Professional Documents

Culture Documents

Cat D8T: Track-Type Tractor

Cat D8T: Track-Type Tractor

Uploaded by

Richard R M ThodéCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Holes Lesson PlanDocument3 pagesHoles Lesson Planapi-270543697No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MF5400 Manual 05-EnDocument462 pagesMF5400 Manual 05-EnSelmirije2100% (2)

- Decision-Making Competence in Everyday Life.Document6 pagesDecision-Making Competence in Everyday Life.Chelsea AcostaNo ratings yet

- Contradictions of Plato's IdeasDocument6 pagesContradictions of Plato's Ideaskissinger2020No ratings yet

- 2019 Recitation Chap 2 PDFDocument21 pages2019 Recitation Chap 2 PDFGull100% (1)

- Advances in The Theory of Plates and Shells, Edited by G.Z. Voyiadjis and D. KaramanlidisDocument35 pagesAdvances in The Theory of Plates and Shells, Edited by G.Z. Voyiadjis and D. KaramanlidisHasanain AlmusawiNo ratings yet

- 4 Elfospace sp14m001gb 04 - 1520073972076Document4 pages4 Elfospace sp14m001gb 04 - 1520073972076Justin ReyesNo ratings yet

- EKKO ProjectDocument2 pagesEKKO ProjectGeofisica GusZavNo ratings yet

- MIR - LML - Golovina L. I. and Yaglom I. M. - Induction in GeometryDocument134 pagesMIR - LML - Golovina L. I. and Yaglom I. M. - Induction in Geometryavast2008100% (2)

- Asus ROG Zephyrus S GX531: 1.what Are The Main Characteristics?Document3 pagesAsus ROG Zephyrus S GX531: 1.what Are The Main Characteristics?mihaelahristeaNo ratings yet

- (Worksheet 13.1) - (Power Sharing)Document5 pages(Worksheet 13.1) - (Power Sharing)DeepikaNo ratings yet

- GTP Strategic Plan Proposal PDFDocument227 pagesGTP Strategic Plan Proposal PDFPak Ngah LebayNo ratings yet

- Instalment Payment Plan FormDocument1 pageInstalment Payment Plan Formckeat_2No ratings yet

- GT Lube Oil FlushingDocument11 pagesGT Lube Oil Flushingshubham raj bhawsarNo ratings yet

- np2 6-12Document2 pagesnp2 6-12api-170472102No ratings yet

- 48V TXT Service Manual PDFDocument192 pages48V TXT Service Manual PDFJim Campbell De Castro100% (3)

- High Resolution Video Endoscopy System: Sonoscape Medical CorpDocument4 pagesHigh Resolution Video Endoscopy System: Sonoscape Medical CorpTaha OpedNo ratings yet

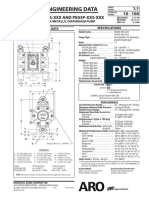

- Sales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1Document4 pagesSales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1jarosNo ratings yet

- UAS General English-2-2021Document12 pagesUAS General English-2-2021Putri Pradnya DewantiNo ratings yet

- Addressing Sexual Harassment at Workplace - Without Author's NameDocument15 pagesAddressing Sexual Harassment at Workplace - Without Author's Namemehjabin ferdous moneesaNo ratings yet

- REPORT Compressed Image Processing 45Document23 pagesREPORT Compressed Image Processing 45Mahender YadavNo ratings yet

- Tall Buildings in CopenhagenDocument140 pagesTall Buildings in CopenhagenMorten Kent HansenNo ratings yet

- Essential Oil Nanoemulsions As Antimicrobial Agents in FoodDocument19 pagesEssential Oil Nanoemulsions As Antimicrobial Agents in FoodpradeepqNo ratings yet

- Cat - Dcs.sis - Controller (12H - 8MN)Document2 pagesCat - Dcs.sis - Controller (12H - 8MN)Warley Moraes Oliveira100% (1)

- Week 3-Tals: 1. The Student Learning MovementDocument5 pagesWeek 3-Tals: 1. The Student Learning MovementPrincess PauleNo ratings yet

- Project ManagementDocument41 pagesProject ManagementOm Prakash SharmaNo ratings yet

- LEX1 Data SheetDocument2 pagesLEX1 Data Sheetpreetharajamma6025No ratings yet

- Activity Completion Report: A Lampshade Making ProjectDocument7 pagesActivity Completion Report: A Lampshade Making ProjectciriloNo ratings yet

- Chapter 2 Vectors and Two Dim Motion - Gen - Med - All SectionsDocument60 pagesChapter 2 Vectors and Two Dim Motion - Gen - Med - All Sectionsnader siamNo ratings yet

- Redis Cluster Specification-12Document1 pageRedis Cluster Specification-12Kajaruban SurendranNo ratings yet

Cat D8T: Track-Type Tractor

Cat D8T: Track-Type Tractor

Uploaded by

Richard R M ThodéOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat D8T: Track-Type Tractor

Cat D8T: Track-Type Tractor

Uploaded by

Richard R M ThodéCopyright:

Available Formats

Cat D8T ®

Track-Type Tractor

Ease of Operation Sustainability

• New color touch-screen display puts the machine’s programmable • Meets U.S. EPA Tier 4 Final/EU Stage IV/Japan 2014 (Tier 4 Final)

control features right at your fingertips. emission standards.

• Selectable electro-hydraulic maps let you set implement • Improved fuel economy over Tier 4 Interim and efficient use of

response/speed to match operator preferences and application. Diesel Exhaust Fluid (DEF) gives you excellent overall fluid efficiency.

• Enjoy added operator comforts like a quieter cab, adjustable • In cooler conditions, the hydraulic demand fan reduces speed to

armrests and a heated/ventilated seat option. conserve power, save fuel and decrease sound levels.

• Emissions technology is transparent – no action required from the

operator, no stopping for regeneration. Safety

• Smoother shifting based on load and operating conditions, as well

• Convenient steps, handles and guardrail help you get on and off

as greater benefi ts from Enhanced Auto Shift.

the tractor with greater ease, and access lighting can be turned

• Enhanced Auto Shift allows operators to select the optimum ground on from a ground level switch.

speed for the job. Helps save fuel by automatically choosing the

• New seat belt indicator reminds the operator to buckle up for safety,

most efficient gear based on load.

and logs seat belt use to help with compliance/safety practices.

• Electronic fluid level verification at startup for coolant, power train

Technology and engine oil means you can make fewer trips up and down from

• Cat ® Grade Control 3D is a factory-integrated grade control system the cab.

that enables operators to improve grading efficiency, accuracy and • Operator Presence Detection System allows the machine to idle

productivity in production dozing and fine grading applications. when the operator is not seated, but locks out the power train

• The integrated design moves the antennas to the top of the cab, and front implements to avoid unintentional movement.

eliminating masts and cables traditionally on the blade. • Operator Presence system also locks brakes and hydraulic system

• Productivity enhancing features integrated with Cat Grade Control – when operator leaves the seat for an extra safety measure.

AutoCarry™, Auto Blade Assist, and Automatic Ripper Control – • A rear vision camera and cylinder mounted mirrors are available

turn the D8T into a high production dozing system. to enhance visibility around the machine.

• Cat AccuGrade™ machine control and guidance option helps

operators improve productivity and accuracy by as much as

50% over conventional methods.

• D8T is Grade Control Ready out of the factory, making installation

of AccuGrade system an easy retrofi t down the road.

• Product Link™/VisionLink ® connects owners to their equipment,

providing access to machine data such as location, hours, fuel

consumption, idle time, events, and diagnostic codes.

D8T Track-Type Tractor

Engine Service Refill Capacities

Engine Model Cat C15 ACERT™ Fuel Tank 627 L 165 gal

U.S. EPA Tier 4 Final/ Diesel Exhaust Fluid Tank 24 L 6.3 gal

Emissions EU Stage IV/Japan 2014 Cooling System 86 L 22.7 gal

(Tier 4 Final)

Engine Crankcase* 38 L 10 gal

Net Power (Rated) – 1,900 rpm

Power Train 155 L 41 gal

ISO 9249/SAE J1349 233 kW 312 hp

Final Drives (each) 12.5 L 3.3 gal

ISO 9249/SAE J1349 (DIN) 308 hp

Roller Frames (each) 65 L 17.2 gal

Net Power (Maximum) – 1,700 rpm

Pivot Shaft Compartment 40 L 10.6 gal

ISO 9249/SAE J1349 252 kW 335 hp

Hydraulic Tank 75 L 19.8 gal

ISO 9249/SAE J1349 (DIN) 330 hp

*With oil filter

Displacement 15.2 L 928 in 3

All non road U.S. EPA Tier 4, EU Stage IIIB and IV, and Japan 2011 and 2014

(Tier 4 Interim and Tier 4 Final) diesel engines are required to use only

Operating Weight

Ultra Low Sulfur Diesel (ULSD) fuels containing 15 ppm (mg/kg) sulfur or Standard 39 420 kg 86,900 lb

less. Biodiesel blends up to B20 (20% blend by volume) are acceptable LGP 37 420 kg 82,496 lb

when blended with 15 ppm (mg/kg) sulfur or less ULSD. B20 should meet

ASTM D7467 specification (biodiesel blend stock should meet Cat biodiesel

spec, ASTM D6751 or EN 14214). Cat DEO-ULS™ or oils that meet the Transmission

Cat ECF-3, API CJ-4, and ACEA E9 specification are required. Consult your 1 Forward 3.4 km/h 2.1 mph

OMM for further machine specific fuel recommendations. 2 Forward 6.1 km/h 3.8 mph

• DEF used in Cat Selective Catalytic Reduction (SCR) systems must 3 Forward 10.6 km/h 6.6 mph

meet the requirements outlined in the International Organization for

Standardization (ISO) standard 22241. 1 Reverse 4.5 km/h 2.8 mph

2 Reverse 8 km/h 5 mph

Blades 3 Reverse 14.2 km/h 8.8 mph

Capacity Width (over end bits) Drawbar Pull

8SU 8.6 m 3

11.3 yd 3

3931 mm 12.9 ft 1 Forward 661.1 kN 148 lbf

8U 11.8 m 3

15.4 yd 3

4251 mm 13.9 ft 2 Forward 363.1 kN 81 lbf

8A 5.2 m 3

6.8 yd 3

5045 mm 16.6 ft 3 Forward 197.5 kN 44 lbf

8SU LGP 9.9 m 3 12.9 yd 3 4531 mm 14.9 ft

Dimensions

Standard Non-Suspended LGP

Width of Tractor (without trunnions/standard shoe width) 2693 mm 106.0 in 2693 mm 106.0 in 3302 mm 130.0 in

Machine Height to ROPS 3602 mm 141.8 in 3593 mm 141.5 in 3491 mm 137.4 in

Length of Track on Ground 3206 mm 126.2 in 3258 mm 128.3 in 3206 mm 126.2 in

Length of Basic Tractor (tag link trunnion to tip of rear grouser)* 4647 mm 183.0 in 4647 mm 183.0 in 4647 mm 183.0 in

Ground Pressure 89.6 kPa 13.0 psi 89.6 kPa 13.0 psi 53.3 kPa 7.7 psi

Ground Clearance 613 mm 24.1 in 606 mm 23.8 in 613 mm 24.1 in

*Add the following measurements for attachments: Ripper (single shank) 1519 mm/59.8 in; Ripper (multi-shank) 1613 mm/63.5 in; Drawbar 406 mm/16.0 in;

SU Blade 1844 mm/72.6 in; U Blade 2241 mm/88.2 in; A Blade (not angled) 2027 mm/79.8 in; A Blade (angled 25 degrees) 3068 mm/120.8 in.

www.cat.com

AEXQ1163

North America

© 2014 Caterpillar • All Rights Reserved • Printed in USA

CAT, CATERPILLAR, BUILT FOR IT, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow” and the “Power Edge” trade dress,

as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Holes Lesson PlanDocument3 pagesHoles Lesson Planapi-270543697No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MF5400 Manual 05-EnDocument462 pagesMF5400 Manual 05-EnSelmirije2100% (2)

- Decision-Making Competence in Everyday Life.Document6 pagesDecision-Making Competence in Everyday Life.Chelsea AcostaNo ratings yet

- Contradictions of Plato's IdeasDocument6 pagesContradictions of Plato's Ideaskissinger2020No ratings yet

- 2019 Recitation Chap 2 PDFDocument21 pages2019 Recitation Chap 2 PDFGull100% (1)

- Advances in The Theory of Plates and Shells, Edited by G.Z. Voyiadjis and D. KaramanlidisDocument35 pagesAdvances in The Theory of Plates and Shells, Edited by G.Z. Voyiadjis and D. KaramanlidisHasanain AlmusawiNo ratings yet

- 4 Elfospace sp14m001gb 04 - 1520073972076Document4 pages4 Elfospace sp14m001gb 04 - 1520073972076Justin ReyesNo ratings yet

- EKKO ProjectDocument2 pagesEKKO ProjectGeofisica GusZavNo ratings yet

- MIR - LML - Golovina L. I. and Yaglom I. M. - Induction in GeometryDocument134 pagesMIR - LML - Golovina L. I. and Yaglom I. M. - Induction in Geometryavast2008100% (2)

- Asus ROG Zephyrus S GX531: 1.what Are The Main Characteristics?Document3 pagesAsus ROG Zephyrus S GX531: 1.what Are The Main Characteristics?mihaelahristeaNo ratings yet

- (Worksheet 13.1) - (Power Sharing)Document5 pages(Worksheet 13.1) - (Power Sharing)DeepikaNo ratings yet

- GTP Strategic Plan Proposal PDFDocument227 pagesGTP Strategic Plan Proposal PDFPak Ngah LebayNo ratings yet

- Instalment Payment Plan FormDocument1 pageInstalment Payment Plan Formckeat_2No ratings yet

- GT Lube Oil FlushingDocument11 pagesGT Lube Oil Flushingshubham raj bhawsarNo ratings yet

- np2 6-12Document2 pagesnp2 6-12api-170472102No ratings yet

- 48V TXT Service Manual PDFDocument192 pages48V TXT Service Manual PDFJim Campbell De Castro100% (3)

- High Resolution Video Endoscopy System: Sonoscape Medical CorpDocument4 pagesHigh Resolution Video Endoscopy System: Sonoscape Medical CorpTaha OpedNo ratings yet

- Sales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1Document4 pagesSales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1jarosNo ratings yet

- UAS General English-2-2021Document12 pagesUAS General English-2-2021Putri Pradnya DewantiNo ratings yet

- Addressing Sexual Harassment at Workplace - Without Author's NameDocument15 pagesAddressing Sexual Harassment at Workplace - Without Author's Namemehjabin ferdous moneesaNo ratings yet

- REPORT Compressed Image Processing 45Document23 pagesREPORT Compressed Image Processing 45Mahender YadavNo ratings yet

- Tall Buildings in CopenhagenDocument140 pagesTall Buildings in CopenhagenMorten Kent HansenNo ratings yet

- Essential Oil Nanoemulsions As Antimicrobial Agents in FoodDocument19 pagesEssential Oil Nanoemulsions As Antimicrobial Agents in FoodpradeepqNo ratings yet

- Cat - Dcs.sis - Controller (12H - 8MN)Document2 pagesCat - Dcs.sis - Controller (12H - 8MN)Warley Moraes Oliveira100% (1)

- Week 3-Tals: 1. The Student Learning MovementDocument5 pagesWeek 3-Tals: 1. The Student Learning MovementPrincess PauleNo ratings yet

- Project ManagementDocument41 pagesProject ManagementOm Prakash SharmaNo ratings yet

- LEX1 Data SheetDocument2 pagesLEX1 Data Sheetpreetharajamma6025No ratings yet

- Activity Completion Report: A Lampshade Making ProjectDocument7 pagesActivity Completion Report: A Lampshade Making ProjectciriloNo ratings yet

- Chapter 2 Vectors and Two Dim Motion - Gen - Med - All SectionsDocument60 pagesChapter 2 Vectors and Two Dim Motion - Gen - Med - All Sectionsnader siamNo ratings yet

- Redis Cluster Specification-12Document1 pageRedis Cluster Specification-12Kajaruban SurendranNo ratings yet