Professional Documents

Culture Documents

21.65 Kips/bolt Shear Strength Controls: Section at A

21.65 Kips/bolt Shear Strength Controls: Section at A

Uploaded by

Suneesh POriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

21.65 Kips/bolt Shear Strength Controls: Section at A

21.65 Kips/bolt Shear Strength Controls: Section at A

Uploaded by

Suneesh PCopyright:

Available Formats

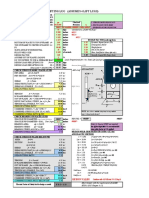

PROJECT: STEEL BUILDING DESIGN CASE STUDY

SUBJECT: Tension member design. Bolted connection. SHEET 101 of 131

Connection for a 38.3 foot long tension member that has to resist 78 kips of already factored load.

No slip is permitted, so this connection is slip critical.

t = resistance factor relating to tensile strength

Ag = gross cross-sectional area

Ae = U*An

U = reduction coefficient

Fy = specified (ASTM) minimum yield stress

Fu = specified (ASTM) minimum tensile strength

d = diameter of the bolt

An = net area

Rn = strength

Rstr = slip critical strength

Lc = distance from edge of hole to edge of connected part

t = thickness of connected part

Ab = nominal bolt area

Pu = factored load to be resisted

Fv = ultimate shearing strength

= mean slip coefficient (coefficient of static friction)

Tb = minimum fastener tension

Agv = gross area acted upon by shear

Agt = gross area acted upon by tension

Anv = net area acted upon by shear

Ant = net area acted upon by tension

Because the bolt size and layout will affect the net area of the tension member, we will begin with

the selection of the bolts. Use A325 bolts and A572 Grade 36 steel for both the tension member and

the gusset plate (standard holes).

Pu = 76 (kips)

t= 3/4 in = 0.75

Fv = 48 (ksi)

= 0.33

Fy = 36 (ksi)

Fu = 58.0 (ksi)

L = 38.3 (ft)

Section at A

A

TRY : 7/8 (in) bolts Tb = 39 (kips) from table J3.1 LRFD

2

Ab = 0.60 (in ) Ns = 2

Shear strength:

Rn= Fv Ab (assuming that the threads are in the shear plane)

Rn= 21.65 Kips/bolt

Rstr = (1.13 Tb b Ns) Rstr = 29.09 Kips/bolt

Shear strength controls Rn = 21.65 Kips/bolt

Red font indicates user input

PROJECT: STEEL BUILDING DESIGN CASE STUDY

SUBJECT: Bolted connection SHEET 102 of 131

Number of bolts required = 3.51 bolts

Try = 4 bolts

Minimum spacing : the distance between centers of standard, oversized, or slotted holes, shall

not be less than 3d (from AISC J3.3).

s =3 d= 2.63 in

say, s = 3 in

Minimum edge distance : (from AISC table J3.4)

Le = 1.5 in

Ag req. 2.3457 in

2

U= 0.85 (from commentary to the AISC specification)

Ae req. 1.7471 in2

An req. 2.0554 in2

minimum radius of gyration:

r min = 1.532 in

TRY 2L5x3x1/2LLBB

bolts placed in the long leg at the usual gage distance (check LRFD page 10-10)

usual gage = 3 in

2

Ag = 7.51 in > 2.35 in2 OK!

r = 1.58 in > 1.53 in OK!

t= 0.5 in

An = 7.01 in2 > 2.0554 in2 OK!

x = 0.736 in

U = 0.91822 < 0.9 use U = 0.9

Ae = 6.309 in2 > 1.7471 in2 OK!

Check Bearing strength:

for bearing strength computation use a hole diameter of h = 15/16 in

Rn = (1.2 Lc t Fu) if Lc < 2 d

Rn = (2.4 d t Fu) if Lc > 2 d

For the hole nearest the edge of the member :

Lc = 1.03 in

2d= 1.75 in Rn = 26.92 kips/bolt

For the other holes:

Lc = 2.06 in

2d= 1.75 in Rn = 45.68 kips/bolt

Total bearing strength of the connection :

Rn = 163.94 kips > 76 kips OK!

Red font indicates user input

PROJECT: STEEL BUILDING DESIGN CASE STUDY

SUBJECT: Bolted connection SHEET 103 of 131

Check Block shear:

Shear areas:

2

Agv = 5.25 in

2

Anv = 3.50 in

Tension areas:

2

Agt = 0.50 in

2

Ant = 0.25 in

Shear rupture design strength Vn: LRFD J4-1

(.6*Fu)*Anv = 91.35 kips

Tension rupture design strength Tn: LRFD J4-2

Fu*Ant = 10.875 kips

The larger fracture term controls: LRFD J4-1 controls

Block shear strength:

Rn = 104.85 kips < 102.23

Rn = 102.225 kips > Pu/2 = 38 kips OK!

Le = 1.5 in

Le = 1.5 in s= 3 in.

g= 3 in

Use a 2L5x3x1/2LLBB with the long leg connected.

Use 4 7/8 in. A325 bolts.

Red font indicates user input

You might also like

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- Problem Set 1Document13 pagesProblem Set 1tansuNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- LiftingLugStress Rev 1.5Document17 pagesLiftingLugStress Rev 1.5mohdshakir bahariNo ratings yet

- Princess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCDocument3 pagesPrincess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCNats SantosNo ratings yet

- Design of Base PlateDocument26 pagesDesign of Base Plateraghav abudhabiNo ratings yet

- Design of Beam To Beam Connection Using Web CleatDocument2 pagesDesign of Beam To Beam Connection Using Web CleatAnonymous UUAriPf8KqNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- Brackets For Circular Platforms at Vertical VesselsDocument4 pagesBrackets For Circular Platforms at Vertical Vesselsameya natuNo ratings yet

- Eccentric Loads On Vertical Parallel Weld GroupsDocument1 pageEccentric Loads On Vertical Parallel Weld GroupsPriodeep ChowdhuryNo ratings yet

- Web Flange WeldDocument1 pageWeb Flange Weldakgupta733779No ratings yet

- Base Plate Hinged - Moment On Anchors Adjusted 09-06-2021Document2 pagesBase Plate Hinged - Moment On Anchors Adjusted 09-06-2021ahmed osmanNo ratings yet

- POS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Document26 pagesPOS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Nguyễn Duy QuangNo ratings yet

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarNo ratings yet

- Wind Load Calculation NZS PDFDocument1 pageWind Load Calculation NZS PDFSantoshNo ratings yet

- Steel Beam DesignDocument1 pageSteel Beam DesignURVESHKUMAR PATELNo ratings yet

- Plate GirderDocument15 pagesPlate GirderPriodeep ChowdhuryNo ratings yet

- Setting Bolt CalculationDocument1 pageSetting Bolt Calculationrina2393No ratings yet

- Lifting Lug Stress - 4 - PointsDocument2 pagesLifting Lug Stress - 4 - PointsDipak ZopeNo ratings yet

- Chapter 6 Plate GirderDocument23 pagesChapter 6 Plate Girderolomu100% (1)

- Beam Tutorial 1 Worked SolutionDocument8 pagesBeam Tutorial 1 Worked SolutionMeyer EdouardNo ratings yet

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- I-Beam Properties (Old)Document5 pagesI-Beam Properties (Old)vinit soodNo ratings yet

- Anchor Bolt Design BP1Document29 pagesAnchor Bolt Design BP1satyakamNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- Weld StrengthDocument9 pagesWeld StrengthRUDHRA DHANASEKAR50% (2)

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Design of Brace Connection: Input InformationDocument6 pagesDesign of Brace Connection: Input InformationJonatas PrandiniNo ratings yet

- Crane Beam Web Splice DesignDocument7 pagesCrane Beam Web Splice DesignCrystal JaneNo ratings yet

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059No ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- Sag RodDocument1 pageSag Rodspk ReviewNo ratings yet

- HILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)Document3 pagesHILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)inti lestariNo ratings yet

- AISC Connection-2nd Edition (2+2) Bolts Conn Between Tub Col & I-BeamDocument4 pagesAISC Connection-2nd Edition (2+2) Bolts Conn Between Tub Col & I-BeamTuấnThanhNo ratings yet

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7No ratings yet

- Pin Connected Tension MemberDocument2 pagesPin Connected Tension MemberAUNGPSNo ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Calculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesDocument7 pagesCalculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesYunizar Putra MahardikaNo ratings yet

- Com ColumnDocument2 pagesCom ColumnHarjasa AdhiNo ratings yet

- Wind Load Calculations On VesselsDocument3 pagesWind Load Calculations On VesselssudhakarebvnNo ratings yet

- FND BoltDocument1 pageFND BoltArunkumar RackanNo ratings yet

- Cleat Design - C-605Document4 pagesCleat Design - C-605shaishavNo ratings yet

- Moment Splice - BackupDocument74 pagesMoment Splice - BackupKiran AcharyaNo ratings yet

- Torsion Validation ShayanDocument10 pagesTorsion Validation ShayanGicuNo ratings yet

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckHomer SilvaNo ratings yet

- Corner Bracing Connection Capacity Based On AISC 360-10/16 Design CriteriaDocument10 pagesCorner Bracing Connection Capacity Based On AISC 360-10/16 Design CriteriaMahesh MNo ratings yet

- BGSCM14 C08 Ex ProbDocument85 pagesBGSCM14 C08 Ex ProbamachmouchiNo ratings yet

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraNo ratings yet

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureDocument2 pagesWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- Skid LiftDocument2 pagesSkid LiftAmi PutraNo ratings yet

- PEC EN STN C 13619 17 Mar 2014Document169 pagesPEC EN STN C 13619 17 Mar 2014Raja RamNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- ASD-Design of Steel BeamDocument5 pagesASD-Design of Steel BeamsivakumarNo ratings yet

- Book 3Document6 pagesBook 3Sasikumar Jothi100% (1)

- Bracing Connection - Rev EDocument32 pagesBracing Connection - Rev EHeberth SanchezNo ratings yet

- Stair Stringer DesignDocument2 pagesStair Stringer DesignTerry CheukNo ratings yet

- Aisc 28Document4 pagesAisc 28mirfanjpcgmailcomNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AAravindanNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AKARTHIK SGNo ratings yet

- Civil & Architectural Engineering Department: June 23, 2016Document71 pagesCivil & Architectural Engineering Department: June 23, 2016Suneesh PNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationSuneesh PNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inSuneesh PNo ratings yet

- LC V4-0 LightingCalculator 20180402Document323 pagesLC V4-0 LightingCalculator 20180402Suneesh PNo ratings yet

- 171 The Seismic Design of Industrial Plants: 4, DECEMBER 1982Document14 pages171 The Seismic Design of Industrial Plants: 4, DECEMBER 1982Suneesh PNo ratings yet

- Design of Purlins Revised 2005 1Document42 pagesDesign of Purlins Revised 2005 1Law MolinaNo ratings yet

- General Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailDocument53 pagesGeneral Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailbetojulioNo ratings yet

- Hoda Emami CSA LRFD ComparisonDocument19 pagesHoda Emami CSA LRFD ComparisonhkchungNo ratings yet

- Continuous Assessment Test I: January 2019 Reg. No.Document2 pagesContinuous Assessment Test I: January 2019 Reg. No.Venkatram PrabhuNo ratings yet

- CE 437 - PDF 04 - Intro 04 - Steel - (Design of Steel Structure)Document6 pagesCE 437 - PDF 04 - Intro 04 - Steel - (Design of Steel Structure)Md Mufazzel Hossain ChowdhuryNo ratings yet

- ASD Vs LRFD ComparisonDocument107 pagesASD Vs LRFD Comparisonpandiangv0% (1)

- 07 Group Work Tension MemberDocument12 pages07 Group Work Tension MemberRi MarkuNo ratings yet

- Bolted-Welded Connection DesignDocument33 pagesBolted-Welded Connection DesignGuilmer VictorioNo ratings yet

- 4 Tension MemberDocument15 pages4 Tension Memberhari1008108No ratings yet

- Practice Problems - Tension MembersDocument3 pagesPractice Problems - Tension MembersFayyazAhmad100% (1)

- TENSION MEMBER (Compatibility Mode)Document44 pagesTENSION MEMBER (Compatibility Mode)ArThur BangunNo ratings yet

- CE6603-Design of Steel Structures QBDocument7 pagesCE6603-Design of Steel Structures QBAarohiShirkeNo ratings yet

- Design Strength of Tension MembersDocument72 pagesDesign Strength of Tension MembersSurja Gain50% (2)

- Lec1 Steel Design 2nd Sem 2011-12Document6 pagesLec1 Steel Design 2nd Sem 2011-12Jesus Ray M. MansayonNo ratings yet

- Aisc 28Document4 pagesAisc 28Lyhalim SethNo ratings yet

- Design of BoltsDocument19 pagesDesign of Boltsmoganna73No ratings yet

- Steel DesignDocument18 pagesSteel DesignJaninaRuzzleSilangNo ratings yet

- Design of Steel Structure - Steel Design Tension MembersDocument24 pagesDesign of Steel Structure - Steel Design Tension MembersshingkeongNo ratings yet

- Structural Steel Design: Eng Fuad Dhunkal in Civil EngineeringDocument18 pagesStructural Steel Design: Eng Fuad Dhunkal in Civil Engineeringfuaad dhunkaalNo ratings yet

- Lecture 3Document16 pagesLecture 3Amr Zein Al DeinNo ratings yet

- LECTURE 3.0 - Analysis of Tension Members PDFDocument69 pagesLECTURE 3.0 - Analysis of Tension Members PDFAnn loraine BanzonNo ratings yet

- Design of Steel StructuresDocument4 pagesDesign of Steel StructuresprkshdvNo ratings yet

- Chapter 2. Tension MemberDocument12 pagesChapter 2. Tension MemberaskannancvNo ratings yet

- 03 Intro. Tension MemberDocument10 pages03 Intro. Tension MemberRi MarkuNo ratings yet

- Exercises and REVIEW QUESTIONS 2018Document12 pagesExercises and REVIEW QUESTIONS 2018Thiên LongNo ratings yet

- Splice LRFD-LFD DesignDocument23 pagesSplice LRFD-LFD DesignYANIshaNo ratings yet

- Design of Tension Members: Rafter Suspenders Sag Rod PurlinDocument15 pagesDesign of Tension Members: Rafter Suspenders Sag Rod PurlinMohammed Junaid ShaikhNo ratings yet

- Solucionario Capitulo 7 PDFDocument47 pagesSolucionario Capitulo 7 PDFCesar Marron Matta100% (1)

- Aisc 28Document4 pagesAisc 28Ramesh SahasrabudheNo ratings yet

- Example Problems For Tension Members SteelDocument5 pagesExample Problems For Tension Members SteelTesfa HunderaNo ratings yet

- Chapter 2 Tension MembersDocument8 pagesChapter 2 Tension MembersGamtesa EjetaNo ratings yet