaner 100 ml.

20 Cutting and Bending tool Cutting plier, tweezer, and nose plier. 1 set.

set.

21 Screw driver set Assorted 1set.

Version 3 – May 2018 Skill – Electronics 9

Section – E

E. Instructions for candidates

• All Competitors must use safety glasses when using any hand, power, or machine tools or

• Equipment likely to cause or create chips or fragments that may injure the eyes

• Experts will use the appropriate personal safety equipment when inspecting, checking, or

working with a Competitor's project.

• The documentation ‘Safety and Fairness’ will be prepared by the Experts;

• The Competitor must comply with the machine manufacturer’s safety instructions.

• All individuals must have Electrostatic Discharge (ESD) awareness and use ESD straps

when working with components/circuits.

• All individuals must wear eye protection while soldering or cutting components. It is

recommended that shoes have closed toes and be ESD safe

Version 3 – May 2018 Skill – Electronics 10

Section – F

F. Health, Safety, and Environment

1. All accredited participants, and supporting volunteers will abide by rules and

regulations with regards to Health, Safety, and Environment of the Competition venue.

2. All participants, technicians and supporting staff will wear the required protective

Personnel clothing.

3. All participants will assume liability for all risks of injury and damage to property, loss

of property, which might be associated with or result from participation in the event.

The organizers will not be liable for any damage, however in case of Injury the

competitor will immediately inform the immediate organizer for medical attention.

Version 2 – March 2018 Skill- Electronics 11

You might also like

- LED Matrix Display Project ReportDocument81 pagesLED Matrix Display Project ReportAmar Shrestha81% (16)

- Assignment 2 Unit 19Document4 pagesAssignment 2 Unit 19maysNo ratings yet

- Course Code: 4361103: Page 1 of 8Document8 pagesCourse Code: 4361103: Page 1 of 8rashmin tannaNo ratings yet

- Electrical AplicationDocument11 pagesElectrical AplicationAbah DudiNo ratings yet

- University of Namibia Digital Electronics 2019 Laboratory Experiment 2: Seven Segment Decoder Design 1 ObjectiveDocument1 pageUniversity of Namibia Digital Electronics 2019 Laboratory Experiment 2: Seven Segment Decoder Design 1 ObjectivetuyaNo ratings yet

- Olympus Rover Trials CDR Template 2021Document47 pagesOlympus Rover Trials CDR Template 2021nived hareeshNo ratings yet

- Expt 9Document4 pagesExpt 9Amogha kantakNo ratings yet

- Drawing Drafting Standard V2Document28 pagesDrawing Drafting Standard V2yodtosheetdigiNo ratings yet

- Sample Test Project: District / Zonal Skill Competitions Category: Manufacturing & Engineering TechnologyDocument15 pagesSample Test Project: District / Zonal Skill Competitions Category: Manufacturing & Engineering TechnologyVISHNU KUMARNo ratings yet

- ELX-311-MODULE-1 Introduction To ECADDocument4 pagesELX-311-MODULE-1 Introduction To ECADErvert SoteraniaNo ratings yet

- WSMB2022 - TP Final Esp - Electronics - V2Document25 pagesWSMB2022 - TP Final Esp - Electronics - V2Abd Rahim KasimanNo ratings yet

- DEPANEL OFFLINE VERIFIER Version Nov 6Document31 pagesDEPANEL OFFLINE VERIFIER Version Nov 6ClintNo ratings yet

- Engr2105 ProjectDocument6 pagesEngr2105 ProjectSUPER AMAZINGNo ratings yet

- About Company: 1.1 HistoryDocument45 pagesAbout Company: 1.1 Historynambratha BNo ratings yet

- Eshan Rao - 19ETEC004016 (EBD)Document12 pagesEshan Rao - 19ETEC004016 (EBD)eshanraoNo ratings yet

- Department of Computer Science and Engineering CSE 251 Electronic Circuits (Course Project)Document2 pagesDepartment of Computer Science and Engineering CSE 251 Electronic Circuits (Course Project)Minhaz AhmedNo ratings yet

- ESD-Ch5 2022Document44 pagesESD-Ch5 2022Tú Phan Lê TuấnNo ratings yet

- By Ethan Byrd Suneil Hosmane: Led Matrix ControllerDocument25 pagesBy Ethan Byrd Suneil Hosmane: Led Matrix ControllerBibhu Prasad PandaNo ratings yet

- Autodesk Autocad Electrical Training: IntroductonDocument5 pagesAutodesk Autocad Electrical Training: Introductonsanjay mishraNo ratings yet

- ESD Ch2Document73 pagesESD Ch2Khánh QuốcNo ratings yet

- PCB To Schematic Diagram - Printed Circuit Board Manufacturing & PCB Assembly - RayMingDocument16 pagesPCB To Schematic Diagram - Printed Circuit Board Manufacturing & PCB Assembly - RayMing1soundsteelNo ratings yet

- Job Profile Chart (JPC) : Competency Competency UnitDocument12 pagesJob Profile Chart (JPC) : Competency Competency UnitMohamad SallihinNo ratings yet

- Ee 492 Final ReportDocument36 pagesEe 492 Final Reportapi-532525398No ratings yet

- Parul-Circuit & PCB01052017 PDFDocument6 pagesParul-Circuit & PCB01052017 PDFAntuNo ratings yet

- LED Matrix Display Project ReportDocument81 pagesLED Matrix Display Project ReportIonicNo ratings yet

- ESD-Ch2 2019Document47 pagesESD-Ch2 2019Lee NguyễnNo ratings yet

- ESD-Ch5 2016 PDFDocument44 pagesESD-Ch5 2016 PDFngoc an nguyenNo ratings yet

- Activity 1 Group 9Document16 pagesActivity 1 Group 9RUEL ALEJANDRONo ratings yet

- Physical Design Implementation of 32bit RISC Processor Using Synopsys ICC Primetime & StarRC XTDocument6 pagesPhysical Design Implementation of 32bit RISC Processor Using Synopsys ICC Primetime & StarRC XTFeroz AhmedNo ratings yet

- IT5103 Graphics Gaming TechnologiesDocument8 pagesIT5103 Graphics Gaming TechnologiesIT2025Chinmay KamlaskarNo ratings yet

- Thesis 082238FDocument73 pagesThesis 082238Fsreedhar_vkNo ratings yet

- BCA - 404-B Theory Assignment - Computer GraphicsDocument1 pageBCA - 404-B Theory Assignment - Computer GraphicsShubhamNo ratings yet

- Camd 3331906 PDFDocument7 pagesCamd 3331906 PDFjayyadavvpcNo ratings yet

- A Tutorial On PCB DesignDocument49 pagesA Tutorial On PCB DesignXiaoguang LiuNo ratings yet

- Unit3 - PPT - CSBS COA-1Document62 pagesUnit3 - PPT - CSBS COA-1mayankrajput13626No ratings yet

- LDR ReportDocument20 pagesLDR Reportvasanthimraju82No ratings yet

- EPAS10ADocument58 pagesEPAS10APaul MonroidNo ratings yet

- Eshan Rao - 19ETEC004016 (ES and IOT)Document11 pagesEshan Rao - 19ETEC004016 (ES and IOT)eshanraoNo ratings yet

- Autocad Electrical Course OutlineDocument7 pagesAutocad Electrical Course OutlineAddisu TsehayNo ratings yet

- Creating Value Through TestDocument6 pagesCreating Value Through Testjonjon10871No ratings yet

- Automatic PCB Defect Detection Using Image ProcessingDocument4 pagesAutomatic PCB Defect Detection Using Image ProcessingIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- S4 & S5-EEE-Designing of PCB Using Proteus - FinalDocument4 pagesS4 & S5-EEE-Designing of PCB Using Proteus - FinalSaif HassanNo ratings yet

- 2038 Engg Graphics Using CADDDocument32 pages2038 Engg Graphics Using CADDalwingracious02No ratings yet

- Exercise 5 - PCB Layout (21-22)Document3 pagesExercise 5 - PCB Layout (21-22)Siegrique Ceasar A. JalwinNo ratings yet

- Electronic Products Assembly and Servicing Ncii Competency-Based Learning Materials List of CompetenciesDocument35 pagesElectronic Products Assembly and Servicing Ncii Competency-Based Learning Materials List of CompetenciesLcst UrdanetaNo ratings yet

- N217 DocumentationDocument108 pagesN217 DocumentationSyed MohiuddinNo ratings yet

- Lin Bus Based Data Acquisition and Control System Using PsocDocument47 pagesLin Bus Based Data Acquisition and Control System Using PsocMani KandanNo ratings yet

- Pcblabedp2 PDFDocument51 pagesPcblabedp2 PDFBinh Phan TranNo ratings yet

- A Basic Introduction For Designing A Printed Circuit Board (PCB)Document11 pagesA Basic Introduction For Designing A Printed Circuit Board (PCB)pcbcircuit3No ratings yet

- AVR® Microcontroller Hardware Design ConsiderationsDocument26 pagesAVR® Microcontroller Hardware Design Considerationslumix345-web1802No ratings yet

- CH 2Document11 pagesCH 2DƯƠNG NGUYỄN THÁI BÌNHNo ratings yet

- Unit 46 Assignment Embedded SystemsDocument7 pagesUnit 46 Assignment Embedded SystemsHeba AzizNo ratings yet

- Calculation 3DG-E34E General Information About Calculation On Electrical SystemDocument23 pagesCalculation 3DG-E34E General Information About Calculation On Electrical Systemmohammadkassar100% (1)

- A Project Report OnDocument84 pagesA Project Report OnyaminiNo ratings yet

- PCB - Design Guidlines PDFDocument31 pagesPCB - Design Guidlines PDFAbdul MajeedNo ratings yet

- PCB Designing Using OrCAD CaptureDocument35 pagesPCB Designing Using OrCAD CaptureGECM85No ratings yet

- Skill Lab Report Group-B (HK)Document12 pagesSkill Lab Report Group-B (HK)Harsh KumarNo ratings yet

- C Programming for the Pc the Mac and the Arduino Microcontroller SystemFrom EverandC Programming for the Pc the Mac and the Arduino Microcontroller SystemNo ratings yet

- Workshope On Arduino21Document17 pagesWorkshope On Arduino21Nikhil ShahNo ratings yet

- Pressure Control WorkbenchDocument3 pagesPressure Control WorkbenchNikhil ShahNo ratings yet

- Multi PLC Workbench Scientech 2482Document6 pagesMulti PLC Workbench Scientech 2482Nikhil ShahNo ratings yet

- 2458 ManDocument31 pages2458 ManNikhil ShahNo ratings yet

- Supervisory Control and Data Acquisition (SCADA) : FeaturesDocument2 pagesSupervisory Control and Data Acquisition (SCADA) : FeaturesNikhil ShahNo ratings yet

- Scientech 2453: Features Technical SpecificationsDocument1 pageScientech 2453: Features Technical SpecificationsNikhil ShahNo ratings yet

- Iplc GatewayDocument2 pagesIplc GatewayNikhil ShahNo ratings yet

- Design of A Low-Power Low-Cost UHF RFID Reader ModDocument10 pagesDesign of A Low-Power Low-Cost UHF RFID Reader ModNikhil ShahNo ratings yet

- Hbe-Robonova Ai 3: High-Speed Stand-Alone Embedded System Mounted Intelligent Biped RobotDocument6 pagesHbe-Robonova Ai 3: High-Speed Stand-Alone Embedded System Mounted Intelligent Biped RobotNikhil ShahNo ratings yet

- Crisp Ext 4401 Sep29Document1 pageCrisp Ext 4401 Sep29Nikhil ShahNo ratings yet

- Offer Form With List of Procurement For: Laboratory / Department: Electronics & EmbeddedDocument3 pagesOffer Form With List of Procurement For: Laboratory / Department: Electronics & EmbeddedNikhil ShahNo ratings yet

- HDFC Loan Application FormDocument4 pagesHDFC Loan Application FormNikhil ShahNo ratings yet

- 8051 03days Workshop TimetableDocument1 page8051 03days Workshop TimetableNikhil ShahNo ratings yet

- Memory Foam Technical DetailDocument4 pagesMemory Foam Technical DetailshahruchirNo ratings yet

- Nortel PBX Cheat SheetDocument13 pagesNortel PBX Cheat SheetRahul Saini100% (1)

- Planning AND Materiali TY: Subject: Basic Audit Lecturers: Nguyen Thi Mai HuongDocument53 pagesPlanning AND Materiali TY: Subject: Basic Audit Lecturers: Nguyen Thi Mai HuongMạnh hưng Lê100% (1)

- Initio 2009 RoadmapDocument9 pagesInitio 2009 RoadmapStefan DimitrovNo ratings yet

- Sensitivity AnalysisDocument10 pagesSensitivity AnalysisMORSHEDNo ratings yet

- ISE II Sample Paper 4 (With Answers)Document13 pagesISE II Sample Paper 4 (With Answers)Marta Navarro LópezNo ratings yet

- RITI HRM Diploma Handouts - Full VersionDocument246 pagesRITI HRM Diploma Handouts - Full Versionmohammed barghothiNo ratings yet

- SAP - MM Introduction & Enterprise StructureDocument40 pagesSAP - MM Introduction & Enterprise Structuresruthimannam28No ratings yet

- Web Technologies Black BookDocument2 pagesWeb Technologies Black BookZaid ShaikhNo ratings yet

- Sis 2.0Document27 pagesSis 2.0mahmodNo ratings yet

- Mad 1Document7 pagesMad 1abbcs8544No ratings yet

- University of Zakho College of Engineering Petroleum DepartmentDocument8 pagesUniversity of Zakho College of Engineering Petroleum DepartmentNazeer AlyasNo ratings yet

- POETSPoster Aircraft 3Document2 pagesPOETSPoster Aircraft 3Khương Lê DuyNo ratings yet

- Fundamentals of Early LiteracyDocument21 pagesFundamentals of Early LiteracyJay-Ar Ricafranca MitraNo ratings yet

- TOPIC 3 - Customer ServiceDocument24 pagesTOPIC 3 - Customer ServiceLê Tú NgọcNo ratings yet

- ADB Annual Report 1999Document317 pagesADB Annual Report 1999Asian Development BankNo ratings yet

- Itp For SanitaryDocument4 pagesItp For SanitaryDebesh Chaudhary100% (2)

- How To Avoid Negative Float in P6 Time ScheduleDocument2 pagesHow To Avoid Negative Float in P6 Time SchedulevouphNo ratings yet

- Happiness Rats (STUDENT)Document2 pagesHappiness Rats (STUDENT)bieliqpl112No ratings yet

- Strama Quiz 4Document5 pagesStrama Quiz 4Norhel FangedNo ratings yet

- Additions Basic Salary Fixed Allowance Days AttendedDocument3 pagesAdditions Basic Salary Fixed Allowance Days AttendedThiyagaraja ThilackshanNo ratings yet

- Virgin America Brand GuidelinesDocument32 pagesVirgin America Brand Guidelinesnicoagudelo82No ratings yet

- ARCH 113 Graphics 2: Research No. 1 "Architectural Lettering"Document6 pagesARCH 113 Graphics 2: Research No. 1 "Architectural Lettering"Keisha Pearl Jaime Silla0% (1)

- Limits, Fits and TolerancesDocument17 pagesLimits, Fits and TolerancesSarswati SuryawanshiNo ratings yet

- The Role of SAI in Combating CorruptionDocument21 pagesThe Role of SAI in Combating CorruptionAdem SylejmaniNo ratings yet

- 21st Century Literature From The Philippines and The World 1.1Document4 pages21st Century Literature From The Philippines and The World 1.1Kiefer SebastianNo ratings yet

- Malaysia ReportDocument136 pagesMalaysia ReportKhashayar NarooeiNo ratings yet

- WEG Regulador Automatico de Tension Wrga 02 10001284080 Manual EspanolDocument97 pagesWEG Regulador Automatico de Tension Wrga 02 10001284080 Manual EspanolEstalin Ochoa100% (1)

- External Assessment:: A Framework For Organizational StrategizingDocument31 pagesExternal Assessment:: A Framework For Organizational StrategizingMelai NfmbjNo ratings yet

- Stuart Goldsmith - Do You Have Enough AlreadyDocument8 pagesStuart Goldsmith - Do You Have Enough AlreadyJesuisquelquundebienNo ratings yet