Professional Documents

Culture Documents

Astm d6927

Astm d6927

Uploaded by

Tally AnuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm d6927

Astm d6927

Uploaded by

Tally AnuCopyright:

Available Formats

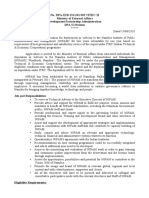

CCIL / LABORATORY INSPECTION CHECKLIST

Preparation of Marshall Specimens (from bituminous mixes)

ASTM D6927-06

APPARATUS

1. Breaking Head / Clause 4.1 …………………………………………………………………….. ____

2. Compression Loading Machine / Clause 4.2

a. Load – uniform vertical movement maintained at 50 ± 5mm/min ……………….. ____

3. Load Measuring Device / Clause 4.3

a. Dial indicator graduated in increments of 0.00025 mm (0.0001 in.) or

finer …………………………………………………………………………………… ____

4. Flowmeter / Clause 4.4

a. Graduation of the flowmeter gauge 0.25 mm (0.01) or finer ……………………... ____

5. Water Bath / Clause 4.5

a. Water level maintained at a minimum of 30 mm above the top of specimens

……………………………………………………………………………………………. ____

b. Thermostatically controlled to ± 1.0°C (2.0°F) at any point in the tank ………... ____

c. Perforated false bottom or shelf to support specimens 50 mm (2.0 in) above

tank bottom ………………………………………………………………………........ ____

d. Equipped with a mechanical water circulator ……………………………………… ____

6. Oven / Clause 4.6

a. Able to maintain the specified temperature at ± 1°C (2°F) ……………………….. ____

7. Thermometers / Clause 4.8

a. Calibrated thermometers readable to 0.2°C (0.4°F) ……………………............... ____

PROCEDURE / Clause 5.0

a. Minimum of 3 specimens tested (per mixture)? ………………………………...... ____

b. After compaction, specimens cooled to room temperature on a smooth, flat

surface? ……………………………………………………………………………….. ____

c. Thickness of specimen measured according to ASTM D3549? ………………… ____

Note 1: laboratory molded specimens shall comply with the thickness

requirements of 63.5 ± 2.5mm.

Page 2

Preparation of Marshall Specimens (from bituminous mixes)

ASTM D6927-06

PROCEDURE (continued)

e. Specimens conditioned to specified temperature

- Temperature set at 60 ± 1°C (140 ± 2 °C) for water bath or oven ....... ____

- Placed in water bath for 30 to 40 minutes ..……………………………… ____

- Placed in oven for 120 to 130 minutes ………………………………… ____

Note 2: Specimens can be conditioned for testing once they reach

ambient room temperature (clause 5.3).

f. Cleaned and lubricated guide rods of testing head ……………………………... ____

g. Testing head assembly between 20 to 40°C (70 to 100°F) …………………… ____

h. Specimen removed from conditioning and placed in testing head assembly … ____

i. Flowmeter positioned over guide rod and adjusted to zero …………...……….. ____

j. Applied load to specimen at 50 ± 5mm/min. until load begins to decrease …… ____

k. Elapsed time specimen removed from conditioning to final load determination

completed within 30 s ………………………………………………………………. ____

i. Testing completed within 24 hr after compaction ………………………………… ____

CALCULATIONS / Clause 6.0

a. Correction factor based on volume or thickness ………………………………… ____

Example: A = B x C

Where: A = corrected stability,

B = measure of stability (load),

C = correlation ratio from Table 1 (Reference ASTM D6926 - 06 / Pg 7)

REPORTING / Clause 7.0

a. Type of sample (laboratory, plant or core specimen) ………………………………. ____

b. Nature of bituminous mixture, aggregate type, grading, binder grade and binder

content – if available? ....………………………………………………………………. ____

c. Individual and average BRD’s? ……………………………………………………….. ____

d. Height of specimens to the nearest 0.25 mm (0.01 in.)? ……………….................. ____

e. Individual and average Marshall Flow values (clause 7.1.6)? ………….................. ____

f. Test temperature to the nearest 0.2°C (0.4°F)? ……………………………………… ____

COMMENTS:

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

You might also like

- Sweetie's Cookies Business PlanDocument32 pagesSweetie's Cookies Business PlanLiew202081% (42)

- Astm C920 02Document3 pagesAstm C920 02Tally Anu100% (1)

- Eric Alexander - Improvising With The Whole Step Triad Combination Scale (2012)Document79 pagesEric Alexander - Improvising With The Whole Step Triad Combination Scale (2012)nikonel100% (25)

- Random Sampling of Construction Materials: Standard Practice ForDocument13 pagesRandom Sampling of Construction Materials: Standard Practice ForaraNo ratings yet

- C373.22947 Absorción AguaDocument7 pagesC373.22947 Absorción AguaLuisa AcevedoNo ratings yet

- The Business of 21st Century Robert T KiyosakiDocument5 pagesThe Business of 21st Century Robert T KiyosakiTally AnuNo ratings yet

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDocument5 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForHandyNo ratings yet

- D 692 - 00 Rdy5mi0wmaDocument2 pagesD 692 - 00 Rdy5mi0wmaRufo Casco0% (1)

- Astm D-5361Document3 pagesAstm D-5361mohammad sahmoud100% (1)

- Density, Yield and Air Content of Concrete (AASHTO T121)Document10 pagesDensity, Yield and Air Content of Concrete (AASHTO T121)DeRudyNo ratings yet

- Astm D6938 NuclearDocument3 pagesAstm D6938 NuclearRey Rapay100% (1)

- ASTM C332-17 Standard Specification For Lightweight Aggregates For Insulating ConcreteDocument4 pagesASTM C332-17 Standard Specification For Lightweight Aggregates For Insulating Concretebenedick barquinNo ratings yet

- Astm C 87Document4 pagesAstm C 87mickyfelixNo ratings yet

- Mineral Filler For Asphalt MixturesDocument2 pagesMineral Filler For Asphalt MixturesAnonymous x7VY8VF7No ratings yet

- ASTM D3625 Effects of Water On Asphalt Coated Aggregate Using Boiling MethodDocument2 pagesASTM D3625 Effects of Water On Asphalt Coated Aggregate Using Boiling MethodRamy HusseinNo ratings yet

- Flow of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForDocument3 pagesFlow of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForEvert RiveraNo ratings yet

- D244Document8 pagesD244samuelNo ratings yet

- Chemical Analysis of Hydraulic Cement: 1. ScopeDocument27 pagesChemical Analysis of Hydraulic Cement: 1. ScopeEvert RiveraNo ratings yet

- ASTM Designation: C 1305 - 08Document3 pagesASTM Designation: C 1305 - 08Lupita RamirezNo ratings yet

- Sampling Aggregates: Standard Practice ForDocument8 pagesSampling Aggregates: Standard Practice ForAbbasi HussainNo ratings yet

- Astm C33 C33M 23Document5 pagesAstm C33 C33M 23عبدالمعز المليانNo ratings yet

- d36 Softening Point Test Ring and BallDocument5 pagesd36 Softening Point Test Ring and BallNurul RizalNo ratings yet

- ASTM D 545 2005, Standard TestDocument4 pagesASTM D 545 2005, Standard TestJhon100% (1)

- C943Document4 pagesC943Jorge Luis Arevalo Lopez100% (1)

- Aggregate For Masonry MortarDocument2 pagesAggregate For Masonry MortarNada KhlifNo ratings yet

- Kinematic Viscosity of Asphalts (Bitumens) : Standard Test Method ForDocument10 pagesKinematic Viscosity of Asphalts (Bitumens) : Standard Test Method ForMohamed Maamoun T.No ratings yet

- Aashto T 309-15Document3 pagesAashto T 309-15William VasquezNo ratings yet

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocument2 pagesSieve Analysis of Mineral Filler For Bituminous Paving MixturesArnold RojasNo ratings yet

- Resistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusDocument7 pagesResistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem Apparatusgrats_singcoNo ratings yet

- Temperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForDocument3 pagesTemperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForCory BradleyNo ratings yet

- Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesDocument4 pagesBulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesKev SantiagoNo ratings yet

- Astm C 618 02 1Document4 pagesAstm C 618 02 1Ciro Arnold Gonzales PauccarNo ratings yet

- Portland Cement: Standard Specification ForDocument9 pagesPortland Cement: Standard Specification ForPedroNo ratings yet

- D 2041 - 00Document4 pagesD 2041 - 00harisahamedNo ratings yet

- Amount of Water Required For Normal Consistency of Hydraulic Cement PasteDocument3 pagesAmount of Water Required For Normal Consistency of Hydraulic Cement PasteThurain Aung KyawNo ratings yet

- 226 PDFDocument8 pages226 PDFBatepola BacNo ratings yet

- Laboratory Soils TestingDocument5 pagesLaboratory Soils TestingNavam NanthanNo ratings yet

- C1542 Longitud de Nucleos PDFDocument2 pagesC1542 Longitud de Nucleos PDFTavo Suarez C100% (1)

- Astm C1064.2104017 1Document3 pagesAstm C1064.2104017 1elmer portilloNo ratings yet

- C1621Document8 pagesC1621muhanadNo ratings yet

- Aashto t27Document4 pagesAashto t27binoNo ratings yet

- Astm C305Document4 pagesAstm C305Rafael Bolivar Diaz GranadosNo ratings yet

- 5 Astm c123 c123m 2011 Lighweight Particles in AggregateDocument4 pages5 Astm c123 c123m 2011 Lighweight Particles in AggregateGeorges Abi JaoudeNo ratings yet

- Density, Absorption, and Voids in Hardened Concrete: Standard Test Method ForDocument3 pagesDensity, Absorption, and Voids in Hardened Concrete: Standard Test Method ForMohamed BelmokaddemNo ratings yet

- Distillation of Cutback Asphaltic D402 08Document5 pagesDistillation of Cutback Asphaltic D402 08Pedro AlvelaisNo ratings yet

- ASTM D 2042 - 97 Standard Test Method For PDFDocument3 pagesASTM D 2042 - 97 Standard Test Method For PDFm_seyedNo ratings yet

- Packaged, Pre-Blended, Dry, Combined Materials For Use in Wet or Dry Shotcrete ApplicationDocument4 pagesPackaged, Pre-Blended, Dry, Combined Materials For Use in Wet or Dry Shotcrete Applicationsmanoj354No ratings yet

- D 2939 - 98 Rdi5mzktukveDocument9 pagesD 2939 - 98 Rdi5mzktukvedaovandongpktNo ratings yet

- C156 PDFDocument5 pagesC156 PDFMateriales FicNo ratings yet

- Unit Weight and Voids in Aggregate: Standard Method of Test ForDocument4 pagesUnit Weight and Voids in Aggregate: Standard Method of Test ForEvert RiveraNo ratings yet

- C490 Practice For Use of Apparatus For The Determination ofDocument5 pagesC490 Practice For Use of Apparatus For The Determination ofCarineMolzNo ratings yet

- C88-13 Standard Test Method For Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate PDFDocument5 pagesC88-13 Standard Test Method For Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate PDFdiego rodriguezNo ratings yet

- Astm D7234 21Document5 pagesAstm D7234 21Jaime Benitez AlvarezNo ratings yet

- Chemical Analysis Test (ASTM C114)Document8 pagesChemical Analysis Test (ASTM C114)Ayaz AhmadNo ratings yet

- Evaluation of Cement Mortars by Ultrasound N.Gözde Özerkan, Đ. Özgür YamanDocument11 pagesEvaluation of Cement Mortars by Ultrasound N.Gözde Özerkan, Đ. Özgür YamanAdam PapworthNo ratings yet

- Astm C73Document2 pagesAstm C73ml_sanchezcruz7875100% (1)

- Concrete Aggregates': Standard Specification ForDocument8 pagesConcrete Aggregates': Standard Specification ForAhmed AbidNo ratings yet

- ASTMC39Document5 pagesASTMC39Isaac NuñezNo ratings yet

- Astm D698Document4 pagesAstm D698Rofi Trianto S100% (1)

- Astm D6926 PDFDocument4 pagesAstm D6926 PDFAakashNo ratings yet

- Astm D2172Document5 pagesAstm D2172Joaquin Dix's100% (1)

- Astm c127 CADocument3 pagesAstm c127 CAWellington CastilloNo ratings yet

- Astm c128 FaDocument4 pagesAstm c128 FakinlaychengNo ratings yet

- ASTM D2041 aashto T209 ефект процент битума PDFDocument4 pagesASTM D2041 aashto T209 ефект процент битума PDFanon_711474514No ratings yet

- C CD26 TM 11 0904 PDFDocument2 pagesC CD26 TM 11 0904 PDFTally AnuNo ratings yet

- Apcotrak Is: Product DescriptionDocument2 pagesApcotrak Is: Product DescriptionTally Anu0% (1)

- Shaft ExtensionsDocument2 pagesShaft ExtensionsTally AnuNo ratings yet

- MC-250 Physical SpecificationsDocument2 pagesMC-250 Physical SpecificationsTally AnuNo ratings yet

- 3719 Hot-Poured, Crumb-Rubber Type Crack Sealer 3719.1 SCOPEDocument1 page3719 Hot-Poured, Crumb-Rubber Type Crack Sealer 3719.1 SCOPETally AnuNo ratings yet

- 15 PDFDocument1 page15 PDFTally AnuNo ratings yet

- 630 340480 Earth Resistance Tester MS5209 PDFDocument6 pages630 340480 Earth Resistance Tester MS5209 PDFTally AnuNo ratings yet

- Deputation Out of India F.R. 50. No Deputation of A Government Servant Out ofDocument7 pagesDeputation Out of India F.R. 50. No Deputation of A Government Servant Out ofTally AnuNo ratings yet

- Tremco Guide For Applying Sealant in Cold Weather PDFDocument2 pagesTremco Guide For Applying Sealant in Cold Weather PDFTally AnuNo ratings yet

- Correct Link For Opening SPARROW PDFDocument1 pageCorrect Link For Opening SPARROW PDFTally AnuNo ratings yet

- No. DPA-II/B-2311/01/2017/ITEC-II Ministry of External Affairs Development Partnership Administration DPA II DivisionDocument2 pagesNo. DPA-II/B-2311/01/2017/ITEC-II Ministry of External Affairs Development Partnership Administration DPA II DivisionTally AnuNo ratings yet

- Apcotrak WBR: Product DescriptionDocument2 pagesApcotrak WBR: Product DescriptionTally AnuNo ratings yet

- DAC II 50mm DAC I 50mm DBM 60mm DBM 60mm DBM 170mm 8mm X 25mm Groove Filled With Sealant or Elastomeric Concrete Expansion JointDocument1 pageDAC II 50mm DAC I 50mm DBM 60mm DBM 60mm DBM 170mm 8mm X 25mm Groove Filled With Sealant or Elastomeric Concrete Expansion JointTally AnuNo ratings yet

- Use of Pavement Under Overload Operations (61kb)Document4 pagesUse of Pavement Under Overload Operations (61kb)Tally AnuNo ratings yet

- Honest Information About Your Septic System - YOU Make The Decision!Document4 pagesHonest Information About Your Septic System - YOU Make The Decision!Tally AnuNo ratings yet

- Certificate To Be Furnished by A Central Government Servant For Claiming House Rent AllowanceDocument1 pageCertificate To Be Furnished by A Central Government Servant For Claiming House Rent AllowanceTally AnuNo ratings yet

- 4 2 Treatment of Canine Atopic DermatitisDocument8 pages4 2 Treatment of Canine Atopic DermatitisTally AnuNo ratings yet

- 9 9 21 367 PDFDocument7 pages9 9 21 367 PDFaihuutran51No ratings yet

- Just For Fun (Unit 4) : Page 1 of 2Document2 pagesJust For Fun (Unit 4) : Page 1 of 2Wilmer BalonNo ratings yet

- Attitudes Towards Artificial IntelligenceDocument3 pagesAttitudes Towards Artificial IntelligencePhạm Quang DuyNo ratings yet

- KimDocument104 pagesKimBayby SiZzle'zNo ratings yet

- Detecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Document5 pagesDetecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Hernan MartNo ratings yet

- SOP SAP Landed Cost 0.1Document9 pagesSOP SAP Landed Cost 0.1supendra phuyalNo ratings yet

- ConsumptionDocument21 pagesConsumptionAnikNo ratings yet

- Lethe Bear Varimixer RN10 VL2 MANDocument21 pagesLethe Bear Varimixer RN10 VL2 MANGolden OdyesseyNo ratings yet

- Chemistry Project Project-2Document21 pagesChemistry Project Project-2Jijin SajeevNo ratings yet

- Eurosa Furniture (Co) Pte LTD: Quality Control/Inspection/Enduring Testing ManualDocument6 pagesEurosa Furniture (Co) Pte LTD: Quality Control/Inspection/Enduring Testing ManualBelal AhmedNo ratings yet

- Tracer Study Questionnaire: A. Personal InformationDocument4 pagesTracer Study Questionnaire: A. Personal InformationJerome Bon QuiñonezNo ratings yet

- Hitachi: 9900/9900V Open Shadowima Ge Quick Reference GuideDocument3 pagesHitachi: 9900/9900V Open Shadowima Ge Quick Reference GuiderahulhclNo ratings yet

- Annabi Cockburn Decaluwe2006Document44 pagesAnnabi Cockburn Decaluwe2006hieputcNo ratings yet

- Drug & Narcotics: Presented By: A K M Shawkat Islam Additional Director Department of Narcotics ControlDocument38 pagesDrug & Narcotics: Presented By: A K M Shawkat Islam Additional Director Department of Narcotics ControlFarhan ShawkatNo ratings yet

- Leica Absolute Interferometer White Paper enDocument4 pagesLeica Absolute Interferometer White Paper entheflamebearerNo ratings yet

- Shirdi TicketDocument2 pagesShirdi TicketPOORVA GURAVNo ratings yet

- B2-Hasebroock - PD Topics Completed 2015-2016Document2 pagesB2-Hasebroock - PD Topics Completed 2015-2016api-319600132No ratings yet

- 1SDA066561R1 A3n 400 TMF 400 4000 3p F FDocument3 pages1SDA066561R1 A3n 400 TMF 400 4000 3p F FJessika duperly rueda vasquezNo ratings yet

- Cholera Outbreak Guidelines: Preparedness, Prevention and ControlDocument105 pagesCholera Outbreak Guidelines: Preparedness, Prevention and ControlOxfamNo ratings yet

- Google Classroom Quick Guide For StudentsDocument3 pagesGoogle Classroom Quick Guide For StudentsIlly Zue Zaine GangosoNo ratings yet

- ANC Guidelines - 18 July 2022 - Final-3 (6942)Document238 pagesANC Guidelines - 18 July 2022 - Final-3 (6942)Sara YehiaNo ratings yet

- Booklist Grade 3Document3 pagesBooklist Grade 3solid_impactNo ratings yet

- Chronic Otitis Media, Cholesteatoma, and Mastoiditis in AdultsDocument14 pagesChronic Otitis Media, Cholesteatoma, and Mastoiditis in AdultschristineNo ratings yet

- Defence FOI 046 2324 - DocumentsDocument58 pagesDefence FOI 046 2324 - Documentschristopher.august.elliottNo ratings yet

- Enerpac WMC Series CatalogDocument1 pageEnerpac WMC Series CatalogTitanplyNo ratings yet

- How To Upgrade TP-Link Pharos DevicesDocument5 pagesHow To Upgrade TP-Link Pharos DevicesGina LópezNo ratings yet

- Alignment Systems Products and Services Overview DOC 01.400 05-09-13 enDocument12 pagesAlignment Systems Products and Services Overview DOC 01.400 05-09-13 enSikasep TeaNo ratings yet

- Brief - Social Media Plan UpdatedDocument4 pagesBrief - Social Media Plan UpdatedPrasadSuryawanshiNo ratings yet