Professional Documents

Culture Documents

Performance and Emission Characteristics of Di Diesel Engine Fuelled With Camphor Oil-Diesel Blends

Performance and Emission Characteristics of Di Diesel Engine Fuelled With Camphor Oil-Diesel Blends

Uploaded by

Ram KrishOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance and Emission Characteristics of Di Diesel Engine Fuelled With Camphor Oil-Diesel Blends

Performance and Emission Characteristics of Di Diesel Engine Fuelled With Camphor Oil-Diesel Blends

Uploaded by

Ram KrishCopyright:

Available Formats

IJSRD - International Journal for Scientific Research & Development| Vol.

4, Issue 03, 2016 | ISSN (online): 2321-0613

Performance and Emission Characteristics of Di Diesel Engine Fuelled

with Camphor Oil-Diesel Blends

S. M. Sivagami1 S. Vignesh2

1

Faculty 2P.G. Scholar

1,2

Department of Mechanical Engineering

1,2

Government College of Technology, Coimbatore – 641013

Abstract— In recent years, the usage of vehicles have been the brake thermal efficiency of the conventional diesel

increased and this leads to the demand for fossil fuels. It has engine by 5% [4]. This experimental work shows that pine

become an urgent need to carry out the research work on oil is blended directly with diesel and 100% pine oil is

alternate source of energy to reduce the demand of fossil successfully used as a fuel in diesel engine. Kasiraman

fuels and also to reduce the emission. Biofuel is one of the reported that cashew nut shell oil was blended with camphor

alternative sources of energy. The aim of the paper is to oil and it has low viscous property. Due to its low viscous

blend the camphor oil with diesel fuel at various proportions property, it burns quickly and improves combustion

by volume. The camphor oil is directly blended with diesel efficiency. As a result, 30% camphor oil blended with

fuel without any trans-esterification process, because of its cashew nut shell oil gives better performances compared to

low viscous property. The prepared blends were tested in a other blend ratio & diesel fuel with respect to BTE

single cylinder DI Diesel engine at various load running at [5].Vegetables oil is used as a fuel in diesel engine but it is

constant engine speed of 1500 RPM and coupled to eddy more expensive than diesel fuel. Many researchers have

current dynamometer. Finally the observed performance and made several efforts to use some of the oil as a fuel namely

emission value of these blends were compared with pure sunflower, jatropa, pongamia, rubber seed and it is naturally

diesel fuel operations. Among the results, the B15 blends edible. Some researchers have decided to use non edible

gives better performance compared to B20 & diesel based vegetables oil as a biofuel in conventional diesel engines

on BTE. The B15 blends gives BTE (34%), B20 (BTE

32.95%) and diesel (BTE 31.5%) at full load conditions. II. CAMPHOR OIL

The B20 blends emit 676 ppm of NOX, while diesel emits Camphor oil is generally extracted from cinnamomum

617 ppm of NOX. camphora (also known as Laurus camphora) and is also

Key words: Diesel, Camphor Oil, Viscosity, Nox Emission named as true camphor and Formosa camphor. It has toxic

effects. The camphor oil is used to clean the defected lungs

I. INTRODUCTION and also dispel apathy. For psychosomatic ailments benefits

Emission from conventional diesel engine directly affects the camphor oil is used with great important. The camphor

the environment and it leads to global effects. Many tree will grow upto 35 meters tall. The camphor tree is more

researchers have searching some alternative solution to founded in china and japan. Camphor oil have good

improve the conventional diesel engine working at better aromatic and durable properties.

performance with minimum emissions. For that reasons, Camphor

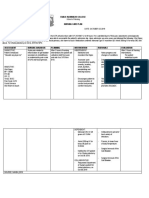

many researchers have concentrated on modifying the Properties Units Diesel

Oil

engine operating parameters such as ignition timing, fuel

injection pressure and multipoint fuel injector [1]. Density at 150C kg/m3 840 894.2

One of the alternative source of energy is biodiesel. Kinematic viscosity

CSt 3.4 1.9

Biodiesel are made from various sources such as animal at 400C

o

fats, edible oil, algae and non-edible oil. The biodiesel is Flash point C 50 50

o

prepared from various methods like Micro emulsions, Fire point C 72 68

Thermal cracking (pyrolysis) and Trans-esterification Cetane number - 52 5

(Alcoholysis) [2]. Calorific value kJ/kg 42700 38200

Vegetables oil is biodegradable, non-toxic, low Table 1: Properties of Diesel and camphor oil

emission level and it is environmentally beneficial. The idea Camphor oil is prepared from the steam

of using the vegetable oil as the fuel in conventional diesel distillations of chipped wood and branches under vacuum.

engine is not a new technique. In 1900, Rudolf operating the Then the filter products is pressed, distilled and rectification

diesel engines fuelled with peanut oil. Jatropa oil is used as under vacuum. Finally the filtered oil is collected at 3

a biofuel in conventional diesel engine by using different fractions of oil. Normally white, yellow, and brown

techniques such as blending with some other vegetables oil camphor oil. The brown and yellow camphor is toxic, also

and blending with additives. The variation of brake thermal used in the treatment for muscular aches and pains. The

efficiency was clearly noted at different techniques. The molecular formula of camphor oil is C10H16O. Molecular

jatropa oil is used as fuel in diesel engine which gives weight is 152.23 g/mol. The viscosity of camphor oil is 1.9

28.5% BTE and jatropa oil is blended with methanol gives Cst. The study on the physical and chemical properties of

30% BTE [3]. pine oil is comparatively similar to that of diesel and is

Vallinayagam reported that pine oil is directly tabulated in Table 1.

blended with diesel fuel without any trans-esterifying

process. The pine oil has low viscosity compared to that of

diesel fuel. At full load condition, 100% pine oil increases

All rights reserved by www.ijsrd.com 1407

Performance and Emission Characteristics of Di Diesel Engine Fuelled with Camphor Oil-Diesel Blends

(IJSRD/Vol. 4/Issue 03/2016/373)

III. ENGINE SETUP AND INSTRUMENTATION IV. RESULTS AND DISCUSSIONS

The Kirloskar is a single cylinder – four stroke, vertical, Different proportion of the blended fuels were tested in the

water cooled DI diesel fuelled engine. This engine setup is DI diesel engine, in which performance parameter and

used to carry out the performance and emission exhaust gases emissions were noted and tabulation were

characteristics of the diesel and camphor oil-diesel blends is formulated for finding the performance.

shown in Figure1.

A. Performance Characteristics

The engine is to produce rated power of 3.5kW at

rated speed of 1500rpm. Diesel fuel and camphor oil blends The variations of brake thermal efficiency with respect to

were tested in same engine without any modification such as applied load were discussed for diesel, Camphor oil-diesel

ignition timing, ignition pressure and operating speed etc. blends in the following sections. Figure 2 shows the

There are different types of engine loading are variation of brake thermal efficiency with applied load for

used. In this experiments, eddy current dynamometer are camphor oil and its blends in comparison with diesel. The

chosen to apply various load such as 0%, 25%, 50%, 75%, brake thermal efficiency indicates that how the heat energy

100%. Fuel is injected directly into the cylinder by means of is effectively converted into work energy and also indicate

fuel injector and the engine is cranked manually. The fuel combustion of fuel. As a result, the brake thermal efficiency

consumption is measured by using a burette and time is increases with increase in applied load. The calorific value

noted for a sample of 10 cc volume consumptions. of Camphor oil is comparable to diesel. It can be seen from

Exhaust emission from diesel engines such as Figure 2 that the proportionate addition of camphor oil with

carbon dioxide, carbon monoxide, hydrocarbons and oxides diesel increases the efficiency of the engine. The variations

of nitrogen is measured by AVL Di-gas analyzer. One end of Brake Thermal Efficiency for the blend fuels were nearly

of the cable is fitted with inlet side of the gas analyzer and comparable to that of diesel fuel.

other end of the cables is fitted with the exhaust tail pipe of

the engine Gases from the exhaust are subjected to a

moisture separator and filter element in order to trap

particulates and vapor. HC and NOX are measured in terms

of parts per million (ppm), whereas the oxides of carbon are

measured in terms of percentage volume (%). These

emission measurements are measured using selective

absorption principle.

Fig. 2: Load vs BTE

Fig. 1: Engine setup

A. Experimental Procedure

Initially the engine is running with diesel fuel for the

Fig. 3: Load vs BSFC

duration of 10 to 15 minutes before using camphor oil

The Figure 3 shows the SFC values for various

blends in order to attain stable working environment. After

that diesel fuel is completely drained out from the fuel tank applied load were plotted for Camphor oil diesel blend. At

and then the sample of (500 ml) camphor oil-diesel blends maximum load conditions, diesel shows higher specific fuel

consumption, which means poor fuel efficiency and mileage

are poured into the fuel tank. It is important to note that

than camphor oil blends. This may be due to the superior

whether the engine has attained its optimum (warm)

evaporation and mixing of camphor oil over diesel. The

temperature conditions. At constant speed of 1500 rpm,

lower viscosity of the camphor oil provokes better

engine is loaded with 0%, 25%, 50%, 75%, 100% load by

using an eddy current dynamometer. The B15 & B20 atomization, which helps accomplish a faster and more

proportions of camphor oil blends are tested at all load complete combustion. It is well known that specific fuel

consumption is inversely proportional to the brake thermal

conditions running at constant speed, where the

efficiency.

experimental procedure is same for every proportion to be

tested.

All rights reserved by www.ijsrd.com 1408

Performance and Emission Characteristics of Di Diesel Engine Fuelled with Camphor Oil-Diesel Blends

(IJSRD/Vol. 4/Issue 03/2016/373)

the engine is operating at 25 % load conditions, the fuel air

ratio is very low and the induction of oxygen from camphor

oil further reduces and leads to affect the combustion

process, there by resulting in a relatively higher CO

emissions for camphor oil and its blends.

2) Carbon Dioxide

The variations of carbon dioxide emissions with respect to

load are depicted in Figures 7 for diesel, camphor oil-diesel

blends. Figure 6 shows the variations of carbon dioxide

emissions with load of camphor oil blends with diesel.

The experimental results proved that B20 blend

shows better reduction of carbon dioxide emissions

compared to diesel. At higher load conditions diesel fails to

control CO2 emissions over camphor oil blends.

Fig. 4: Load vs Mechanical Efficiency

The Figure 4 shows the mechanical efficiency with

load of camphor oil blend with diesel fuel. It was learn that

mechanical efficiency with camphor oil diesel blend was

comparable to that of diesel fuel. The mechanical efficiency

of diesel fuel is higher than that of biodiesel diesel blends.

This is due to excess amount of fuel supplied to the engine

compared to diesel in order to maintain the equal energy

output to the engine. The fuel pump of the engine delivers in

volumetric basis, such that the density of blended fuel is

marginally higher than that of diesel. This does not create a

great impact on the discharge quantity of blended fuel

compared to that of diesel. The camphor oil diesel blends

having similar spray characteristics and comparable

viscosity when compared to diesel. As a result the B20 give

more mechanical efficiency than that of B15 blends and also Fig. 6: Load Vs CO2 emission

closer to that of diesel value. 3) Oxides of Nitrogen

The exhaust emissions such as CO, CO2, HC and NOx are

B. Emission Characteristics

measured and analyzed. From the above mentioned

Emissions such as CO, CO2, NOx and HC do rely mainly on emissions, NOx is the most important emissions for diesel

fuel – air ratio and in – cylinder temperature. The variation engine due to increase in temperature and combustion

of emission characteristics are discussed as follows. diffusion in the combustion chamber. The variations are

1) Carbon Monoxide shown in the Figure 7.

When the engine is operating at high load

conditions, a higher NOx emission level is observed for

camphor oil blends. This is due to increased temperature

caused by increased premixed burning. Because of the

prolonged ignition delay, there is accumulation of air-fuel

mixture in the combustion chamber while burning Camphor

oil and its blends.

Fig. 5: Load vs CO emission

The Figure 5 shows the CO emissions of the camphor oil

diesel blends. CO is an intermediate combustion product

which is formed by incomplete combustion of fuel. At full

load, a reduction in CO emission level was observed for

Camphor oil B15 blends. Furthermore, CO emission

decreases with the increase of Camphor oil percentage. This

Fig. 7: Load vs Oxides of Nitrogen

is due to the oxygen content present in the camphor oil

As a result, the emission level of NOx is more for

increases the combustion rate. However, when the engine is

20% camphor oil blends compared to diesel, since NOx is

operating at low load conditions, diesel produces less CO

proportional to the operating temperature. However, at low

than camphor oil and its blends, the reason behind is when

load conditions, more NOx is produced for the diesel due to

All rights reserved by www.ijsrd.com 1409

Performance and Emission Characteristics of Di Diesel Engine Fuelled with Camphor Oil-Diesel Blends

(IJSRD/Vol. 4/Issue 03/2016/373)

the fact that it has relatively higher fuel to air ratio, which REFERENCES

dominates the combustion process at extreme low load [1] Monyem A, Van Gerpen JH, Canakci M. The effect of

conditions. timing and oxidation on emissions from biodiesel-

4) Hydrocarbon Emission fueled engines. Trans ASAE 2001; 44:35-42.

[2] Fangrui Ma, Milford A. Biodiesel production: a review

Bioresource Technology 70 (1999) 1-15.

[3] Senthil Kumar M, Ramesh A, Nagalingam B.

AComparison of the different methods of using jatropa

oil as fuel in a compression ignition engine.

Transactions of ASME, Journal of Engineering for Gas

Turbines and Power 2010;132:1-10.

[4] R. Vallinayagam, S. Vedharaj, W.M. Yang, P.S. Lee,

K.J.E. Chua, S.K. Chou. Combustion performance and

emission characteristics study of pine oil in a diesel.

Energy 57 (2013) 344-351.

[5] Kasiraman G,Nagalingam B, Balakrishnan M.(2012)”

Performance, emission and combustion improvements

in a direct injection diesel engine using cashew nut shell

Fig. 8: Load Vs HC emission oil as fuel with camphor oil blending”, Energy 47

The Figure 8 shows the impact of camphor oil blend over (2012) 116-124.

the emission of HC. The increased evaporation rate of fuel [6] Prem Anand B, Saravanan C.G, Ananda Srinivasan

with air inside the cylinder makes the fuel burns completely. C.(2009)”Performance and exhaust emission of

At 25% load conditions, diesel emits less HC compared to turpentine oil powered direct injection diesel engine”,

B15 & B20 blends due to the increased evaporation and Renewable Energy 35 (2010) 1179-1184.

mixing rate of fuel. It is also observed that the addition of [7] Yashiyuki. K, Changlin. Y, Kei, M. Effects of fuel

load, the emission of HC increases as the mass of the fuel properties on combustion and emission characteristics

inducted into the cylinder is more and the fuel to air ratio is of direct injection diesel engine. SAE paper NO 2000-

increased for camphor oil biofuel. It is seen that B15 & B20 01-1831; 2000.

blends give the higher amount of HC emission compared to [8] Karthikeyan R, Mahalakshmi N, Performance and

that of diesel at all load conditions. This is due to the emission characteristics of a turpentine-diesel dual fuel

availability of relatively low oxygen content inside the engine. Energy 2007, 32(7):1202-9.

cylinder for the combustion. [9] Agarwal D, Sinha S ,Agarwal AK, Experimental

investigation of control of NOx Emissions in biodiesel-

V. CONCLUSION fuelled compression ignition engine .Renew Energy

A single cylinder DI Diesel engine was operated 2006;31(14):2356-69.

successfully using diesel and blends of diesel with 15% and

20% of camphor oil respectively. Fuel consumption, brake

power, brake power output, and emissions such as CO, HC,

and NOx were measured at various loads. The performance

and emission characteristics of diesel engine using these

blend were compared with diesel fuel operation at 0, 25%,

50%, 75% and 100% load conditions. At 25% load

conditions, the B15 & B20 blends emits lower level of NOX

compared to that of diesel. The NOx emission from B15 &

B20 blend at full load conditions are higher than that of

diesel fuel. The B15 blend gives higher brake thermal

efficiency compared to diesel & B20 blend at full load

conditions.

B15 & B20 blends show better reduction of

emissions than that of diesel at full load operating

conditions. The Emission of HC is increased with the

addition of camphor oil at all load conditions compared to

that of diesel. At full load conditions, B15 blends consumed

lower fuel consumption and higher brake thermal efficiency

compared to diesel. As a result, the B15 blends significantly

improves the performance & ecofriendly for DI diesel

engine.

All rights reserved by www.ijsrd.com 1410

You might also like

- Datta mantra Sudharnavamu, దత్త మంత్రం సుధార్ణవ PDFDocument340 pagesDatta mantra Sudharnavamu, దత్త మంత్రం సుధార్ణవ PDFRam Krish71% (7)

- Steam Tracing With MS ExcelDocument14 pagesSteam Tracing With MS ExcelRaul Bautista100% (2)

- Vegan AestheticsDocument12 pagesVegan AestheticselyseNo ratings yet

- Computer System Validation Risk Assessment ToolDocument3 pagesComputer System Validation Risk Assessment Toolcpkakope100% (1)

- Agama Rahasya Sudhakar MalaviyaDocument966 pagesAgama Rahasya Sudhakar MalaviyaRam Krish88% (8)

- Form 1 Science NotesDocument19 pagesForm 1 Science NotesQQLove93% (14)

- Engine CharacteristicsDocument7 pagesEngine Characteristicss sivaNo ratings yet

- Performance and Emission Characteristics of Palm Oil As An Alternate Fuel in Diesel EngineDocument8 pagesPerformance and Emission Characteristics of Palm Oil As An Alternate Fuel in Diesel EngineTJPRC PublicationsNo ratings yet

- The Effect of Jatropha Oil Methyl Ester Towards Diesel Engine PerformanceDocument4 pagesThe Effect of Jatropha Oil Methyl Ester Towards Diesel Engine PerformanceAhmad Razin JasmiNo ratings yet

- 95-f30032بيرلوسس مهم جدااDocument6 pages95-f30032بيرلوسس مهم جدااmohamed aliNo ratings yet

- Putranjiva Roxburghii Non-Edible Oil PDFDocument5 pagesPutranjiva Roxburghii Non-Edible Oil PDFVaibhav MoonNo ratings yet

- Applied Energy: K. Muralidharan, D. VasudevanDocument10 pagesApplied Energy: K. Muralidharan, D. VasudevanSubhadip DasNo ratings yet

- IJEDR1803105Document7 pagesIJEDR1803105ramadevi.vNo ratings yet

- Neem Oil Methyl Ester A Promising Source To Power DI-CI Engine.Document3 pagesNeem Oil Methyl Ester A Promising Source To Power DI-CI Engine.Anonymous CUPykm6DZNo ratings yet

- yerrennagoudaru2017Document12 pagesyerrennagoudaru2017Aakash TiwariNo ratings yet

- Performance and Evaluation of Pongamia (Karanj) Oil As An Alternative Fuel For Surface TransportationDocument7 pagesPerformance and Evaluation of Pongamia (Karanj) Oil As An Alternative Fuel For Surface Transportationrahuldbajaj2011No ratings yet

- v4 2 11Document7 pagesv4 2 11api-19662887No ratings yet

- Using Cottonseed Oil: Performance Improvement of A Di Diesel EngineDocument8 pagesUsing Cottonseed Oil: Performance Improvement of A Di Diesel EngineARVINDNo ratings yet

- Venkatesh and BhaghaviDocument10 pagesVenkatesh and BhaghavilarryNo ratings yet

- Biodiesel As A Blended Fuel in Compressi PDFDocument4 pagesBiodiesel As A Blended Fuel in Compressi PDFDiyar NezarNo ratings yet

- Lemon Peel Oil A Novel Renewable AlternaDocument12 pagesLemon Peel Oil A Novel Renewable AlternaRicardo Mario Rueda OrtegaNo ratings yet

- Performance Characteristics of A Variable Compression Ratio Engine Using Transesterified Mahua OilDocument5 pagesPerformance Characteristics of A Variable Compression Ratio Engine Using Transesterified Mahua OilEditor IJTSRDNo ratings yet

- Biofuel-Production-From-Jatropha-Curcas-Oil-As-Non-edible-Feedstock-And-Its-Use-In-Diesel-EngineDocument4 pagesBiofuel-Production-From-Jatropha-Curcas-Oil-As-Non-edible-Feedstock-And-Its-Use-In-Diesel-EngineamalNo ratings yet

- Agarwal2009 PDFDocument13 pagesAgarwal2009 PDFroberto gomezNo ratings yet

- Performance Characteristics of A Low Heat Rejection Diesel Engine Operating With BiodieselDocument7 pagesPerformance Characteristics of A Low Heat Rejection Diesel Engine Operating With BiodieselbalakaleesNo ratings yet

- Analysis of Performance and Emission Parameters of Methyl Esters of Coconut Oil and Eucalyptus Oil Blends in Vcr-Ci EngineDocument6 pagesAnalysis of Performance and Emission Parameters of Methyl Esters of Coconut Oil and Eucalyptus Oil Blends in Vcr-Ci EngineTJPRC PublicationsNo ratings yet

- Experimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsDocument7 pagesExperimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsAshokNo ratings yet

- Equivalence Ratio DiagramDocument26 pagesEquivalence Ratio DiagramAymenNo ratings yet

- Evaluating Performance and Emissions of Ci Engine Run by Blends of Mosambi Peel Methyl Ester and Diesel FuelDocument8 pagesEvaluating Performance and Emissions of Ci Engine Run by Blends of Mosambi Peel Methyl Ester and Diesel FuelTJPRC PublicationsNo ratings yet

- Performance and Emission Characteristics of CI Engine With Methyl Esters of Palm Stearin Under Varying Compression Ratios and Fuel Injection PressuresDocument9 pagesPerformance and Emission Characteristics of CI Engine With Methyl Esters of Palm Stearin Under Varying Compression Ratios and Fuel Injection PressuresT Hari PrasadNo ratings yet

- Characterization of Mahua Methyl Ester in DI Diesel EngineDocument7 pagesCharacterization of Mahua Methyl Ester in DI Diesel EngineIJAERS JOURNALNo ratings yet

- 5 Ijmperddec20185Document12 pages5 Ijmperddec20185TJPRC PublicationsNo ratings yet

- Ab 02417411746Document6 pagesAb 02417411746IJMERNo ratings yet

- Biodiesel Production From Palm Oil Technology: Research Journal of Agricultural Science, 43 (4), 2011Document6 pagesBiodiesel Production From Palm Oil Technology: Research Journal of Agricultural Science, 43 (4), 2011Sywie ARydivolyaNo ratings yet

- Potency of Clove Oil and Turpentine Oil As A Diesel Fuel BioadditiveDocument7 pagesPotency of Clove Oil and Turpentine Oil As A Diesel Fuel BioadditiveTrina ViskhawatNo ratings yet

- IJETR021268Document5 pagesIJETR021268erpublicationNo ratings yet

- Analysis of Four Stroke Single Cylinder Compression Ignition Engine Operated With Blends of Waste Cooking Oil Biodiesel DieselDocument6 pagesAnalysis of Four Stroke Single Cylinder Compression Ignition Engine Operated With Blends of Waste Cooking Oil Biodiesel Dieselshreshthagandhi13No ratings yet

- Research ArticleDocument12 pagesResearch Articlemert tıglıNo ratings yet

- D.I Engne ManuscriptDocument12 pagesD.I Engne ManuscriptChandramanikandanNo ratings yet

- Phase 01Document15 pagesPhase 01naveenNo ratings yet

- Load and Emission Characteristics of Pongamia Pinnata Oil in ACI EngineDocument9 pagesLoad and Emission Characteristics of Pongamia Pinnata Oil in ACI EngineJournals MECNo ratings yet

- Performance and Emission Characteristics of A Diesel Engine With Castor OilDocument7 pagesPerformance and Emission Characteristics of A Diesel Engine With Castor OilArati SakhalkarNo ratings yet

- (IJCST-V10I2P8) :yalamanchili Ramprasad, S.T. P Sarath Chandra, Nallamala NowhithDocument10 pages(IJCST-V10I2P8) :yalamanchili Ramprasad, S.T. P Sarath Chandra, Nallamala NowhithEighthSenseGroupNo ratings yet

- Performance and Emission Characteristics of Compressed Ignition Engine by Using Non-Edible Coconut BiodieselDocument10 pagesPerformance and Emission Characteristics of Compressed Ignition Engine by Using Non-Edible Coconut BiodieselSudheer KumarNo ratings yet

- Performance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditiveDocument21 pagesPerformance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditiveLOKESHNo ratings yet

- ICER 2017 - IITB - Soapnut Biodiesel Performance - v2Document5 pagesICER 2017 - IITB - Soapnut Biodiesel Performance - v2Vaibhav MoonNo ratings yet

- Effects of Open Combustion Chamber Geometries On The Performance of PongamiaDocument8 pagesEffects of Open Combustion Chamber Geometries On The Performance of PongamiaVaibhav MoonNo ratings yet

- Investigatory ProjectDocument10 pagesInvestigatory Projectjoana dequinaNo ratings yet

- A Comparative Study of Diesel Engine Performance and Emission Characteristics of Biodiesel Blends With DieselDocument5 pagesA Comparative Study of Diesel Engine Performance and Emission Characteristics of Biodiesel Blends With DieselerpublicationNo ratings yet

- An Analysis of VCR Engine Using Watermelon Seed Oil and N-Butanol As Fuel AdditiveDocument8 pagesAn Analysis of VCR Engine Using Watermelon Seed Oil and N-Butanol As Fuel AdditiveTJPRC PublicationsNo ratings yet

- Cottonseed Trimethylolpropane (TMP) Ester As Lubricant and Performance Characteristics For Diesel EngineDocument8 pagesCottonseed Trimethylolpropane (TMP) Ester As Lubricant and Performance Characteristics For Diesel Engineelias chernetNo ratings yet

- 2012 BP Pattanaik Et Al. Performance & Emission Studies On A Single Cylinder DI Diesel Engine Fueled With Diesel and Rice Bran Oil Methyl Ester BlendsDocument9 pages2012 BP Pattanaik Et Al. Performance & Emission Studies On A Single Cylinder DI Diesel Engine Fueled With Diesel and Rice Bran Oil Methyl Ester BlendsBP PattanaikNo ratings yet

- Experimental Investigation of Compressed Ignition Engine Using Cotton Seed Oil Methyl Ester As Alternative FuelDocument5 pagesExperimental Investigation of Compressed Ignition Engine Using Cotton Seed Oil Methyl Ester As Alternative FuelresearchinventyNo ratings yet

- Performance and Emission Analysis of Compression Ignition Engine in Dual Fuel Mode Using Rice Bran Biodiesel and LPGDocument7 pagesPerformance and Emission Analysis of Compression Ignition Engine in Dual Fuel Mode Using Rice Bran Biodiesel and LPGAJER JOURNALNo ratings yet

- 1.1 Background of Bio-DieselDocument41 pages1.1 Background of Bio-DieselTaheer MatturNo ratings yet

- Discharge and Performance Investigation of Unconventional Diesel Combination in Compressed Ignition EngineDocument6 pagesDischarge and Performance Investigation of Unconventional Diesel Combination in Compressed Ignition EngineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Journal Pre-Proof: Process Safety and Environmental ProtectionDocument31 pagesJournal Pre-Proof: Process Safety and Environmental ProtectionChirag PatidarNo ratings yet

- Performance of CI Engine Using Soapnut BiodieselDocument7 pagesPerformance of CI Engine Using Soapnut BiodieselVaibhav MoonNo ratings yet

- Influence of Injection Timing On VCR Diesel Engine Characteristics Using Safflower Oil With Antioxidant Ao1202Document14 pagesInfluence of Injection Timing On VCR Diesel Engine Characteristics Using Safflower Oil With Antioxidant Ao1202SekarNo ratings yet

- Synopsis Second Group Blank FormatDocument5 pagesSynopsis Second Group Blank FormatAbhijit BansodeNo ratings yet

- ManuscriptDocument5 pagesManuscriptAanshu SinghNo ratings yet

- Experimental Investigation of Performance and Emission Characteristics of Diesel Engine With Jatropha Biodiesel BlendsDocument4 pagesExperimental Investigation of Performance and Emission Characteristics of Diesel Engine With Jatropha Biodiesel BlendserpublicationNo ratings yet

- Performance Characteristics of A Diesel Engine Using Diesel-Cashew Nut Shell Oil BlendsDocument3 pagesPerformance Characteristics of A Diesel Engine Using Diesel-Cashew Nut Shell Oil BlendspatelpiyushbNo ratings yet

- Experimental Studies On The Combustion and Emission Characteristics of A Diesel EngineFuelled With Used Cooking Oil Methyl Esterand Its Diesel BlendsDocument7 pagesExperimental Studies On The Combustion and Emission Characteristics of A Diesel EngineFuelled With Used Cooking Oil Methyl Esterand Its Diesel BlendsShashikanth MohrirNo ratings yet

- 17 909 PDFDocument6 pages17 909 PDFedison avvaiNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Vedic Sukta Sangrah Gitapress PDFDocument250 pagesVedic Sukta Sangrah Gitapress PDFRam KrishNo ratings yet

- Fhsstphy PDFDocument397 pagesFhsstphy PDFRam KrishNo ratings yet

- Asta BhairavaDocument2 pagesAsta BhairavaRam KrishNo ratings yet

- DM TeluguDocument22 pagesDM TeluguRam KrishNo ratings yet

- DM Telugu PDFDocument258 pagesDM Telugu PDFRam Krish80% (5)

- System of Units:-: Physical Quantity Symbol Dimension Measurement Unit UnitDocument5 pagesSystem of Units:-: Physical Quantity Symbol Dimension Measurement Unit UnitRam KrishNo ratings yet

- The Order of Reciting Durga Saptashati Parayana Daily Is: Trayanga Mantra, Devi Mahatmya Text Followed by Devi SuktamDocument2 pagesThe Order of Reciting Durga Saptashati Parayana Daily Is: Trayanga Mantra, Devi Mahatmya Text Followed by Devi SuktamRam KrishNo ratings yet

- Technical inDocument1 pageTechnical inRam KrishNo ratings yet

- Laghaya Navāvara A PūjāDocument33 pagesLaghaya Navāvara A PūjānavinnaithaniNo ratings yet

- An Analysis of Specific Philosophical HymnsDocument135 pagesAn Analysis of Specific Philosophical HymnsRam Krish100% (1)

- FundamentalsofLearning Heritageetal PDFDocument16 pagesFundamentalsofLearning Heritageetal PDFRam KrishNo ratings yet

- Vancha Kalpalata Jayanti Bhashya Shiva Dutta Mishra Shastri PDFDocument100 pagesVancha Kalpalata Jayanti Bhashya Shiva Dutta Mishra Shastri PDFRam Krish100% (1)

- Ts Set 2018 ResultsDocument17 pagesTs Set 2018 ResultsRam KrishNo ratings yet

- Anna Lingarchana Vidhanam PDFDocument2 pagesAnna Lingarchana Vidhanam PDFRam KrishNo ratings yet

- Anna Lingarchana Vidhanam PDFDocument2 pagesAnna Lingarchana Vidhanam PDFRam KrishNo ratings yet

- Basic Concepts and Applied Aspect of Sharir RachnaDocument122 pagesBasic Concepts and Applied Aspect of Sharir RachnaRam Krish100% (1)

- Kama ShastramDocument193 pagesKama ShastramRam KrishNo ratings yet

- Laghaya Navāvara A PūjāDocument33 pagesLaghaya Navāvara A PūjānavinnaithaniNo ratings yet

- Shri Sookta Vidhanam + Soubhagya Lakshmi Upanishads PDFDocument6 pagesShri Sookta Vidhanam + Soubhagya Lakshmi Upanishads PDFRam KrishNo ratings yet

- Atharva Veda Samhita Swami Satyaprakash Saraswati Udaya Vir Viraj Vol 1Document426 pagesAtharva Veda Samhita Swami Satyaprakash Saraswati Udaya Vir Viraj Vol 1Ram Krish100% (5)

- Tube (I.e. And: You Get YourDocument14 pagesTube (I.e. And: You Get YourRam KrishNo ratings yet

- Distribution Network of Coca-ColaDocument16 pagesDistribution Network of Coca-ColaRahul panditaNo ratings yet

- Short Table of Muscle Control Exercises - The MaxaldingDocument48 pagesShort Table of Muscle Control Exercises - The MaxaldingHugo Mantilla90% (10)

- Chemistry Project 2021-2022Document19 pagesChemistry Project 2021-2022Rudra SathwaraNo ratings yet

- PhilRice - Fertilizer CalculationDocument21 pagesPhilRice - Fertilizer CalculationMichelle Ann SoledadNo ratings yet

- Promotion Letter ShwetaDocument2 pagesPromotion Letter ShwetayogeshNo ratings yet

- Sentinel Collim Rev1.2 CompressedDocument2 pagesSentinel Collim Rev1.2 CompressedBauyrzhanNo ratings yet

- Bence Bays Resume July 2015Document2 pagesBence Bays Resume July 2015api-292242662No ratings yet

- Ramsay Health Care - BudgetDocument13 pagesRamsay Health Care - BudgetTatiana Garcia MendozaNo ratings yet

- Emilio Aguinaldo College: School of NursingDocument2 pagesEmilio Aguinaldo College: School of NursingAwani ONo ratings yet

- Gujarat Cancer and Research Institute RatesDocument33 pagesGujarat Cancer and Research Institute RatesNimhans HospitalNo ratings yet

- Riko Technical Brochure PDFDocument29 pagesRiko Technical Brochure PDFGrigoreOzonNo ratings yet

- Weekly Report ExampleDocument3 pagesWeekly Report Examplewawan setiawanNo ratings yet

- NT TR 459 - Guideline For The Validation of Functional Safety According To IEC 61508 - Nordtest Technical ReportDocument54 pagesNT TR 459 - Guideline For The Validation of Functional Safety According To IEC 61508 - Nordtest Technical ReportManish MehtaNo ratings yet

- Model: Stored Energy Solutions For A Demanding World: Dimensions MM InchDocument2 pagesModel: Stored Energy Solutions For A Demanding World: Dimensions MM Incheddywidjaya9No ratings yet

- OSH SeminarDocument2 pagesOSH SeminarSahar Ulu JeruasNo ratings yet

- Mina NEGRA HUANUSHA 2 ParteDocument23 pagesMina NEGRA HUANUSHA 2 ParteRoberto VillegasNo ratings yet

- Parent Medical CoverageDocument9 pagesParent Medical CoveragecampeonNo ratings yet

- Natural Rubber WikiDocument9 pagesNatural Rubber WikiMyra Wardati SNo ratings yet

- Silvestres Grupo 5Document39 pagesSilvestres Grupo 5Juliana DiazNo ratings yet

- Covalence S1301-M Epoxy Primer: DescriptionDocument4 pagesCovalence S1301-M Epoxy Primer: DescriptionJuan Carlos Contreras CherresNo ratings yet

- Women Mental Health:: Postpartum DepressionDocument62 pagesWomen Mental Health:: Postpartum DepressionTickablingbling Alwaysshine Likeatenglarious100% (1)

- A Country Boy Quits SchoolDocument4 pagesA Country Boy Quits SchoolJamaica Bianca Baynosa AnguloNo ratings yet

- Obat Kausatif Infeksi: 6ggpo, 0shqwlget Grad Corporis Ult Hui Form 3DDocument5 pagesObat Kausatif Infeksi: 6ggpo, 0shqwlget Grad Corporis Ult Hui Form 3DMaulana Malik IbrahimNo ratings yet

- SPS Plans PDFDocument7 pagesSPS Plans PDFSalin ShresthaNo ratings yet

- Artificial Intelligence in PharmacyDocument8 pagesArtificial Intelligence in PharmacyMeraNo ratings yet

- CSF PDFDocument58 pagesCSF PDFVas KannanNo ratings yet