Professional Documents

Culture Documents

PTO Shaft Information Sheet

PTO Shaft Information Sheet

Uploaded by

Mathilda MoreaCopyright:

Available Formats

You might also like

- Ospmdah-150e-21 Mower ManualDocument86 pagesOspmdah-150e-21 Mower ManualWesley Trajano100% (1)

- Workshop Manual SDF 1000.3.4.6w EuroiiDocument170 pagesWorkshop Manual SDF 1000.3.4.6w EuroiiFR78% (27)

- 3000 HP RigDocument1 page3000 HP RigPrakash SekarNo ratings yet

- HR Blowers Uk LTD: Installation & Operating ManualDocument20 pagesHR Blowers Uk LTD: Installation & Operating ManualAditya ShrivastavaNo ratings yet

- Valve Servicing Procedure 01Document14 pagesValve Servicing Procedure 01Faiz Zainudin100% (2)

- Motor Grader 672aDocument4 pagesMotor Grader 672aSteve LuceNo ratings yet

- 7628 SCRAPER: Engine PerformanceDocument4 pages7628 SCRAPER: Engine PerformanceJorgeBravoG.No ratings yet

- L1204c Plus Spec New MercDocument2 pagesL1204c Plus Spec New MercMoodNo ratings yet

- PRODUCT CATALOG XCMG - CompressedDocument2 pagesPRODUCT CATALOG XCMG - CompressedYuda WiratamaNo ratings yet

- Eaton Fuller 11 Speed Transmissions Brochure trsl0253 en UsDocument2 pagesEaton Fuller 11 Speed Transmissions Brochure trsl0253 en UspowermanagerNo ratings yet

- Brochure Specificatitions (KS EN050)Document9 pagesBrochure Specificatitions (KS EN050)Muhamad Dwi CahyonoNo ratings yet

- Brochure Specifications (KS EN050Q)Document9 pagesBrochure Specifications (KS EN050Q)Muhamad Dwi CahyonoNo ratings yet

- Jd670 Motor Grader: Engine Performance Features Add Versatility WithDocument3 pagesJd670 Motor Grader: Engine Performance Features Add Versatility Withjadan tupuaNo ratings yet

- E-Series ADT MK 2 StageII (B20E) DataSheet-webDocument2 pagesE-Series ADT MK 2 StageII (B20E) DataSheet-webPfariso TshivhizoNo ratings yet

- Satoh Buck S-470 & S-470D SpecificationsDocument2 pagesSatoh Buck S-470 & S-470D Specificationscc7.eaiNo ratings yet

- Yanmar Type 6SY-650: Rear View Right Side ViewDocument2 pagesYanmar Type 6SY-650: Rear View Right Side ViewAlbertoNo ratings yet

- Dumper Spec FinalDocument1 pageDumper Spec FinalJackson PhinniNo ratings yet

- Kruger Ventilation Industries Pte LTD No. 17 Tuas Avenue 10 Singapore 639141 Tel: +65 6861 1577 Fax: +65 6861 3577 Date Company Attention Project Reference NotesDocument1 pageKruger Ventilation Industries Pte LTD No. 17 Tuas Avenue 10 Singapore 639141 Tel: +65 6861 1577 Fax: +65 6861 3577 Date Company Attention Project Reference NotesHiei ArshavinNo ratings yet

- Operation and Maintenance Manual Bulletin Nh220Document4 pagesOperation and Maintenance Manual Bulletin Nh220Cordova MarcosNo ratings yet

- Axera6 226 FichaDocument3 pagesAxera6 226 FichaFer GarciaNo ratings yet

- Axera6 226Document3 pagesAxera6 226Jesinaldo DantasNo ratings yet

- Lit2236 R4 4-2010Document2 pagesLit2236 R4 4-2010EiSerVasquezNo ratings yet

- Sandvic DD420 60C SpecDocument4 pagesSandvic DD420 60C SpecAlterSon Grafi KalayNo ratings yet

- SM401Document8 pagesSM401sistemavictorsinaisNo ratings yet

- General Specifications: Torque OutputDocument2 pagesGeneral Specifications: Torque OutputDuck youNo ratings yet

- Catalogue: 2 Workingcondition 3 Maintechnicaldata 4 &Document11 pagesCatalogue: 2 Workingcondition 3 Maintechnicaldata 4 &henry vegaNo ratings yet

- EN PC3000 11SP01 - ExcavatorDocument3 pagesEN PC3000 11SP01 - ExcavatorRaffa GamingNo ratings yet

- Dozer Bulldozer 850 6545Document4 pagesDozer Bulldozer 850 6545AbdulRasheedNo ratings yet

- Cursor 13 Entm 50.10Document4 pagesCursor 13 Entm 50.10GLGNo ratings yet

- Multi-Speed Performance Curve: Customer ReferenceDocument1 pageMulti-Speed Performance Curve: Customer ReferenceAaron Marius JuliusNo ratings yet

- Fe170 DatasheetDocument2 pagesFe170 DatasheetduconNo ratings yet

- Bunch Press & Shredder ComparisonDocument3 pagesBunch Press & Shredder ComparisonAdie JZNo ratings yet

- 01 VLI GT46AC Intro & Product FamiliarizationDocument18 pages01 VLI GT46AC Intro & Product FamiliarizationRafael Dutil LucianaNo ratings yet

- Hitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164Document11 pagesHitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164patrickhoyer93No ratings yet

- T 858Document1 pageT 858Ahmed EzzeddineNo ratings yet

- FD620D-Lawnmower Engine DrawingDocument2 pagesFD620D-Lawnmower Engine Drawingmarcinko203No ratings yet

- M11 Falcon UF Concentrator 2018Document2 pagesM11 Falcon UF Concentrator 2018Mamoudou MagassoubaNo ratings yet

- 6991 1757 01 BoylesC8Ctechspec Lowres tcm836-3509938Document4 pages6991 1757 01 BoylesC8Ctechspec Lowres tcm836-3509938Francis100% (1)

- CD100MV Dri-Prime Pumps: FeaturesDocument2 pagesCD100MV Dri-Prime Pumps: FeaturesAbcehmu EgiNo ratings yet

- Allison HT-740 SpecsDocument4 pagesAllison HT-740 SpecsDiegoNo ratings yet

- DL420 15c SpecificationsDocument4 pagesDL420 15c Specificationsesteban muñozNo ratings yet

- Principles of Operation RetarderDocument7 pagesPrinciples of Operation Retardervitor santosNo ratings yet

- SM Mla 628 - 547860enDocument749 pagesSM Mla 628 - 547860enaritmeticsNo ratings yet

- SCH 5000Document2 pagesSCH 5000Anonymous xxFArUCS100% (3)

- Axera 7260t Sandvik Mining and ConstructionDocument4 pagesAxera 7260t Sandvik Mining and ConstructiondaniloNo ratings yet

- Hitachi EX3600 Hydraulic Excavator PDFDocument11 pagesHitachi EX3600 Hydraulic Excavator PDFChaerul Umami100% (1)

- FRR 1o7-21o TipperDocument4 pagesFRR 1o7-21o Tipperakash shahNo ratings yet

- T 849Document1 pageT 849Ahmed EzzeddineNo ratings yet

- Short MODU Specs of Tam Dao 03Document2 pagesShort MODU Specs of Tam Dao 03Them Bui XuanNo ratings yet

- tAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderDocument2 pagestAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderAdolfito PBNo ratings yet

- AdriaticDocument2 pagesAdriaticrathnakumar vNo ratings yet

- Nps 250 300 Crew 4-CylDocument4 pagesNps 250 300 Crew 4-Cyl刘凯威No ratings yet

- Enerpac PTA Series CatalogDocument2 pagesEnerpac PTA Series CatalogTitanplyNo ratings yet

- SpecificationsDocument4 pagesSpecificationsvipulNo ratings yet

- YANMAR SV16 Crawler Excavator MY2014Document6 pagesYANMAR SV16 Crawler Excavator MY2014Alin GrigorescuNo ratings yet

- DS 6lpa-Ztzp2 A4 022021 HRDocument2 pagesDS 6lpa-Ztzp2 A4 022021 HRMiguel Alcides Cueva HuamaliesNo ratings yet

- ZX210LC 5G Ka En160Document5 pagesZX210LC 5G Ka En160Mameds MefNo ratings yet

- T 801Document1 pageT 801Ahmed EzzeddineNo ratings yet

- Sandvik De811 Spec SheetDocument1 pageSandvik De811 Spec SheetAhmed GhoneimNo ratings yet

- Sandvik DE740: Heavy Duty Core DrillDocument3 pagesSandvik DE740: Heavy Duty Core Drillclaudio67% (3)

- Jumbo Dl420 7cDocument4 pagesJumbo Dl420 7cRodrigo ContrerasNo ratings yet

- Brake Chassis Dyno Design Tool V3Document4 pagesBrake Chassis Dyno Design Tool V3Eko Dicky PrasetyoNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Mineral and Synthetic Lubricants SummaryDocument6 pagesMineral and Synthetic Lubricants SummaryDarmawan PutrantoNo ratings yet

- 05 Materials Technical InformationsDocument7 pages05 Materials Technical InformationsEustahije BrzicNo ratings yet

- Cable Tensionmeter-TN-001-T5 Operation and Service ManualDocument28 pagesCable Tensionmeter-TN-001-T5 Operation and Service ManualDade SobarnaNo ratings yet

- Casquillos INADocument55 pagesCasquillos INAFrancisco PalomeroNo ratings yet

- Mobilgrease XHP 322 Special PdsDocument2 pagesMobilgrease XHP 322 Special Pdsppanagos5664No ratings yet

- Predictive Maintenance - Training CourseDocument130 pagesPredictive Maintenance - Training CourseWaleed Tahawy100% (6)

- Grease Manufacturers and Suppliers - Nandan Petrochem LTDDocument22 pagesGrease Manufacturers and Suppliers - Nandan Petrochem LTDNandan Petrochem LtdNo ratings yet

- KZ550 - GT550 G1-G9 Part 1Document68 pagesKZ550 - GT550 G1-G9 Part 1sucmass533No ratings yet

- STLE 2021 Virtual AMPGDocument112 pagesSTLE 2021 Virtual AMPGWan Imran100% (1)

- LubricantsDocument8 pagesLubricantsMd Mujibur RahmanNo ratings yet

- 12 Info and Work Sheet Perform Under Chassis Preventive MaintenanceDocument50 pages12 Info and Work Sheet Perform Under Chassis Preventive MaintenanceDEATHSTAR GAMINGNo ratings yet

- SPM - EXL PLUG VALVE CM20211129-9a392-39da4Document32 pagesSPM - EXL PLUG VALVE CM20211129-9a392-39da4Julio Cesar Narvaez LaraNo ratings yet

- Abb Training ReportDocument43 pagesAbb Training ReportSandeep Kumar100% (1)

- Dodge E&K Type Housing UNitsDocument70 pagesDodge E&K Type Housing UNitsgrupa2904No ratings yet

- Advanced Machine Design AssignDocument45 pagesAdvanced Machine Design AssignAlan ChenNo ratings yet

- LubeCoach Volume and Frequency Recommendations PDFDocument13 pagesLubeCoach Volume and Frequency Recommendations PDFEstebanRivera100% (1)

- Watson-Marlow Baseplate Mounted Pumps Installation and Operating Instructions 701FB/RDocument24 pagesWatson-Marlow Baseplate Mounted Pumps Installation and Operating Instructions 701FB/RDeniMestiWidiantoNo ratings yet

- Operation and Maintenance ManualDocument39 pagesOperation and Maintenance Manualhdf17No ratings yet

- Filtracion Lubricantes NuevosDocument100 pagesFiltracion Lubricantes NuevosHernan Andres GarciaNo ratings yet

- IOM - iHTDocument50 pagesIOM - iHTkarun agrawalNo ratings yet

- SZLH575×210 Pellet Mill: Concise Operation ManualDocument52 pagesSZLH575×210 Pellet Mill: Concise Operation ManualClau BMNo ratings yet

- HGM-E LSHT Wheel Motor BLN-52198 - P9Document25 pagesHGM-E LSHT Wheel Motor BLN-52198 - P9JoeNo ratings yet

- GL XX Mobilgear SHC SeriesDocument3 pagesGL XX Mobilgear SHC Seriesanibal_rios_rivasNo ratings yet

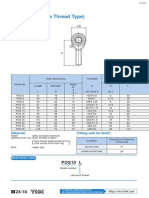

- POS 10 End Bearing DimensionDocument2 pagesPOS 10 End Bearing DimensionherrysugarNo ratings yet

- Product Catalogue: Lubricants For Cars and TrucksDocument17 pagesProduct Catalogue: Lubricants For Cars and TrucksceljkoNo ratings yet

- Part No.508000003127 V1 08/2019Document37 pagesPart No.508000003127 V1 08/2019Tinto MenacheryNo ratings yet

PTO Shaft Information Sheet

PTO Shaft Information Sheet

Uploaded by

Mathilda MoreaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTO Shaft Information Sheet

PTO Shaft Information Sheet

Uploaded by

Mathilda MoreaCopyright:

Available Formats

Page 7

TRIMMING IMPLEMENT PTO SHAFT

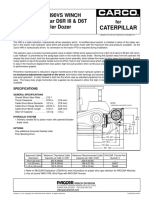

BARE-CO PTO SHAFT SPECIFICATIONS TO SUIT YOUR TRACTOR

INS 142

Dynamic Capacity Minimum Life.

NOTE: End thrust from over length shafts (or seized telescopic tubes) can destroy your tractors internal

Standard Shaft At 5 Degrees 1000HRS. At 10 Degrees 100 HRS.

PTO drive or implement clutch and gearbox, voiding your machine warranty.

Wide Angle Shaft At 10 Degrees 1000HRS. At 18 Degrees 100 HRS.

SHAFT NOMINAL POWER NOMINAL MAXIMUM

SERIES @540RPM @1000RPM TORQUE SPEED 1) Measure groove to groove dis-

tance from implement shaft to

tractor shaft with implement in

12KW 19KW 210NM 1100 RPM shortest position.

16HP 26HP

NOTE: Length will vary as imple-

ment is raised or lowered

16KW 26KW 270NM 1100 RPM

21HP 35HP

2) Remove safety guard from new

shaft and measure length between

shaft lock buttons or clamp bolts

with shaft in closed position.

26KW 42KW 460NM 1100 RPM

35HP 56HP

3) Required length of shaft is groove

to groove length (step 1)

48KW 77KW 830NM 1100 RPM less a minimum of 76mm (3”) to

allow for disconnection from trac-

64HP 102HP tor and prevent end thrust damage.

If shaft is shorter than this, ensure

that 50% of telescopic tubes over-

lap.

79KW 126KW 1390NM 1100 RPM

106HP 170HP 4) Amount to cut off shaft;

Length of new shaft (step 2)

Less groove to groove measure-

ment (step 1)

79KW 126KW 1390NM 1100 RPM plus 76mm (3”).

106HP 170HP Cut this amount off both inner and

outer drive tubes. Remove burrs

and grease tubes.

E.g. New shaft 1194mm (47”) 6

90KW 144KW 1400NM 1100 RPM Less grove to groove requirement - 890mm (35”)

120HP 192HP plus clearance 76mm + 76mm (3”)

Amount to cut off 380mm (15”)

This is example only

Insert your own measurements.

Page 2

CUTTING SAFETY GUARD TO REQUIRED LENGTH FAILURE PREVENTION

Shaft Operating Angle

Adjust tractor hydraulic control to minimise lift height. High lift and large shaft angle will destroy universal joint.

All Bare-Co PTO shafts (single universal joint)

1 Short time running: Maximum angle 25 degrees

Continuous operation: Maximum angle 17 degrees

All Bare-Co Wide Angle PTO shafts (double universal joint)

Short time running (or stationary): Maximum angle 80 degrees

Continuous operation: Maximum angle 25 degrees

LUBRICATION

Sliding Members

Use high temperature grease similar to HP multi-purpose chassis grease.

2 Grease sliding members prior to assembly and after every 20 hours of use. For applications with high tele-

scoping movement grease every 8 hours.

Bare-Co shafts from 8 series upwards are equipped with a grease nipple which can be accessed by releasing

the patent guard to align access hole.

Universal Joints

Grease standard joints every 20 hours or 8 hours for severe conditions. Wide angle joints every 8 hours un-

der wide angle conditions. Operating standard shafts at greater than 10 degrees angle or wide angle shafts at

greater than 18 degrees angle dramatically reduces cross bearing life and requires more frequent lubrication.

4

IMPORTANT: Grease follows the easiest path through internal

3

ports to the four cross bearings.

Over heating and poor quality grease baked in one port will

prevent grease reaching that bearing, resulting in failure of indi-

vidual cross bearings.

“B” = “A” – 76mm (3”)

(“B” is 76mm (3”) less than “A”) Typical cross failure due to blocked internal grease port

MOST IMPORTANT!

Fully open guard covers to ensure grease flows to all cross bearings

Greasing through small guard access holes is not good enough!

5

How to prevent wide angle shaft failures:

6

1) If 80 degree wide angle shafts are angled at greater than 80 degrees (Jack knifing implement with shaft

stationary or rotating), the centre support ball and socket will break (not covered by warranty). To

avoid over angling , fit turn limiters to your implement draw bar. Correctly fitted turn limiters will con-

tact tractor tyre prior to over angling.

2) The very large centre disc lubrication cavity must be completely full before any grease transfers from

the cavity to the centre support ball and socket. More than half a cartridge of grease is required to fill

this cavity on initial shaft installation.

3) Wide angle covers should be completely removed to ensure grease flows to the centre support ball

and all eight cross bearings

You might also like

- Ospmdah-150e-21 Mower ManualDocument86 pagesOspmdah-150e-21 Mower ManualWesley Trajano100% (1)

- Workshop Manual SDF 1000.3.4.6w EuroiiDocument170 pagesWorkshop Manual SDF 1000.3.4.6w EuroiiFR78% (27)

- 3000 HP RigDocument1 page3000 HP RigPrakash SekarNo ratings yet

- HR Blowers Uk LTD: Installation & Operating ManualDocument20 pagesHR Blowers Uk LTD: Installation & Operating ManualAditya ShrivastavaNo ratings yet

- Valve Servicing Procedure 01Document14 pagesValve Servicing Procedure 01Faiz Zainudin100% (2)

- Motor Grader 672aDocument4 pagesMotor Grader 672aSteve LuceNo ratings yet

- 7628 SCRAPER: Engine PerformanceDocument4 pages7628 SCRAPER: Engine PerformanceJorgeBravoG.No ratings yet

- L1204c Plus Spec New MercDocument2 pagesL1204c Plus Spec New MercMoodNo ratings yet

- PRODUCT CATALOG XCMG - CompressedDocument2 pagesPRODUCT CATALOG XCMG - CompressedYuda WiratamaNo ratings yet

- Eaton Fuller 11 Speed Transmissions Brochure trsl0253 en UsDocument2 pagesEaton Fuller 11 Speed Transmissions Brochure trsl0253 en UspowermanagerNo ratings yet

- Brochure Specificatitions (KS EN050)Document9 pagesBrochure Specificatitions (KS EN050)Muhamad Dwi CahyonoNo ratings yet

- Brochure Specifications (KS EN050Q)Document9 pagesBrochure Specifications (KS EN050Q)Muhamad Dwi CahyonoNo ratings yet

- Jd670 Motor Grader: Engine Performance Features Add Versatility WithDocument3 pagesJd670 Motor Grader: Engine Performance Features Add Versatility Withjadan tupuaNo ratings yet

- E-Series ADT MK 2 StageII (B20E) DataSheet-webDocument2 pagesE-Series ADT MK 2 StageII (B20E) DataSheet-webPfariso TshivhizoNo ratings yet

- Satoh Buck S-470 & S-470D SpecificationsDocument2 pagesSatoh Buck S-470 & S-470D Specificationscc7.eaiNo ratings yet

- Yanmar Type 6SY-650: Rear View Right Side ViewDocument2 pagesYanmar Type 6SY-650: Rear View Right Side ViewAlbertoNo ratings yet

- Dumper Spec FinalDocument1 pageDumper Spec FinalJackson PhinniNo ratings yet

- Kruger Ventilation Industries Pte LTD No. 17 Tuas Avenue 10 Singapore 639141 Tel: +65 6861 1577 Fax: +65 6861 3577 Date Company Attention Project Reference NotesDocument1 pageKruger Ventilation Industries Pte LTD No. 17 Tuas Avenue 10 Singapore 639141 Tel: +65 6861 1577 Fax: +65 6861 3577 Date Company Attention Project Reference NotesHiei ArshavinNo ratings yet

- Operation and Maintenance Manual Bulletin Nh220Document4 pagesOperation and Maintenance Manual Bulletin Nh220Cordova MarcosNo ratings yet

- Axera6 226 FichaDocument3 pagesAxera6 226 FichaFer GarciaNo ratings yet

- Axera6 226Document3 pagesAxera6 226Jesinaldo DantasNo ratings yet

- Lit2236 R4 4-2010Document2 pagesLit2236 R4 4-2010EiSerVasquezNo ratings yet

- Sandvic DD420 60C SpecDocument4 pagesSandvic DD420 60C SpecAlterSon Grafi KalayNo ratings yet

- SM401Document8 pagesSM401sistemavictorsinaisNo ratings yet

- General Specifications: Torque OutputDocument2 pagesGeneral Specifications: Torque OutputDuck youNo ratings yet

- Catalogue: 2 Workingcondition 3 Maintechnicaldata 4 &Document11 pagesCatalogue: 2 Workingcondition 3 Maintechnicaldata 4 &henry vegaNo ratings yet

- EN PC3000 11SP01 - ExcavatorDocument3 pagesEN PC3000 11SP01 - ExcavatorRaffa GamingNo ratings yet

- Dozer Bulldozer 850 6545Document4 pagesDozer Bulldozer 850 6545AbdulRasheedNo ratings yet

- Cursor 13 Entm 50.10Document4 pagesCursor 13 Entm 50.10GLGNo ratings yet

- Multi-Speed Performance Curve: Customer ReferenceDocument1 pageMulti-Speed Performance Curve: Customer ReferenceAaron Marius JuliusNo ratings yet

- Fe170 DatasheetDocument2 pagesFe170 DatasheetduconNo ratings yet

- Bunch Press & Shredder ComparisonDocument3 pagesBunch Press & Shredder ComparisonAdie JZNo ratings yet

- 01 VLI GT46AC Intro & Product FamiliarizationDocument18 pages01 VLI GT46AC Intro & Product FamiliarizationRafael Dutil LucianaNo ratings yet

- Hitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164Document11 pagesHitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164patrickhoyer93No ratings yet

- T 858Document1 pageT 858Ahmed EzzeddineNo ratings yet

- FD620D-Lawnmower Engine DrawingDocument2 pagesFD620D-Lawnmower Engine Drawingmarcinko203No ratings yet

- M11 Falcon UF Concentrator 2018Document2 pagesM11 Falcon UF Concentrator 2018Mamoudou MagassoubaNo ratings yet

- 6991 1757 01 BoylesC8Ctechspec Lowres tcm836-3509938Document4 pages6991 1757 01 BoylesC8Ctechspec Lowres tcm836-3509938Francis100% (1)

- CD100MV Dri-Prime Pumps: FeaturesDocument2 pagesCD100MV Dri-Prime Pumps: FeaturesAbcehmu EgiNo ratings yet

- Allison HT-740 SpecsDocument4 pagesAllison HT-740 SpecsDiegoNo ratings yet

- DL420 15c SpecificationsDocument4 pagesDL420 15c Specificationsesteban muñozNo ratings yet

- Principles of Operation RetarderDocument7 pagesPrinciples of Operation Retardervitor santosNo ratings yet

- SM Mla 628 - 547860enDocument749 pagesSM Mla 628 - 547860enaritmeticsNo ratings yet

- SCH 5000Document2 pagesSCH 5000Anonymous xxFArUCS100% (3)

- Axera 7260t Sandvik Mining and ConstructionDocument4 pagesAxera 7260t Sandvik Mining and ConstructiondaniloNo ratings yet

- Hitachi EX3600 Hydraulic Excavator PDFDocument11 pagesHitachi EX3600 Hydraulic Excavator PDFChaerul Umami100% (1)

- FRR 1o7-21o TipperDocument4 pagesFRR 1o7-21o Tipperakash shahNo ratings yet

- T 849Document1 pageT 849Ahmed EzzeddineNo ratings yet

- Short MODU Specs of Tam Dao 03Document2 pagesShort MODU Specs of Tam Dao 03Them Bui XuanNo ratings yet

- tAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderDocument2 pagestAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderAdolfito PBNo ratings yet

- AdriaticDocument2 pagesAdriaticrathnakumar vNo ratings yet

- Nps 250 300 Crew 4-CylDocument4 pagesNps 250 300 Crew 4-Cyl刘凯威No ratings yet

- Enerpac PTA Series CatalogDocument2 pagesEnerpac PTA Series CatalogTitanplyNo ratings yet

- SpecificationsDocument4 pagesSpecificationsvipulNo ratings yet

- YANMAR SV16 Crawler Excavator MY2014Document6 pagesYANMAR SV16 Crawler Excavator MY2014Alin GrigorescuNo ratings yet

- DS 6lpa-Ztzp2 A4 022021 HRDocument2 pagesDS 6lpa-Ztzp2 A4 022021 HRMiguel Alcides Cueva HuamaliesNo ratings yet

- ZX210LC 5G Ka En160Document5 pagesZX210LC 5G Ka En160Mameds MefNo ratings yet

- T 801Document1 pageT 801Ahmed EzzeddineNo ratings yet

- Sandvik De811 Spec SheetDocument1 pageSandvik De811 Spec SheetAhmed GhoneimNo ratings yet

- Sandvik DE740: Heavy Duty Core DrillDocument3 pagesSandvik DE740: Heavy Duty Core Drillclaudio67% (3)

- Jumbo Dl420 7cDocument4 pagesJumbo Dl420 7cRodrigo ContrerasNo ratings yet

- Brake Chassis Dyno Design Tool V3Document4 pagesBrake Chassis Dyno Design Tool V3Eko Dicky PrasetyoNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Mineral and Synthetic Lubricants SummaryDocument6 pagesMineral and Synthetic Lubricants SummaryDarmawan PutrantoNo ratings yet

- 05 Materials Technical InformationsDocument7 pages05 Materials Technical InformationsEustahije BrzicNo ratings yet

- Cable Tensionmeter-TN-001-T5 Operation and Service ManualDocument28 pagesCable Tensionmeter-TN-001-T5 Operation and Service ManualDade SobarnaNo ratings yet

- Casquillos INADocument55 pagesCasquillos INAFrancisco PalomeroNo ratings yet

- Mobilgrease XHP 322 Special PdsDocument2 pagesMobilgrease XHP 322 Special Pdsppanagos5664No ratings yet

- Predictive Maintenance - Training CourseDocument130 pagesPredictive Maintenance - Training CourseWaleed Tahawy100% (6)

- Grease Manufacturers and Suppliers - Nandan Petrochem LTDDocument22 pagesGrease Manufacturers and Suppliers - Nandan Petrochem LTDNandan Petrochem LtdNo ratings yet

- KZ550 - GT550 G1-G9 Part 1Document68 pagesKZ550 - GT550 G1-G9 Part 1sucmass533No ratings yet

- STLE 2021 Virtual AMPGDocument112 pagesSTLE 2021 Virtual AMPGWan Imran100% (1)

- LubricantsDocument8 pagesLubricantsMd Mujibur RahmanNo ratings yet

- 12 Info and Work Sheet Perform Under Chassis Preventive MaintenanceDocument50 pages12 Info and Work Sheet Perform Under Chassis Preventive MaintenanceDEATHSTAR GAMINGNo ratings yet

- SPM - EXL PLUG VALVE CM20211129-9a392-39da4Document32 pagesSPM - EXL PLUG VALVE CM20211129-9a392-39da4Julio Cesar Narvaez LaraNo ratings yet

- Abb Training ReportDocument43 pagesAbb Training ReportSandeep Kumar100% (1)

- Dodge E&K Type Housing UNitsDocument70 pagesDodge E&K Type Housing UNitsgrupa2904No ratings yet

- Advanced Machine Design AssignDocument45 pagesAdvanced Machine Design AssignAlan ChenNo ratings yet

- LubeCoach Volume and Frequency Recommendations PDFDocument13 pagesLubeCoach Volume and Frequency Recommendations PDFEstebanRivera100% (1)

- Watson-Marlow Baseplate Mounted Pumps Installation and Operating Instructions 701FB/RDocument24 pagesWatson-Marlow Baseplate Mounted Pumps Installation and Operating Instructions 701FB/RDeniMestiWidiantoNo ratings yet

- Operation and Maintenance ManualDocument39 pagesOperation and Maintenance Manualhdf17No ratings yet

- Filtracion Lubricantes NuevosDocument100 pagesFiltracion Lubricantes NuevosHernan Andres GarciaNo ratings yet

- IOM - iHTDocument50 pagesIOM - iHTkarun agrawalNo ratings yet

- SZLH575×210 Pellet Mill: Concise Operation ManualDocument52 pagesSZLH575×210 Pellet Mill: Concise Operation ManualClau BMNo ratings yet

- HGM-E LSHT Wheel Motor BLN-52198 - P9Document25 pagesHGM-E LSHT Wheel Motor BLN-52198 - P9JoeNo ratings yet

- GL XX Mobilgear SHC SeriesDocument3 pagesGL XX Mobilgear SHC Seriesanibal_rios_rivasNo ratings yet

- POS 10 End Bearing DimensionDocument2 pagesPOS 10 End Bearing DimensionherrysugarNo ratings yet

- Product Catalogue: Lubricants For Cars and TrucksDocument17 pagesProduct Catalogue: Lubricants For Cars and TrucksceljkoNo ratings yet

- Part No.508000003127 V1 08/2019Document37 pagesPart No.508000003127 V1 08/2019Tinto MenacheryNo ratings yet