Professional Documents

Culture Documents

Examination For Compete T Pers NSF Inspection and Certification of Boilers - A IL - 2 11 Regulations, Welding, Heat Treatment and Safety

Examination For Compete T Pers NSF Inspection and Certification of Boilers - A IL - 2 11 Regulations, Welding, Heat Treatment and Safety

Uploaded by

agniva dattaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Examination For Compete T Pers NSF Inspection and Certification of Boilers - A IL - 2 11 Regulations, Welding, Heat Treatment and Safety

Examination For Compete T Pers NSF Inspection and Certification of Boilers - A IL - 2 11 Regulations, Welding, Heat Treatment and Safety

Uploaded by

agniva dattaCopyright:

Available Formats

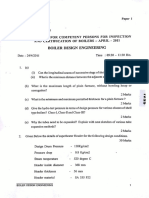

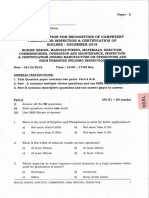

Paper 2

Regn No: _

Name: _

(To be written by the candidate)

EXAMINATION FOR COMPETENT PERSONS FOR INSPECTION

AND CERTIFICATION OF BOILERS - APRIL - 2011

REGULATIONS, WELDING, HEAT TREATMENT AND SAFETY

Date : 24/4/2011 Time : 11:30 - 12:30 Hrs.

Marks: 100

1. Boiler means any closed vessel exceeding capacity which is used expressly for generat-

ing steam under pressure

(a) 2.275 liters (b) 200 liters

(c) 25 liters (d) 22.75 liters

2. Steam pipe means any pipe through which steam passes if,

(a) Pressure exceeds 2 kg/cm2 and ID greater than 250 mm

(b) Pressure exceeds 2.5 kg/cm2 and ID greater than 100 mm

(c) Pressure exceeds 5kg/cm2 and ID greater than 50 mm

(d) Pressure exceeds 3 kg/cm2 and ID greater than 75 mm

3. Certificate for use of boilers

(a) Formll . (b) Form III

(c) Form VI (d) Formmc.

4. Inspecting authorities certificate of inspection during construction of boilers for

which variations from standard conditions have been permitted

(a) Formll (b) FormlIA

(c) FormilB (d) Form IIIC

5. A certificate authorizing the use of boiler shall cease to be in force

(a) Expiry of the period for which it was granted

(b) Whenever any accident occur to the boiler

(c) Whenever any structural alteration, addition or renewal is done in the boiler

(d) All the above

REGULATIONS, WELDING, HEAT TREATMENT AND SAFETY 1

Paper 2

6. The minimum tensile strength of carbon steel plates the maxi-

mum tensile strength of carbon steel plates in Kgf / mm2

(a) 37, 52 (b) 42,62

(c) 45,62 (d) 37, 62

7. What is the limit of carbon content for materials used in flame cutting or welding

(a) 0.25% (b) 0.20 %

(c) 0.30% (d) 0.35 %

8. The specification for boiler quality plates in Indian Standards

(a) IS 2062 (b) IS 266

(c) IS 2002 (d) IS 2066

9. The range of graduation on pressure gauge for working pressure over 35 kg! em' shall

be

(a) Zero to 1.25 times the working pressure

••••

(b) Zero to 2 times the working pressure

C

w

en (c) Zero to 1.5 times the working pressure

(d) Zero to 1.0 times the working pressure

10. The yield strength of plate at room temperature shall not be less than

(a) 45% (b) 55%

(c) 50%

11. The angle of bend on a mandrel of diameter 3t

(a) 120Deg (b) 90Deg.

(c) 180Deg. (d) 150 Deg

12. The maximum design temperature permitted for carbon steel tubes and pipes

(a) 350 deg C (b) 404 deg C

(c) 454p deg C (d) 450 deg C

13. Seamless steel tubes made to other international standards for boilers are permitted for

use in Boilers

(a) True (b) False

INS, WELDING, HEAT TREATMENT AND _ 2

Paper 2

14. The minimum hydraulic test pressure to which the boiler quality tubes is tested at tube

manufacturers works

(a) 40 kg Icm2 (b) 70 kg Icm2

(c) 60 kg /cm2 (d) 100 kg Icm2

15. What is the minimum and maximum tensile strength in Kgf I mm2 of Forgings

(a) 37 ,52 (b) 42,62

(c) 45,62 (d) 37,62

16. The minimum percentage elongation is calculated for castings by using Formula

(a) 93- Rml 2.2 (b) 73- Rml 2.2

(c) 93- Rml 1.2 (d) 93- Rml 3.2

Where Rm is Measured Tensile Strength in Kgflmm2 at room temperature

17. The minimum size and maximum tensile strength of mild steel electrodes are -- (

inch) and -Tons I sq .inch.

(a) 3/32, 33 (b) 3/8,35

(c) 1 14, 65 (d) 1 18 , 55

18. Electrodes intended for use for more than one type of current and polarity shall be

tested using each type of current and polarity

r (a) Yes (b) No

(c) No mention in IBR

19. Departure from circularity fusion welded drums permitted is -- % of nominal In-

ternal Diameter

(a) 0.5. (b) 2

(c) 1 (d) depends on Internal Diameter

20. The butt joints of boiler drum shall be tested by

(a) lO%RT (b) 100% UT

(c) 100 %RT (d) 100%MT

REGULATIONS, WELDING, HEAT TREATMENT AND SAFETY 3

Paper 2

21. The size of Transverse Tensile test specimen for weld joints for plate thickness above

30mm shall at least be

(a) 25 mm (b) 30 mm

(c) equal to plate thickness (d) Discretion of Inspecting Authority

22. The minimum tensile strength & percentage elongation inAlI weld tensile tests on butt

weld joints shall have a minimum of

(a) 35 kgf/mm2, 17 (b) 62 kgf/mm2, 20

(c) 55 kgf/mm2, 18 (d) that of the base material

23. The hydraulic test pressure that the drum shall be subjected to at works - Working

Pressure

(a) 1.5 times (b) 1.0 times

(c) 2.0 times (d) 1.25 times

24. The extent of thinning and departure from circularity permitted in tube bends are

(a) 10%, 10% (b) 100 I 4*RlD + 2, 10 %.

(c) 100 I 2 *RID + 2, 10 % (d) 10%,15%

25. The least thickness of the tube permitted for use in coiled tubes for forced flow!

circulation type boilers?

(a) 2.9 mm (b) 2.03 mm

(c) 1.62 mm (d) 3.25 mm

26. The number oftest plates required for fusion welded pipes are

(a) one per 60M (b) Two per 60M

(c) Every pipe (d) One per 30 M

27. The minimum pipe thickness required for the pipe before bending shall be -- times

calculated pipe thickness

(a) 1.0 (b) 1.125

(c) 1.25 (d) 2.0

REGULATIONS, WELDING, HEAT TREATMENT AND SAFETY 4

Paper 2

28. The minimum angle of branch welded to the main pipe shall be

(a) 60 deg (b) 45 deg

(c) 75 deg (d) 30 deg

29. The Hydro-test pressure of Waste Heat Boilers upto 50 Kg/cm2 is - times Working

Pressure

(a) 1.5 (b) 1.25

(c) 1.5 (d) 1.125

30. Whether hydraulic test is mandatory on expiry of certificate for power utility boilers of

working pressure less than 50kg/Cm2

(a) Yes (b) No

(c) discretion of Inspecting Authority

31. The maximum percentage allowed for accumulation of pressure in steam test at site is

(a) 5% (b) 3%

(c) 10% (d) 8%

32. The maximum depth permitted in engraving of register number is

(a) lrnm (b) 0.5mm

(c) O.4mm (d) 0,2mm

33. The circularity deviation permitted in shells of shell type boilers is

(a) 1% (b) 2%

(c) +or-l%. (d) 0.5 %

34. The variation in Internal Diameter allowed in internal flues is

(a) 1% (b) 6mm or t of plate

(c) 6mm or Y2 t of plate (d) 2%

35. The size of manhole of Shell Type boilers over 4 ft prescribed in IBR is

(a) 12" x 12" (b) 14" x 12"

(c) 16" x 12" (d) 18" x 12"

REGULATIONS, WELDING, HEAT TREATMENT AND SAFETY 5

Paper 2

l

36. The Institution or Individual responsible for conducting and certifying welder's test

(a) Inspecting Officer (b) InspectingAuthority

(c) Competent person (d) Competent Authority

37. The minimum thickness of the plate used for welders initial / requalification test is

(a) 25mm (b) 13 mm

(c) 16mm (d) 19mm

38. The minimum diameter of the main pipe in welders initial qualification is

(a) 102 mm (b) 127mm

(c) 89mm (d) 159mm

39. A welder is continuously engaged on production weld can be permitted to take the test

as in actual Production.

(a) Yes (b) No

(c) Not mentioned

40. Can any welder qualified for higher grade of steel may be permitted to weld lower grade?

(a) Yes (b) No

(c) Not explicitly mentioned

41. The correct Form for certifying welder's qualification test is:

(a) Form VI (b) Form xm.

(c) Form II (d) FormIV(a)

42. The pipes are Certified by Well Known steel maker by the given below Form :

(a) Form ilIA (b) Form IV

(c) Form lIrE (d) Form IIID

43. For Boilers operating at pressures higher than 60 kg /Cm2, the quality of feed water

shall be as per the following Indian Standard:

(a) 3025 (b) 3550

(c) 10496 (d) 2062

REGULATIONS, WELDING, HEAT TREATMENT AND SAFETY 6

Paper 2

44. The categorization of Repairers of Boilers with Operating Pressure greater than 17.5

but less than 40 Kg/cm2 falls into:

(a) IIIrd Class (b) IIndClass

(c) 1st Class (d) Special Class

45. Every boiler shall be provided with atleast

(a) one safety valve (b) two safety valves

(c) electromatic relief valve

46. The set pressure of one safety valve should be at least equal to

(a) superheater outlet pressure (b) drum pressure

(c) feedwater pressure (d) 110% of superheater pressure

47. The safety valves used in water tube boilers in power plants normally of type

(a)

(c)

ordinary lift

full lift

(b)

(d)

high lift

none ofthe above

-

-=U

U

48. The constant C used in calculating discharge capacity of safety valve may be more than

0.24 provided

(a) discretion of inspecting authority (b) as detailed by Appendix L

(c) by actual demonstration

49. One ofthe two safety valves in boiler drum is having an isolation valve. Is it permis-

sible?

(a) Yes (b) No

50. The minimum distance between gauge cocks in water level indicators shall be

(a) 175mm (b) IOOmm

(c) 200mm

...................... End of Paper .

REGULATIONS, WELDING, HEAT TREATMENT AND SAFETY 7

You might also like

- Indian Boiler Regulations 1950Document150 pagesIndian Boiler Regulations 1950mishtinil33% (3)

- M47 Aux Boiler Inst Manual 1-2Document399 pagesM47 Aux Boiler Inst Manual 1-2Ajit PrabhakaranNo ratings yet

- API 653 PC 26feb05 Question BankDocument44 pagesAPI 653 PC 26feb05 Question BankShaalan AliNo ratings yet

- 510 Practice Exam 5 OB QuestionsDocument0 pages510 Practice Exam 5 OB QuestionsGireesh Hegde100% (1)

- File No. 10 - API 936Document19 pagesFile No. 10 - API 936praveentien100% (6)

- API 936 Questions 01Document19 pagesAPI 936 Questions 01Mohamed Nouzer100% (3)

- CBB QuestionPapersDocument83 pagesCBB QuestionPapersVaibhav Bode100% (2)

- l6ll2l20L8: Fifth 2018Document16 pagesl6ll2l20L8: Fifth 2018dileepNo ratings yet

- Paper 1 2018Document12 pagesPaper 1 2018Rakesh Kumar LenkaNo ratings yet

- API 653 PC 26feb05 Exam Final ClosedDocument8 pagesAPI 653 PC 26feb05 Exam Final ClosedNuwan Ranaweera100% (1)

- JWM 2017 Question PaperDocument38 pagesJWM 2017 Question PaperManish KumarNo ratings yet

- Examination Board of Boilers: Instructions To Candidates.Document9 pagesExamination Board of Boilers: Instructions To Candidates.9766224189No ratings yet

- API 572 Study Guide: Practice QuestionsDocument26 pagesAPI 572 Study Guide: Practice QuestionsMohamad Shafey100% (1)

- Welding Q6Document14 pagesWelding Q6Ahmed HaridiNo ratings yet

- AFCAT 02-2015 EKT Question Paper - MechanicalDocument4 pagesAFCAT 02-2015 EKT Question Paper - MechanicalNatarajan NattuNo ratings yet

- API 653 PREPARATION/ Question N°10 Close BookDocument8 pagesAPI 653 PREPARATION/ Question N°10 Close BookkorichiNo ratings yet

- (A) The Weld Could Be Hard and Brittle: Page 3 of 43Document29 pages(A) The Weld Could Be Hard and Brittle: Page 3 of 43Jigar PrajapatiNo ratings yet

- Power Plant ElementsDocument33 pagesPower Plant ElementsPaulo Gallera50% (2)

- Api 653 Preparatory Course: Final Exam - Closed BookDocument8 pagesApi 653 Preparatory Course: Final Exam - Closed Bookanisanis100% (1)

- Technology 7 AnsDocument12 pagesTechnology 7 AnsnoorNo ratings yet

- UK Legislation & Guidan#F0ADocument3 pagesUK Legislation & Guidan#F0ANicolas BesnardNo ratings yet

- Regular Paper 2 - Set BDocument15 pagesRegular Paper 2 - Set BPalashNo ratings yet

- Api 936 Refractory Question BankDocument74 pagesApi 936 Refractory Question BankAliDadKhan100% (1)

- Energy Audit Questions Paper For BEE 17Document1 pageEnergy Audit Questions Paper For BEE 17NatarajNo ratings yet

- Technical Test Welding SCDocument14 pagesTechnical Test Welding SCsundaravel malayalanNo ratings yet

- Cswip QueDocument28 pagesCswip QueJigar PrajapatiNo ratings yet

- GATE ME 1992 Question PaperDocument7 pagesGATE ME 1992 Question PaperFlyNarutoFly27No ratings yet

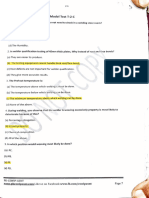

- Model Question Paper - 2006Document12 pagesModel Question Paper - 2006Sampat PrajapatiNo ratings yet

- Set IDocument98 pagesSet IPritamjit RoutNo ratings yet

- Boe Exam Paper Sep 2013Document8 pagesBoe Exam Paper Sep 2013Sandip WarbheNo ratings yet

- API 570 - Practice Qns (API 571) 2019Document5 pagesAPI 570 - Practice Qns (API 571) 2019StevenQuek100% (2)

- All CodesDocument13 pagesAll CodesMohammed YoussefNo ratings yet

- 12-0-2016 Cpi, Equip - Plant Design-QuestionaireDocument3 pages12-0-2016 Cpi, Equip - Plant Design-QuestionaireShania Caroline CanaoNo ratings yet

- 142 BDocument15 pages142 BarunachalamNo ratings yet

- API - 653 Question - BankDocument79 pagesAPI - 653 Question - BankOsama MohamedNo ratings yet

- Furnace Design WT - 8 PDFDocument2 pagesFurnace Design WT - 8 PDFalphamale3No ratings yet

- CSWIPDocument3 pagesCSWIPBox Empty100% (1)

- Power Plant ElementsDocument36 pagesPower Plant ElementsJosell CaipangNo ratings yet

- Welding Q8Document10 pagesWelding Q8Ahmed HaridiNo ratings yet

- Ata Vol-02Document120 pagesAta Vol-02hassan aliNo ratings yet

- Welding E BookDocument19 pagesWelding E BookunitybeginsathomeNo ratings yet

- Paper IIDocument142 pagesPaper IIPritamjit RoutNo ratings yet

- Paper 10Document8 pagesPaper 10Kani Al Bazir0% (1)

- Food Processing TechnologyDocument12 pagesFood Processing TechnologyK.P BHOGAYATANo ratings yet

- API 653 PC 15may04Document120 pagesAPI 653 PC 15may04Bharath GeegiNo ratings yet

- 0065 (Me 605)Document3 pages0065 (Me 605)Devanshi SharmaNo ratings yet

- Che 520L: Prelim Exam: Calculations 1Document4 pagesChe 520L: Prelim Exam: Calculations 1Nicole Anne BorromeoNo ratings yet

- 2a KeyDocument16 pages2a KeyHimanshu RanjanNo ratings yet

- CPM POWER PLANT ELEMENTS - 1 - 1 1Document33 pagesCPM POWER PLANT ELEMENTS - 1 - 1 1Captain AmericaNo ratings yet

- Final 2022Document8 pagesFinal 2022mm9542382No ratings yet

- Question BankDocument27 pagesQuestion BankselvaNo ratings yet

- Technology 3Document6 pagesTechnology 3ابومحمد الكناني100% (1)

- Practice Exam #3 Flashcards - QuizletDocument24 pagesPractice Exam #3 Flashcards - Quizletks_irdeNo ratings yet

- Exam - PHD Chemical Engineering Department University of Baghdad Date 13/8/2015 Time: 3 HrsDocument6 pagesExam - PHD Chemical Engineering Department University of Baghdad Date 13/8/2015 Time: 3 Hrshiba thamirNo ratings yet

- Energy Audit Questions Paper For BEE 26Document1 pageEnergy Audit Questions Paper For BEE 26NatarajNo ratings yet

- Model Question Paper-2006Document12 pagesModel Question Paper-2006Sampat PrajapatiNo ratings yet

- api 510 اسئلة متنوعة لكل الكورسDocument42 pagesapi 510 اسئلة متنوعة لكل الكورسhussam ghiathNo ratings yet

- BP - DuplexDocument6 pagesBP - DuplexAdam BatesNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Mechanical Engineering at the National Research Council of Canada: 1929-1951From EverandMechanical Engineering at the National Research Council of Canada: 1929-1951No ratings yet

- O M ManualDocument131 pagesO M Manualagniva dattaNo ratings yet

- Limits, Fits & CalculationsDocument28 pagesLimits, Fits & Calculationsagniva dattaNo ratings yet

- Carborundum Universal LTDDocument3 pagesCarborundum Universal LTDagniva dattaNo ratings yet

- Tube-To-tubesheet Joints - ASME (Mechanical) Code Issues - Eng-TipsDocument4 pagesTube-To-tubesheet Joints - ASME (Mechanical) Code Issues - Eng-Tipsagniva dattaNo ratings yet

- Norton Saint Gobian AbrasivesDocument2 pagesNorton Saint Gobian Abrasivesagniva dattaNo ratings yet

- Ansi B4.1 Fit Chart - Engineering Tolerance - IndustriesDocument1 pageAnsi B4.1 Fit Chart - Engineering Tolerance - Industriesagniva datta0% (1)

- Limit and Fit - ISO Hole Chart - ToleranceDocument2 pagesLimit and Fit - ISO Hole Chart - Toleranceagniva datta100% (2)

- Bhopal: Technical Specification For Drilling of Tube Holes in SS-overlayed Tube PlatesDocument2 pagesBhopal: Technical Specification For Drilling of Tube Holes in SS-overlayed Tube Platesagniva dattaNo ratings yet

- ISO Hole Tolerance, ISO Hole Tolerances, Hole Tolerance, ISO 286-2 Hole Tolerances 3mm-400mm PDFDocument3 pagesISO Hole Tolerance, ISO Hole Tolerances, Hole Tolerance, ISO 286-2 Hole Tolerances 3mm-400mm PDFagniva dattaNo ratings yet

- Hole Quality Defined - CompositesWorldDocument3 pagesHole Quality Defined - CompositesWorldagniva dattaNo ratings yet

- Steel and Its Alloy in Power BoilerDocument3 pagesSteel and Its Alloy in Power Boileragniva dattaNo ratings yet

- Boilers, Pressure Vessels, Thermal-Oil Installations and IncineratorsDocument51 pagesBoilers, Pressure Vessels, Thermal-Oil Installations and Incineratorsagniva dattaNo ratings yet

- Table of Metric Hole Tolerances Per. ISO 286 Chart Calculator - GD&T Tolerances - Engineers EdgeDocument4 pagesTable of Metric Hole Tolerances Per. ISO 286 Chart Calculator - GD&T Tolerances - Engineers Edgeagniva dattaNo ratings yet

- General ISO Geometrical Tolerances Per. ISO 2768 - GD&T Tolerances - ISO G&T Tolerances - Engineers EdgeDocument4 pagesGeneral ISO Geometrical Tolerances Per. ISO 2768 - GD&T Tolerances - ISO G&T Tolerances - Engineers Edgeagniva dattaNo ratings yet

- TH 1790Document77 pagesTH 1790agniva dattaNo ratings yet

- Engineering, Manufacturing Tolerance Limits Fits Charts - ISO 286 Tolerances - Metric Tolerance Chart - Engineers EdgeDocument12 pagesEngineering, Manufacturing Tolerance Limits Fits Charts - ISO 286 Tolerances - Metric Tolerance Chart - Engineers Edgeagniva dattaNo ratings yet

- International Tolerance (IT) Grades Table Chart - Engineers EdgeDocument3 pagesInternational Tolerance (IT) Grades Table Chart - Engineers Edgeagniva dattaNo ratings yet

- The Metallurgy of Power BoilersDocument4 pagesThe Metallurgy of Power Boilersagniva dattaNo ratings yet

- Aa10455 1Document5 pagesAa10455 1agniva dattaNo ratings yet

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesDocument9 pagesDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesagniva dattaNo ratings yet

- Amonia Hot Gas DefrostDocument4 pagesAmonia Hot Gas DefrostSergio HernandezNo ratings yet

- General Instructions For Safe Operation of High Pressure CompressorsDocument6 pagesGeneral Instructions For Safe Operation of High Pressure CompressorsTansu MavunacıNo ratings yet

- Dust Collector PDFDocument28 pagesDust Collector PDFMoneycomeNo ratings yet

- Proportional Electro-Hydraulic Relief Valves: SpecificationsDocument9 pagesProportional Electro-Hydraulic Relief Valves: SpecificationsMohammed SaeidNo ratings yet

- PrdsDocument0 pagesPrdssandi1111No ratings yet

- Recommended Hydrostatic Test ProcedureDocument18 pagesRecommended Hydrostatic Test ProcedureRamy OmarNo ratings yet

- Auxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Document81 pagesAuxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Arif MechanicalNo ratings yet

- Challenges in Designing API Safety Relief ValvesDocument5 pagesChallenges in Designing API Safety Relief Valveshans nijmeijerNo ratings yet

- PSV TestingDocument26 pagesPSV Testingmanoj thakkar100% (1)

- Pressure Drop of Vent SilencerDocument4 pagesPressure Drop of Vent SilencerGeorge EdwinNo ratings yet

- Astm-C151-09 C151M-09Document4 pagesAstm-C151-09 C151M-09samar2090% (1)

- Steam Regulation of 1930Document22 pagesSteam Regulation of 1930Shafnur HamdiNo ratings yet

- Almig Booster Operating ManualDocument12 pagesAlmig Booster Operating ManualAndy MitchellNo ratings yet

- 20 ISO Tank Container enDocument5 pages20 ISO Tank Container enSmart LauNo ratings yet

- Relief Valve Safety ValveDocument3 pagesRelief Valve Safety ValveMat AjeNo ratings yet

- Api 510 Exam: Api576 Questions - 01Document3 pagesApi 510 Exam: Api576 Questions - 01korichiNo ratings yet

- 19 Series - Safety Valve: Installation, Operation, & MaintenanceDocument6 pages19 Series - Safety Valve: Installation, Operation, & MaintenanceADAN CESSANo ratings yet

- Lesson 4. Boiler MountingsDocument4 pagesLesson 4. Boiler MountingsalexdenychenkoNo ratings yet

- Subsurface Safety EquipmentDocument36 pagesSubsurface Safety EquipmentLuis David Concha CastilloNo ratings yet

- Instruction Manual Shinva 45litre Autoclave240V With PrinterDocument21 pagesInstruction Manual Shinva 45litre Autoclave240V With PrinterEnfant Perdu100% (3)

- Leser Certificate For Global ApplicationDocument2 pagesLeser Certificate For Global ApplicationThiago Souza da SilvaNo ratings yet

- CoP - 49.0 - Compressed Gases and AirDocument26 pagesCoP - 49.0 - Compressed Gases and AirWasim AkramNo ratings yet

- Chapter 8 PNEUMATIC SYSTEMDocument19 pagesChapter 8 PNEUMATIC SYSTEMJoranas SiminauskasNo ratings yet

- Series 851: TÜV/CE Safety Valves Angle-Type For Industrial ApplicationsDocument5 pagesSeries 851: TÜV/CE Safety Valves Angle-Type For Industrial ApplicationsVlade NaumovskiNo ratings yet

- You Are Here: Safety Valve NoiseDocument5 pagesYou Are Here: Safety Valve NoiseJoseAgaptoNo ratings yet

- FMA Steam Boiler and UPV 1970 MalaysiaDocument59 pagesFMA Steam Boiler and UPV 1970 MalaysiaarifhonNo ratings yet

- SPD0056ERN - 1 DepressuringDocument25 pagesSPD0056ERN - 1 Depressuringchuntao fengNo ratings yet

- ASTM C 151 - 2005 - Standart Test Method For Autoclave Expansion of Hydraulic CementDocument3 pagesASTM C 151 - 2005 - Standart Test Method For Autoclave Expansion of Hydraulic CementLennon Araújo100% (1)