Professional Documents

Culture Documents

Oumf With Intro and Cover

Oumf With Intro and Cover

Uploaded by

api-291218440Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oumf With Intro and Cover

Oumf With Intro and Cover

Uploaded by

api-291218440Copyright:

Available Formats

Technology

Issue 16 UK £6.99 USA $12.00

Today's technology in yesterday's cars

McRae Subaru

Getting Colin’s iconic Impreza WRC back onto the stages

PLUS

Re-creating

the Triumph SLR

Students’ farmyard innovation

‘RUBBER DUCK’ READY TO FLY

14

16

16

9 772055 593004

Austin Seven restoration examined

INTRODUCTION 5

EDITOR

William Kimberley

Encouraging

young

ASSISTANT EDITOR

Alan Stoddart

engineers

CONTRIBUTORS

Chris Pickering

Hal Ridge

CONSULTANT EDITOR

T

Mark Skewis

HERE is no doubt that historic Student and Formula SAE, of course,

HEAD OF DIGITAL CONTENT

motor racing is on an upswing which are tremendous, but just a fraction

Sara Kimberley

providing many companies of the students get involved.

ART EDITOR which specialise in the restoration As featured in this issue, the Oxford

Paul Bullock and preparation of such cars with an Universities Motorsport Foundation

ADVERTISING MANAGER enormous amount of work. However, provides just such a hands-on

Mike Norman there are one or two small clouds on the experience for those students who want

COMMERCIAL DIRECTOR horizon which could prove to grow rather to get out of the classroom, who are

Maryam Lamond too large over the next few years. prepared to get dirty fingernails and

MANAGING DIRECTOR

Whenever I visit companies, one of figure out how to race prepare a car.

Adrian Goodsell the questions I ask is how do they The trouble is that it’s virtually unique,

find recruiting young engineers and although there are a few other schemes

PUBLISHING DIRECTOR

technicians, and the universal response run by universities and colleges, and it

Soheila Kimberley

is with great difficulty, especially when it has absolutely no funding. It’s a charity

comes to recruiting young graduates. For that relies on tooling and materials that

those who have a degree in motorsport as Alan Stoddart, who wrote the article

engineering, it seems that generally quotes they have to “wangle” to get.

they have their eyes set on only one I’m not sure how, but surely there must

place and that is Formula 1. It’s easy be a way of formalising what OUMF and

to understand why. It’s wonderfully other such organisations are doing to

glamorous and high-tech and to be enhance what they are already achieving

involved in a car competing at the with little or no resources. I have to

highest level of the sport is exhilarating. confess that I am confused when it

Forget that you might just be a small comes to apprenticeships. From what

cog in a large wheel it’s nonetheless I understand, they aren’t really cost-

scintillating for them. effective for smaller businesses that

However, the argument put forward have to put more in than they can take

by those in historic racing is the reverse out. When they are working on tight

as the graduate can play a very major margins and where every person has

role and be totally hands-on across to count, they don’t have the luxury of

the entire car, not just a bit of it. The training anyone. If this is the case, then

job satisfaction for true engineers and the apprenticeship scheme should be

technicians is extremely rewarding, they reformed to make it more viable.

@historicrace argue, if not quite as glamorous. To be Quite where we go from here I’m not

fair, though, some of the venues visited sure but in all honesty I cannot see

facebook.com/ such as Monaco, Le Mans, Spa and anything changing in the short or even

HistoricRaceTechnology other great circuits are pretty glamorous medium term. The historic racing industry

in their own right. You don’t have to be is going to have to rely on the current

part of a Formula 1 or World Endurance workforce keeping going and hope that

Championship team to visit them. fresh blood is injected before they all

Technology

The trouble is that most motorsport retire and their skills are lost to us all.

engineering courses are understandably

841 High Road, Finchley biased towards modern racing car

London N12 8PT technology but from what I understand,

Tel: +44 (0) 208 446 2100 much of the hands-on skills are William Kimberley

Fax: +44 (0) 208 446 2191 neglected as they tend to be classroom Editor

www.kimberleymediagroup.com and computer focused. There is Formula

HISTORIC RACING TECHNOLOGY Issue 16 5

28 OUMF RILEYS

A lesson in

Jeff Bloxham

engineering

Alan Stoddart is dispatched on a farmyard visit

with a difference, discovering students benefiting

from front-line engineering experience

T

UCKED away down a hidden a good time to put all that theory to the

lane, not far from Oxford city test then. This philosophy also means

centre, is a small farmyard that any and all ideas are encouraged,

encircled by sheds, which until not and with students continually

too long ago were dilapidated, with progressing through the foundation, it

collapsed walls, damaged roofs and means that there are always a plethora

dirt floors. of new innovations to consider.

It is here that the students of the While their current main project is a

Oxford Universities Motorsport British Motor Heritage/Halls Garage-

Foundation build, maintain and sponsored ‘Sebring’ Sprite race car, the

upgrade its historic race and rally main test beds for all these ideas have

car projects. The foundation was been a Mk 2 Golf and a pair of Riley

established by students, for students, One-Point-Fives, one of which is kitted

to provide practical hands-on out for circuit racing and the other set

engineering experience. up for rallying. Into the Rileys, which

Many of the students in the foundation, have both been imposingly painted in

who come equally from Oxford and Lesonal ‘North Korean Racing Grey’,

Oxford Brookes universities, feel there have gone an astonishing number

that they want to supplement their of modifications and improvements. The

predominantly theoretical courses with engine in the racer particularly has been

oily-fingered and skinned-knuckled extensively fettled, with the team even

motorsport experience. All of this is done going as far as cutting another engine

on a budget of “effectively nothing”, into slices to be able to look inside and

which means that not only does all identify where problems may originate,

tooling and materials have to be, to use and where advantages be gained.

the technical term, wangled, but nearly

all of the components used on the BATTERY EXPERIMENT

project cars are supplied by companies

that are aware of the alarming skills One of the recent experiments has

gap, see the benefit of the foundation’s been made possible thanks to SuperB’s

activities, and want to support it. batteries. It all started last year when

As well as providing sound practice for the battery maker decided to support

the engineers who could well end up the foundation by giving it one of its

controlling tight budgets as managers lightweight lithium ion motorsports

in a cash-strapped race team, these batteries. This in itself was quite an

limitations mean that the foundation’s improvement, immediately taking nine

members, in the finest tradition, need kilograms out of the Riley Racer, which

to get creative. They must figure out weighing in at around 865 kg, is already

ingenious solutions to be able to hold a big chunk and the single biggest piece

their own against better funded rivals – of lightweighting the team did last year.

28 Issue 16 HISTORIC RACING TECHNOLOGY

OUMF RILEYS 29

Once you explain

that the Riley is

basically a current

touring car, but

in granddad’s

clothing, you have

their attention”

need to deliver sufficient charge for the

length of a race.”

Impressively, it all worked at the

opening round of the HRDC at

Silverstone. The car was not only able

to complete the warm-up and make

it home after a 30-minute race, but

the team also managed to win their

class. They have since had class wins

in both HRDC races at the Donington

Historic Festival – running with a belt

– so the jury is still out as the research

continues. It still remains for the team

to see how running total loss affects

the all important output figure. Last time

the engine was dynoed, it was putting

out around 133 horsepower, which is

an already significant gain over the

engine’s originally quoted 95 hp, but the

ABOVE & BELOW The students are team is excited to see how the total loss

fortunate to be racing with, and learning system and other small modifications

from, some of the best. Here the OUMF Riley have changed that figure.

leads the Jordans’ A40 at HRDC Thruxton in

2016 en route to its first overall win

REVELATION

However, the team has since switched

to a slightly bigger battery from SuperB, Even things as simple as cleaning the

which has enabled it to experiment with engine properly inside have been

running the car on a total loss system. revelatory. Looking inside the sliced up

Usually on the ‘B’ Series engine, both the engine block, it is possible to see the

water pump and the alternator are driven build up of rust and other deposits in

by the crank. “THINK Automotive and the water galleries, which is impossible

Davies Craig donated an electric fan and to reach manually. It is only by cutting

water pump system respectively, which the engine up you can actually get

makes the original pump redundant, so an appreciation for the scale and

with a SuperB battery fitted, the power- significance of the rock hard deposits of

sapping drivebelt can be removed,” muck. Additionally, emphasises Boston,

says Oxford Universities Motorsports “This is on a block that was totally

Foundation founder Ding Boston. rebuilt around 1800 miles before we got

One of OUMF’s members, Vlad to it. To all intents and purposes this is a

Ardeleanu, continues: “The thing is, you block that has been built fairly recently

have some losses through the belt, so to the best abilities of the engine

we decided to take it off and just run builder, but look at that build up round

the car off the battery. We calculated the liners and how it might compromise

the losses through the belt, and worked the cooling of the cylinder.”

out how much battery power we’d The solution, he says, is Lenton

HISTORIC RACING TECHNOLOGY Issue 16 29

30 OUMF RILEYS

ABOVE Vibration Free helped balance

the crank and flywheel to 0.12 g/mm

Treatments. Its unique process, which

involves dipping engine castings in a

hot caustic solution, is able to get in all

of the otherwise inaccessible galleries

within the block and bring it back to an

as-new condition, without any damage

or distortion. “And do you know how

much they charge to leave the block as

naked as the day it was made? From

around 40 quid!” he enthuses. “You try

ABOVE One of the key pieces of CAD

and clean a block as well – which by the

data owned by the students is that

way you can’t – for that!” detailing the upright – a suspension

component which the OUMF team is

AWKWARD INCLINATION aware is both delicate and critical

A similar story can be told of plugged

drill access holes within the block.

Cutting open an engine showed that

some of these holes were at such an

inclination that sediment would gather

in them and fill them up to the brim. This

is particularly problematic if the engine

is subject to any unusually extreme

forces, in the event of an on-track

knock for example, and all this grot is

dislodged straight into the oil. Not good.

After identifying the problem, however,

the access holes were drilled out and

tapped, then grub screws inserted to

ensure that they could be thoroughly

cleaned in future.

ABOVE The beginnings of the Riley

These incremental gains are endless.

Racer at the barn. The car was

The team runs the Riley with an 1860 cc stripped to clean metal ready for

five-bearing MGB engine in HRDC Class inspection, lightening and reinforcing

30 Issue 16 HISTORIC RACING TECHNOLOGY

OUMF RILEYS 31

B, but during its initial build, they saw

the chance to do some lightweighting

with a powerfile (no prizes for guessing

that tool’s workshop nickname!). Casting

marks, unused bosses and even the

‘1800’ engine size digits were removed,

all saving around half a kilo. Before it

was painted, a student wag cast up a

‘1500’ in epoxy and glued it in place

– enabling him to boast that the team

had the only five-bearing 1500 ‘B’ series

engine in existence!

DIMINISHING RETURNS

A good joke, perhaps, but it does show

ABOVE HRDC chief Julius Thurgood (left) and OUMF founder

the extent to which the team is having

Ding Boston have both steered the team in the right direction

to get creative to further take weight

out of the car, one of the areas where

the cutting edge skills from university

can be very valuable. “What we plan

to do soon is a finite element analysis

to ascertain where you can safely take

more weight from. Andy [an OUMF

member and Masters student] is

convinced that if you carefully take weight

from appropriate points lying outside

of a triangle which takes in the crank

longitudinally, it can be advantageous

and may avoid the drawbacks you might

expect,” says Boston.

“It’s tempting to take a powerfile to a

thick part of a casting, but if you took off

material from some places, yes you’d

lose weight, but you’d also lose critical

stiffness. This could cause engine failure

ABOVE Contour Autocraft’s Bruce Macleod is one of the star

through flexing – or we’d need to put a

guests to have passed on their skill and experience to the

block plate back on to stiffen it all back students, teaching them a few tricks on the English wheel

up again. It’s often diminishing returns

when you are trying to lose weight.” make the difference between making foundation’s members still find things

Other gains are more concrete, even if it back on track or watching the race don’t always go to plan.

the biggest advantage isn’t necessarily from the pits. Just by using Zircotec, the

One of the engine issues the team has

what was intended. This has been team is now able to work on the engine had recently has been when switching

the case with the Zircotec coating after about two minutes of it being over to ARP bolts. Boston stresses that

the team has had put on the Riley switched off – a very precious benefit in

ARP bolts are much better and much

Racer’s beautifully crafted BTB Exhaust adverse circumstances. more reliable than the originals they

manifold. While it does do all the things previously used, but explains that this

it advertises, like keeping heat from STAGGERING SCRUTINY didn’t stop OUMF’s lack of knowledge

under the bonnet and protecting other causing difficulties. What the team

components and the paint in the engine Thanks in part to generations of didn’t realise is that the extra torque

bay, the main advantage OUMF has students coming through the foundation, recommended to tighten ARP’s bolts is

found is that it actually allows the car the engine has been subjected to a sometimes enough to distort the main

to be worked on far, far quicker than staggering amount of scrutiny with even caps and alter their tolerances.

they could without it. When there is a specialist balancing company Vibration This became apparent when the team

problem between qualifying and the Free helping to try and iron out the was invited down to Swiftune’s Kent

race, for example, just a few minutes can smallest imbalances. Despite this, the headquarters to learn the dark arts

HISTORIC RACING TECHNOLOGY Issue 16 31

32 OUMF RILEYS

of ‘A’ series engine tuning from Nick

Swift. Before their visit Swift insisted

that the team completely dry build the

Sebring Sprite’s engine, so that it would

just be a question of him having the

engine there to check and assemble

the component parts. So, diligently,

before travelling to Swiftune, OUMF

had Owslebury Crankshaft Services

machine it ready for Swift to go through

it with a fine-toothed comb.

BIG SURPRISE

Well, when OUMF dry built the engine ABOVE Ah, the glamour! As an unfunded initiative, OUMF is

they used brand new standard bolts entirely dependent on sponsorship and donations, be they

in the form of workshop consumables and tools or finance

and bearings and it “spun like a dream”,

but having gained the backing of ACL to line bore the block to suit because put his name to it. I asked if we couldn’t

via Engine Parts UK for the bearings, it it was just picking up. It came as a just fettle it? He replied that if there was

seemed a good time to make the switch. great surprise to us all that the varied such a thing as ‘line fettling’, or we were

However, when the ACL bearings went torques and tolerances between in the paddock with a race to win, then

in – which were, on paper, exactly the fixings and bearings from different yes, we could, but unfortunately, it’s

same size – the crank wouldn’t spin manufacturers is so specific that even called ‘line boring’!

freely. It turns out that the tolerance on a one thou difference between similar “We were all bowled over by

ACL bearings is just that much tighter. components can create a critical witnessing Swiftune’s attention to detail

“So that was it, and assembly was put problem,” says Boston. first hand. When this is coupled to its

on hold. Nick uses nearby Gosnays “Nick said we couldn’t go any further legendary customer support – and the

Engineering and asked them to help with it because he wasn’t prepared to results his cars get on track – it’s easy to

ABOVE The team went so far as to slice up an engine to identify ABOVE The ‘Sebring’ Sprite race car

where problems may originate or advantages be gained is one of the current projects

ABOVE With even the ‘1800’ engine size digits removed in the ABOVE The team

quest to save weight, only a little epoxy and glue was required to pictured with the

create the only five-bearing 1500 ‘B’ series engine in existence! stripped Riley Rally

32 Issue 16 HISTORIC RACING TECHNOLOGY

34 OUMF RILEYS

ABOVE 3D scan data of the Riley ABOVE Students worked closely

upright has been manipulated into with engineers at Helix to design

three pieces and then 3D printed in and manufacture the OUMF 184 mm

ABS on the team’s mini printer multi-plate clutch and flywheel

see why the ‘A’ series world beats a path out of date composites, supplied by for the grille and other rare parts should

to Nick’s door!” ex-OUMF members now working in race they have an incident which means that

Gains haven’t just been made in the teams. All old members are invited to they need to be replaced.

engine though. Right at the front of the come back and to pass on new skills Modern technology and techniques

car, the grille and other bits of chrome and experience to the current students, have been adopted elsewhere in the

trim, which are no doubt a grand way to which also allows the team to expand on car too. One of the things helping

adorn the nose, are rather on the heavy their very limited experience of working them to develop the car into a really

side – especially since all that weight with such materials at university. serious racer is the Cartek electrics, and

is hanging out in front of the wheels. the sensors and data logging system

They are increasingly expensive, which MODERN TECHNOLOGY BENEFITS installed with the help of Julian Thomas

is at odds for a team running on the at Racelogic and Peter Trevor at KA

aforementioned shoestring. Soon, they hope that OUMF’s Riley Sensors. This has allowed the team to

In the HRDC series most chromed Racer will sport a front grille and other enjoy similar benefits as better financed

bumpers, over-riders, and the like are precious and vulnerable chrome trim professional competitors on the grid,

made of moulded fibreglass. As such made from inexpensive materials. They and allowed them to experiment with

the students are presently trying to will not only be lighter, but – more the set-up of the car when practising

remake such chrome trim out of ‘lifed’, importantly – the team will have a mould and testing. At present, the 2k VBOX

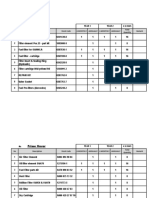

ABOVE Data logging is one of the

tools the students learn to exploit. This

graph shows the relationship between

oil pressure vs throttle position

34 Issue 16 HISTORIC RACING TECHNOLOGY

36 OUMF RILEYS

ABOVE With budget constraints forcing

the students to get creative, the Riley

Racer has provided a platform that has

been subjected to many experiments

must be removed from the Riley Racer get the most out of the car. Moreover, printer meant that when top prototyping

for the actual races, but at all other it is great for getting new students company Chasestead offered a full 3D

times it allows the students to watch the involved in the foundation as data scan of the Riley, a front upright was

on-board video and interpret the data logging experience is so important in converted to a 3D CAD file, and then the

plots. By creating traces showing graphs modern motorsport. team 3D printed it in plastic.

such as speed vs time, and highlighting “Once you explain to a fresher – who’s Technology has had a big impact on

delta T where time is being lost at key looking at the Riley as just an old car – what goes inside the engine as well.

points around the circuit, the team gets that in respect of data it is basically a Fuchs Lubricants not only provides the

a much clearer understanding of what current touring car, but in granddad’s team with all the TITAN Race oil it uses,

the car is doing. clothing, you have their attention. And but its lab technicians also analyse

when you tell them they’ve got the the car’s oil after every race to look

DATA LOGGING CLUES chance to play with it and learn all about for incipient signs of problems and tell

data logging from all the various sensors the team what state the engine is in.

“We record everything from air on it, they suddenly realise, ‘Wow, this Fuchs also advised the team to defy

temperature, to brake pressure, steering car is really exciting’!” Boston adds. conventional wisdom and switch oil

wheel position, damper movement,

the force through the Panhard rod, An astonishing number of

throttle position, exhaust temperature,

and lambda readings,” says Ardeleanu.

modifications and improvements”

“It’s a great help to have a lot of data A recent additional resource is a grade from a 20/50 to a 10/40.

and a lot of practice making sense of rudimentary 3D printer donated by an “Most advice about what oil you

it, because you don’t always have the old OUMF member. It is used to make should run in ‘B’ series engines is a

same problem.” small prototype components, like good classic 20/50,” says Boston. “No

It can help the team work out whether brackets, which means that students way! When the team were given a

they need to change something can now use the CAD skills which tour of Fuchs’ headquarters in Stoke,

mechanical because it is not behaving they learn every day as part of their followed by a comprehensive lecture,

as it should, whether changes in set degree courses to actually make parts it was explained to them why this is

up can be made to accommodate a to confirm fit or function, and if the simply not the case anymore. They

different driving style, or whether the designs are successful they can then be have worked with us to establish that

driver needs to do things differently to made on the lathe or mill. Having this what we actually needed was 10/40

36 Issue 16 HISTORIC RACING TECHNOLOGY

OUMF RILEYS 37

– not 20/50, or even 10/60. That’s the

optimum oil for this particular engine.

Maybe not what many people would

advise, but for us the difference in

reliability has been huge.”

For the students, these modifications

and changes, and the accompanying

detailed study of the rules, is all

excellent ‘real life’ experience and

practise for when they embark on

their professional motorsport careers.

Boston thinks it vital that students

learn to develop lateral thinking,

and engineering skills and insight to

allow them to exploit a situation to

the fullest. That is part of what the

foundation offers: actual front-line

engineering experience.

Ding is, however, very careful about

encouraging students in a way which,

although sometimes audacious, is

never abrasively so. “We joke like

crazy about modifying and fiddling

about in general, but always with ABOVE A data trace showing the Riley traction circle for a lap of Silverstone, with two

regard to the spirit of the whole sport different suspension setups for direct comparison. Testing was originally performed as

part of a student’s thesis on the rear suspension setup of the Riley historic touring car

too. You have to be aware of it and

respect it,” he emphasises. have the opportunity to be rubbing members on one-year placements.

“Creative students continually suggest shoulders with such respected figures This gives the students access to,

things that could be done, but the in motorsport, both on and off the track. and knowledge of, a wide range of

rulebook is their guide, and lines have “OUMF is voluntary and self-funded, processes – from CNC machining and

to be drawn.” and obviously everything must take dynamic balancing, to say, foundries

second place to the students’ degree and laminators. Students can find

ROLE MODELS work, so we can’t compete in time themselves spending a day at G&S

or money. But we can try and learn learning how valves are made; gas-

For Boston, this line falls in a place as much as possible from others flowing and building a race head with

that allows the students to get and make up for it in our ingenuity, Dave Crisell at All Stage; or visiting

experience with a car that is beginning relentless checking for reliability, the Pilkington Auto glass factory. It is

to be able to hold its own against far never say die enthusiasm, and the this mixture of social networking and

more professional outfits, without fantastic encouragement of our industry experience which Boston

taking liberties with the amazing generous supporters with tools, believes sets OUMF apart from any

opportunity they have been given parts and services. Without these other historic race team or student

by Julius Thurgood (HRDC’s founder strengths, the students wouldn’t even project in the UK.

and race director). “The point is,” get a chance to, say, try data logging,” What the team has achieved in

he continues, “that professionals concludes Boston. its once-dilapidated farmyard is

like the Jordans [Andy and Mike of He adds that the team would not be impressive. The tireless building and

the Jordan Racing Team, one of the able to function without the level of rebuilding of the car, the stream of

HRDC’s most successful outfits] have industrial sponsorship and a supporters’ students coming through the foundation

the means and experience to optimise network which it works tirelessly to and their voracious appetite for learning

everything to a far greater extent than maintain by frequent team visits to top from the very best companies in the

we are able to – through relentless motorsport companies like Quaife, business, has meant that the team

practice, data acquisition, and peerless TOYO Tires, Lifeline, and NGK. Some, and its cheerily resilient Rileys have

preparation of their own and their like Bilstein, Helix Autosport, Thermex, been able to achieve some pretty

customers’ cars. They are fantastic Eurolec, and Crossthwaite & Gardiner, spectacular results; as have many of

guys and tremendous role models for work closely with the students, the foundation’s growing number of

the students to try and emulate. The developing products for historic alumni, who are making great strides

students know how lucky they are to competition cars, and having OUMF throughout the world of motorsport.

HISTORIC RACING TECHNOLOGY Issue 16 37

You might also like

- The Mechanic - The Secret World of The F1 Pitlane by Marc Elvis' PriestleyDocument213 pagesThe Mechanic - The Secret World of The F1 Pitlane by Marc Elvis' PriestleyAna Ionescu50% (2)

- Final Report On Electric Car JackDocument30 pagesFinal Report On Electric Car JackAmit Raj73% (22)

- Vol 1Document274 pagesVol 1Marcelo Brigard CarvajalNo ratings yet

- LEAN SERVICE: A Practical Guide for SME Owner / ManagersFrom EverandLEAN SERVICE: A Practical Guide for SME Owner / ManagersRating: 3 out of 5 stars3/5 (2)

- DIXON, J. C. (1996) - Tires, Suspension and HandlingDocument13 pagesDIXON, J. C. (1996) - Tires, Suspension and HandlingAlef GoncalvesNo ratings yet

- 964 New Rogue Trader Ship HullsDocument2 pages964 New Rogue Trader Ship Hullstopherfuzz100% (3)

- Performance Boat TermsDocument6 pagesPerformance Boat TermsParamaet TamNo ratings yet

- Racecar Engineering Formula Student 2015 PDFDocument22 pagesRacecar Engineering Formula Student 2015 PDFtushar girotra100% (1)

- Formula Student 2014Document27 pagesFormula Student 2014alex94kgNo ratings yet

- Formulastudent2014 PDFDocument27 pagesFormulastudent2014 PDFDionisis SpiliopoulosNo ratings yet

- RaceCar Engineering-Formula StudentDocument18 pagesRaceCar Engineering-Formula StudentJeff Hawkins100% (3)

- Getting Started V1.0Document42 pagesGetting Started V1.0GautamNo ratings yet

- Design & Analysis of The BCU Formula Student TrailerDocument48 pagesDesign & Analysis of The BCU Formula Student TrailerChristos Kalavrytinos100% (1)

- TSA BIM Ready CompleteDocument19 pagesTSA BIM Ready CompleteSaif AliNo ratings yet

- The Oredigger Issue 9 - November 8, 2010Document12 pagesThe Oredigger Issue 9 - November 8, 2010The OrediggerNo ratings yet

- FS2011 Event ProgrammeDocument84 pagesFS2011 Event ProgrammeesukemNo ratings yet

- H PointDocument224 pagesH PointMarco100% (1)

- Biler 2006 PDFDocument68 pagesBiler 2006 PDFProt0nNo ratings yet

- Training Report: Submitted in Partial Fulfillment of The Requirement For 6 Weeks Industrial TrainingDocument5 pagesTraining Report: Submitted in Partial Fulfillment of The Requirement For 6 Weeks Industrial TrainingRJagatdeep Singh RanaNo ratings yet

- Current BrochureDocument12 pagesCurrent BrochureOfficial Sarvesh EkandeNo ratings yet

- FS 2014 Digimag WebDocument32 pagesFS 2014 Digimag WebVyssionNo ratings yet

- Personal Statement: Fraser08's University ChoicesDocument7 pagesPersonal Statement: Fraser08's University ChoicesRizqi Ilmal YaqinNo ratings yet

- SAICE Civil EngineeringDocument84 pagesSAICE Civil EngineeringtevredeNo ratings yet

- BIM Ready Complete BrochureDocument20 pagesBIM Ready Complete BrochureReshma RayNo ratings yet

- Bim Ready (Architecture Structure)Document19 pagesBim Ready (Architecture Structure)Reshma RayNo ratings yet

- BP EssayDocument4 pagesBP EssayChaNo ratings yet

- Dokumen - Tips Advanced Mechanisms in Delmia v5Document179 pagesDokumen - Tips Advanced Mechanisms in Delmia v5AlexanderNo ratings yet

- 200 Oct 147Document1 page200 Oct 147api-291218440No ratings yet

- Sponsorship Proposal Final 301006Document8 pagesSponsorship Proposal Final 301006paul.ifrimNo ratings yet

- Master Thesis Naval ArchitectureDocument8 pagesMaster Thesis Naval Architecturebsqkr4kn100% (2)

- Wood Group Mustang Magazine Spring 2012Document48 pagesWood Group Mustang Magazine Spring 2012Kyaw Kyaw AungNo ratings yet

- FS2014 Event Guide WEBDocument96 pagesFS2014 Event Guide WEBPCezzzNo ratings yet

- An Interview With A Marine EngineerDocument6 pagesAn Interview With A Marine Engineerritesh kumarNo ratings yet

- Razcecar Eng 12Document2 pagesRazcecar Eng 12errrrrrNo ratings yet

- ITR ReportDocument39 pagesITR ReportOm KalkeriNo ratings yet

- Engineering Success Using: TeamworkDocument17 pagesEngineering Success Using: TeamworkAndrewNguyenNo ratings yet

- The Mechanic - The Secret World of The F1 Pitlane (Marc 'Elvis' Priestley)Document230 pagesThe Mechanic - The Secret World of The F1 Pitlane (Marc 'Elvis' Priestley)Dark LightNo ratings yet

- P Dewson ThesisDocument149 pagesP Dewson ThesisSiau ShuangNo ratings yet

- HR 19692FB17 October - BOOK 0915 PDFDocument2 pagesHR 19692FB17 October - BOOK 0915 PDFMustapha BouregaaNo ratings yet

- FLR2263 Subsea Engineering FLR2263HA101Document4 pagesFLR2263 Subsea Engineering FLR2263HA101frmarzoNo ratings yet

- MbasatsheshDocument73 pagesMbasatsheshHarichandran KarthikeyanNo ratings yet

- Tu Munich-Essay SDocument2 pagesTu Munich-Essay SNaveen RaiNo ratings yet

- Special Edition, February 2015: 2015 Training and Development GuideDocument20 pagesSpecial Edition, February 2015: 2015 Training and Development GuideEbby OnyekweNo ratings yet

- Desktop Engineering - 2012-06Document62 pagesDesktop Engineering - 2012-06Бушинкин ВладиславNo ratings yet

- Diwakar - SOPDocument2 pagesDiwakar - SOPDiwakar SelvanayagamNo ratings yet

- SanjeevNe SIT Report 16001174Document47 pagesSanjeevNe SIT Report 16001174Sanjeev Nehru100% (1)

- Advanced Mechanisms in DELMIA V5Document179 pagesAdvanced Mechanisms in DELMIA V5Rushikesh Harkal100% (3)

- The Summer of 2012: Category: Pat S CornerDocument3 pagesThe Summer of 2012: Category: Pat S CornerAnonNo ratings yet

- Final Report On Electric Car Jack 3 PDFDocument30 pagesFinal Report On Electric Car Jack 3 PDFify100% (2)

- Turbulent-Laminar Flow Hull DesignDocument5 pagesTurbulent-Laminar Flow Hull DesignGamemasterNo ratings yet

- Internship Repot BobDocument43 pagesInternship Repot BobHARSH SHAHNo ratings yet

- Automotive EnggDocument15 pagesAutomotive EnggRakesh DwivediNo ratings yet

- Automotive EngineeringDocument3 pagesAutomotive EngineeringRoshan Shanmughan100% (1)

- Rohan JK Report NewDocument46 pagesRohan JK Report NewAshokkhaireNo ratings yet

- Racecar Engineering January 2018Document100 pagesRacecar Engineering January 2018Big FloresNo ratings yet

- HUFS Bulletin: A Message From Jerome Greenhalgh, Team PrincipalDocument5 pagesHUFS Bulletin: A Message From Jerome Greenhalgh, Team PrincipalhullfsNo ratings yet

- FloEFD ApplicationsDocument168 pagesFloEFD ApplicationsDavid SalaverríaNo ratings yet

- Papandreouch SwathDocument108 pagesPapandreouch SwathSunil Kumar P GNo ratings yet

- Glasgow-Lanarkshire-Scotland: The Future For Searl Technology LTD in Manufacturing Lies in Added Value and InnovatingDocument50 pagesGlasgow-Lanarkshire-Scotland: The Future For Searl Technology LTD in Manufacturing Lies in Added Value and InnovatingSamuel KinsNo ratings yet

- Foundational Experience: The Magazine For Student Members of Sae InternationalDocument28 pagesFoundational Experience: The Magazine For Student Members of Sae InternationalSomesh SharmaNo ratings yet

- In Steel and Computing the Rise of the Dip Tech Sandwich Generation: A Personal PerspectiveFrom EverandIn Steel and Computing the Rise of the Dip Tech Sandwich Generation: A Personal PerspectiveNo ratings yet

- How To Disable The Alarm On A 2000 Ford Expedition: InstructionsDocument4 pagesHow To Disable The Alarm On A 2000 Ford Expedition: Instructionsedin1234No ratings yet

- Date Informal Entries PAL (55 Paircargo (A02) PSI (A03)Document98 pagesDate Informal Entries PAL (55 Paircargo (A02) PSI (A03)Collection Division NAIANo ratings yet

- Lexus Case - Emotional PriceDocument2 pagesLexus Case - Emotional PriceAnonymous dUZFpCzLNo ratings yet

- Bill of Lading From ClientDocument20 pagesBill of Lading From ClientShanky ChakrabortyNo ratings yet

- MerchandisingproductlistingguideDocument2 pagesMerchandisingproductlistingguidemicheleNo ratings yet

- Model Boats June 2022Document76 pagesModel Boats June 2022Ognjen MočevičNo ratings yet

- ERA Standard Technical Specifications 2002Document759 pagesERA Standard Technical Specifications 2002Geby BridgeNo ratings yet

- Airthmetic Session Updated GAURAVDocument6 pagesAirthmetic Session Updated GAURAVmukeshsurendraNo ratings yet

- List of Scheduled OperatorsDocument11 pagesList of Scheduled OperatorsNeha BhatiaNo ratings yet

- Guia 2022 ENG WebDocument124 pagesGuia 2022 ENG WebLourdes OONo ratings yet

- As990 Scheduled Servicing For 2 Years - Lube and FiltersDocument3 pagesAs990 Scheduled Servicing For 2 Years - Lube and FiltersChin Wei SteNo ratings yet

- Chapter TwoDocument18 pagesChapter TwoammarfanosNo ratings yet

- Training Schemes FOR Officer Cadets: Academic Year 2007/2008Document17 pagesTraining Schemes FOR Officer Cadets: Academic Year 2007/2008MH PartisanNo ratings yet

- Methodeinstallation FRP Pipes and FittingDocument42 pagesMethodeinstallation FRP Pipes and Fittingdwi noviana nugrohoNo ratings yet

- Vijayawada Tirupati: 11:00 PM 6:30 AMDocument3 pagesVijayawada Tirupati: 11:00 PM 6:30 AMAnil Puvada100% (1)

- Airframe Control and RiggingDocument17 pagesAirframe Control and RiggingIdrisNo ratings yet

- Presentation 1Document13 pagesPresentation 1Aye Hnin PhyuNo ratings yet

- Modelling Flow Rutting in In-Service Asphalt Pavements Using The Mechanistic-Empirical Pavement Design GuideDocument21 pagesModelling Flow Rutting in In-Service Asphalt Pavements Using The Mechanistic-Empirical Pavement Design GuideLuthfi PratamaNo ratings yet

- Financial Strategies Adopted by Indian RailwaysDocument109 pagesFinancial Strategies Adopted by Indian RailwaysDarvesh SinghNo ratings yet

- Infantry Magazine Jan-Jun 1958Document232 pagesInfantry Magazine Jan-Jun 1958Glenn Stover100% (2)

- A0056220020-Audi A6 Current Flow Wiring Diagram - Basic Equipment From Model Year 2003Document642 pagesA0056220020-Audi A6 Current Flow Wiring Diagram - Basic Equipment From Model Year 2003Thomas HallwrightNo ratings yet

- Mitsubishi KudaDocument6 pagesMitsubishi Kudamaswid14No ratings yet

- Maritime SAR Plan PDFDocument85 pagesMaritime SAR Plan PDFTarek KaaberNo ratings yet

- Ahmedabad TMICC PDFDocument129 pagesAhmedabad TMICC PDFnamanNo ratings yet

- w203 PDFDocument400 pagesw203 PDFStomatološkaOrdinacijaKovačević83% (6)

- 20MY - Jaguar XF - SpecsheetDocument2 pages20MY - Jaguar XF - SpecsheetGaneshNo ratings yet

- V100 DampingDocument245 pagesV100 DampingAnonymous oTrMzaNo ratings yet