Professional Documents

Culture Documents

Exploring The Differences Between R-410A and R-22

Exploring The Differences Between R-410A and R-22

Uploaded by

aungwinnaingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exploring The Differences Between R-410A and R-22

Exploring The Differences Between R-410A and R-22

Uploaded by

aungwinnaingCopyright:

Available Formats

Exploring the Differences Between R-410A and R-22

R-410A

is the HFC refrigerant most original equip-

Come Jan. 1, 2010, OEMs will no ment manufacturers have selected to use in

new air-conditioning units when the HCFC

R-22 is phased out of all new equipment at the beginning of

longer be able to produce 2010. This is another step in the overall Montreal Protocol

phaseout plan that will ultimately result in the elimination of

HCFC-refrigerant use altogether.

new equipment with R-22 A large number of R-410A units already have been in-

stalled and are being serviced today. However, since R-22 will

continue to be available for years to come, HVACR techni-

refrigerant—and with R-410A cians will find themselves working with both R-22 and R-

410A units in the field when servicing installed units. Un-

poised to serve as the dominant derstanding the key differences of each refrigerant and the

units in which they are used allows technicians to manage

the transition period without problems. Following are a few

replacement, it is important of the major differences between the refrigerants and some

guidance on how to handle them.

to understand why. Getting physical

Exploring the physical properties of these refrigerants is a

good place to start. R-22 is an HCFC and contains a small

amount of chlorine, which gives it an ODP of greater than

0–0.055. Although this number is very small, especially com-

By Gus Rolotti pared to the ODP of R-11 or R-12, it is still greater than zero.

R-410A, conversely, is an HFC, and has an ODP of 0.

The elimination of ODP, however, is not the only reason

that R-410A has become the leading replacement choice over

other available HFC candidates. One of the most beneficial

properties is its large volumetric capacity, which enables it

to remove more heat than R-22 for the same unit of volume.

That greater volumetric capacity allowed designers to develop

smaller systems that deliver the same cooling capacity as R-22

units. In many cases, OEMs have capitalized on this. The

benefits of R-410A have allowed OEMs to comply with strict-

er DOE-mandated energy regulations imposed on new sys-

tems without increasing the spatial “footprint” of the system.

Despite some of the advantages of using R-410A as a re-

placement for R-22 in A/C applications, it has not seen much

incorporation or development on the refrigeration side, where

refrigerants such as R-404A and R-507A have taken the lead.

14 RSES Journal NOVEMBER 2009 w w w. r s e s j o u r n a l . co m

Because R-410A has a much high-

er pressure than R-22—about 50%

or more higher under the same tem-

perature conditions—technicians

must have pressure gauges, hoses

and recovery equipment rated to

deal with those higher pressures.

Beware of the mix Oil recommendations for R-410A

R-22 and R-410A, while intended for the same type of appli- R-410A requires the use of POE oils because the refriger-

cations, are indeed very different refrigerants. Therefore, they ant will not work with the common R-22 oils. The issue here

cannot be mixed, and the equipment they are used in will be is oil circulation and compressor lubrication. Common oils

different. Neither refrigerant can be used to top off a system used with R-22 are not miscible with R-410A and, therefore,

that contains the other, and units designed for one refriger- will not circulate in the system. This will cause, at the very

ant cannot be charged with the other. Cross charging can minimum, the accumulation of oil in the evaporator and

result in poor or no operation; equipment failure; or, in some lead to reduced performance and cooling capacity. This also

extreme cases, create a safety hazard. This also means that R- may cause the compressor to run with less than the required

410A can never be used as a retrofit refrigerant for R-22 units. amount of oil, which could lead to premature wear and even-

Retrofitting and servicing R-22 units require the use of one of tual failure due to a lack of proper lubrication.

the many R-22 retrofit refrigerants available. On the subject of oils, it is important to remember that

On a very basic, practical level, R-22 and R-410A have POE oils are hygroscopic and should be treated with care to

three obvious differences: operating conditions—particularly, avoid increasing their moisture level. Unused oil containers

system pressures; lubricating oil requirements; and charging should always be capped. [Editor’s Note: For more information

procedures. on this topic, see the May 2009 RSES Journal MSAC Hotline

A comparison of the pressure-temperature relationship of on pg. 39.] Systems should only be open to the atmosphere

the two refrigerants at saturation conditions shows that R- for the shortest time necessary, and using proper evacuation

410A’s pressures are much higher than R-22’s for the same techniques is a must. Keeping POE oil dry is important, not

temperature. In fact, R-410A’s pressures can be about 50% only to prevent moisture from entering the system, but also

or more higher for the same temperature conditions, which because moisture can break up some of the chemical bonds

is why R-410A cannot be used as a retrofit in R-22 equip- within the oil in a process called hydrolysis, which decom-

ment. This also explains why many of the tools, accessories poses it. This decomposition would result in the separation of

and components used for R-22 cannot be used with R-410A. the basic building blocks of the oil—alcohols and acids. If a

Pressure gauges and hoses need to be rated for the higher large quantity of acid forms, it could corrode the system’s in-

pressures, or they can be damaged. Recovery equipment—es- ternal components and reduce its life.

pecially cylinders—needs to be rated to a minimum of 400 [Editor’s Note: RSES Journal’s Technical Review Committee

psi. Incidentally, properly pressure-rated cylinders filled with also offered the following information on this subject: The POE

R-410A should be handled in the same manner as R-22 cylin- lubricant is made from an acid. It is then combined with a neu-

ders; this will ensure the same level of safety, regardless of the tralizer and a resultant water is produced. The water is extract-

higher pressures of R-410A. ed, an additive is inserted—with the result being the POE, which

w w w. r s e s j o u r n a l . co m NOVEMBER 2009 RSES Journal 15

Jeff Staub, Application Engineering Manager for Danfoss North America’s Refrig-

eration & Air Conditioning Division, offers insight about the HVACR industry’s

transition from R-22 to R-410A.

Refrigerant Reflections

RSES Journal: What does the R-22 phaseout and switch to R-410A refrigerant

mean to service technicians? What major issues should concern them?

Jeff Staub: I believe the phaseout will drastically affect service technicians,

based on the EPA’s regulation on the manufacture and distribution of R-22. As far

as the R-410A transition, this is a move largely affecting OEMs in new-equipment

design; some technicians have been using R-410A for 10 years. However, there

is a significant pressure increase when comparing R-22 and R-410A. R-22 has a

typical high-side pressure of 260 psig, while R-410A’s is 420 psig. Technicians

must take care in the handling of R-410A and the POE oil in the system, as both

have a much greater affinity to water than R-22 and mineral oil. Water in a refrig-

eration system is detrimental, as it can form ice, or react with the refrigerant or

oil and form acids, which could reduce the reliability of the system.

Technicians need to become familiar with alternative HFC-blended refriger-

ants. In particular, they need to focus on capacity matching, oil compatibility

and pressure deviations when considering an HFC blend to retrofit a system.

There are several HFC-refrigerant blends out there—407A, 407C, 422B and

422D, to name a few—used to replace R-22. Each alternative refrigerant will

have a different capacity match—up to 25% deviation of what R-22 currently

provides. Some alternative refrigerants are compatible with mineral oil, while

others require POE oil, which would mean the technician must replace the oil in

the system. Some of the refrigerants have pressures that are similar to R-22 in

a refrigeration application and others in an A/C application, so there is not one

“best fit” solution.

RJ: How should service technicians deal with those issues?

JS: With R-410A, technicians should select all components specifically rated for

R-410A to ensure the system pressures do not exceed the component maximum- is formulated to the compressor manufac-

working pressure. R-22 only can be used for existing installations. turer’s specifications for use in its prod-

Service techs should educate themselves about the differences between alter-

native HFC-blended refrigerants—specifically with regard to capacity difference;

ucts. In the course of time—and use—the

oil miscibility or compatibility; pressure and temperature deviation compared to POE compound may be subjected to a re-

R-22; and if the refrigerant fractionates or has a “glide” associated with it. introduction of water. That in and of itself

When you look at a refrigerant cycle—specifically during evaporation and conden- is not a problem; however, when water is

sation when the refrigerant is in a saturated condition—glide is the temperature

difference between the two phases, a liquid phase and a vapor phase. With glide,

introduced in conjunction with an operat-

there is a phase change that occurs over a temperature range instead of a single ing system and the normal heat, the wa-

temperature. If there is a high glide in a system that isn’t suited to accommodate ter will reverse the original manufacturing

the glide, the system could see a decrease in capacity or fractionation of the process in the hydrolysis process. There-

refrigerant. If there is a leak in a system using a refrigerant that fractionates,

typically only one of the refrigerants in the blend will escape. Therefore, the

in lies the problem: the compound now

technician would not be able to top off the system, and would have to pull out all becomes close to the original acid base

the refrigerant and recharge the system. and can damage the system components.

The replacing of driers will not correct or

RJ: What can/should technicians do to prepare for the phaseout?

“fix” the damaged lubricant. The dam-

JS: First, technicians need to evaluate their current inventory of R-22 and make aged compound will need to be removed;

sure it is being used to service existing equipment. R-410A is the replacement new, dry and properly formulated com-

refrigerant of choice for new-installation A/C applications. When it comes to R- pound (POE) must be reinstalled; and the

410A, technicians will need new pressure gauges and new cylinders rated for the

higher working pressures. With alternative HFC-blended refrigerants, technicians

system will need to be rebalanced as a dry

can use their current gauges and recovery cylinders rated for use with R-22. operating system.]

Technicians need to educate themselves about the alternative HFC-blended

refrigerants, and keep in mind that R-22 is not a banned refrigerant; it’s just

banned from OEMs using it in new equipment. There is the possibility that there

Charging and glide

will be a shortage of R-22 at the end of 2010, so that’s why education about the

The charging of R-410A also poses

alternatives is so important. Still, an R-22 shortage is a speculation—while the EPA some challenges. R-22 is a single-com-

will begin introducing production caps on R-22, we don’t know what the existing ponent refrigerant, whereas R-410A is

inventory level is and we don’t know to what extent R-22 will be stockpiled prior a 50/50 blend consisting of R-32 and

to year end.

R-125. R-22 will not exhibit a glide, but

Staub has more than 15 years of HVACR experience, and is responsible for all lev- R-410A—as all blends do—will have

els of customer application support for Danfoss’ products, including compressors, a glide and could possibly fractionate.

controls, heat exchangers and line components. For more information, e-mail This small glide measures just a frac-

JeffStaub@danfoss.com or call 410-513-1189.

tion of a degree and, in practical terms,

cannot be measured using the stan-

dard tools of the trade and has little ef-

16 RSES Journal NOVEMBER 2009 w w w. r s e s j o u r n a l . co m

“

R-22 is a single-component refrig-

erant, whereas R-410A is a 50/50

blend consisting of R-32 and R-125.

mixing will give R-410A equipment the

best chance to achieve the durability

”

and high performance for which it was

designed.

Gus Rolotti is the Technical Marketing

Director of the Fluorochemicals Group for

fect on performance. Having such small principles and practices used today for Arkema Inc. and has dealt with refriger-

glide, its vapor and liquid pressures (dew R-22 also apply to R-410A. Keeping in ant-related issues for more than 20 years

and bubble pressures) at saturation are mind the higher pressures of R-410A; at Arkema’s Technical Center in King of

almost the same. This is the reason why its need for a POE lubricant; utilizing Prussia, PA. He can be reached via e-mail

most pressure-temperature charts listing proper charging techniques; and using at gus.rolotti@arkema.com.

R-410A include only one pressure—the dedicated gauge sets and hoses to avoid

liquid pressure—for superheat and sub-

cooling calculations in the field. This

is unlike what is seen for some other

blends—such as R-407C—that require

technicians to have the vapor and liq-

uid pressures in order to compute super-

heat and subcooling. In this regard, the

use of a pressure-temperature chart for

R-410A is similar to its use with R-22.

But in spite of its very low glide, R-

410A still should be treated as a blend

that can fractionate.

R-410A always should be removed

from the cylinders in liquid form and

introduced into a system as a liquid,

if possible. If the refrigerant is being

charged in the vapor side of a running

system, it should be allowed to evapo-

rate to avoid damaging the compres-

sor. The effects of fractionation during

a leak—or even in operation in sys-

tems with a flooded evaporator—will

be minimal and, in most cases, almost

undetectable. However, they should be

avoided as much as possible to minimize

the potential compounding effect due

to repetition.

Finishing up

While R-22 and R-410A are very dif-

ferent refrigerants that require spe-

cial handling and care, the same basic

Circle Reader Service No. 66

w w w. r s e s j o u r n a l . co m NOVEMBER 2009 RSES Journal 17

You might also like

- Full Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full ChapterDocument36 pagesFull Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full Chapterrabate.toiler.vv5s091% (23)

- Is Constant Use of Electronic Media Changing Our MindsDocument4 pagesIs Constant Use of Electronic Media Changing Our MindsVi Le50% (4)

- Lexus - GS300 - GS430 - Service - Manual 9Document18 pagesLexus - GS300 - GS430 - Service - Manual 9seregap84100% (2)

- Booking Report 11-23-2021Document3 pagesBooking Report 11-23-2021WCTV Digital TeamNo ratings yet

- Tecumseh Guidelines For Utilization of R134aDocument7 pagesTecumseh Guidelines For Utilization of R134aAnibal RiosNo ratings yet

- Comparison-R407c and R410aDocument5 pagesComparison-R407c and R410aKartik PrabhakarNo ratings yet

- A Smart Motor Controller For E-Bike Applications PDFDocument4 pagesA Smart Motor Controller For E-Bike Applications PDFaungwinnaing100% (1)

- Forane Refrigerants PropertiesDocument20 pagesForane Refrigerants PropertiespetrcNo ratings yet

- Freon 407c Retrofit GuidelinesDocument8 pagesFreon 407c Retrofit GuidelinesbudayaNo ratings yet

- Technical Topic Refrigeration Oils (Jan 2011) - EN PDFDocument4 pagesTechnical Topic Refrigeration Oils (Jan 2011) - EN PDFPreeti gulatiNo ratings yet

- Technical Digest: Hfcs HcfcsDocument20 pagesTechnical Digest: Hfcs HcfcsChevy CheNo ratings yet

- An Introduction To A2L Refrigerants and Their Use in Refrigeration, Air Conditioning and Heat Pump ApplicationsDocument15 pagesAn Introduction To A2L Refrigerants and Their Use in Refrigeration, Air Conditioning and Heat Pump ApplicationsHasib KhanNo ratings yet

- The Difference Between R22 and R410A Refrigerant - AND ServicesDocument3 pagesThe Difference Between R22 and R410A Refrigerant - AND ServicesHumayun BaigNo ratings yet

- r22 Phase Out EnglishDocument12 pagesr22 Phase Out EnglishPavankumarNo ratings yet

- Refrigerant Changeover GuidelinesDocument7 pagesRefrigerant Changeover GuidelinesPanji SegaraNo ratings yet

- Refrigerant Recovery SystemDocument12 pagesRefrigerant Recovery SystemScribdTranslationsNo ratings yet

- Technical Bulletin #R-100 Refrigerant: R410a vs. R407cDocument1 pageTechnical Bulletin #R-100 Refrigerant: R410a vs. R407cmunggangNo ratings yet

- Refrigerant Changeover Guidelines: Leading The Industry With Environmentally Responsible Refrigerant SolutionsDocument7 pagesRefrigerant Changeover Guidelines: Leading The Industry With Environmentally Responsible Refrigerant SolutionsMasoud KarimiNo ratings yet

- Refrigerant Report: 15. EditionDocument40 pagesRefrigerant Report: 15. EditionPedro SilvaNo ratings yet

- Chemours BrochureDocument6 pagesChemours BrochureFerdian AriestaNo ratings yet

- RefrigrationDocument7 pagesRefrigrationJohn Dave VillaNo ratings yet

- Comparacion 407c y 410aDocument5 pagesComparacion 407c y 410aAlan Q'amaháNo ratings yet

- A 501 14Document40 pagesA 501 14fakhrealammmNo ratings yet

- 12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDocument4 pages12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDiaconescu AdrianNo ratings yet

- Module 1 - Introduction To Alternative RefrigerantsDocument47 pagesModule 1 - Introduction To Alternative RefrigerantsMark BrewardNo ratings yet

- Replacement VRV ECPEN13-205 Catalogues EnglishDocument8 pagesReplacement VRV ECPEN13-205 Catalogues Englishba nguyễn vănNo ratings yet

- Refrigeration Retrofitt GuidelinesDocument52 pagesRefrigeration Retrofitt GuidelinesAurelio Jr TambigaNo ratings yet

- Types of Refrigerant Gas PresentationDocument9 pagesTypes of Refrigerant Gas PresentationTAIMOOR HUDANo ratings yet

- Refrigerant Changeover Guide R22 R 407C PDFDocument6 pagesRefrigerant Changeover Guide R22 R 407C PDFkuruvillaj2217No ratings yet

- Copeland LubricantsDocument2 pagesCopeland LubricantsDanLorenaNo ratings yet

- Future Refrigerants Sales SheetDocument8 pagesFuture Refrigerants Sales SheetDaniel MachadoNo ratings yet

- FS 4 Commercial Refrigeration Oct 2015Document8 pagesFS 4 Commercial Refrigeration Oct 2015Daddy LeviNo ratings yet

- Ammonia or R22?: A Design ApproachDocument26 pagesAmmonia or R22?: A Design ApproachSail Vessel J&K Kat100% (1)

- Chapter 14 Refrigerants Refrigerant SelectionDocument10 pagesChapter 14 Refrigerants Refrigerant SelectionkuanyiNo ratings yet

- Applying VRF?: Don't Overlook Standard 15Document7 pagesApplying VRF?: Don't Overlook Standard 15Eric G. MagnayeNo ratings yet

- Danfoss r290 en PDFDocument4 pagesDanfoss r290 en PDFAli Al-Sayyab100% (1)

- CIBSE Propane R290 CPDDocument4 pagesCIBSE Propane R290 CPDYosmar GuzmanNo ratings yet

- GulfSea PE Cooloil Series PDFDocument2 pagesGulfSea PE Cooloil Series PDFObydur RahmanNo ratings yet

- Inlocuire R410A Cu R466ADocument9 pagesInlocuire R410A Cu R466AClaudia MadalinaNo ratings yet

- Rac Ok-1Document29 pagesRac Ok-1rushigarud1249No ratings yet

- The Use of R-407CDocument6 pagesThe Use of R-407CdokundotNo ratings yet

- Introduction To Alternative Refrigerants Other Than HFCDocument15 pagesIntroduction To Alternative Refrigerants Other Than HFCe4erkNo ratings yet

- The Low-Down On R407FDocument2 pagesThe Low-Down On R407FmaestralejonqueNo ratings yet

- Freon 404A enDocument12 pagesFreon 404A enisturmanNo ratings yet

- Freon 410a Very Low Temperature VLT RefrigerationDocument4 pagesFreon 410a Very Low Temperature VLT RefrigerationAzwar DenaraNo ratings yet

- Ac Lubricants It S Not That Simple AirstalDocument9 pagesAc Lubricants It S Not That Simple AirstalIgnasiNo ratings yet

- Refrigerants Eguide1Document10 pagesRefrigerants Eguide1ShuvenduNo ratings yet

- Irreversibility Analysis of Two and Three Stage Vapour Compression Refrigeration Systems With Multi Evaporators and Flash-Intercooler UsingDocument8 pagesIrreversibility Analysis of Two and Three Stage Vapour Compression Refrigeration Systems With Multi Evaporators and Flash-Intercooler UsingIjrei JournalNo ratings yet

- Gas R1234yfDocument7 pagesGas R1234yfAnonymous XPQKHSNo ratings yet

- Danfoss Ammonia RefrigerationDocument31 pagesDanfoss Ammonia RefrigerationMahmoud AbubakrNo ratings yet

- Desirable Properties of A Refrigerant: RefrigerantsDocument12 pagesDesirable Properties of A Refrigerant: RefrigerantsPraveen AbisakeNo ratings yet

- Refrigerant TypesDocument4 pagesRefrigerant Typesch pavan kumar0% (1)

- RefrigerantsDocument5 pagesRefrigerantsn02219827hNo ratings yet

- R-410A Is Here To Stay: Know The Facts: Keep You and Your Customers Safe!Document2 pagesR-410A Is Here To Stay: Know The Facts: Keep You and Your Customers Safe!Francisco Sanchez RNo ratings yet

- Perbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACDocument15 pagesPerbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACYuli RahmawatiNo ratings yet

- The Complete Guide To R454B RefrigerantDocument5 pagesThe Complete Guide To R454B RefrigerantAritra DasguptaNo ratings yet

- Lubricant Offers For Screw Compressors.Document11 pagesLubricant Offers For Screw Compressors.cheNo ratings yet

- Forane R404A Technical Data PDFDocument4 pagesForane R404A Technical Data PDFPi'i Syafi'iNo ratings yet

- R290 As A Substitute of R502 and R22 in Commercial Refrigeration and Air ConditioningDocument7 pagesR290 As A Substitute of R502 and R22 in Commercial Refrigeration and Air Conditioningshank100No ratings yet

- Honeywell Genetron Az20 Technical SpecsDocument4 pagesHoneywell Genetron Az20 Technical SpecsToni TalevskiNo ratings yet

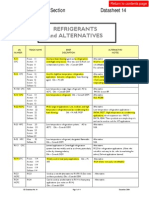

- Refrigerants and Alternatives: Service Engineers' Section Datasheet 14Document4 pagesRefrigerants and Alternatives: Service Engineers' Section Datasheet 14rituneshmNo ratings yet

- Condensing Units: Air CooledDocument12 pagesCondensing Units: Air Cooledkskr_44No ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- BMS Training NoteDocument23 pagesBMS Training NoteaungwinnaingNo ratings yet

- IBMS Control SchematicDocument57 pagesIBMS Control SchematicaungwinnaingNo ratings yet

- YCDC-Republic of The Union of Myanmar Yangon Regional Government PDFDocument39 pagesYCDC-Republic of The Union of Myanmar Yangon Regional Government PDFaungwinnaingNo ratings yet

- Appendix B: Service Overview - Logging While Fishing (LWF )Document16 pagesAppendix B: Service Overview - Logging While Fishing (LWF )aungwinnaingNo ratings yet

- Howard & Associates International, Inc.: Lafayette, LouisianaDocument11 pagesHoward & Associates International, Inc.: Lafayette, LouisianaaungwinnaingNo ratings yet

- Gfe LWF PaperDocument68 pagesGfe LWF PaperaungwinnaingNo ratings yet

- Fishing Best PracticesDocument11 pagesFishing Best PracticesaungwinnaingNo ratings yet

- Wireline Fishing Safety Placard Mar07 4302161 01Document1 pageWireline Fishing Safety Placard Mar07 4302161 01aungwinnaing100% (1)

- Fishing Operations Checklist Basic StepsDocument1 pageFishing Operations Checklist Basic StepsaungwinnaingNo ratings yet

- Measurement Instructions For SFT 157 H349030 4363650 02Document6 pagesMeasurement Instructions For SFT 157 H349030 4363650 02aungwinnaingNo ratings yet

- Logging While Fishing Best Practices-2Document41 pagesLogging While Fishing Best Practices-2aungwinnaingNo ratings yet

- Wawa Evolution of Business Process Design PDFDocument35 pagesWawa Evolution of Business Process Design PDFotchmarzNo ratings yet

- Veritas NetBackup 6.5 Vault Administrator's GuideDocument268 pagesVeritas NetBackup 6.5 Vault Administrator's GuideS LS ChanNo ratings yet

- Nature of Bivariate DataDocument39 pagesNature of Bivariate DataRossel Jane CampilloNo ratings yet

- Crypt Arithmatic Problem SolutionDocument10 pagesCrypt Arithmatic Problem SolutionHariom Patel100% (4)

- 2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimDocument3 pages2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimFung AlexNo ratings yet

- Chapter 10 - Eco LiteracyDocument15 pagesChapter 10 - Eco LiteracyMichelle Bandoquillo100% (1)

- Standard DC Output: Simplified Internal Diagram of The Charger's Output ConnectionsDocument1 pageStandard DC Output: Simplified Internal Diagram of The Charger's Output ConnectionstoufikNo ratings yet

- Financial Summary Statement Period 03/10/23 - 04/09/23: Deposit Accounts Total DepositsDocument14 pagesFinancial Summary Statement Period 03/10/23 - 04/09/23: Deposit Accounts Total DepositsLuis RodríguezNo ratings yet

- Blake Problem ComputationDocument3 pagesBlake Problem ComputationNiño del Mundo75% (4)

- Care Sheet - Neon Tree Dragon (Japalura Splendida)Document2 pagesCare Sheet - Neon Tree Dragon (Japalura Splendida)John Gamesby100% (1)

- 2021 DBaaS Security Architect and SolutionsDocument26 pages2021 DBaaS Security Architect and Solutionsluke luNo ratings yet

- Kubs-Bill 7-LibraryDocument48 pagesKubs-Bill 7-LibrarySharkeela ShukriNo ratings yet

- WPP2019 Pop F01 2 Total Population MaleDocument547 pagesWPP2019 Pop F01 2 Total Population MaleMaria BozhkoNo ratings yet

- Simple Past TenseDocument3 pagesSimple Past TenseClara UbaltonNo ratings yet

- Advanced Baking 1Document61 pagesAdvanced Baking 1Judelmae SisonNo ratings yet

- EC 03 - Archetypes - GM BinderDocument128 pagesEC 03 - Archetypes - GM BinderLeonxdNo ratings yet

- On Advertising A Marxist CritiqueDocument13 pagesOn Advertising A Marxist CritiqueKisholoy AntiBrahminNo ratings yet

- Recruiting StrategiesDocument10 pagesRecruiting StrategiesAbhijeet PatraNo ratings yet

- Chapter 6. Reactions of AlkynesDocument37 pagesChapter 6. Reactions of Alkynesthanhnguyenhhvn100% (1)

- Human Resources Management in 2020.Document11 pagesHuman Resources Management in 2020.DheerajNo ratings yet

- HypertensionDocument5 pagesHypertensionJonathan BreedveldNo ratings yet

- Basic Computer SkillsDocument11 pagesBasic Computer SkillsreneeNo ratings yet

- XAI P T A Brief Review of ExplainableDocument9 pagesXAI P T A Brief Review of Explainableghrab MedNo ratings yet

- An Experiment of DensityDocument4 pagesAn Experiment of DensitySamuel TumewaNo ratings yet

- NI-Predictive Maintenance and Machine Health MonitoringDocument34 pagesNI-Predictive Maintenance and Machine Health Monitoringtườngt_14No ratings yet

- Cela NeseDocument1 pageCela NeseitskapilgargNo ratings yet